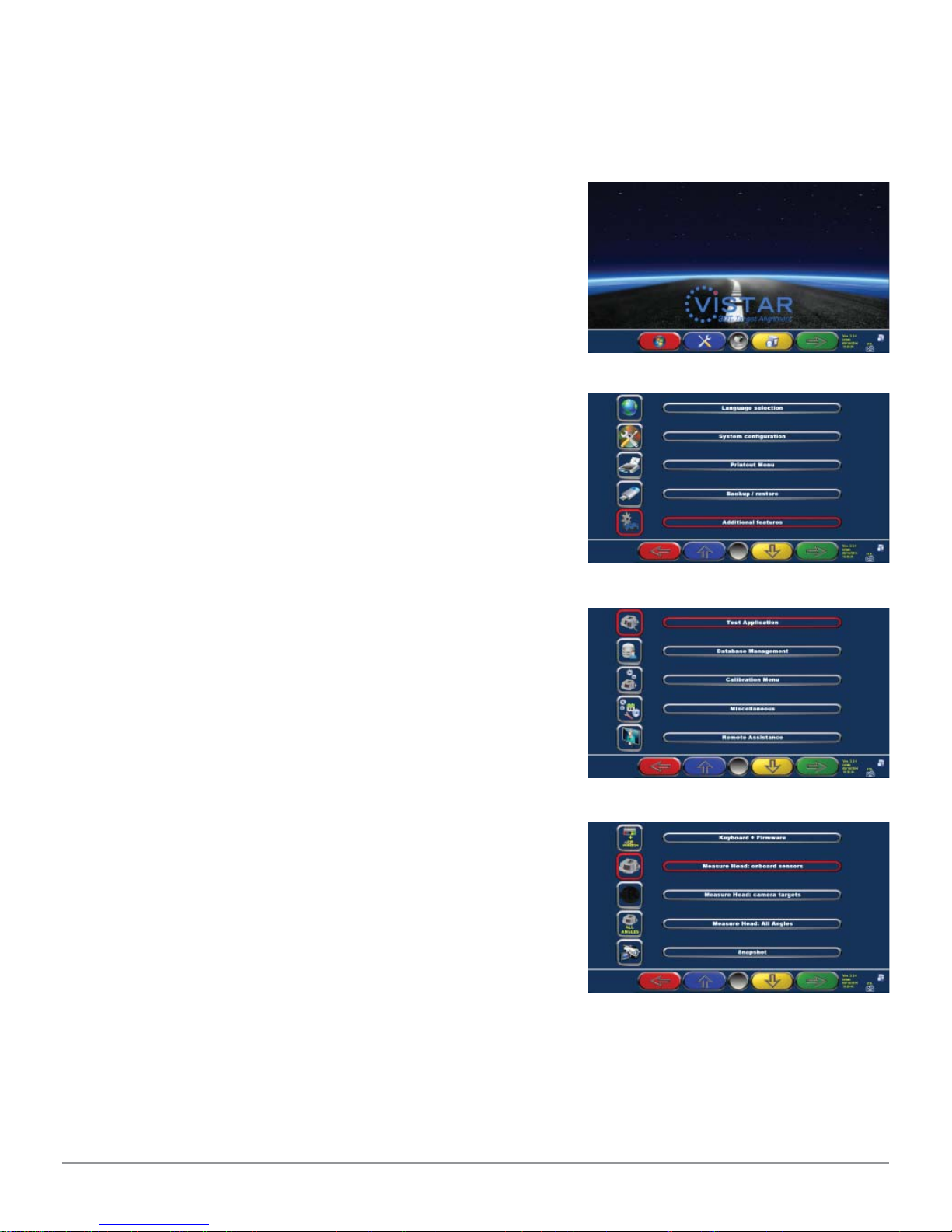

Quick Start Steps 10

Cyclops

If you do not read any values as in this screen, it

can be caused by:

1) The heads are off - turn them on.

2) The heads are on but there is no Bluetooth

connection, Bluetooth icons appear on the screen

are gray - perform the procedure “Searching for

Bluetooth”

3) The heads are on, the Bluetooth icons are

blue colored (connection established), check that

there are no obstructions between the CCD

Under normal conditions, this page displays the

values. Read the values “ICL X” and “ ICL Y “

of the 2 heads; these are the values of the

inclinometers. ICL Y depends on the accuracy

with which you have been carried out the fixing

holes of the heads support to the lift, the optimal

value is 0:00 degrees but a tolerance of +/- 1

degree is acceptable

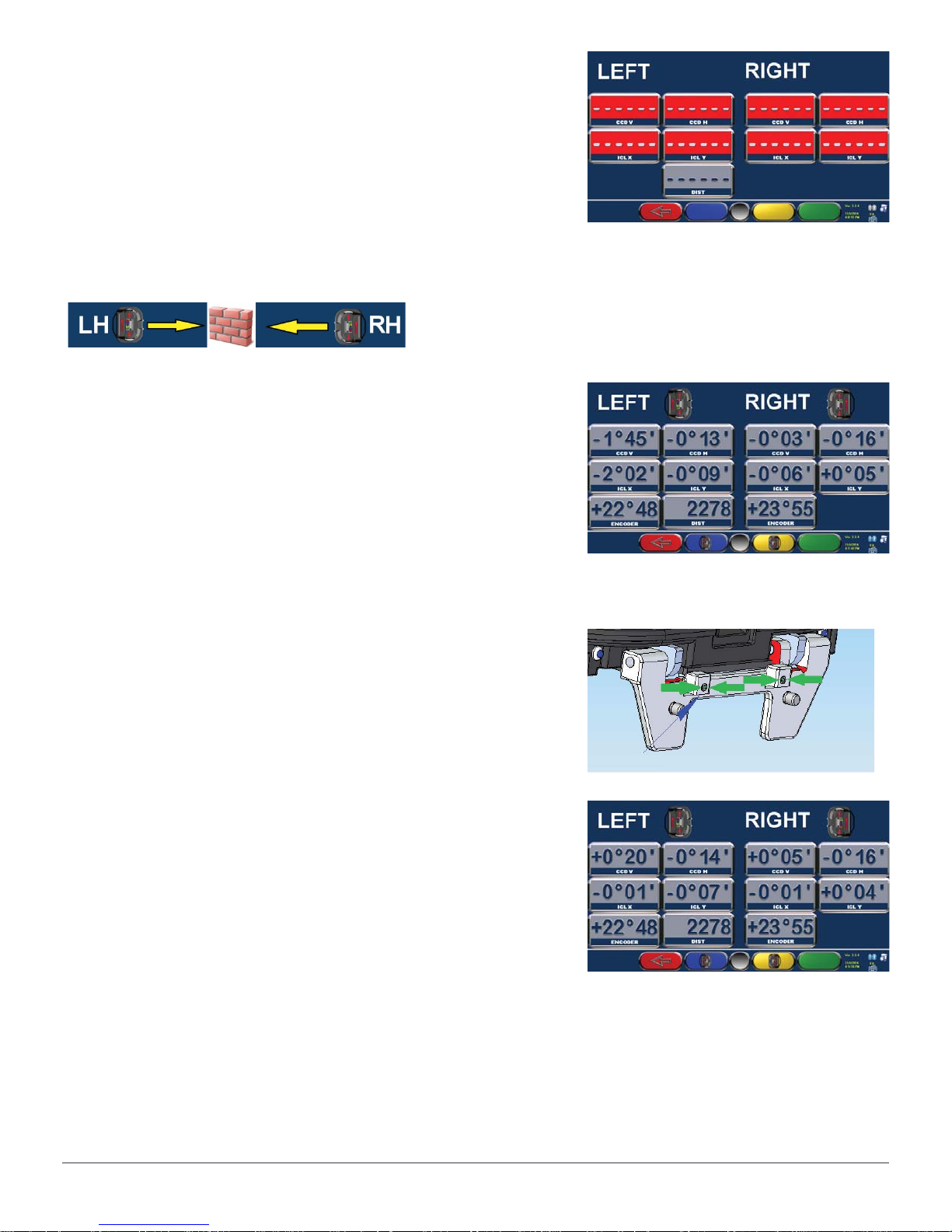

The “ICL X” is adjustable, see picture below.

Acting on the Allen screws (size 3) shown in the

figure, bring the values ICL X to 0.00 degrees.

THESE ADJUSTMENTS SHOULD BE MADE

WITH LIFT COMPLETELY DOWN.

After the adjustment of the ICL X values close to

zero (tolerance +/- 0,05 degrees) it is suggested

to lock the adjustment screws by using a special

glue (thread braker).

ADJUSTING THE VERTICAL CCD ON LIFT

This adjustment is used to compensate different heights between the left and

right ramps of the lift. Installations on the floor (in the pit) and lifts who have

ramps at the same height do NOT require this adjustment.

To perform this procedure: Read the service manual.