2/14

Table of contents

1. INTRODUCTION...............................................................................................................................3

GENERAL INFORMATION...........................................................................................................3

DOCUMENT PURPOSE...............................................................................................................3

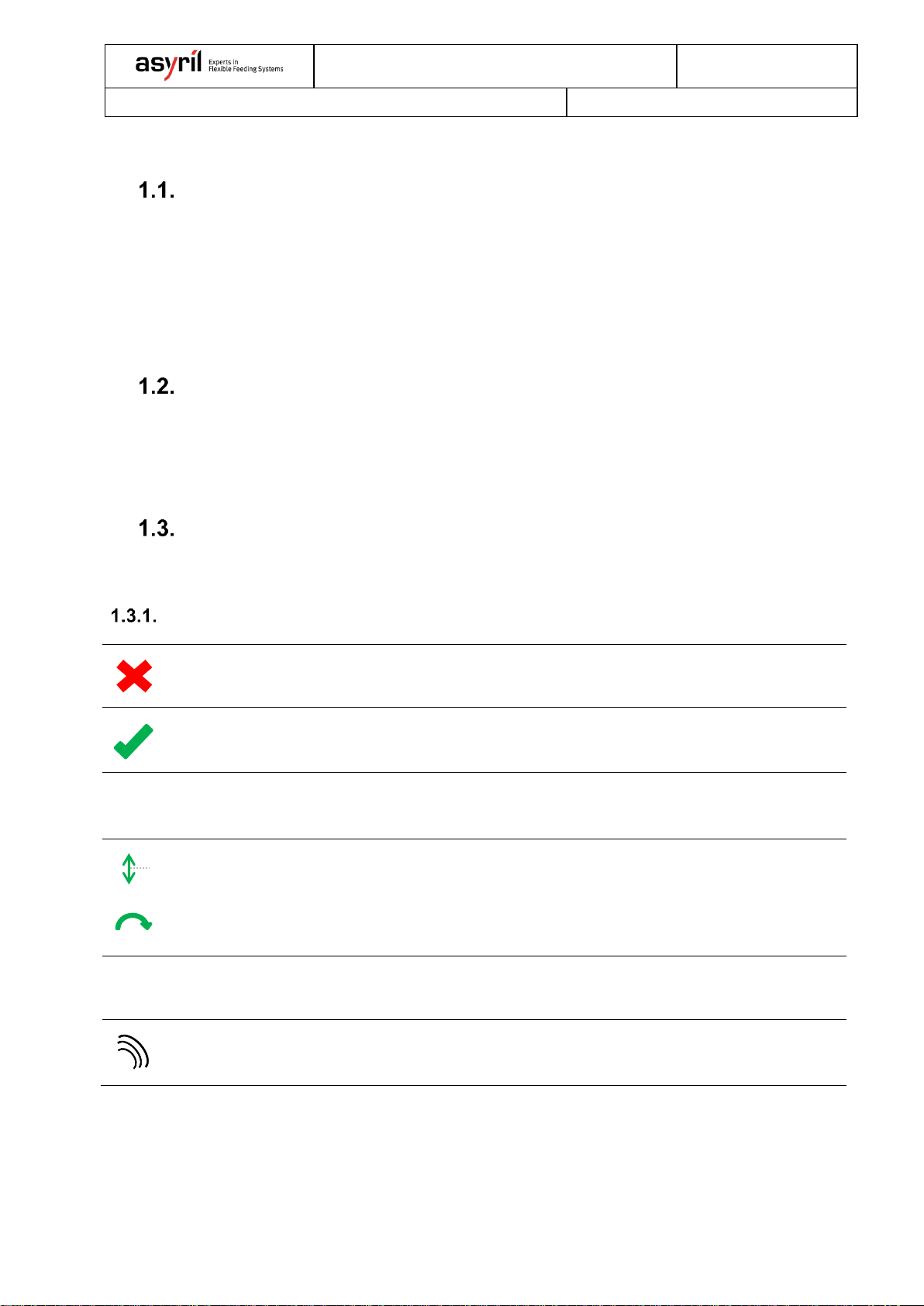

SYMBOLS..................................................................................................................................3

Images....................................................................................................................................3

Acronyms...............................................................................................................................4

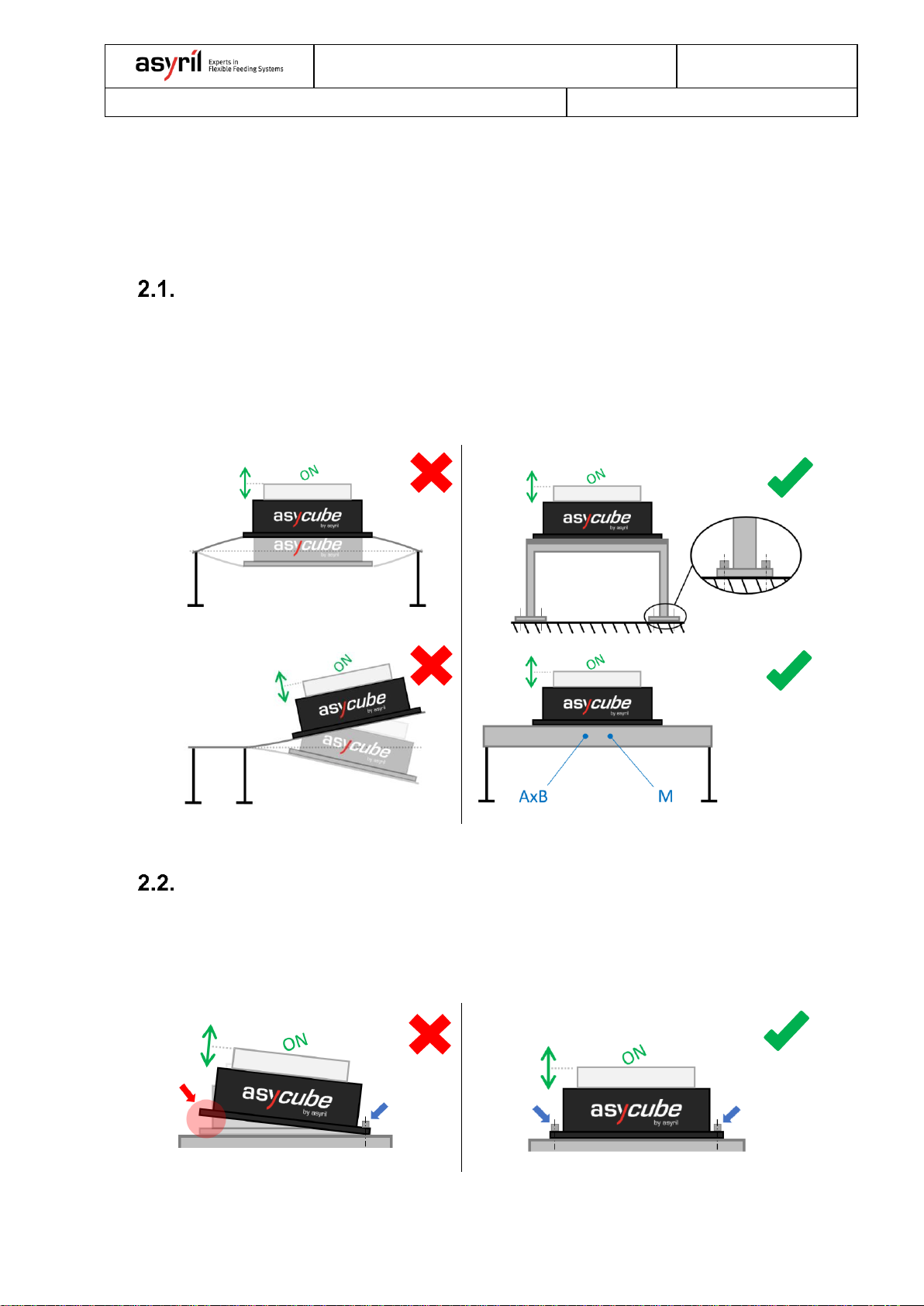

2. ASYCUBE INTEGRATION .............................................................................................................5

ASYCUBE POSITION ON SUPPORT AND SUPPORT CHARACTERISTICS......................................5

FIXING THE ASYCUBE ON ITS SUPPORT ...................................................................................5

3. VIBRATION DECOUPLING............................................................................................................6

DECOUPLING OF MOVING DEVICES ..........................................................................................6

DECOUPLING OF THE CAMERA .................................................................................................8

4. MINIMAL DISTANCE BETWEEN ASYCUBE(S)........................................................................9

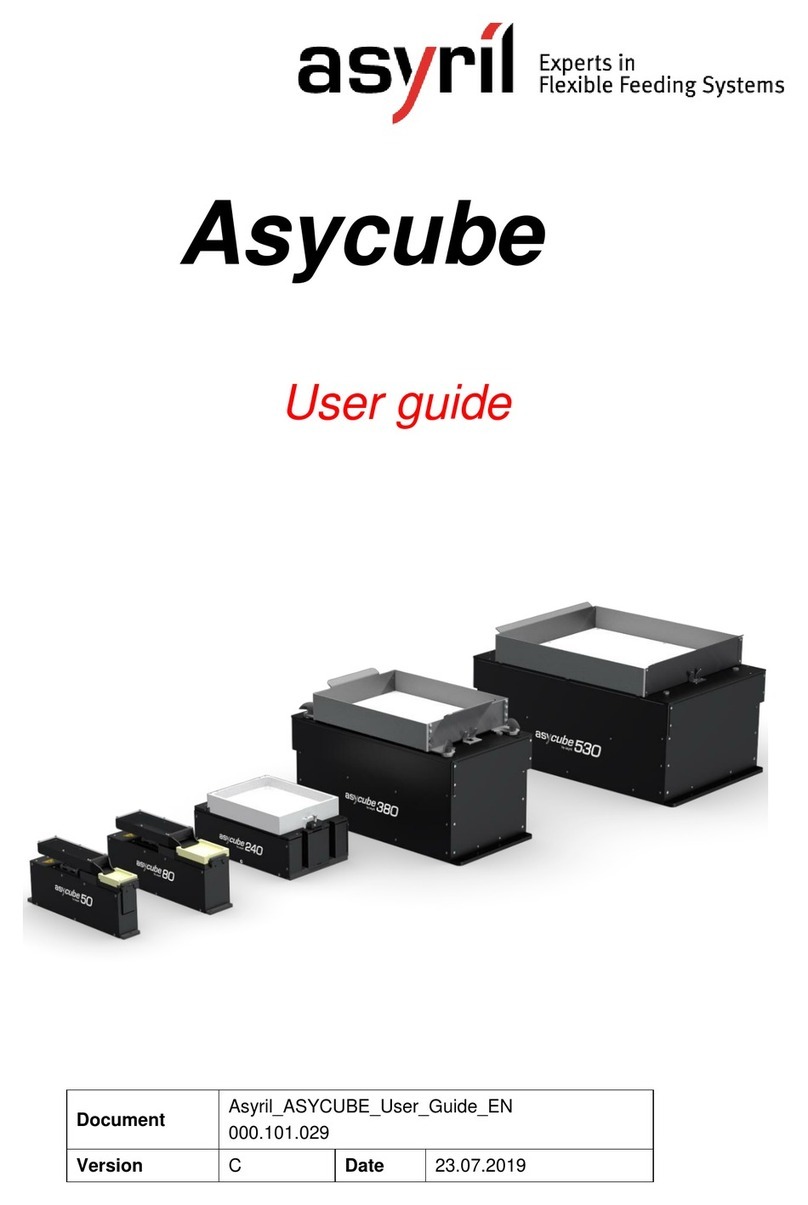

5. TECHNICAL DATA TABLES.......................................................................................................10

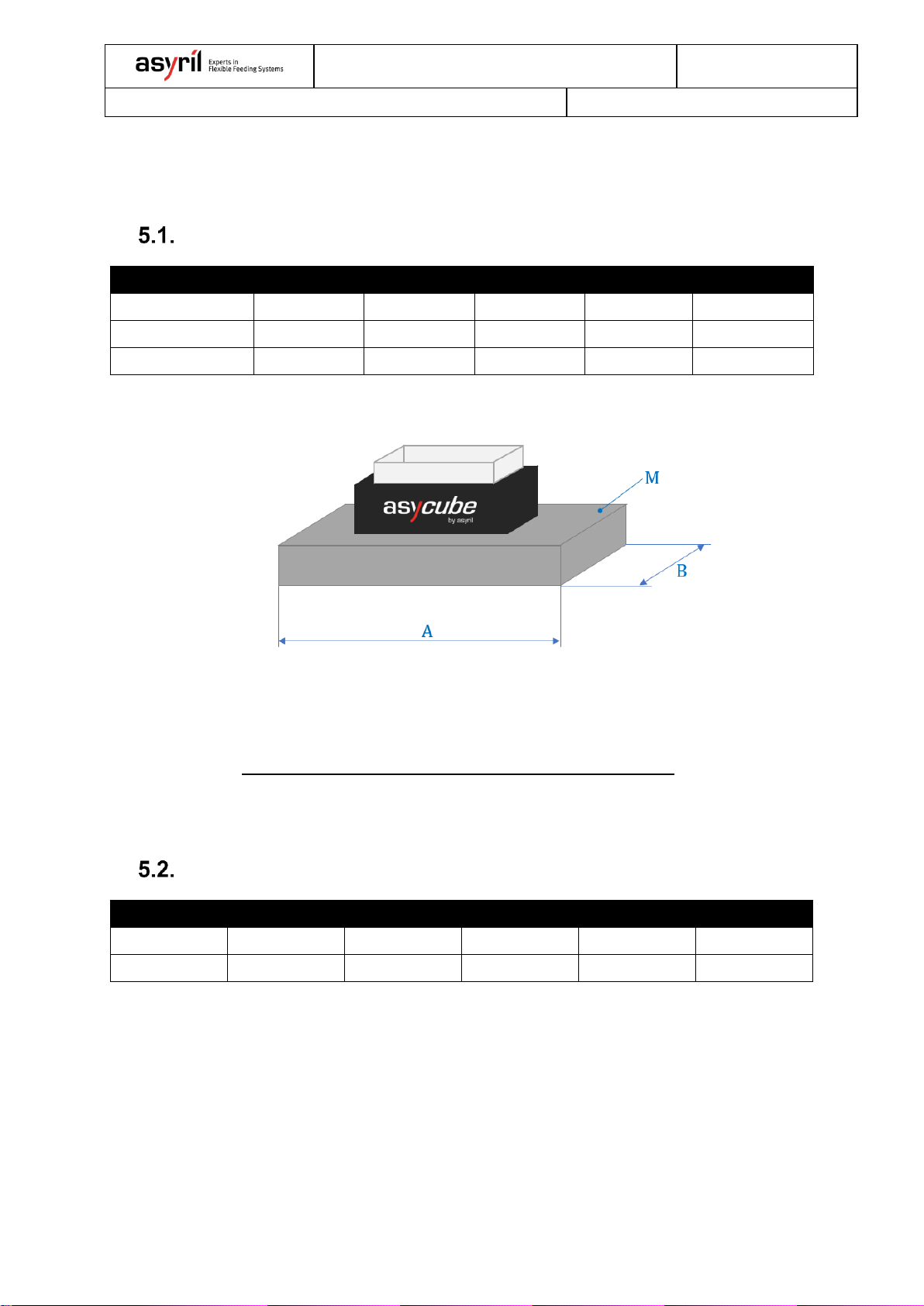

SUPPORT CHARACTERISTICS.................................................................................................10

SCREWS DETAIL .....................................................................................................................10

VIBRATION ISOLATORS DETAILS.............................................................................................11

MINIMAL DISTANCE BETWEEN ASYCUBE(S)...........................................................................12