Manual, Tool Changer, QC‑113

Document #9620‑20‑B‑113 Base Tool Changer‑05

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-1

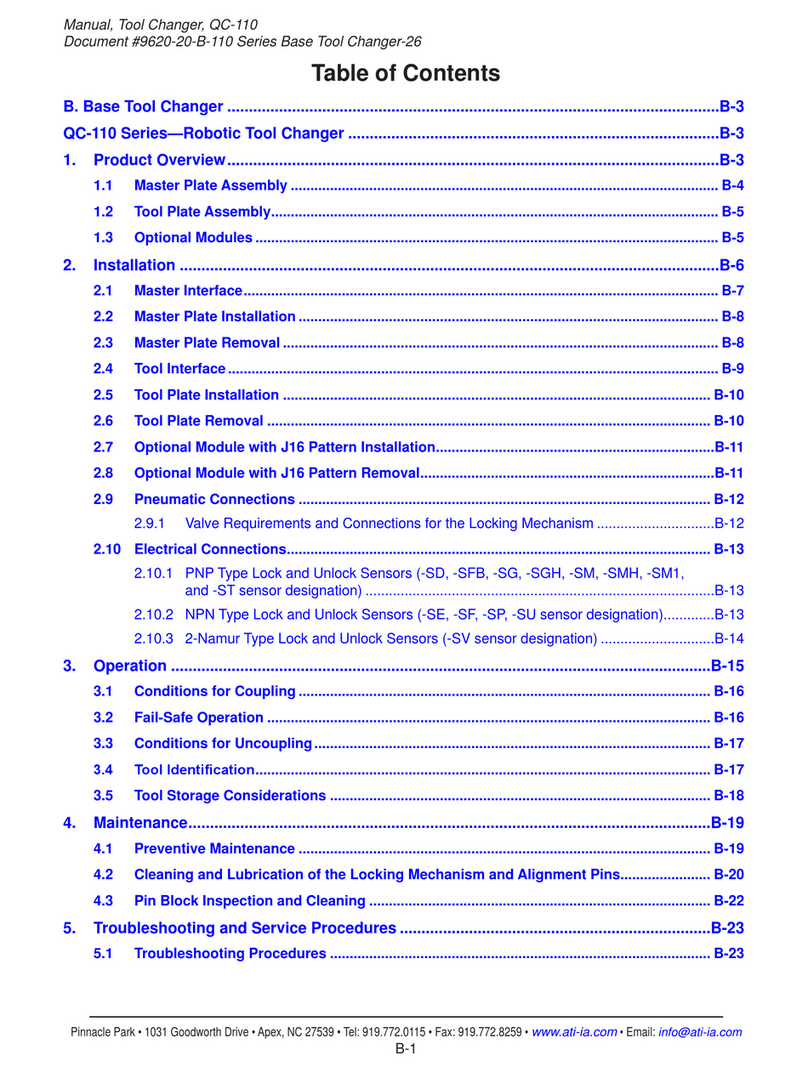

Table of Contents

B. Base Tool Changer .................................................................................................................B-3

QC-113 Series—Tool Changer.....................................................................................................B-3

1. Product Overview..................................................................................................................B-3

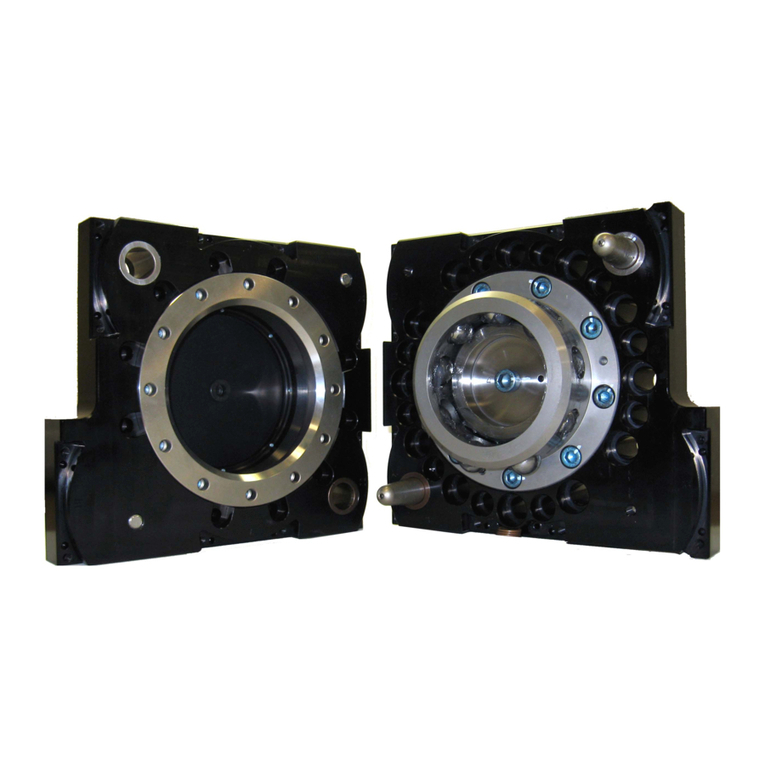

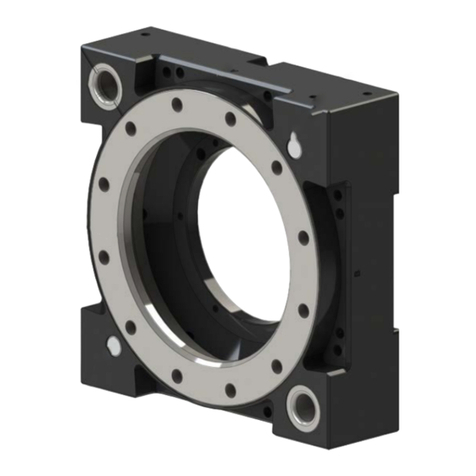

1.1 Master Plate Assembly ............................................................................................................. B-4

1.2 Tool Plate Assembly.................................................................................................................. B-5

1.3 Optional Modules...................................................................................................................... B-5

2. Installation .............................................................................................................................B-6

2.1 Master Interface......................................................................................................................... B-7

2.2 Master Plate Installation........................................................................................................... B-8

2.3 Master Plate Removal............................................................................................................... B-9

2.4 Tool Interface........................................................................................................................... B-10

2.5 Tool Plate Installation ..............................................................................................................B-11

2.6 Tool Plate Removal ..................................................................................................................B-11

2.7 Pneumatic Requirements....................................................................................................... B-12

2.7.1 Valve Requirements for Air Adapter Modules................................................................B-12

2.8 Electrical Connections............................................................................................................ B-13

2.8.1 NPN Type Lock and Unlock Sensors (-SP sensor designation)....................................B-13

3. Operation .............................................................................................................................B-14

3.1 Conditions for Coupling......................................................................................................... B-15

3.2 Fail-Safe Operation ................................................................................................................. B-16

3.3 Conditions for Uncoupling..................................................................................................... B-17

3.4 ToolIdentication.................................................................................................................... B-17

3.5 Tool Storage Considerations ................................................................................................. B-18

4. Maintenance.........................................................................................................................B-18

4.1 Preventive Maintenance ......................................................................................................... B-19

4.2 Cleaning and Lubrication of the Locking Mechanism and Alignment Pins....................... B-20

4.3 Pin Block Inspection and Cleaning ....................................................................................... B-22

5. Troubleshooting ..................................................................................................................B-23

5.1 Troubleshooting Procedures ................................................................................................. B-23

5.2 Service Procedures................................................................................................................. B-24

5.2.1 Alignment Pin Replacement..........................................................................................B-24

5.2.2 Lock and Unlock Sensor Replacement Procedures......................................................B-26

5.2.3 RTL Flat Pack Style Sensor Replacement (R2 Sensor)................................................B-27

5.2.4 RTL Flat Pack Style Sensor Replacement (R1 Sensor)................................................B-29

5.2.5 Seal Inspection and Replacement.................................................................................B-30