000.102.083 2/50

Table of Contents

TABLE OF CONTENTS..............................................................................................................................2

1. INTRODUCTION...............................................................................................................................4

1.1. GENERAL INFORMATION...........................................................................................................4

1.2. OTHER MANUALS......................................................................................................................5

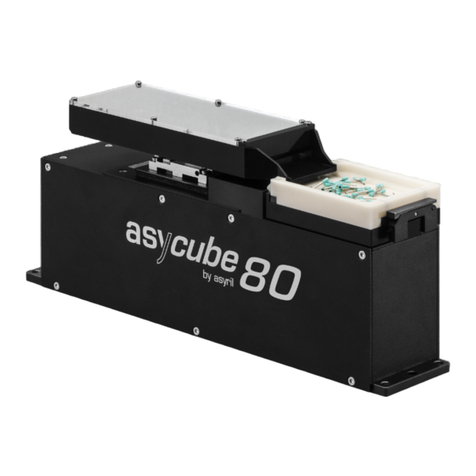

1.3. OVERVIEW ................................................................................................................................5

1.4. COMPATIBILITY.........................................................................................................................6

1.5. GENERAL NOTICE .....................................................................................................................6

2. ASYCUBE CONTROL URCAP INSTALLATION AND CONFIGURATION ...........................7

2.1. INSTALLATION...........................................................................................................................7

2.2. ENABLING THE URCAP ............................................................................................................8

2.3. NETWORK CONFIGURATION......................................................................................................8

2.3.1. Asycube network settings....................................................................................................8

2.3.2. UR robot network settings.................................................................................................10

2.3.3. Connection between the UR robot & the Asycube platform.........................................11

3. STANDARD USE OF THE ASYCUBE CONTROL URCAP....................................................14

3.1. STANDARD CONTROL..............................................................................................................14

3.2. PROGRAMMING WITH THE URCAP.........................................................................................18

3.2.1. Asycube Vibrate..................................................................................................................18

3.2.2. Asycube Backlight..............................................................................................................21

3.2.3. Offline programming...........................................................................................................22

3.3. WARNINGS AND ALARMS........................................................................................................23

4. ADVANCED USE OF THE ASYCUBE CONTROL URCAP ...................................................25

4.1. ADVANCED PROGRAMMING....................................................................................................25

4.1.1. Smart feeding......................................................................................................................25

4.1.2. Smart centering...................................................................................................................29

4.1.3. Sequence node...................................................................................................................32

4.1.4. Asycube Terminal...............................................................................................................35

4.2. MANAGING VARIABLES &LOGS ..............................................................................................36

6. UR PROGRAM EXAMPLES.........................................................................................................38

6.1. EXAMPLES’DESCRIPTION.......................................................................................................38

6.1.1. Flexible_pick_and_place_without_vision_feedback......................................................40

6.2. FLEXIBLE_PICK_AND_PLACE_STRUCTURED_PLATE_WITHOUT_VISION_FEEDBACK............40

6.2.1. Flexible_pick_and_place_with_vision_feedback ...........................................................41

6.3. LOADING AN EXAMPLE............................................................................................................41

7. TROUBLESHOOTING...................................................................................................................43

8. TECHNICAL SUPPORT................................................................................................................45