MINI CONSOLE INSTALLATION:

This page only covers special installation considerations for the mini-console installation. If the video

monitor is to be installed in a vehicle with the mini console, this console may need to be trimmed to fit the

contour of the vehicle headliner.

1) In this installation, the video monitor is mounted directly to the overhead cross-member in the roof

using the mounting screw bosses. These screw bosses should contact the cross-member di-

rectly (i.e.: no gap between the screw boss and the roof structure). Also, be sure that the screws

do not pierce the outer roof skin when fully fastened to the cross-member. The mini-console is

attached to the video monitor using the perimeter screw bosses. It is important that the screws

used in this installation are not overtightened, and that the video monitor and mini-console are

mounted in such a way that the assembly does not distort (or bend) when the mounting screws

are tightened. An alternate method is to use a piece of plywood (12"x9"x3/4"). First secure the

plywood block to the cross-member, then screw the monitor into the plywood. See the drawing on

page 5.

2) It is best to mount the video monitor to the roof structure without the mini-console first. There

should be a gap between the headliner and the outer flange of the video monitor. The mini-console

should be cut to full this gap. Apply masking tape to the outer surface of the mini-console in the

areas where the cut will be made.

3) Mark the cut to follow the necessary contour of the roof. The suggested method of marking is as

follows:

A) First mark the narrowest point of the mini-console on the masking tape. Be careful

to consider not only vertical location, but fore-aft location.

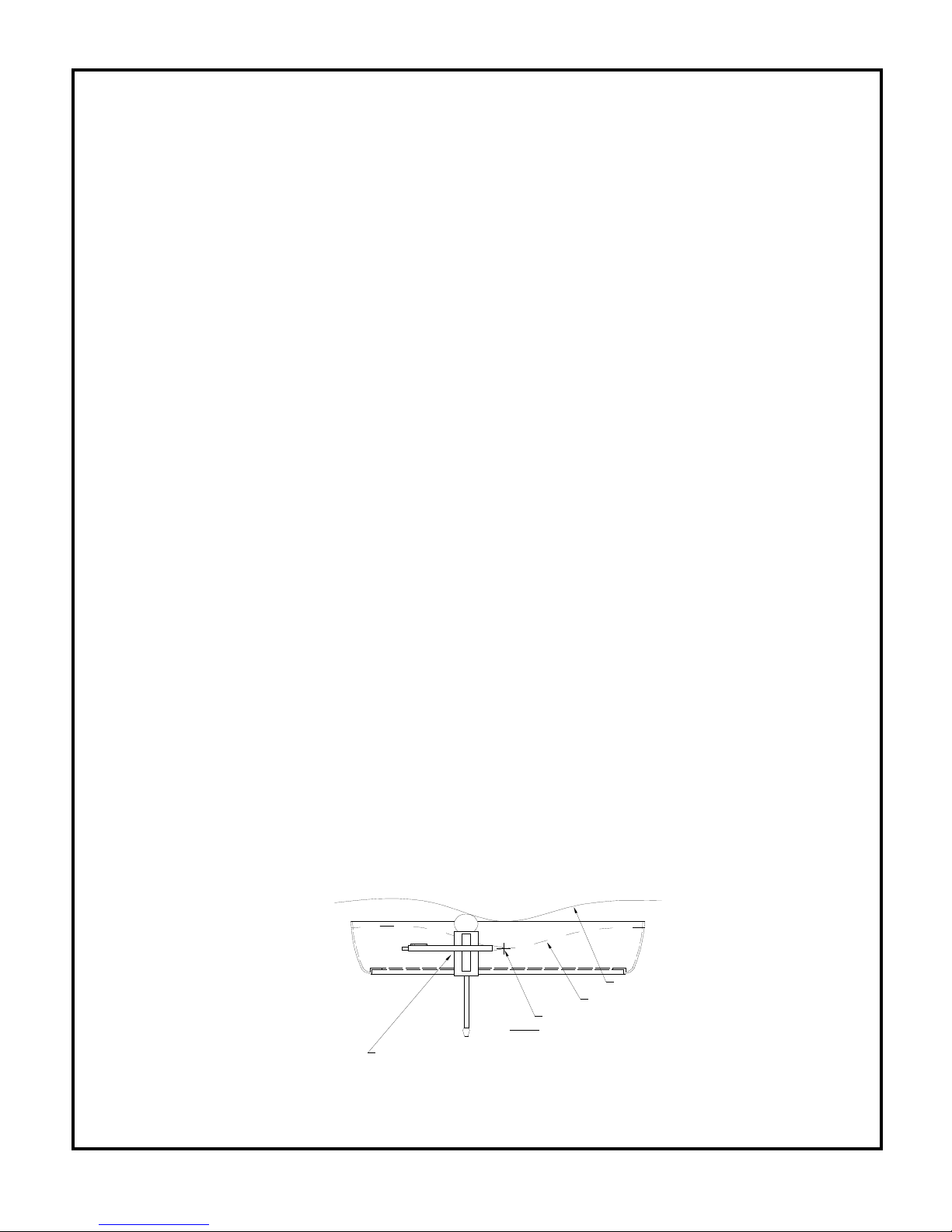

B) Using the handle of a screwdriver, make a “transfer marking tool”. See diagram

below. Place the tool against the roof and the marker against the masking tape on

the mini-console. Trace the cut to be made around the entire perimeter of the mini-

console.

C) Cut the mini-console using a sharp utility knife or shears. Make the cut in several

passes over the marked line, each time cutting a little deeper. It is not necessary to

cut completely through the plastic, the cut only need be over 50% of the wall thick-

ness of the plastic. By bending the cut back and forth several times, the plastic will

break cleanly at the cut.

D) Check the fit of the trimmed console and make any minor adjustments necessary.

4) The mini-console can be painted or covered with a material that matches the headliner before

assembling the mini-console to video monitor

.

5) The finished mini-console should be attached to the video monitor, then attach the assembly to the

roof.

-4-

Mini Console Installation:

This page only covers special insta llation considerations for t he mini console instal lation. If the video pod is to be installed

with a custom full sized overhead console, skip to page 8 now.

If the video pod is to be installed in a vehicle with t hemin i console (part number 1181300), this console mayneed tobe

trimmed to fit the contour of the vehicle headliner.

1) In this installation, the video pod is mounted directl y to the overhead crossmember int her oof using the mountingscrew

bosses (item "L" on p2). These screw bosses should contact the crossmember directly (ie: no gap between the screw boss

and the roof structure). Also, be sure that the screws (#3e on p1) do not pierce the outer r oof skin when fullyfastenedinto

the crossmember. The mini console is attached to the video pod using the perimeter screw bosses (item "K" on p2). It is

important that the screws used in this installation are not overt ightened, and that the video pod and mini consoleare mounted

in such a way that the assembly does not distort (or bend) when the mounting screws are tightened.

2) It is best to mount the video pod to the roof structure without the mini console f irst. There should be agap betweenthe

headliner and the outer flange of the video pod. The mini console should be cut to fill this g ap. A pplymasking tapeto the

outer surface of the mini console in the areas where the cut will be made.

3) Mark the cut to be made following the necessary contour of the roof. Suggested method of marking is as follows:

a) First mark the narrowest point of the mini console on the masking tape. Be careful to consider not onlyvertical

location, but fore-aft location.

b) Using the handle of a screwdriver, make a "transfer marking tool" see fig 6 below. Place the tool against theroof, and

the marker against the masking tape on the mini console. Trace the cut to be made around the entire perimeter of the mini

console.

c) Cut the mini console using a sharp utility knife or shears. Make the cut in s everalp asses overt hemarked line,each

time cutting a little deeper. It is not necessary to cut completel y through the plastic, the cut onlyneed be over50 % of the wall

thickness of the plastic. By bending the cut back and forth several times, t hepla stic will break cleanly atthe cut.

d) Check the fit of the trimmed console and make any minor adjustments necessary.

4) The mini console can be painted or covered with a material that matches the headliner before assembling themini

console to the video pod.

5) The finished mini console should be attached to the video pod, then attach the assembly to the roof. See Fig7.

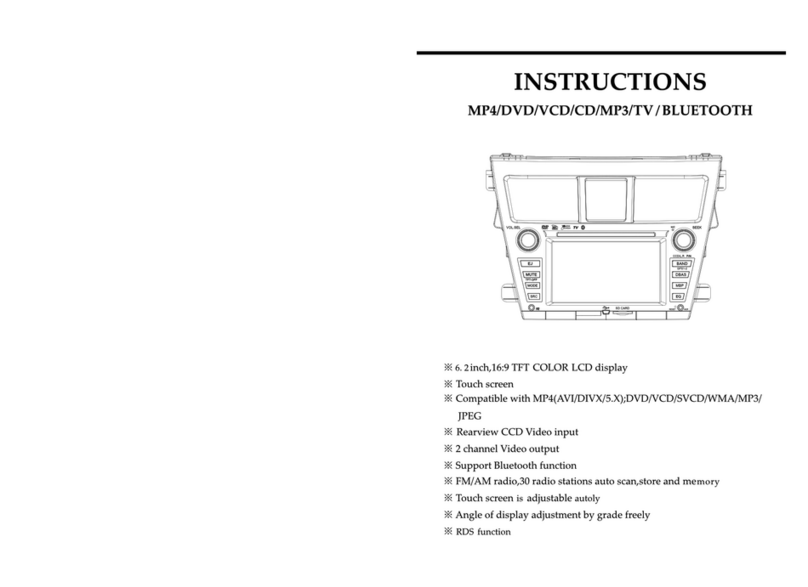

Tape marker to screwdri ver starting at

your mark for the l owest point, then

trace the contour of the roof

Cut Line

Headliner

Lowest Point Mark

Refer to Fig 7 for detail on attaching

console to video pod an d videopod to

vehicle structure.

7

Figure 6

Tape marker to screwdriver starting at

your mark for the lowest point, then

trace the contour of the roof

Cut Line

Headliner

Lowest Point Mark

Refer to Fig 7 for detail on attaching

console to video pod and video pod to

vehicle structure.

Figure 6