OperatingmanualSUNTESTCPS/CPS+

- 2 -

1 Notes for safe operation.................................................................................................................................4

1.1 Explanation of the pictorial signs..................................................................................................................6

1.2 Instructionsforsafeoperation ......................................................................................................................7

2 Installation of unit ..........................................................................................................................................8

2.1 Supplyschedule ..........................................................................................................................................8

2.2 Packingmaterial ..........................................................................................................................................8

2.3 Locationrequirements..................................................................................................................................9

2.4 Installation ...................................................................................................................................................9

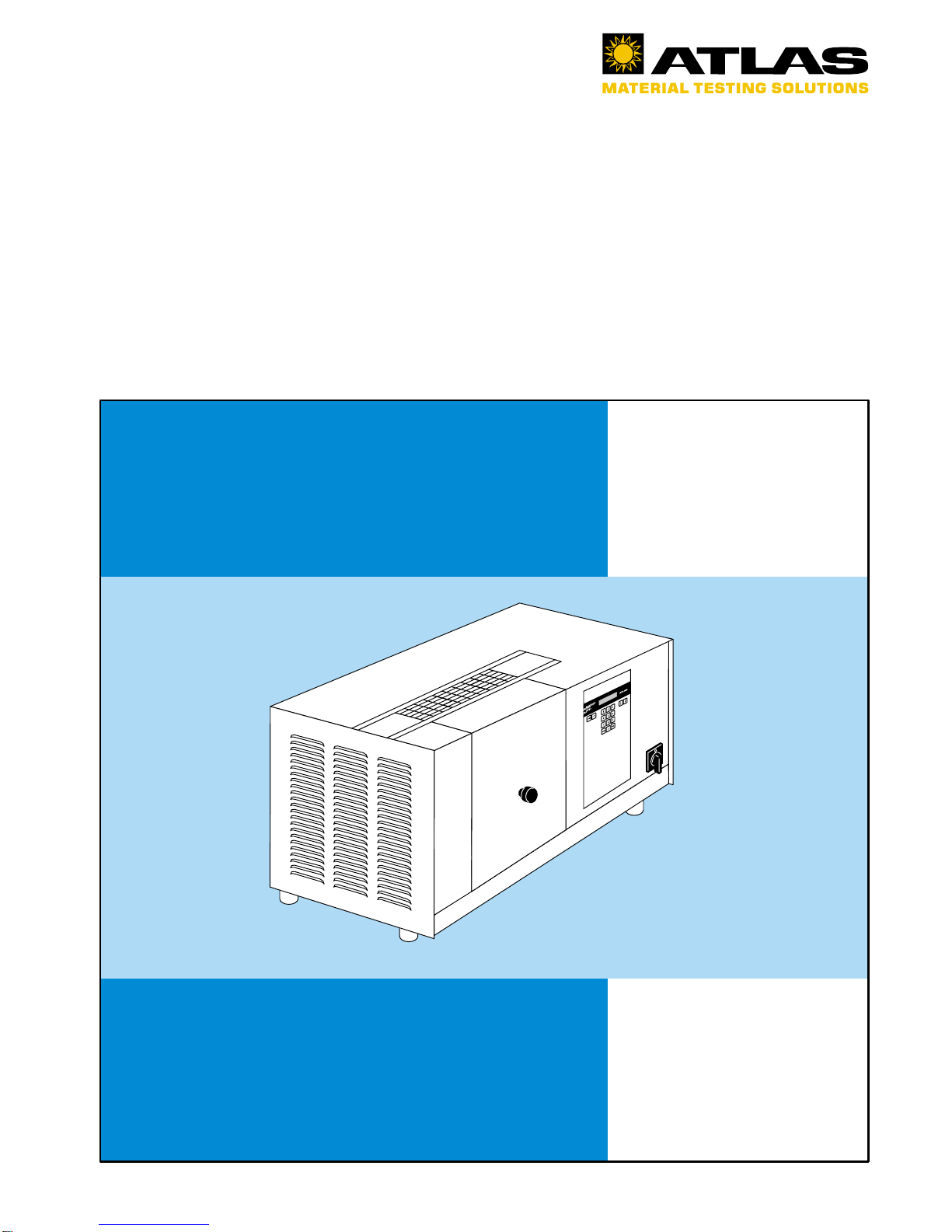

3 Description of unit ........................................................................................................................................10

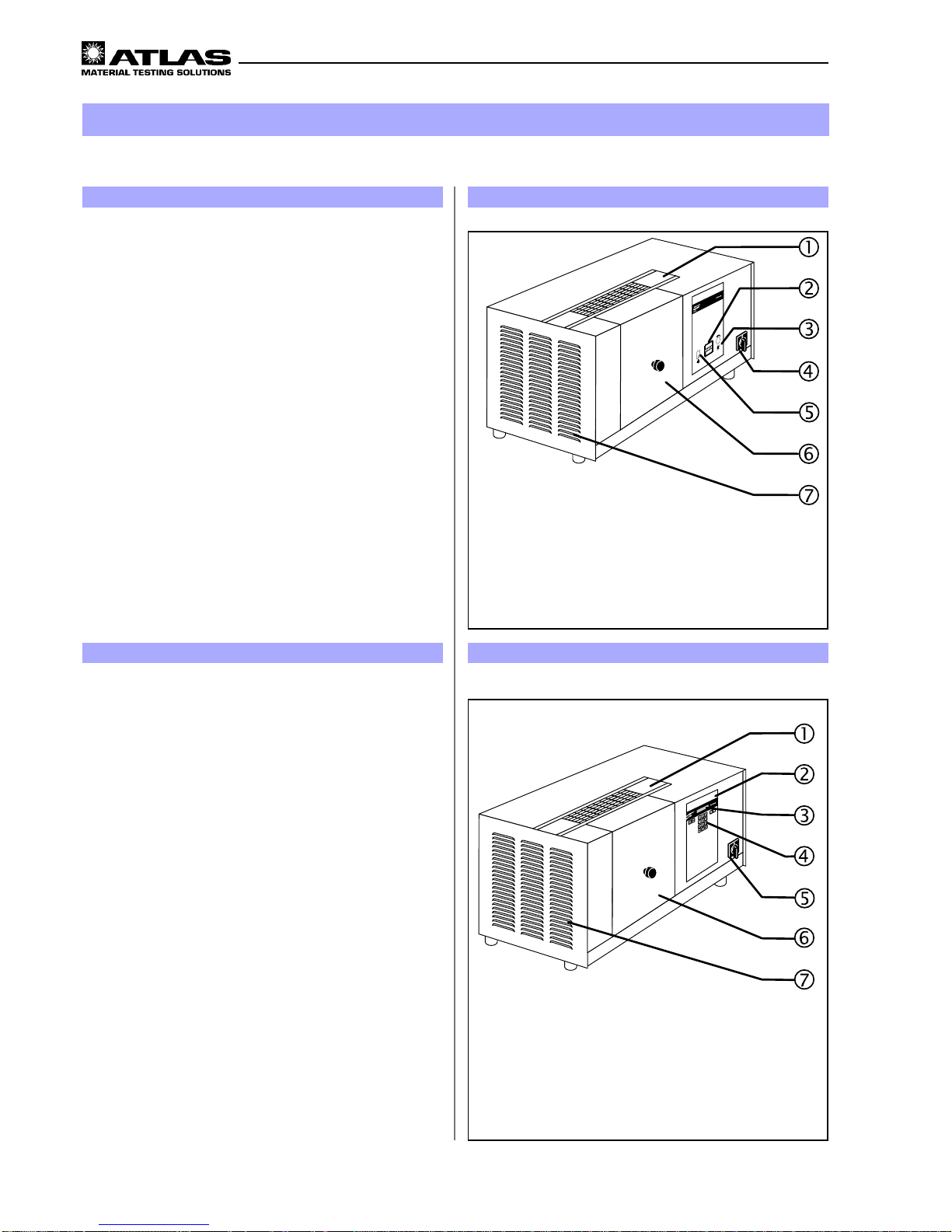

3.1 Description of Suntest CPS .......................................................................................................................10

3.2 Description of Suntest CPS+ .....................................................................................................................10

3.3 Components with similar construction SUNTEST CPS / CPS+ .................................................................. 11

4 Description offunctions ...............................................................................................................................12

4.1 Radiationand filtering.................................................................................................................................12

4.2 Ventilation circuits......................................................................................................................................12

4.3 Spectraldistributionwithadditionalfilters...................................................................................................13

4.4 Sensor system in SUNTEST CPS+ ...........................................................................................................14

4.5 Safetydevices ...........................................................................................................................................15

4.6 Safetymarkings.........................................................................................................................................15

5 Accessories ...................................................................................................................................................16

6 Commissioning .............................................................................................................................................18

6.1 Mountingofspecimentable .......................................................................................................................18

6.2 Assembling the radiation system ...............................................................................................................18

6.3 Connectiontopowersupply .......................................................................................................................21

7 Operation and shutdown .............................................................................................................................22

7.1 Configurationofunit ...................................................................................................................................22

7.2 Standardtestingprocedure ........................................................................................................................22

7.3 Testingprocedurewithoptionalunit............................................................................................................22

7.4 OperationofSUNTEST CPS ......................................................................................................................23

7.5 Operationof SUNTESTCPS+programcontroller......................................................................................23

7.6 Data transfer to a PC .................................................................................................................................24

7.7 Shutdown...................................................................................................................................................24

8 Calibration ....................................................................................................................................................25

8.1 Calibrationof irradiancewiththe XenoCalGlobalSensor ............................................................................25

8.2 Calibrationofirradiance with the RadialuxGlobalSensor ...........................................................................26

8.3 Calibrationoftheblack standardtemperature.............................................................................................27

9 Cleaning / Consumables..............................................................................................................................28

9.1 Cleaning.....................................................................................................................................................28

9.2 Consumables/ Spare parts........................................................................................................................29

10 Maintenance .................................................................................................................................................30

10.1 Maintenanceand care................................................................................................................................30

10.2 Commissioning ..........................................................................................................................................30

11 Technical data ..............................................................................................................................................31

Content Page