Manual, Tool Changer, QC-201

Document #9620-20-B-201 Base Tool Changer-12

Pinnacle Park

1031 Goodworth Drive

Apex, NC 27539

Tel: 919.772.0115

Fax: 919.772.8259

www.ati-ia.com

B - 10

4. Maintenance

The tool changer and optional modules are designed to provide a long life with little

maintenance required.

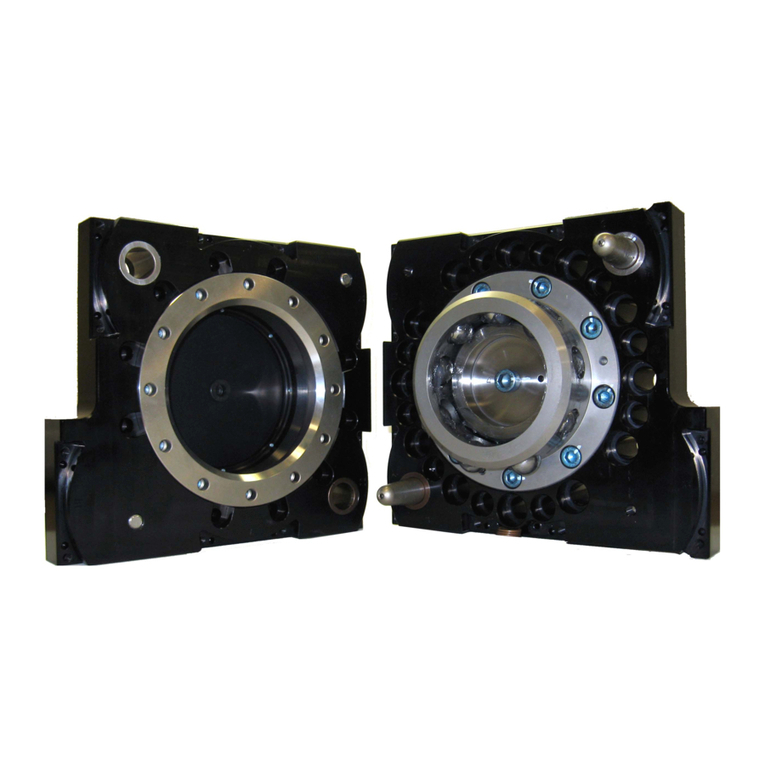

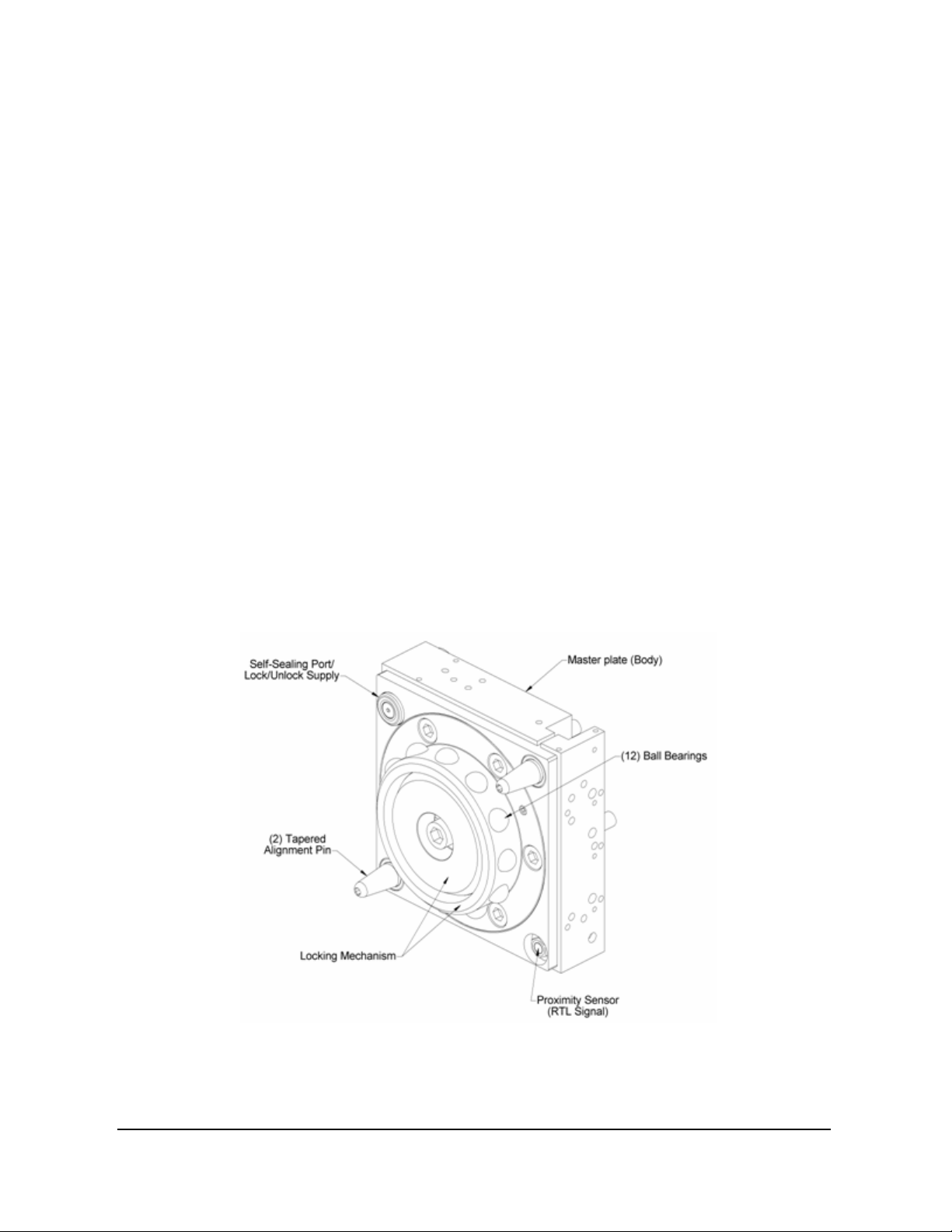

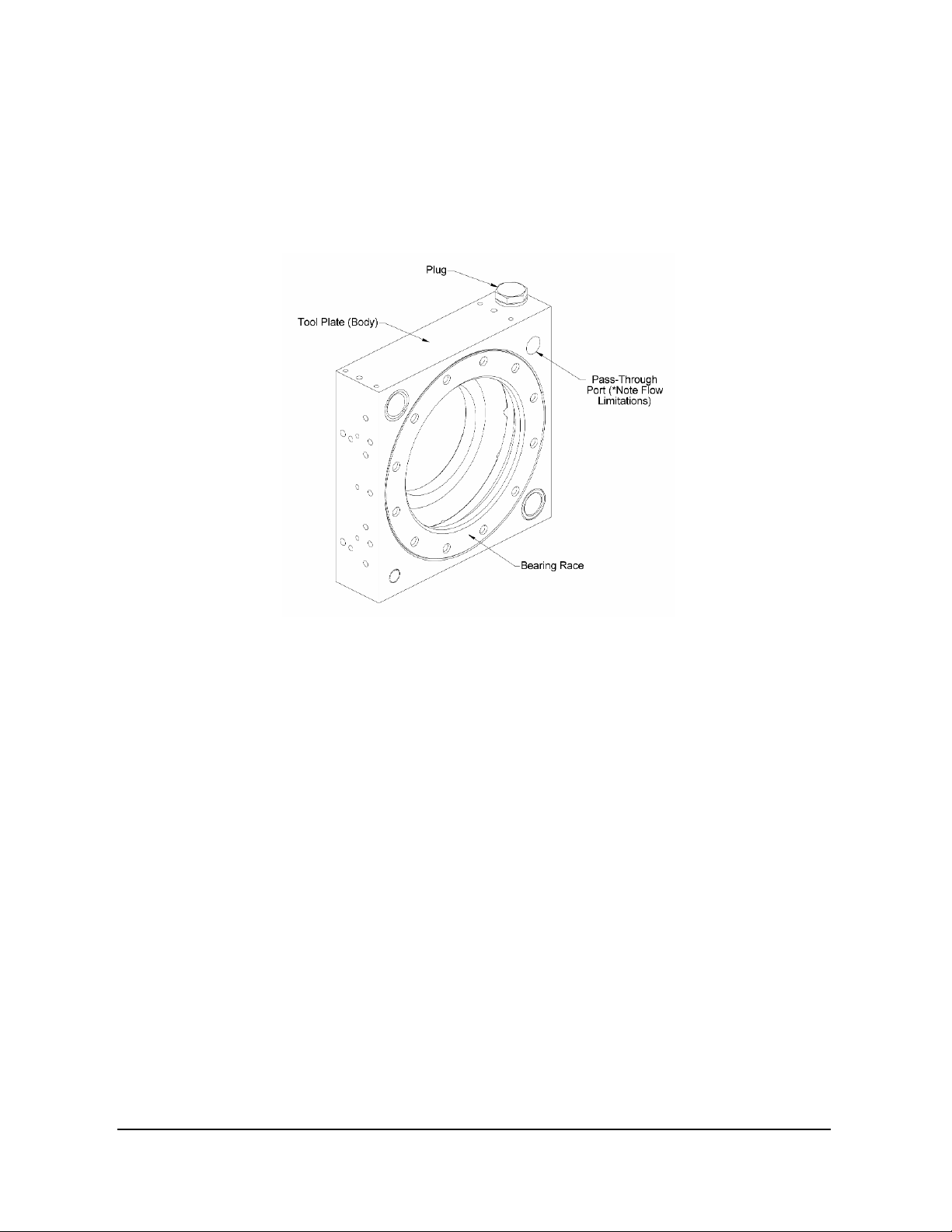

A visual inspection of the locking mechanism is recommended every 100,000 cycles or on a

semi-annual basis, whichever comes first. The ball bearings, alignment pins, bearing race and

alignment pin holes should be inspected for wear and lubrication. Component parts are to be

cleaned thoroughly prior to re-lubricating. A NLGI #2, lithium-based grease with

molybdenum disulfide additive is suggested for ball and alignment pin lubrication.

If alignment pin replacement is required the new alignment pins must be installed with a

torque of 60 in-lbs, and Loctite 242 or similar must be used.

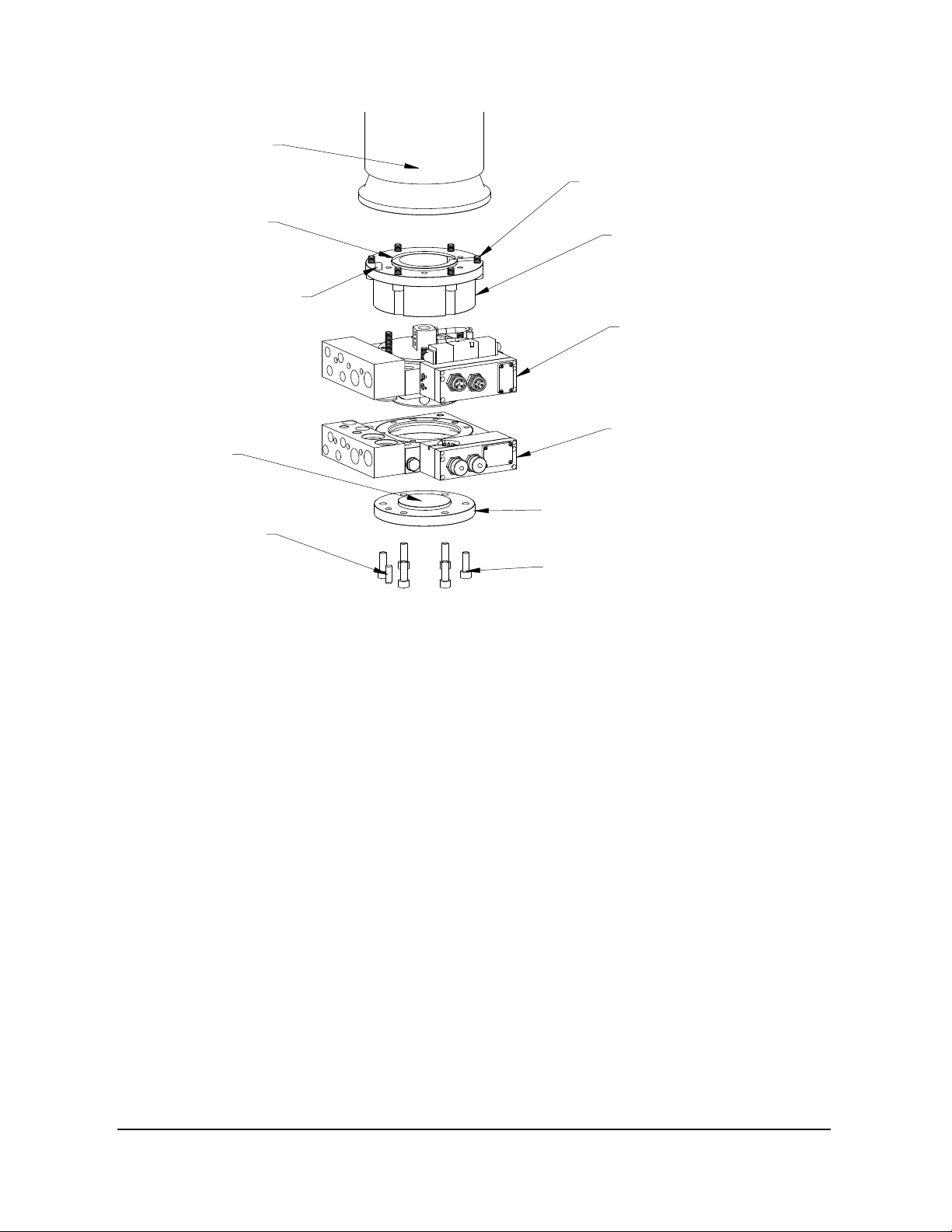

An inspection of the tool stand and tool should be performed periodically for evidence of

wear, bending or other problems that could affect Master and Tool Plate alignment during

coupling and uncoupling.

Rubber bushings should be periodically inspected for wear, abrasion and cuts that can result

from improper handling.

If the tool changer is being used in dirty environments (e.g. welding or deburring applications)

care should be taken to limit the exposure of the tool changer. Unused Tool assemblies should

be covered to prevent debris from settling on the mating surface. Also, the Master Plate

assembly should be exposed for only a short period of time during tool change and down time.

In this instance the customer should determine a suitable inspection schedule.

Detailed assembly drawings are provided in Section 8—Drawings of this manual.

4.1 Preventive Maintenance

The tool changer and optional modules are designed to provide a long life with regular

maintenance required.

A visual inspection and preventative maintenance schedule is provided in the table below

depending upon the application.

Detailed assembly drawings are provided in Section 8—Drawings of this manual.

ATTENTION: The cleanliness of the work environment strongly influences the trouble-free

operation of the changer. The dirtier the environment, the greater the need for protection

against debris. Protection of the entire EOAT, the master, the tool and all of the modules

may be necessary. Protective measures include the following: 1) Placement of tools stands

away from debris generators, 2) covers incorporated into the tool stands (see Section 2.3—

Tool Stand Design), and 3) guards, deflectors, air curtains, and similar devices built into the

ATTENTION: All tool changers are initially lubricated using MobilGrease® XHP222

Special grease. The end user must apply additional lubricant to the locking

mechanism components and alignment pins prior to start of service (See Section

4.2—Cleaning, Lubrication, Adjustment and Replacement). Tubes of lubricant for this

purpose are shipped with every tool changer. Note: MobilGrease® XHP222 Special is

a NLGI #2 lithium complex grease with molybdenum disulfide.