3

Date: November 2006

This Use and Care Guide, for the drying ca-

binet describes:

how it functions

how to use it

This Use and Care Guide

Contents

and also includes instructions for

installation

maintenance

Safety Instructions . . . . . . . . . . . . . . . . 4

Symbols . . . . . . . . . . . . . . . . . . . . . 4

Important points about safety . . . . . 4

Description of the Drying Cabinet . . . . 5

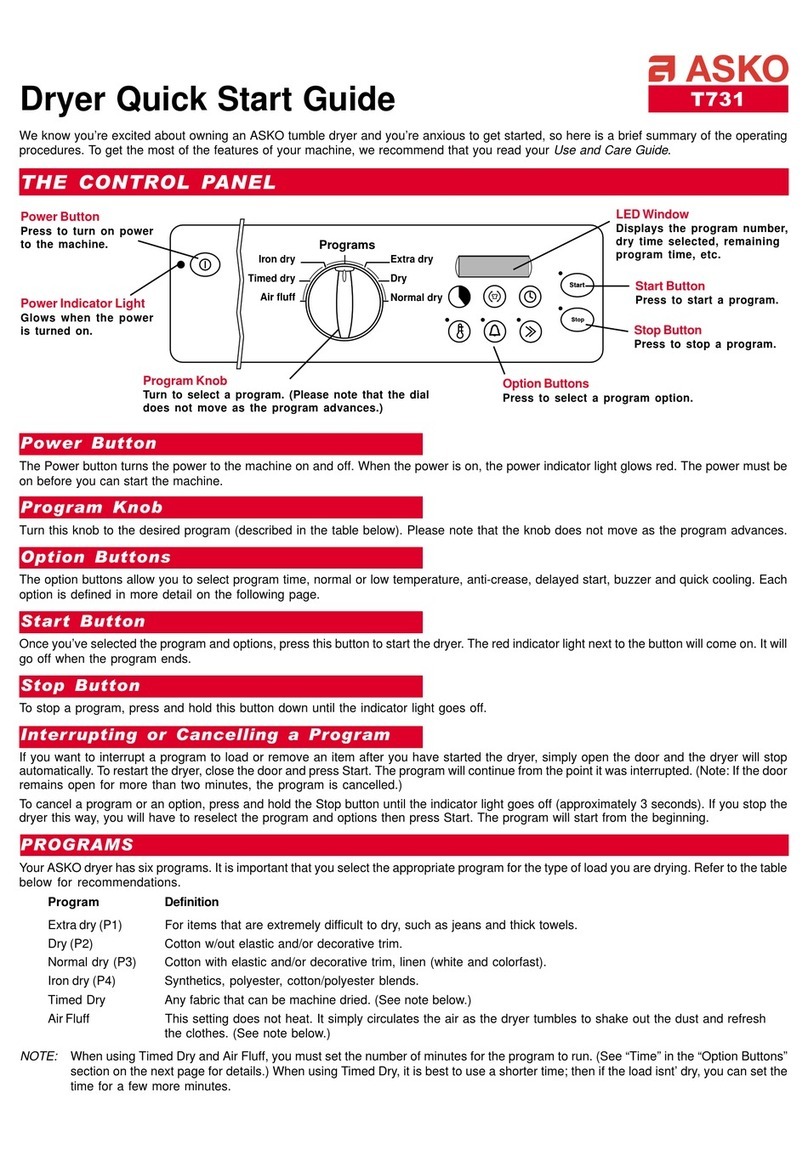

Control Panel . . . . . . . . . . . . . . . . . . . . . 6

Where to install it . . . . . . . . . . . . . . . . . . 7

Electrical requirements . . . . . . . . . . . . . 8

User’s responsibility . . . . . . . . . . . . 8

Electrical connection . . . . . . . . . . . . 8

Ventilation alternatives . . . . . . . . . . . . . 9

Evacuation by ventilating the room

where the drying cabinet is installed

. . 9

Connection to the evacuation duct

. . . . 10

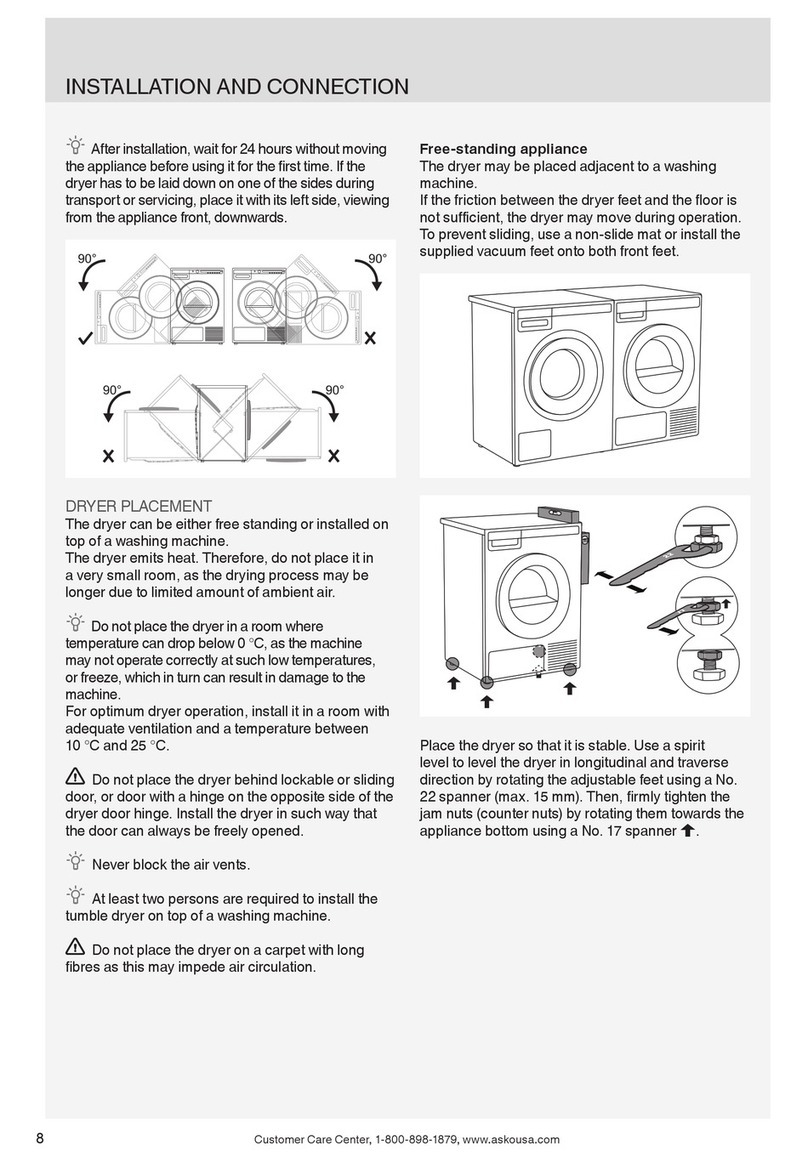

Installation . . . . . . . . . . . . . . . . . . . . . . 12

Unpacking . . . . . . . . . . . . . . . . . . . 12

Complete delivery includes: . . . . . 12

Recommended tools . . . . . . . . . . . 12

Assembly kit . . . . . . . . . . . . . . . . . 13

Reversing the Door Opening. . . . . 14

Horizontal adjustment . . . . . . . . . 15

Mounting . . . . . . . . . . . . . . . . . . . . 15

Mounting inside custom cabinetry 16

Connect Ventilation . . . . . . . . . . . . 18

Electrical connection . . . . . . . . . . . 18

Final check . . . . . . . . . . . . . . . . . . 19

How to use the Drying Cabinet . . . . . 20

Starting . . . . . . . . . . . . . . . . . . . . . 20

Interrupting the drying. . . . . . . . . . 20

Choosing where to place the

washing. . . . . . . . . . . . . . . . . . . . . 20

Some advice for users . . . . . . . . . 21

Setting the temperature selector

knob . . . . . . . . . . . . . . . . . . . . . . . 22

Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cleaning . . . . . . . . . . . . . . . . . . . . 23

When the drying cabinet is not

in use . . . . . . . . . . . . . . . . . . . . . . 23

Trouble Shooting . . . . . . . . . . . . . . . . . 24

Servicing . . . . . . . . . . . . . . . . . . . . . . . 25

Technical Information . . . . . . . . . . . . . 26

Technical characteristics . . . . . . . . 26

Evacuation/Air intake . . . . . . . . . . 26

Energy consumption and drying time

. . . . 26

Manufacturing standards . . . . . . . . 26

Air gap left during mounting . . . . . 26

Personal Notes . . . . . . . . . . . . . . . . . . 27