000.100.501 Operating Manual - Asycube 50 & 80 2/45

Table of Contents

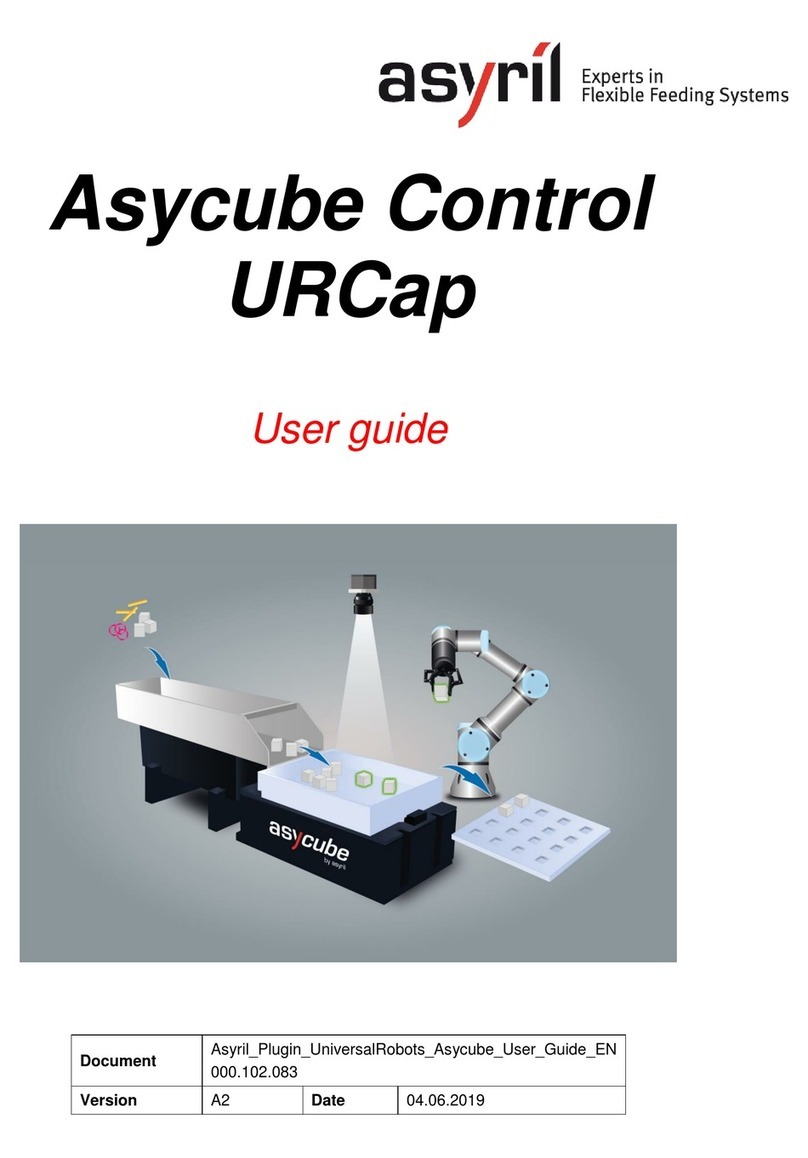

1. INTRODUCTION...............................................................................................................................4

GENERALITIES..........................................................................................................................4

SAFETY PRECAUTIONS.............................................................................................................5

General safety precaution...................................................................................................5

Specific warnings..................................................................................................................6

WARRANTY INFORMATION........................................................................................................7

CE INFORMATION .....................................................................................................................7

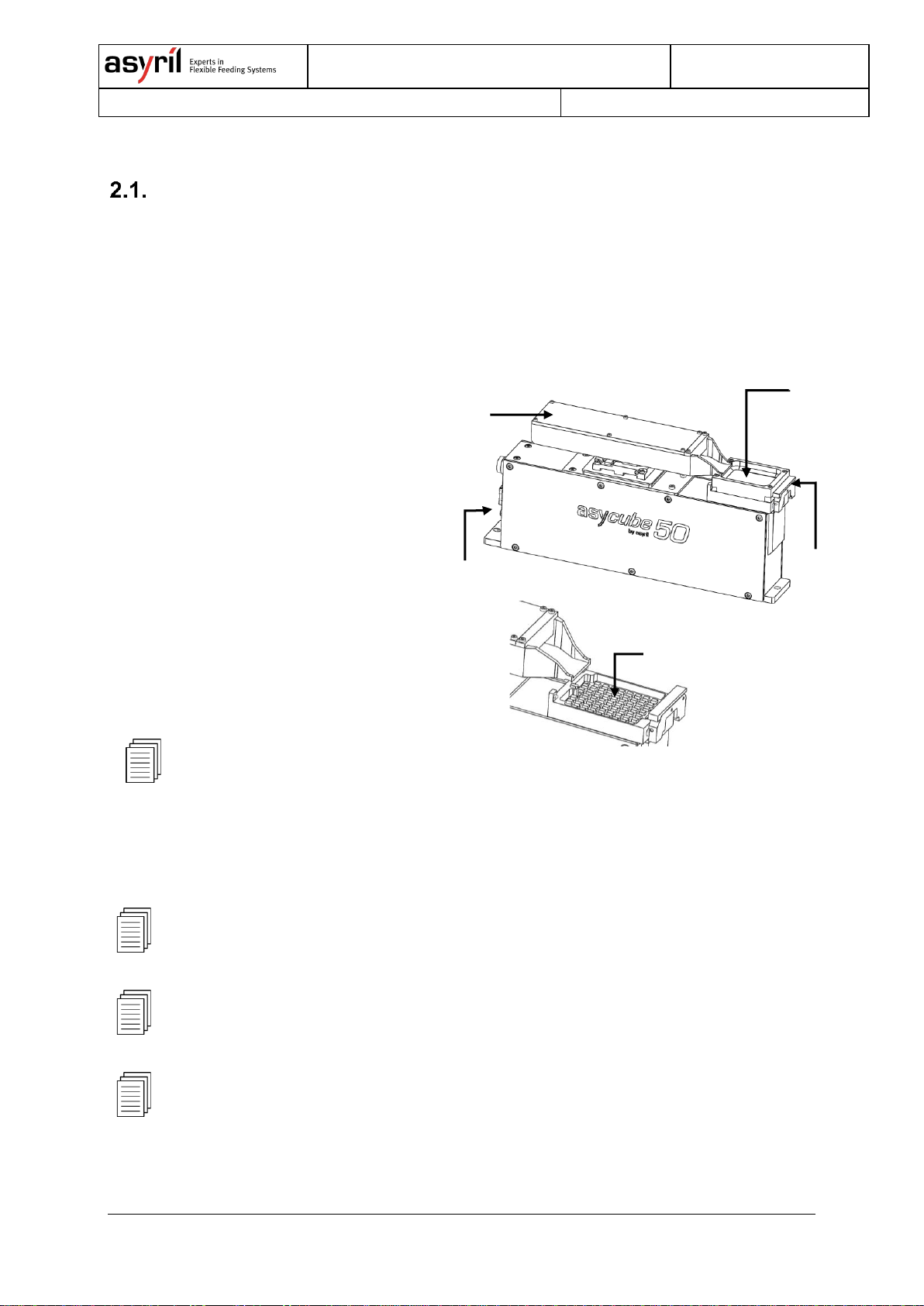

2. DESCRIPTION..................................................................................................................................9

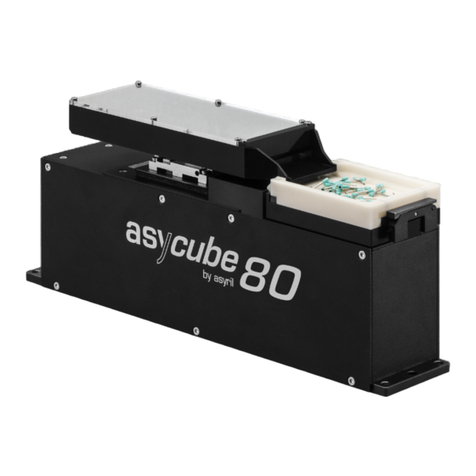

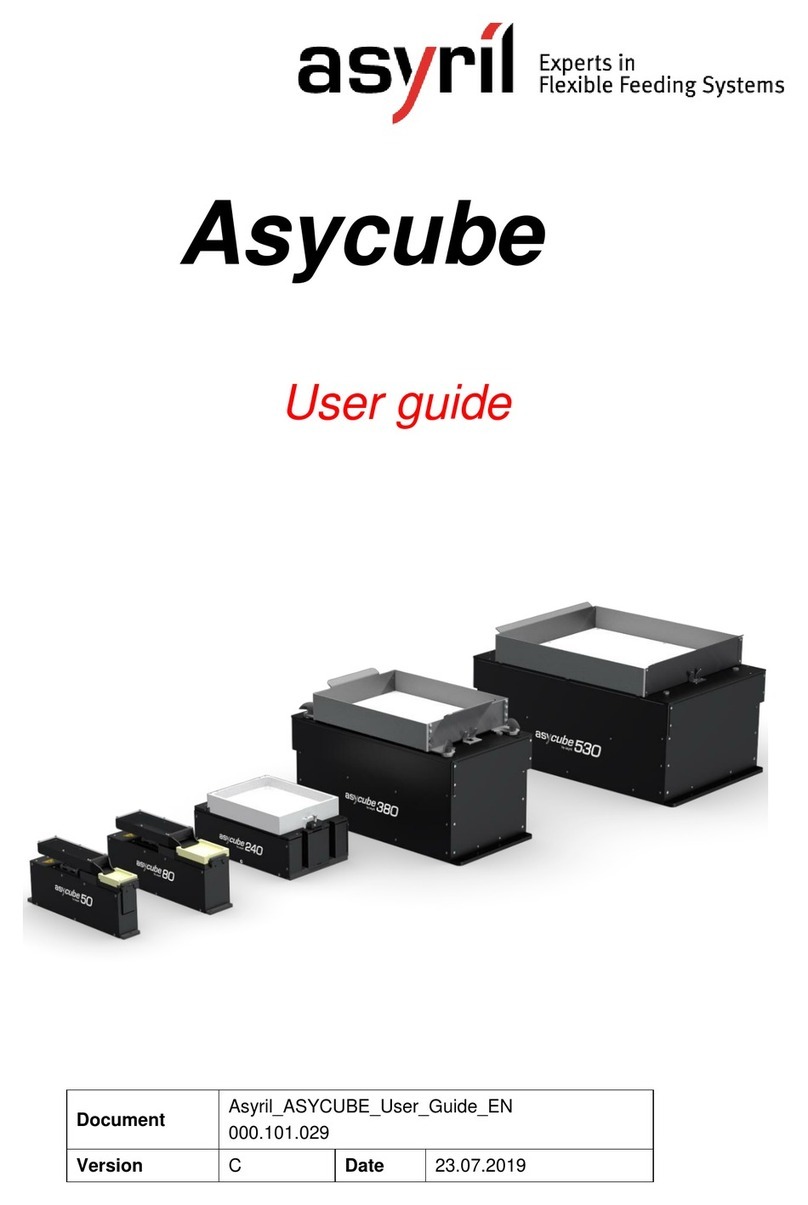

FIRST GLIMPSE AT THE PRODUCT.............................................................................................9

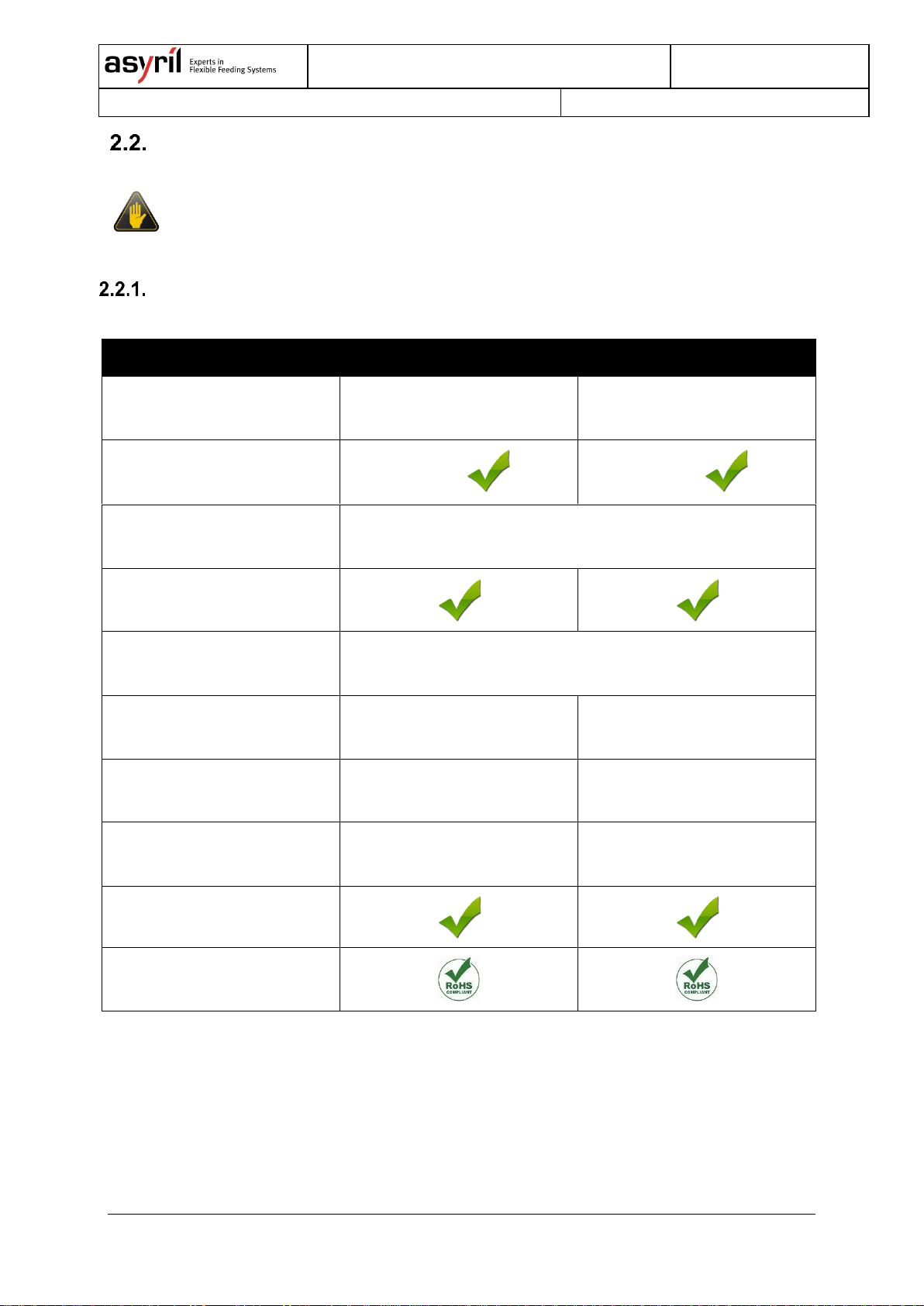

GENERAL CHARACTERISTICS.................................................................................................10

Technical features..............................................................................................................10

Overall dimensions.............................................................................................................11

Visual signals ......................................................................................................................13

Maximum permissible external force on the platform (Asycube 50 and 80)..............14

Permissible platform weight..............................................................................................14

Permissible hopper weight................................................................................................14

Maximum plate displacement...........................................................................................15

Plate Z repeatability ...........................................................................................................15

PERFORMANCE.......................................................................................................................16

Workspace (Picking surface)............................................................................................16

Displacement of the parts..................................................................................................16

ELECTRIC INTERFACES ..........................................................................................................17

Overview..............................................................................................................................17

Power connection...............................................................................................................18

Communication...................................................................................................................20

Backlight Synchronization.................................................................................................20

MECHANICAL INTERFACES .....................................................................................................21

Attachment of the Asycube...............................................................................................21

ACCESSORIES AND OPTIONAL MODULES...............................................................................22

Platform................................................................................................................................22

Platform with purge ............................................................................................................23

Special platform..................................................................................................................24

Hopper..................................................................................................................................28

Backlight ..............................................................................................................................29

Cables..................................................................................................................................29

3. TRANSPORTATION, HANDLING AND INSTALLATION.......................................................30

PACKAGING OF THE PRODUCT,TRANSPORTATION AND HANDLING .......................................30