SmartSight - Asyril SA

Programming Guide

000.100.531 SmartSight - Programming Guide 3/31

Table of Contents

1. INTRODUCTION..............................................................................................................................................4

1.1. GENERAL INFORMATION...........................................................................................................................4

1.2. OTHER MANUALS......................................................................................................................................5

2. GENERAL INTRODUCTION............................................................................................................................6

2.1. OVERVIEW................................................................................................................................................6

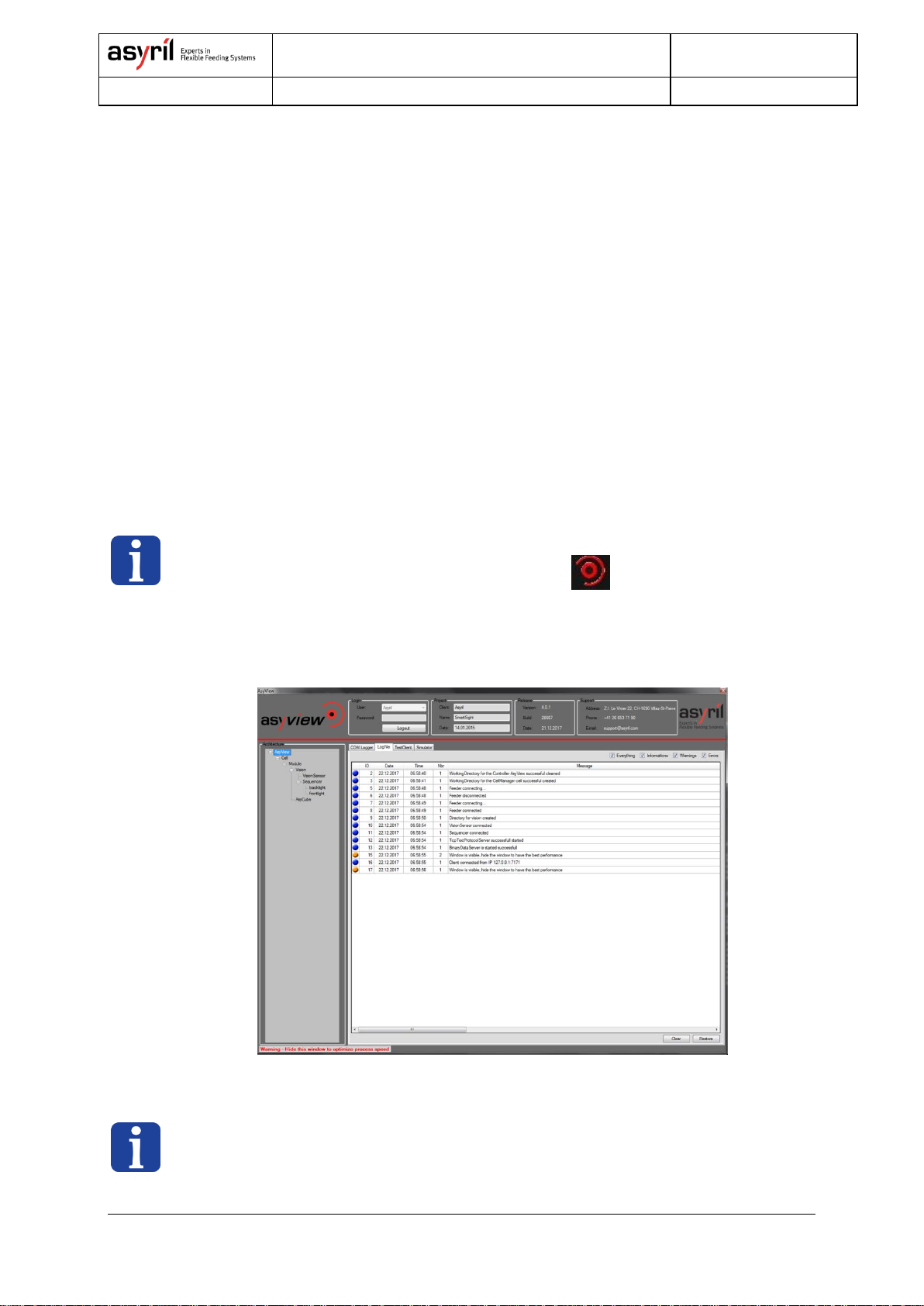

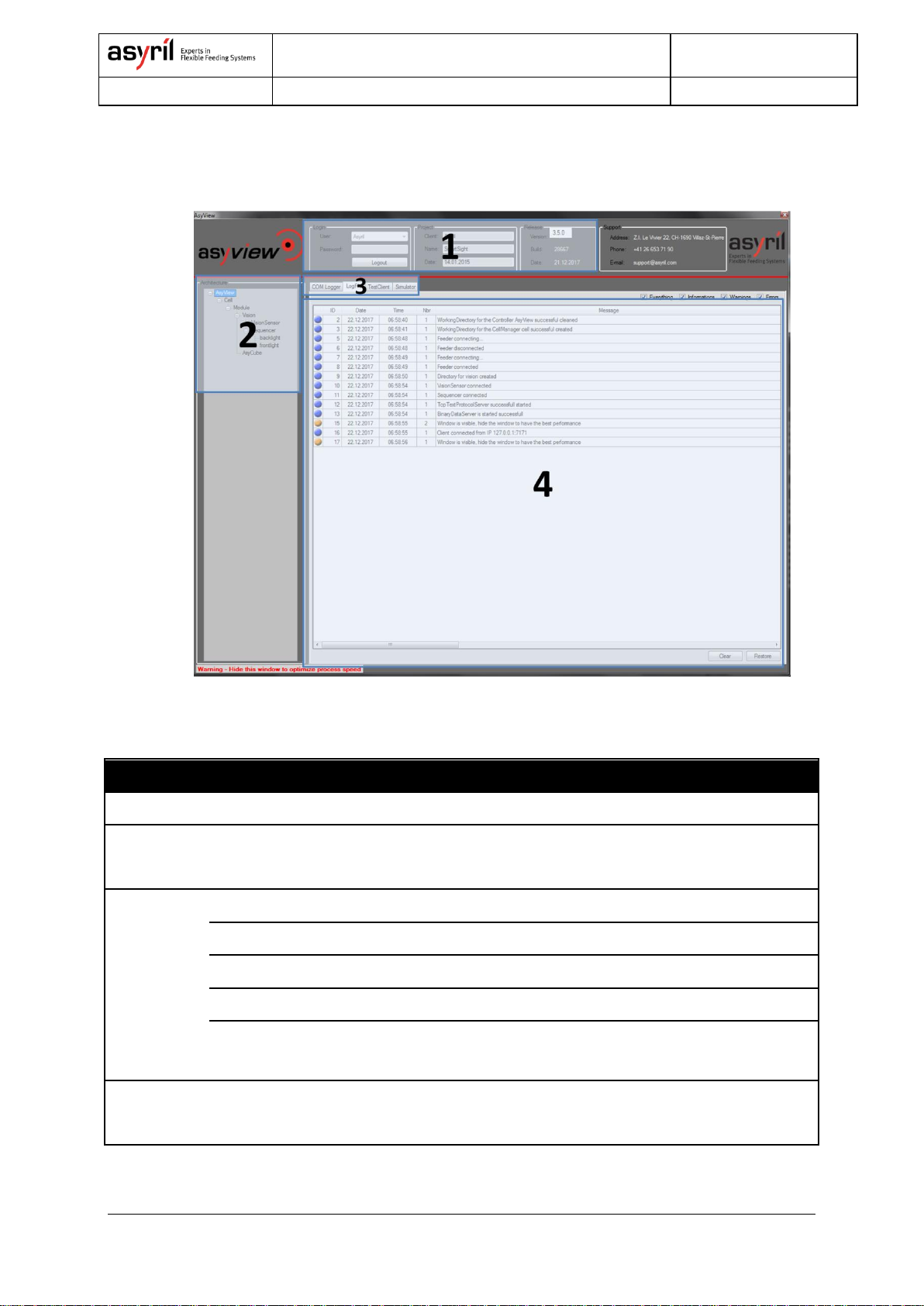

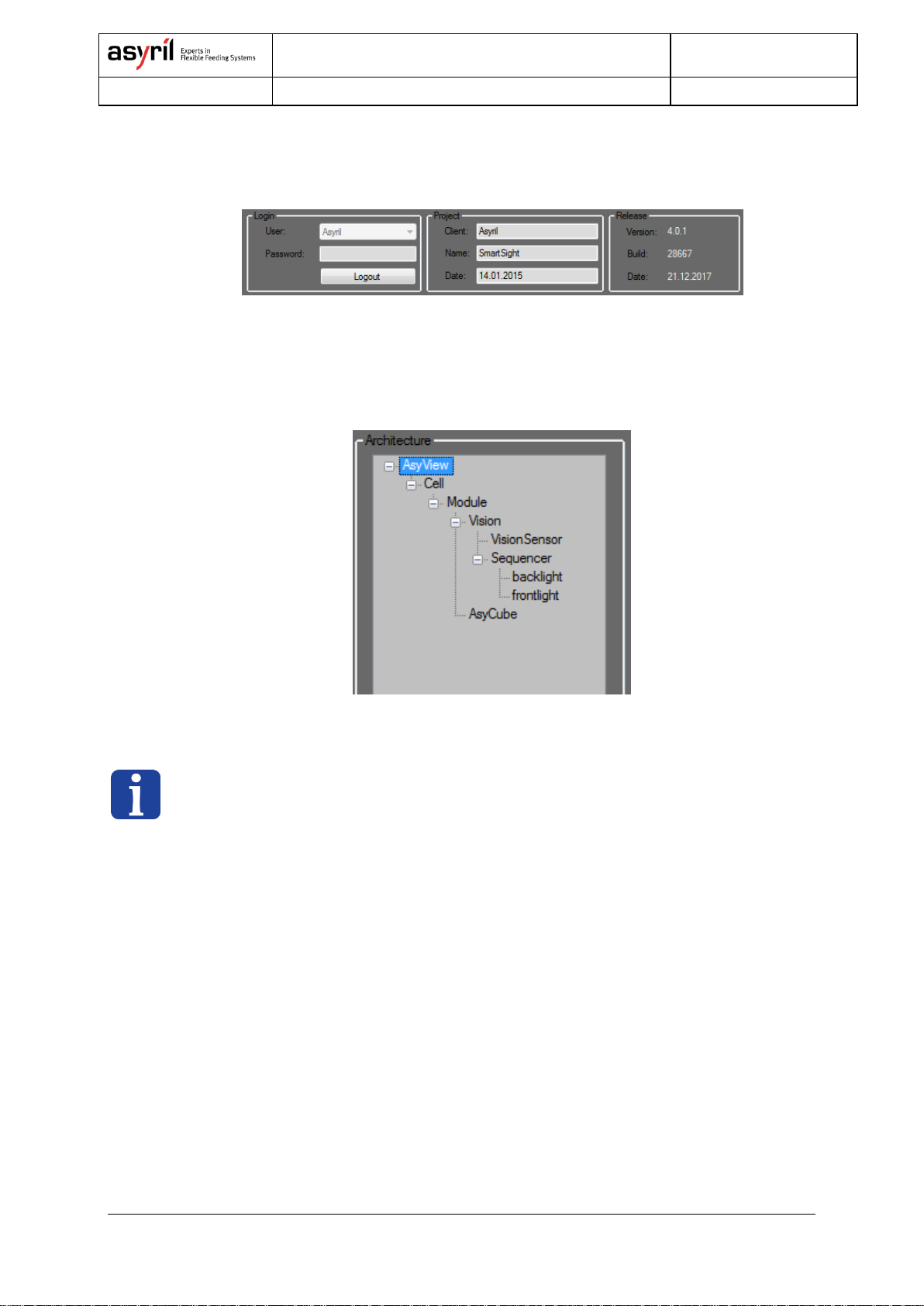

2.1.1. Asyview.......................................................................................................................................... 7

2.1.2. Asyview interface.......................................................................................................................... 7

2.1.3. Human Machine Interface –HMI ............................................................................................. 12

3. COMMUNICATION PROTOCOL...................................................................................................................13

3.1. TCP/IP PARAMETERS............................................................................................................................13

3.2. PROTOCOL.............................................................................................................................................13

3.2.1. Synchronous Mode .................................................................................................................... 14

3.2.2. Asynchronous Mode .................................................................................................................. 14

3.3. ARCHITECTURE AND ADDRESSING.........................................................................................................15

3.4. RESPONSE CODES.................................................................................................................................15

4. METHODS......................................................................................................................................................16

4.1. MODES ...................................................................................................................................................16

4.2. WORKING MODE....................................................................................................................................16

4.2.1. Active Working Mode................................................................................................................. 17

4.2.2. Passive Working Mode.............................................................................................................. 22

4.3. RECIPE...................................................................................................................................................23

5. INSTRUCTIONS.............................................................................................................................................24

6. TECHNICAL SUPPORT.................................................................................................................................29

6.1.1. For a better service … ............................................................................................................... 29

6.1.2. Contact......................................................................................................................................... 29

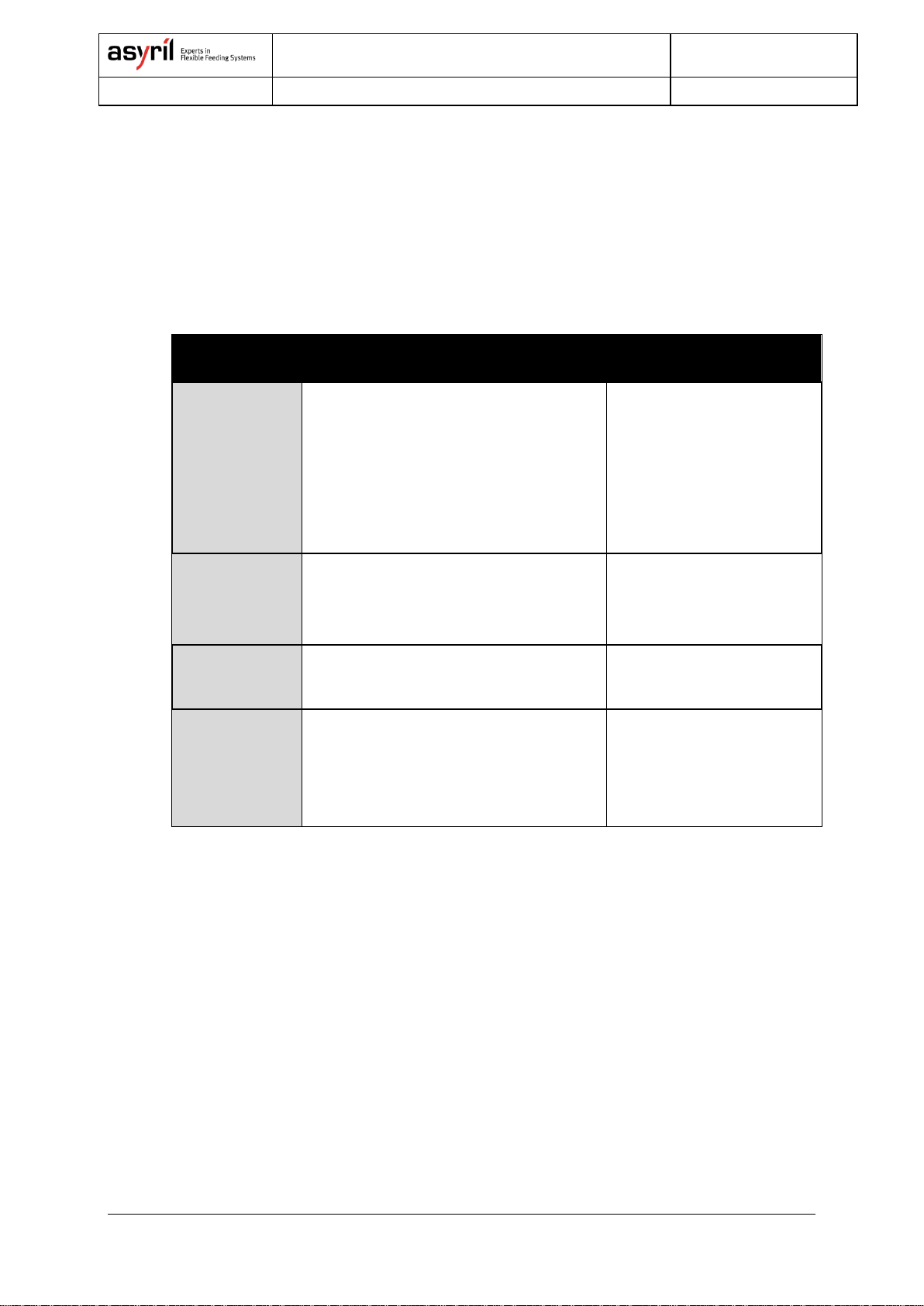

REVISION TABLE .................................................................................................................................................30