TABLE OF CONTENTS:

Introduction . . . . . . . . . . . . . . . . . . . . . . . . .1

Package Contents . . . . . . . . . . . . . . . . . . . .1

Setting Up the Unit . . . . . . . . . . . . . . . . . . .2

Operation Functions . . . . . . . . . . . . . . . . . .3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . .5

Sterilization . . . . . . . . . . . . . . . . . . . . . . . . .6

Maintenance & Cleaning . . . . . . . . . . . . . . .7

Symbol Definition . . . . . . . . . . . . . . . . . . . .7

Troubleshooting . . . . . . . . . . . . . . . . . . . . .8

Warranty . . . . . . . . . . . . . . . . . . .Back Cover

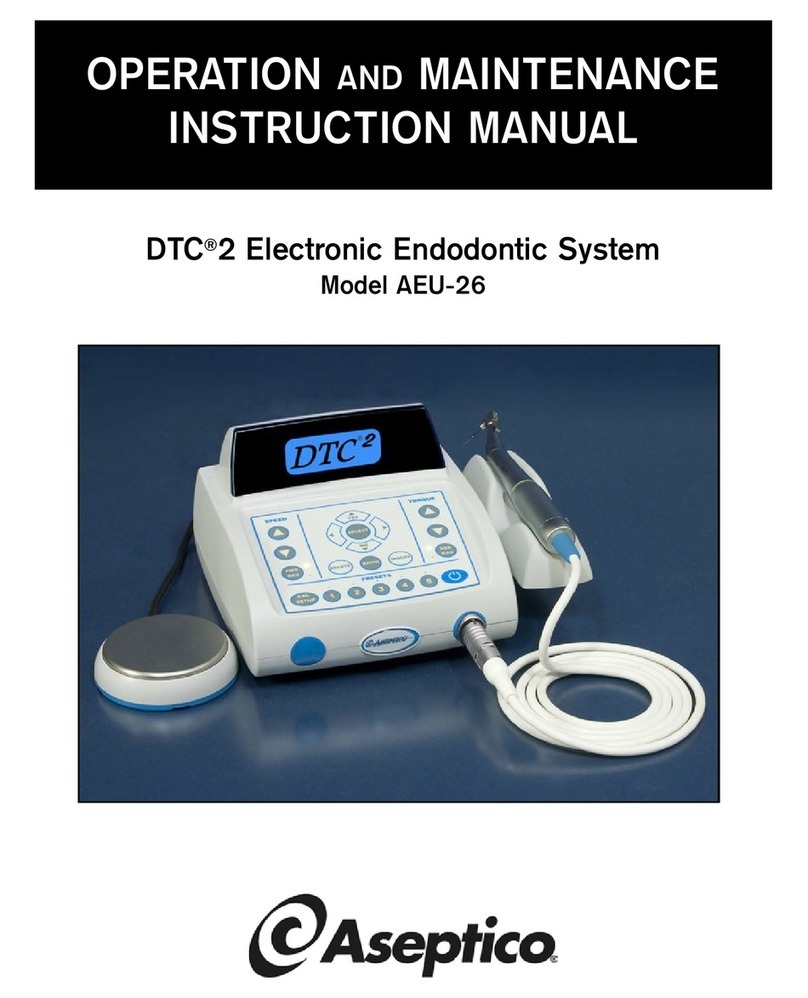

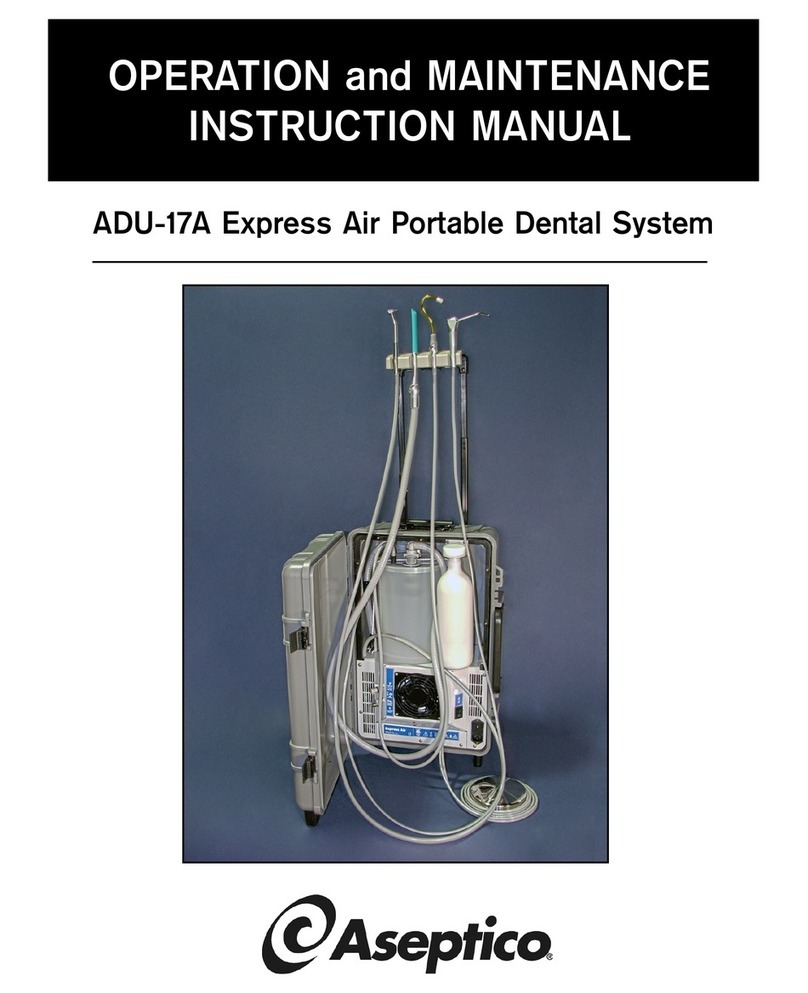

SPECIFICATIONS:

Console Size: 5.80” x 7.21” x 3.03”

(14.73 x 18.31 x 7.70 cm)

Console Weight: 3.5 lbs (1.59 kg)

Power Source: 110V/120V, 60 Hz, or

220V/250V, 50 Hz

Fuse: 0.315A - 110V

0.16A - 230V

Slo-Blo Type

CLASSIFICATIONS:

Class I

Type B Applied Parts

Ordinary Protection

Not suitable for use in the presence of a flam-

mable anaesthetic mixture mixed with air or

with oxygen or nitrous oxide.

Note: The power supply cord is the mains

appliance disconnect means.

To prevent injury to people and damage to property,

please heed relevant warnings and remarks. They

are marked as follows:

WARNING: Serious injury or death may result if

ignored.

CAUTION: Damage to property or the environ-

ment may result if ignored.

NOTE: Important additional information and

hints.

P.O. Box 1548 • Woodinville, WA 98072

8333 216th Street SE • Woodinville, WA 98072

(425) 487-3157 (800) 426-5913

WARNING: This device has been tested and found

to comply with the emissions requirements of IEC

60601-1-2:2001-09. These requirements provide

reasonable protection against harmful electromag-

netic interference in a typical medical installation.

However, high levels of radio-frequency (RF) emis-

sions from electrical devices, such as cellular

phones, may disrupt the performance of this device.

To mitigate disruptive electromagnetic interference,

position this device away from RF transmitters and

other sources of electromagnetic energy.

MEDICAL EQUIPMENT WITH

RESPECT TO ELECTRIC SHOCK,

FIRE, AND MECHANICAL HAZARDS

ONLY IN ACCORDANCE WITH UL

2601-1 CAN/CSA C22.2 No. 601.1

41EJ