AU Tool AST618 User manual

Pulsating Brake Oil Exchanger

User Manual

AUTOOL AST618

Trademark

AUTOOL Technology Co, Ltd. has registered its trademarks in

different countries, the trademark is .With regard to

the other trademark, service logo, domain, icon and company

name mentioned in this manual, they shall all belong to AUTOOL

and its other affiliated company, in other countries without the

registration yet of these trademark, service logo, domain name,

icon and company name of AUTOOL, here we announce they are

owned by AUTOOL. Any company or person shall not use the

trademark, service logo, domain name, icon and company name

of AUTOOL before getting approved by AUTOOL with written

certificates. Please visit our website www.autooltech.com or

email at [email protected] to contact us.

2

1

Precautions

Check the device by visual inspection before use. If it is

damaged, please do not use it and contact the specialist

for maintenance.

The brake fluid dripping on the shell should be cleaned

immediately; otherwise there can be chemical reaction on

the surface which affects the appearance of product.

Please do not put cloth contaminated by organic oil, fuel

or solvent on this product.

Product Introduction

AUTOOL AST618 is controlled by microcontroller unit, which can

control the oil pressure, oil flow and working time accurately.

The high level of automation allows a single person to

operate. It is convenient, time-saving and labor-saving.

AUTOOL AST618 represents the highest technology in

the automobile maintenance field. This product is widely

used and suitable for the replacement of various kinds

of oil and fluid.

Product Features

Can change oil for the four clutch slave cylinders at the

same time, which is fast and labor-saving.

Adjustable pulse unit oil change, which enables the

product to clean the pipeline effectively and change the

4

3

oil or fluid completely.

Outstanding fluid recovery function, which can reclaim the

used brake fluid quickly and concurrently.

Independent pipelines designed for new and used oil to

prevent cross-contamination.

In case moisture mixes with the oil, the air inlet is

equipped with a device that can filter and separate the

water from the air and ensure the quality of the oil.

Equipped with corrosion-resistant oil hose, gorgeous,

durable and easy to move.

Applicable to European, American and Asian cars.

Make brake fluid change more time-saving and labor-saving.

Improve the performance of the braking system and extend

its service life.

Product Introduction

Input voltage: DC12V;

Power: 100W;

Oil change speed: 0.5~1/min;

Pressure range: 0.6~3.5bar;

Structure

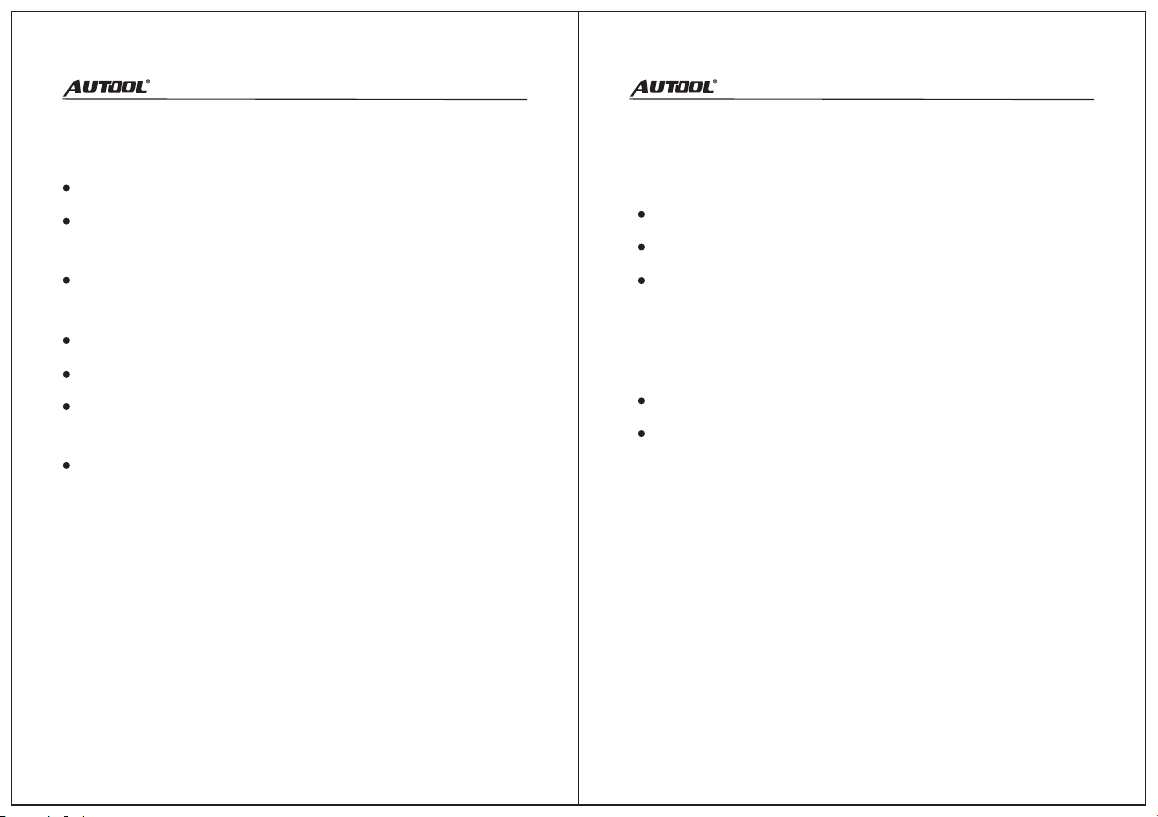

Control Panel

Maximum volume: 5L;

Power cord length: 4M;

Oil hose length: 4M;

Main unit dimensions:

515x438x550mm;

203x172x216 inch;

ATTENTION

Please checkthe product for any damage by visual inspection before use

each time. Pleasedo not use it if it is damaged, and notify the professionals

for repair.

The brake fluid drippingon the shell should be cleaned immediately,

otherwise the externalpart will react chemically and affect the product

appearance.

It’s forbidden toplace cloth with organic oil, fuel or solvent on the product.

Pulse

Time

Stop

Pulse

Time

Pressure Pressure

Start

PULSATING BRAKE OIL EXCHANGER

AST618

1

2

3

4

5

6

7

1-Handle;

2-Pressure tube;

3-Control panel;

4-Used oil recycling bottle

5-Oil adding hose;

6-Oil container;

7-Power interface

Fig.01

Pulse

Time

Stop

Pulse

Time

Pressure Pressure

Start

PULSATING BRAKE OIL EXCHANGER

AST618

Fig.02

1-Pressure gauge; 2-Pressure adjustment;

3-Pulse adjustment 4-Time adjustment;

5-Start/Stop

12

3

4

5

6

5

How to Adjust the Working

Pressure Correctly Note: It’s not necessary to start the vehicle.

The working pressure of the pressure regulator has been set

as 1~1.5 bar before delivery, to ensure that the car reservoir

tank will not deform while changing the fluid, thereby

guaranteeing the sealing performance of the secondary

sealing ring. In addition, it allows you to exhaust the air or

change the liquid at a relatively low working pressure by

adjusting the pressure and the switch. Under the special

circumstances, while operating at a relatively high working

pressure, the pressure is not supposed to be too high,

which may damage the clutch master cylinder of the braking

system.

Operation Instructions

Low-pressure Sealing Performance

Test

By using this (smart)brake fluid replacement machine, you

can exhaust the air and fill the fluid for your brake. You can

also perform low pressure detection on the hydraulic brake.

The device can be connected to the car reservoir tank

through an adapter. Please close all the air valves before the

connection. The air in the braking system is pressurized by

the working pressure of the device (to the pressure required

by the specific car model). Please check the master cylinder

and the braking pipelines in case there is any leakage. If the

brake fluid overflows, it means the braking system is not

completely sealed.

Lift the car to a proper height to make the driving wheels

off the ground.

Connect the four oil tanks of the device to the car clutch

slave cylinder, and loosen the exhaust screws to ensure

there is oil flowing out.

Pour 2 liters of new brake fluid into the fill port of the

device, and connect the adapter that matches the car

model with the port of the brake fluid reservoir of the car

master cylinder.

Connect the device to a 12V car battery and turn on the

power switch.

Press the “START” button to change the brake fluid.

When changing the fluid, please pay attention to the port

of brake fluid reservoir, if the process is too slow, press

the “Accelerate” button and if it’s too fast, press the

“Decelerate” button to slow it down.

After the oil change finishes, the used oil in the tank of

the equipment must be completely drained. If it’s not

emptied, the vacuum pump will be damaged and the oil

change process will fail.

Reminder:

Please check each connection parts when changing the fluid

to see if there is oil leakage and whether the connecting

hose is damaged. Please keep the oil fill port clean.

Product is bought through non-official AUTOOL purchase

channel.

Product failure is caused by incorrect use of the product, use

for other wrong purpose or human factors.

War ranty Access

8

7

War ranty Service

There are 3 years' warranty for AUTOOL product main unit and

1 year warranty for the accessories since the day the customers

have received the product parcel.

Repair or replace the equipment will be done according to the

specific fault conditions;

We guarantee that all replacement parts, accessories or

equipment are brand new;

When there is a product breakdown that can not be solved

within 90 days, customer should provide video and pictures as

proof, we will bear the freight cost and provide customer the

accessories in need to replace. After receiving the product for

more than 90 days, the customer shall bear the freight cost,

we will provide the accessory for free to replace.

War ranty Access

Disclaimer: The AUTOOL Technology Co, Ltd. reserves the right

to change product designs and specifications without prior notice.

The physical appearance and color may differ from those shown

in the instruction manual. Please refer to the actual product. If

you have any question, please contact the dealer or the Autool

service center. The company have the final explanation right of

product and shall not bear any consequences due to

misunderstanding.

9

注意事项

每次使用前通过目测检查本产品是否有损坏,若有损坏请勿使

用并通知专业人员进行维修。

滴在外壳上的刹车油应立即擦除,不然外表局部会起化学反

应,进而影响产品外观。

严禁将沾有机油、燃料、溶剂的抹布放置于产品上。

10

注册商标

偶然公司已在中国及海外若干国家进行了商标注册,其标志

为 。本手册所提及之偶然公司其它商标、服务标志、域

名、图标、公司名称均属偶然及其下属公司之产权。在偶然公司之

商标、服务标志、域名、图标、公司名称还未注册之国家,偶然公

司声明其对未注册商标、服务标志、域名、图标、公司名称之所有

权。本手册所提及之其它产品及公司名称的商标仍属于原注册公司

所有。在未得到拥有人的书面同意之前,任何人不得使用偶然公司

或所提及的其它公司之商标,服务标志,域名,图标,公司名称。

您如有任何疑问,可以访问偶然网址:www.autooltech.com,或

发送邮件至:aftersale@autooltech.com,与偶然公司联系。

产品介绍

AUTOOL AST618采用单片机控制,可以精确的控制油的压

力、油的流量和工作时间,自动化程度高,单人操作即可,使用便

捷、省时、省工,是汽车保养领域最高技术的结晶。本产品使用广

泛,适用于各种油、液的更换。

产品功能

四个分泵同时换油,快捷省时;

可调节脉冲式换油,能够有效清洗管路、更换油液更彻底;

强劲的回收功能,能同时、快速地将旧的制动液回收;

新、旧油管路独立设计,防止新、旧油交叉污染;

11 12

力制动装置进行低压检测;装置通过一个转换器与储液室保持连

接,注意此时关掉所有的排气阀,刹车系统通过装置的工作压力进

行增压(至车型要求的压力);观察整个总泵及刹车管路是否存在

泄露,如有刹车液溢出,则说明刹车系统不密封。

产品参数

进气口带水分分离过滤装置,能分离出空气中的水分,避免与油

液混合,保证油的质量;

耐腐蚀油管,美观、耐用且移动方便;

适用于欧洲、美洲、亚洲各国车型;

有效解决手工更换刹车油时费时费力的问题;

改善刹车系统的工作性能,延长刹车系统的使用寿命;

输入电压:DC12V;

功率:100W;

换油速度:0.5-1L/min;

压力范围:0.6-3.5bar;

最大容积:5L;

电线长度:4M;

油管长度:4M;

主机体积:515*438*550mm;

产品参数

ATTENTION

Please checkthe product for any damage by visual inspection before use

each time. Pleasedo not use it if it is damaged, and notify the professionals

for repair.

The brake fluid drippingon the shell should be cleaned immediately,

otherwise the externalpart will react chemically and affect the product

appearance.

It’s forbidden toplace cloth with organic oil, fuel or solvent on the product.

Pulse

Time

Stop

Pulse

Time

Pressure Pressure

Start

PULSATING BRAKE OIL EXCHANGER

AST618

1

2

3

4

5

6

7

1-拉杆;

2-接气管;

3-控制面板;

4-旧油回收瓶;

5-抽新油管;

6-新油瓶;

7-电源接口。

控制面板

Pulse

Time

Stop

Pulse

Time

Pressure Pressure

Start

PULSATING BRAKE OIL EXCHANGER

AST618

Fig.02

1-压力表; 2-压力调节; 3-脉冲调节;4-时间调节;

5-开始/暂停。

12

3

4

5

正确调节工作压力

该装置出厂时,调压器的工作压力设置为1-1.5bar, 这样可以

保证在换液时储液室不变形,进而确保二级密封圈的密封性。另

外,在较低的工作压力下进行排气或换液也是可行的,可以通过调

节压力和大小开关来实现。在特殊情况下有较高的工作压力操作时

要注意,调节压力过大,会把制动系统刹车总泵损坏。

低压密封性能测试

使用(智能型)刹车油更换机刹车排气充液装置,还可以对液

13 14

声明:偶然公司保留更改产品设计与规格的权利,届时恕不另

行通知。实物外观与颜色可能与说明书中显示的有差别,请以实物

为准。我们已尽最大努力力求使书中所有描述准确,但仍难免有

不妥之处,如有疑问,请联系经销商或偶然售后服务中心,本公

司对产品拥有最终解释权,不承担任何因误解而产生的后果。

售后服务

售后保修:

AUTOOL 整机自客户签收日起享有3年保修期,附件1年保修期。

根据具体的故障情况对设备进行修理或更换;

我方保证所有更换的部件、附件或设备都是全新;

在客户收到产品90天内出现故障同时提供视频和图片,我方承

担运费并免费提供相应配件给客户更换。收到产品超过90天,

客户承担相应的费用,我方免费提供配件给客户更换;

以下情况不再免费保修范围:

非正规渠道购买AUTOOL的产品;

未按产品说明书要求使用和维护造成的损坏;

操作步骤

将汽车举升至合适高度,使驱动轮离地悬空。

将设备4个接油壶分别接在汽车刹车分泵上,并松开刹车分泵排

气螺丝,确保有油流出即可。

从设备“加油口”倒入2L新刹车油,找到匹配车型接头连接到

刹车总泵油壶加油口上。

连接12V汽车电源,打开“电源开关”按键。

按“开始开关”按键进行刹车油更换。

换油过程中,看汽车刹车油油壶口,加油过慢按设备上的“加速

开关”按键加速加油;加油过快按“减速开关”按键减速加油。

换油完成后,必须把设备旧油桶里的油排至干净,若不清空旧油

桶会导致真空泵损坏,无法进行换油操作。

注意:不需要启动车辆

友情提示:换油时注意各连接处是否漏油,连接胶管是否破损,保

持新油加油口的清洁。

Table of contents

Other AU Tool Service Equipment manuals

Popular Service Equipment manuals by other brands

Powerfix Profi

Powerfix Profi PRW 2 A1 operating instructions

Tronair

Tronair 01-1229-0011 Operation & service manual

Maytronics

Maytronics Dolphin Wave User instructions

Westward

Westward 1MZH7 Operating instructions and parts manual

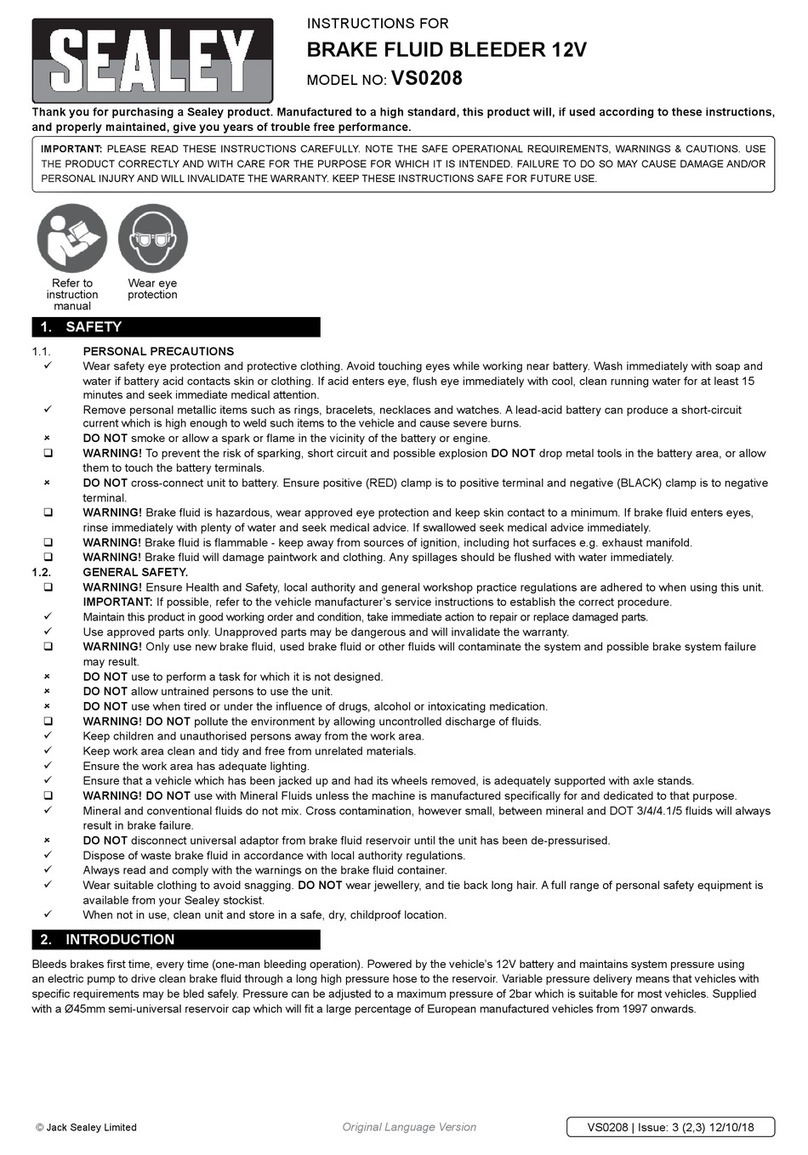

Sealey

Sealey VS0208 instructions

MAHLE

MAHLE BrainBee AIR-NEX 9310 quick start guide