ASCOM H952T User manual

TD 92022EN

3 July 2013 / Ver. G

Installation Guide

H/U952T Terminal Transmitter

TD 92022EN

3 July 2013 / Ver. G

Installation Guide

H/U952T Terminal Transmitter

Contents

1 General ............................................................................................................................ 1

1.1 Regulatory Compliance Statements (EU/EFTA only) ...................................................... 2

1.2 Regulatory Compliance Statements (USA only) .............................................................. 2

2 Board Description ..........................................................................................................3

3 Installation...................................................................................................................... 5

3.1 Mounting .................................................................................................................................... 6

3.2 Opening the Housing............................................................................................................... 7

3.3 Installation Together with Other Units............................................................................... 7

3.4 Wiring Runs ............................................................................................................................... 8

3.5 Connection of Buses and Control Equipment.................................................................... 9

3.6 Connection of Supply Voltage............................................................................................ 10

3.7 Addressing the Terminal Transmitter.............................................................................. 10

3.8 Coax Connection to Antenna.............................................................................................. 11

4 Parameter Settings ...................................................................................................... 12

5 Installation Test Procedure ......................................................................................... 13

5.1 Field Adjustment ................................................................................................................... 13

6 Circuit Board Replacement .......................................................................................... 14

7 Document History ........................................................................................................ 15

Appendix A: Installation of T952SM/FL Speech and Frequency Lock Module ........... 16

Appendix B: Coaxial Connectors..................................................................................... 18

TD 92022EN

3 July 2013 / Ver. G

Installation Guide

H/U952T Terminal Transmitter

1

1 General

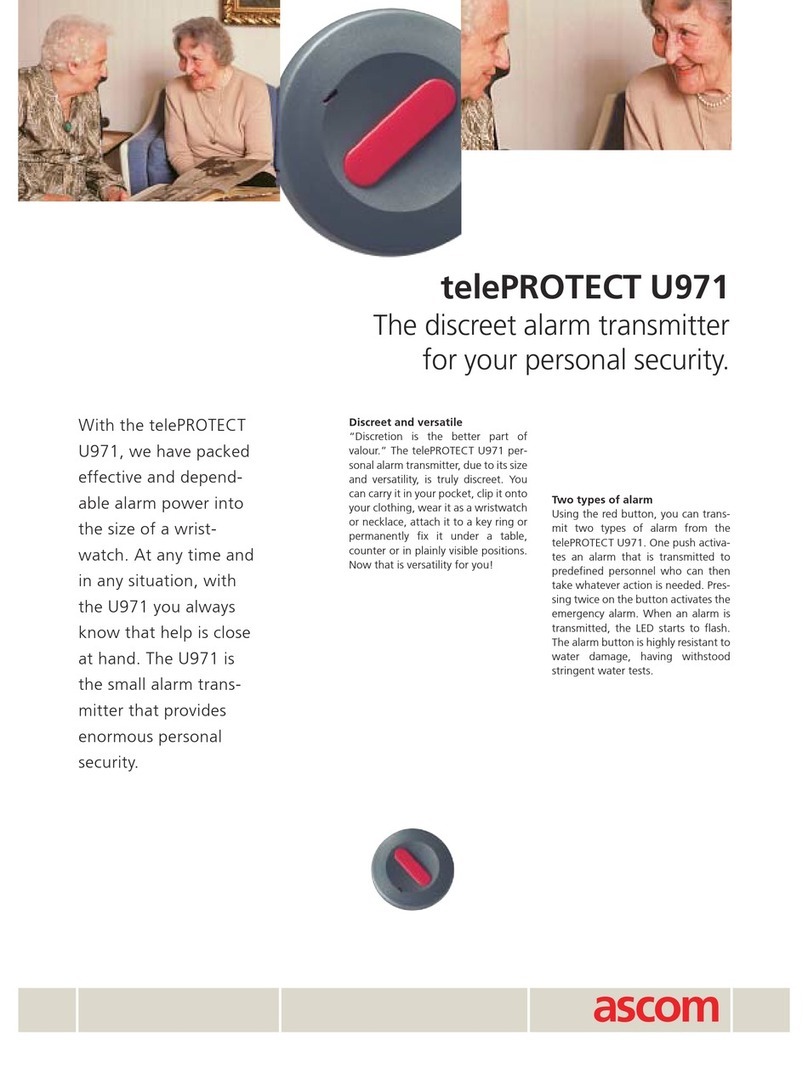

Terminal Transmitter H/U952T is used in the Ascom Paging System. The Terminal

Transmitter operates in both UHF and HF frequency bands.

Figure 1. H/U952T Terminal Transmitter.

U952T is approved for On-board installations. See IMPORTANT: ON-BOARD INSTALLATIONS

on page 5 for more information regarding output power.

H952T U952T

Supply voltage: 12.5 V DC ± 10% 12.5 V DC ± 10%

Max. current consumption: 2.0 A 2.5 A

Max. current consumption during transmission: 1.6 A 1.6 A

Max. current consumption in standby: 0.2 A 0.4 A

IMPORTANT: Protect the unit against current exceeding 20 A. Use power cables with

cross-section 3 mm2.

The Terminal Transmitter is available in two versions:

U952T: 425-475 MHz

H952T: 25-29 MHz, 29-32 MHz, 32-37 MHz, 37-42 MHz, 42-47 MHz, 47-50 MHz

Delivery includes:

• H/U952T Terminal Transmitter

•CoaxconnectorTNC

• Modular bus cabling

Tools etc., required:

•Screwdriver

•Screwsformounting

• Multimeter

As a complement to this Installation Guide, see the System Installation document.

TD 92022EN

3 July 2013 / Ver. G

Installation Guide

H/U952T Terminal Transmitter

2

1.1 Regulatory Compliance Statements (EU/EFTA only)

Hereby, Ascom (Sweden) AB, declares that this equipment is in compliance with the

essential requirements and other relevant provisions of R&TTE Directive 1999/5/EC.

The declaration of conformity may be consulted at:

https://www.ascom-ws.com/doc/

This equipment uses frequencies referring to different rules in the various EU&EFTA

countries.

A radio communications licence is in most cases necessary for the use of the equipment. The

frequencies required for operation of the radio equipment must be notified and assigned

prior to usage of the equipment.

1.2 Regulatory Compliance Statements (USA only)

FCC Compliance Statements

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the transmitting antenna.

•Increase the separation between the equipment and Receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

transmitter is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Information to User

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause

undesired operation.

Modifications

Changes or modifications to the equipment not expressly approved by the party responsible

for compliance could void the user's authority to operate the equipment.

TD 92022EN

3 July 2013 / Ver. G

Installation Guide

H/U952T Terminal Transmitter

3

2 Board Description

J101

J100

SW100

J103

IC101

SW200

J200

J102

L301

LED100

P400

LED302

LED301

LED300

LED201

LED302

LED301

LED300

LED201

C444 (U952T)

L401 (H952T)

15

Figure 2. H/U952T circuit board.

Connectors

J100, J101 For connecting D-, and SP-bus via modular bus cabling.

J102 Supply voltage.

J103 For connecting D-bus (if modular bus cabling is not used) and Control

Equipment.

J200 For connecting the Speech and Frequency (T952SM/FL) Lock module.

Switches

SW100 Address selector switch.

SW200 Test switch, set to OFF during normal operation.

LEDs

LED100 Function indicator for green, red, or orange indication.

LED201 LED, TX ON, indicates carrier.

LED300 LED, TX DATA ON, indicates paging.

LED301 Indicates DSP running (blinks).

LED302 Indicates speech on.

Flash PROM

IC101 Program memory

Adjustable

Components

P400 Potentiometer, for calibration of output power.

L301 Inductance coil, for fine adjustment of reference frequency.

C444 Capacitor, for adjustment of VCO frequency (only U952T).

L401 Inductance coil, for adjustment of VCO frequency (only H952T).

TD 92022EN

3 July 2013 / Ver. G

Installation Guide

H/U952T Terminal Transmitter

4

TD 92022EN

3 July 2013 / Ver. G

Installation Guide

H/U952T Terminal Transmitter

5

3 Installation

The unit should be placed in a dry environment. A temperature between 0 and +40°C is

preferred. The unit will operate in the temp range -15 up to +55°C. The unit can be installed

alone or together with other system units using the modular bus cabling or twisted-pair

wiring.

To prevent dust or moisture from damaging the electronics it is important to have the cover

mounted after installation and during use.

IMPORTANT: ON-BOARD INSTALLATIONS

The U952T Terminal Transmitter is shipped with standard output power. Full compliance

with RECOMMENDATION ITU-R M.1174-2 (Technical characteristics of equipment used for

on-board vessel communications in the bands between 450 and 470 MHz) and EN 300 720

(Electromagnetic compatibility and Radio Spectrum Matters (ERM); Ultra-High Frequency

(UHF) on-board communications systems and equipment, Part 1 and 2) regarding radiated

output power and frequency of operation is the responsibility of the installer.

In short:

ITU-R M.1174-2 recommends, in addition to frequencies of operation, “The effective

radiated power should be limited to the maximum required for satisfactory operations, but

should in no case exceed 2 W.”

EN 300 720 specifies frequencies of operation and a maximum output power of 4 W. Please

refer to the original documents for full details.

TD 92022EN

3 July 2013 / Ver. G

Installation Guide

H/U952T Terminal Transmitter

6

3.1 Mounting

IMPORTANT: The unit must be mounted to a vertical wall with the bottom facing the

floor.

Bottom

Top

The illustration below shows the dimensions in mm for mounting the unit.

9 9

275

56.5

188.5

65 130

112

Dimensions (H x W x D)

275 x 130 x 60 mm

Figure 3. Mounting dimensions in mm.

NOTE: To facilitate service after the unit is installed, we recommend a free space of about

150 mm above and 50 mm below the unit.

TD 92022EN

3 July 2013 / Ver. G

Installation Guide

H/U952T Terminal Transmitter

7

3.2 Opening the Housing

Use a screwdriver or similar to release the cover by applying a light pressure to the two snap

catches (1) and remove the cover (2).

1

1

2

Figure 4. Releasing the cover.

NOTE: The internal metal shield should not be opened.

3.3 Installation Together with Other Units

1

1

1 Remove upper and lower covers. Fasten together the lower rectangular covers of

adjacent units (1).

2 Fasten each unit to the wall with three screws, see figure 3 on page 6.

TD 92022EN

3 July 2013 / Ver. G

Installation Guide

H/U952T Terminal Transmitter

8

3.4 Wiring Runs

Wiring can be run three ways from the unit:

• Remove the rectangular covers and run the cabling out through the side (1).

•Run the cabling through the round holes at the bottom of the case (2).

• Remove the circular covers at the top of the side case (3).

1

2

1

2

3

3

IMPORTANT: Do not make any openings at the bottom of the front cover since this does

not comply with the fire enclosure requirements.

The plastic partition (shaded in the illustration) is scored to facilitate breaking at convenient

intervals.

1 Use pliers to break off a suitable section.

2 Run the wiring out through the cable duct at the bottom.

1 2 3 4 5

slots

3 Use the slots at the opening to secure the wiring with cable straps.

This manual suits for next models

1

Table of contents

Other ASCOM Transmitter manuals

ASCOM

ASCOM A51 - User manual

ASCOM

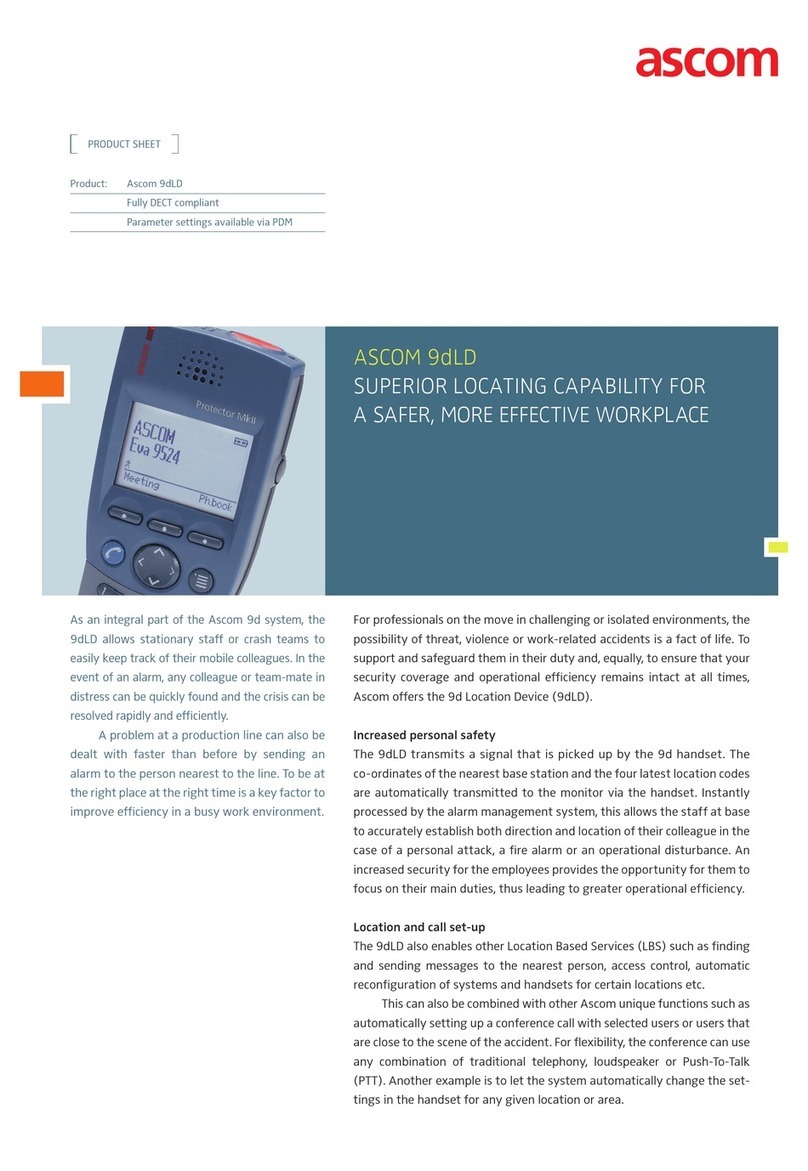

ASCOM 9DLD - DATASHEET 1 User manual

ASCOM

ASCOM HMT 1000 User manual

ASCOM

ASCOM HMT1000 - DATASHEET 1 User manual

ASCOM

ASCOM TELECARE WP - BROCHURE 1 User manual

ASCOM

ASCOM A51 - User manual

ASCOM

ASCOM 9dLD User manual

ASCOM

ASCOM A51 - User manual

ASCOM

ASCOM T942C User manual

ASCOM

ASCOM TELEPROTECT U971 User manual

Popular Transmitter manuals by other brands

Dejero

Dejero EnGo 3x manual

Rosemount

Rosemount 4600 Reference manual

Speaka Professional

Speaka Professional 2342740 operating instructions

trubomat

trubomat GAB 1000 instruction manual

Teledyne Analytical Instruments

Teledyne Analytical Instruments LXT-380 instructions

Rondish

Rondish UT-11 quick start guide