6.

c.) Unscrew and remove Bottle from cap.

d.) Fill Bottle with clean water.

e.) Screw Bottle into the Water Reservoir

Connector.

f.) Plug in the power cord.

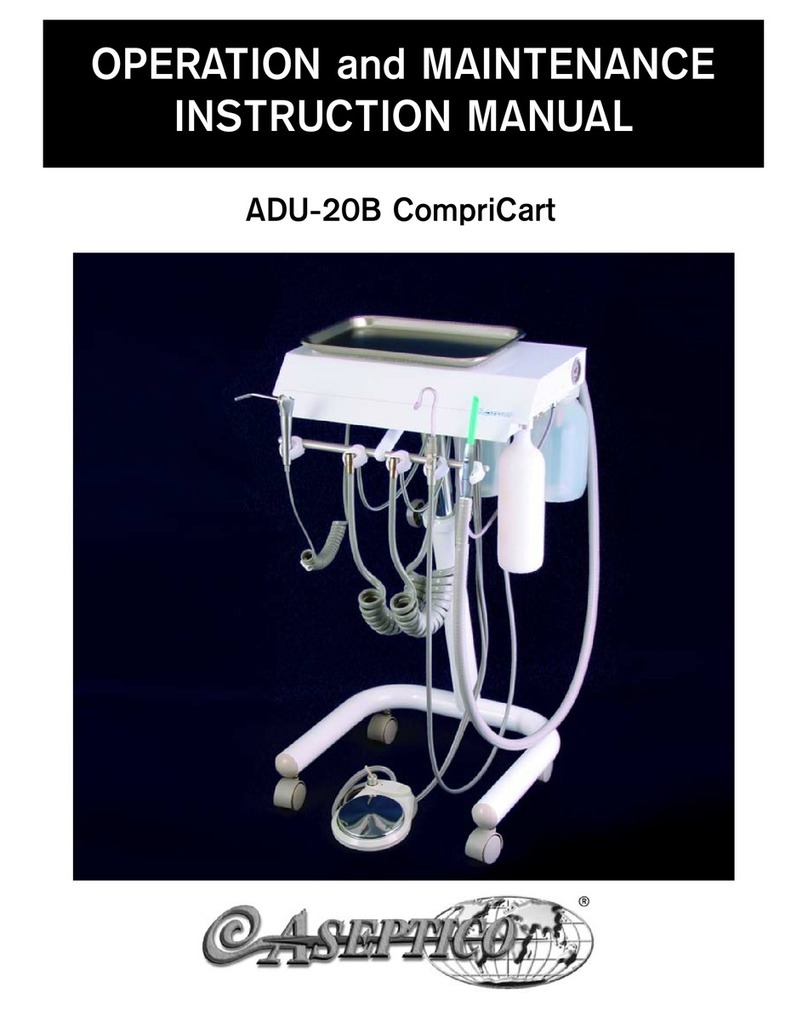

6. HVE and SALIVA EJECTOR VACUUMS:

The Express Air is equipped with a 5-liter Waste

Tank, a High Volume (HVE) hose, and a Low

Volume (Saliva Ejector) hose. Both High and

Low Volume systems operate simultaneously

from the same vacuum source. To gain vacuum

on the HVE, open the HVE valve to full open and

close the Saliva Ejector Valve. To gain vacuum

on the Saliva Ejector, close the HVE and open

the Saliva Ejector to full open.

The vacuum Waste Tank contains a ball float

shutoff to prevent accidental overflow. The Tank

should be emptied when it is ¾ full.

The High Volume (HVE) vacuum system con-

tains a screen inside the Waste Tank container.

The screen is used for collecting large debris

upon vacuum intake. Clean screen when neces-

sary.

To empty the Waste Container:

a.) Unplug the power cord.

b.) Disconnect the hoses.

c.) Empty container.

d.) Reconnect hoses.

e.) Plug in power cord.

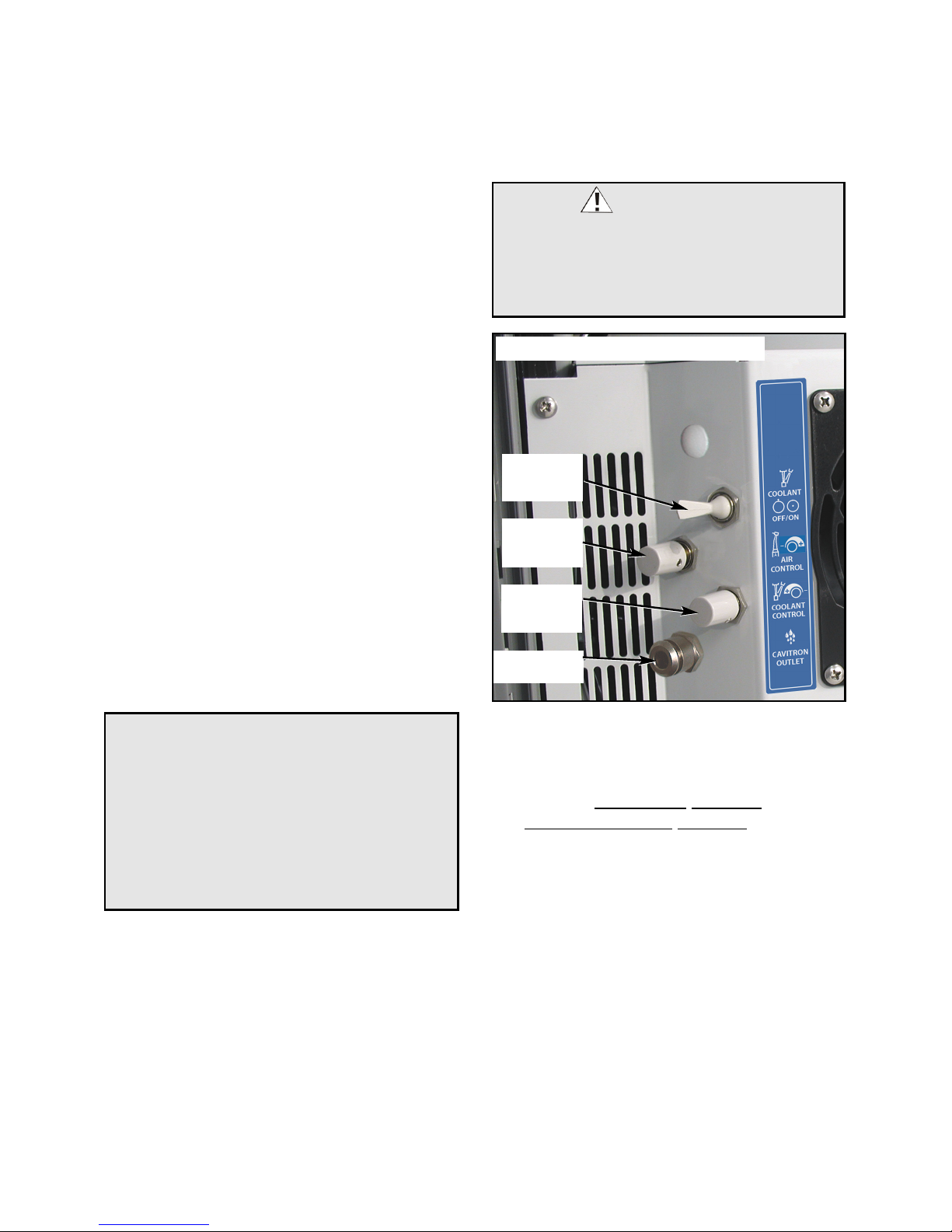

7. CAVITRON WATER OUTLET:

Provides water via standard 1/4” quick discon-

nect to independent Cavitron or scaler units

requiring a water supply.

The waste container has a ball float shutoff to

prevent accidental overflow. If the waste container

becomes full and the ball float activates, the vacu-

um motor may not restart, and could potentially

blow the fuse. Immediately empty waste container

to continue operation.

NOTE:

OPERATION FUNCTIONS:

1. ON/OFF SWITCH:

Turns the ADU-17A system On or Off.

2. AIR FOOT CONTROL:

The handpiece only operates when the foot

pedal is depressed. When the foot pedal is not

being used, the vacuum and syringe remain

operational

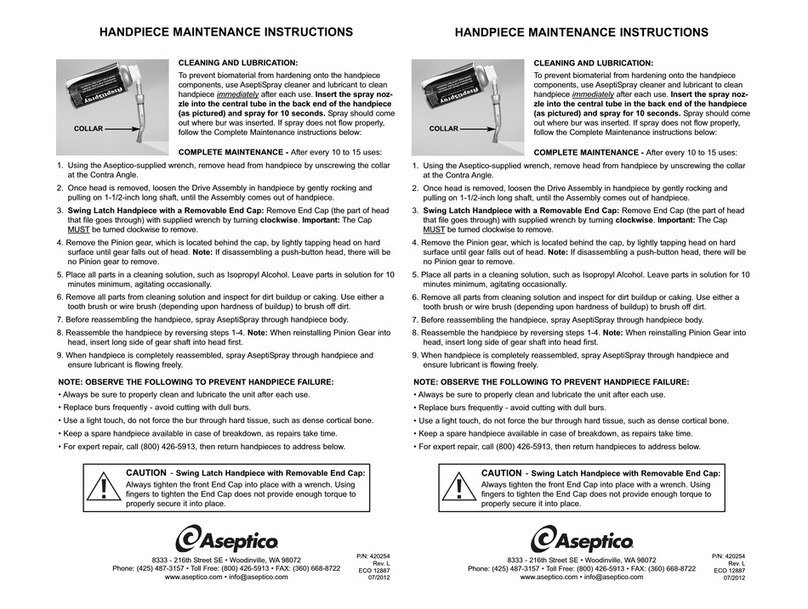

3. HANDPIECE CONTROLS:

a.) Off/On Coolant Toggle Switch - Turns

Handpiece water coolant On/Off.

b.) Air Control Switch - Allows adjustment of air

pressure to the Handpiece.

c.) Coolant Control Switch - Allows adjustment

of water coolant to the Handpiece.

4. THREE-WAY AIR/WATER SYRINGE:

- Pressing the left button dispenses water.

- Pressing the right button dispenses air.

- Pressing both buttons simultaneously

dispenses an air/water mist.

5. WATER SUPPLY BOTTLE:

The Express Air incorporates a self contained

pressurized water system. This system consists

of a 1-liter white bottle, which dispenses water

through the handpiece and 3-Way Air/Water

Syringe. The Water Supply Bottle threads into

the Reservoir Connector, located in the upper

right corner of the case.

To refill the Water Supply Bottle:

a.) Before removing the Bottle for refilling,

unplug the power cord from the Express Air

unit.

b.) Release pressure from Bottle by slightly

loosening bottle from reservoir connector

approximately 1/8-turn, or by depressing the

air button on the 3-Way Syringe.

THE WATER SUPPLY BOTTLE IS

PRESSURIZED DURING OPERATION.

DEPRESSURIZE BOTTLE BEFORE

REMOVAL BY SLIGHTLY LOOSENING

BOTTLE FROM RESERVOIR CONNEC-

TOR.

WARNING: