AUMA SA 48.1 User manual

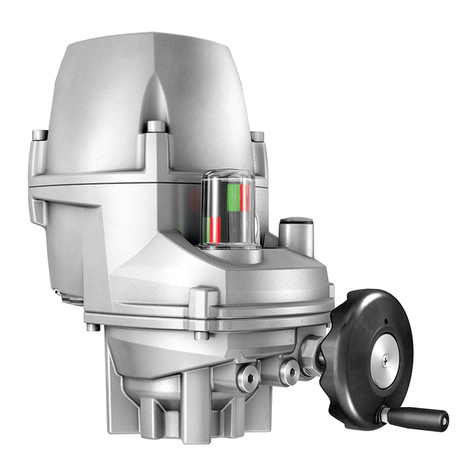

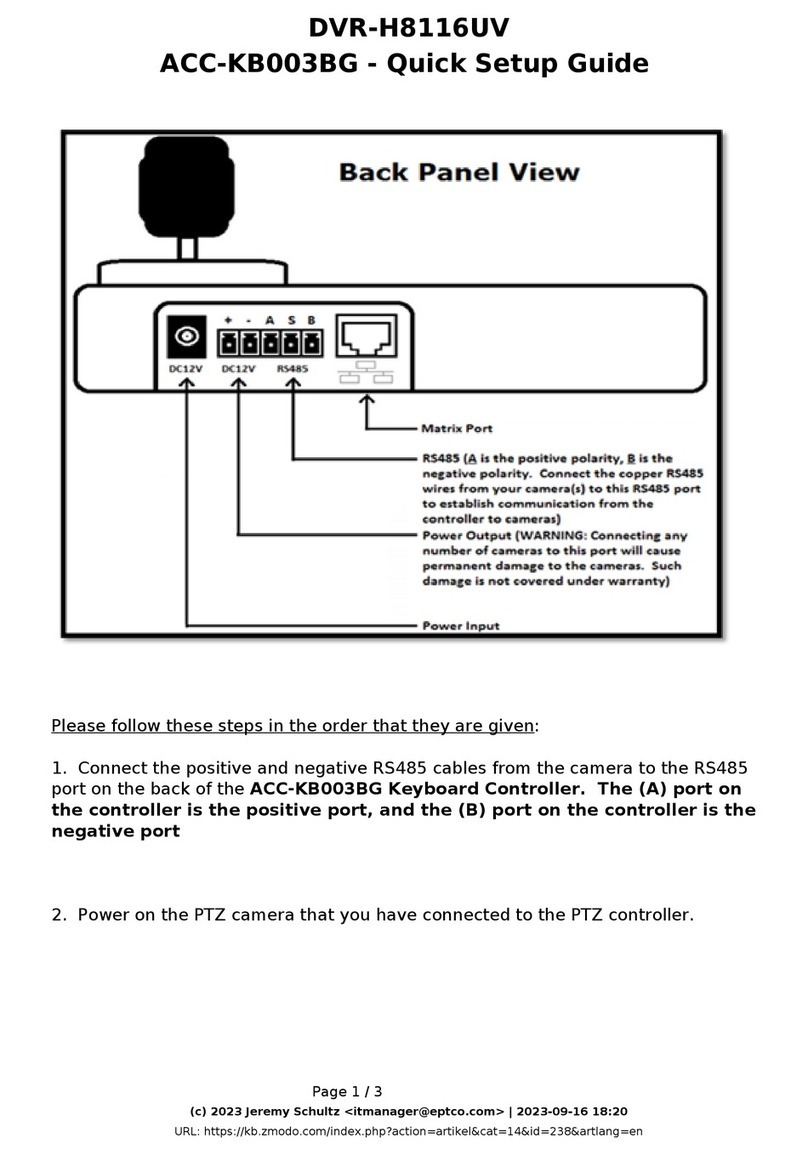

Electric multi-turn actuators

Operation instructions

SA 07.1 – SA 48.1

SAR 07.1 – SAR 30.1

AUMA NORM

for flanges type FA

2

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

AUMA NORM Operation instructions

Scope of these instructions: These instructions are valid for multi-turn actuators of the type range

SA 07.1 – SA 48.1 and SAR 07.1 – SAR 30.1 in version AUMA NORM.

These operation instructions are only valid for “clockwise closing”, i.e. driven shaft

turns clockwise to close the valve.

Table of contents Page

1. Safety instructions 4

1.1 Range of application 4

1.2 Commissioning (electrical connection) 4

1.3 Maintenance 4

1.4 Warnings and notes 4

2. Short description 4

3. Technical data 5

4. Transport, storage and packaging 7

4.1 Transport 7

4.2 Storage 7

4.3 Packaging 7

5. Mounting to valve/gearbox 8

6. Manual operation 10

7. Electrical connection 11

7.1 Connection with AUMA plug/socket connector 11

7.2 Motor connection for the sizes SA(R) 25.1/SAR 30.1 – SA 48.1. 12

7.3 Motor connection for special motors 12

7.4 Delay time 12

7.5 Controls made by AUMA 12

7.6 Heater 12

7.7 Motor protection 12

7.8 Remote position transmitter 12

7.9 Limit and torque switches 13

7.10 Fitting of the cover 13

8. Opening the switch compartment 14

8.1 Removing the switch compartment cover 14

8.2 Pulling off the indicator disc (option) 14

9. Setting the limit switching 15

9.1 Setting the end position CLOSED (black section) 15

9.2 Setting the end position OPEN (white section) 15

9.3 Checking the limit switches 15

10. Setting the DUO limit switching (option) 16

10.1 Setting the direction CLOSE (black section) 16

10.2 Setting the direction OPEN (white section) 16

10.3 Checking the DUO switches 16

11. Setting the torque switching 17

11.1 Setting 17

11.2 Checking the torque switches 17

12. Test run 18

12.1 Check direction of rotation 18

12.2 Check limit switching 18

13. Setting the potentiometer (option) 19

14. Setting the electronic position transmitter RWG (option) 20

14.1 Setting for 2-wire system 4 – 20 mA and 3-/4-wire system 0 – 20 mA 21

14.2 Setting the 3-/4- wire system 4 – 20 mA 22

3

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

Operation instructions AUMA NORM

Page

15. Setting the mechanical position indicator (option) 23

16. Closing the switch compartment 23

17. Enclosure protection IP 68 (option) 24

18. Maintenance 25

19. Lubrication 25

20. Disposal and recycling 26

21. Service 26

22. Spare parts list Multi-turn actuator SA(R) 07.1 – SA(R) 16.1 with plug/socket connector 27

23. Spare parts list Multi-turn actuator SA 25.1 – SA 48.1/SAR 25.1 – SAR 30.1 29

Index 31

Addresses of AUMA offices and representatives 32

1. Safety instructions

1.1 Range of application AUMA actuators are designed for the operation of industrial valves, e.g.

globe valves, gate valves, butterfly valves and ball valves. For other applications,

please consult us. The manufacturer is not liable for any possible damage resulting

from use in other than the designated applications. Such risk lies entirely with the

user.

Observance of these operation instructions is considered as part of the actuator’s

designated use.

1.2 Commissioning

(electrical connection)

During electrical operation, certain parts inevitably carry lethal voltages. Work on

the electrical system or equipment must only be carried out by a skilled electrician

themselves or by specially instructed personnel under the control and supervision

of such an electrician and in accordance with the applicable electrical engineering

rules.

1.3 Maintenance The maintenance instructions (refer to page 25) must be observed, otherwise a

safe operation of the actuator is no longer guaranteed.

1.4 Warnings and notes Non-observance of the warnings and notes may lead to serious injuries or

damage. Qualified personnel must be thoroughly familiar with all warnings and

notes in these operation instructions.

Correct transport, proper storage, mounting, and installation, as well as careful

commissioning are essential to ensure a trouble-free and safe operation.

During operation, the multi-turn actuator warms up and surface temperatures

> 140 °F may occur. Check the surface temperature prior to contact in order to

avoid burns.

The following references draw special attention to safety-relevant procedures in

these operation instructions. Each is marked by the appropriate pictograph.

This pictograph means: Note!

“Note” marks activities or procedures which have major influence on the correct

operation. Non-observance of these notes may lead to consequential damage.

This pictograph means: Electrostatically endangered parts!

If this pictograph is attached to a printed circuit board, it contains parts which may

be damaged or destroyed by electrostatic discharges. If the boards need to be

touched during setting, measurement, or for exchange, it must be assured that

immediately before a discharge through contact with an earthed metallic surface

(e.g. the housing) has taken place.

This pictograph means: Warning!

“Warning” marks activities or procedures which, if not carried out correctly, can

affect the safety of persons or material.

2. Short description AUMA multi-turn actuators type SA 07.1 – SA 48.1 and SAR 07.1 – SAR 30.1 have

a modular design. The limitation of travel is realized via limit switches in both end

positions. Torque seating is also possible in both end positions. The type of seating is

determined by the valve manufacturer.

4

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

AUMA NORM Operation instructions

3. Technical data

5

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

Operation instructions AUMA NORM

Multi-turn actuators AUMA NORM require electric controls. AUMA offers the controls AUMA MATIC AM or AUMATIC AC for the

sizes SA(R) 07.1 - SA(R) 16.1. These can also easily be mounted to the actuator at a later date.

Features and functions

Type of duty 1) Standard: SA Short time duty S2 - 15 min

SAR Intermittent duty S4 - 25 %

Option: SA Short time duty S2 - 30 min

SAR Intermittent duty S4 -50 %

Intermittent duty S5 - 25 %

Motors Standard: 3-ph AC asynchronous motor, type IM B9 according to IEC 34

Options: 1-ph AC motor, type IM B14 according to IEC 34

DC shunt motor, type IM B14 according to IEC 34

DC compound motor, type IM B14 according to IEC 34

Special motors

Insulation class Standard: F, tropicalized

Option: H, tropicalized

Motor protection Standard: Thermoswitches (NC)

Option: PTC thermistors (according to DIN 44082)

Supply voltage Refer to motor nameplate

Self-locking yes; for output speeds from 4,8 to 108 rpm and from size SA 35.1 for output speeds from 4,8 to 26 rpm

Limit switching Counter gear mechanism for end positions CLOSED and OPEN

for 1 to 500 turns per stroke (optional for 1 to 5,000 turns per stroke)

Standard: Tandem switch (2 NC and 2 NO) for each end position; switches galvanically isolated

Options: Single switch (1 NC and 1 NO) for each end position

Triple switch (3 NC and 3 NO) for each end position, switches galvanically isolated

Intermediate position switch (DUO limit switching)

Torque switching adjustable torque switching for direction OPEN and CLOSE

Standard: Single switch (1 NC and 1 NO) for each direction

Options: Tandem switch (2 NC and 2 NO) for each direction, switches galvanically isolated

Non-intrusive setting

(option) Magnetic limit and torque transmitter MWG for the sizes SA 07.1 – SA 48.1

(only possible in combination with actuator controls AUMATIC)

for 1 to 500 turns per stroke or for 10 to 5,000 turns per stroke

Position feedback signal,

analogue (options) Potentiometer or 0/4 – 20 mA

For further details see separate data sheet

Torque feedback signal,

analogue (option) Only in combination with magnetic limit and torque transmitter MWG and actuator controls

AUMATIC

Mechanical position

indicator (option) Continuous indication, adjustable indicator disc with symbols OPEN and CLOSED

Running indication (option) Blinker transmitter

Heater in switch

compartment Standard: self-regulating PTC heater, 5 – 20 W, 110 – 250 V DC/AC

Options: 24 – 48 V DC/AC or 380 – 400 V AC

A resistance type heater (5 W, 24 V DC) is installed in the actuator in combination with the actuator

controls AUMA MATIC or AUMATIC.

Motor heater (option) SA(R) 07.1 – 10.1: 12.5 W

SA(R) 14.1 – 16.1: 25 W

SA(R) 25.1 – 30.1: 50 W

SA 35.1 – 48.1: 50 W

Manual operation Manual drive for setting and emergency operation, handwheel does not rotate during electrical

operation.

Option: Handwheel lockable

Electrical connections Standard: SA(R) 07.1 – 16.1: AUMA plug/socket connector with screw type connection,

SA(R) 25.1 – 48.1: Control connections on AUMA plug/socket connector,

motor connection via terminals

Option: for special motors: Motor connection directly via terminal board at the motor

Threads for cable glands Standard: NPT-threads

Options: Pg-threads, G-threads

Terminal plan Terminal plan according to commission number included in delivery

1) Based on 68 °F ambient temperature and at an average load with running torque according to Technical data SA(R).

Table 1: Multi-turn actuator SA 07.1 – SA 48.1 /SAR 07.1 – SAR 30.1

6

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

AUMA NORM Operation instructions

Service conditions

Output drive types A, B1, B2, B3, B4 according ISO 5210 (A, B2, B4 according to MSS SP-102)

A, B, D, E according to DIN 3210

C according to DIN 3338

Special output drives: AF, AK, AG, IB1, IB3

Enclosure protection

according to EN 60 5292) Standard: IP 67

Options: IP 68

IP 67-DS (Double Sealed)

IP 68-DS (Double Sealed)

(Double Sealed = additional protection of the interior of the housing

against ingress of dust and dirt when removing the plug)

Corrosion protection Standard: KN Suitable for installation in industrial units,

in water or power plants with a low pollutant concentration

Options: KS Suitable for installation in occasionally or permanently aggressive

atmosphere with a moderate pollutant concentration (e.g. in

wastewater treatment plants, chemical industry)

KX Suitable for installation in extremely aggressive atmosphere with high

humidity and high pollutant concentration

KX-G Same as KX, however aluminium-free version (outer parts)

Finish coating Standard: Two part acrylic polyurethane

Color Standard: Dark grey (DB 702, similar to RAL 9007)

Option: Other colours are possible on request

Ambient temperature 3) Standard: SA – 20 to + 80 °C/ – 20 to + 175 °F

SAR – 25 to + 60 °C/ – 20 to + 140 °F

Options: SA – 40 to + 60 °C/ – 40 to + 140 °F (low temperature)

– 50 to + 60 °C/ – 58 to + 140 °F (extreme low temperature)

– 60 to + 60 °C/ – 75 to + 140 °F (extreme low temperature)

– 0 to + 120 °C/ + 32 to + 250 °F (high temperature)

SAR – 40 to + 60 °C/ – 40 to + 140 °F (low temperature)

Vibration resistance

according to IEC 60068-2-6 2 g, for 10 to 200 Hz (only for sizes SA(R) 07.1 – SA(R) 16.1 without controls)

Resistant to vibrations during start-up or for failures of the plant.

However, a fatigue strength may not be derived from this.

Valid for multi-turn actuators in version AUMA NORM (with AUMA plug/socket connector, without

actuator controls). Not valid in combination with gearboxes

Lifetime4) SA 07.1 – SA 10.1 20,000 operating cycles (OPEN - CLOSE - OPEN)

with 30 turns per stroke

SA 14.1 – SA 16.1 15,000 operating cycles

SA 25.1 – SA 30.1 10,000 operating cycles

SA 35.1 – SA 48.1 5,000 operating cycles

SAR 07.1 – SAR 10.14) 5 millon starts

SAR 14.1 – SAR 16.14) 3.5 million starts

SAR 25.1 – SAR 30.14) 2.5 million starts

Other information

Reference documents Product description “Electric multi-turn actuators SA”

Dimension sheets SA(R)

Electrical data sheets SA/SAR

Technical data sheets SA/SAR

2) For 3-phase asynchronous motors in enclosure protection IP 68, higher corrosion protection KS or KX is strongly recommended. Additionally, for enclosure

protection IP 68, we recommend to use the double sealed terminal compartment DS.

For 1-phase AC motors, DC motors, or special motors, the enclosure protection according the name plate applies.

3) Versions with RWG up to max. to + 158 °F

4) The lifetime depends on the load and the number of starts. A high starting frequency will rarely improve the modulating accuracy. To reach the longest possible

maintenance and fault-free operation time, the number of starts per hour chosen should be as low as permissible for the process.

4. Transport, storage and packaging

4.1 Transport .For transport to place of installation, use sturdy packaging.

.Do not attach ropes or hooks to the handwheel for the purpose of lifting by hoist.

.If multi-turn actuator is mounted on valve, attach ropes or hooks for the purpose

of lifting by hoist to valve and not to multi-turn actuator.

Fitting the handwheel: For transport purposes, handwheels from a diameter of 400 mm (1 inch

corresponds to 25.4 mm) are supplied separately.

Engage manual operation prior to mounting the handwheel! If the

manual operation is not engaged, damages can occur at the

change-over mechanism.

.Engage manual operation (figure A-1):

Manually lift the red change-over lever while slightly turning the shaft back and

forth until manual operation engages. The manual operation is correctly engaged

if the change-over lever can be lifted by approx. 85°.

Manual force is sufficient for operating the change-over lever. It is

not necessary to use an extension. Excessive force may damage

the change-over mechanism.

.Install the hand wheel over the red change-over lever on to the shaft (figure A-2).

.Secure handwheel using the snapring supplied.

4.2 Storage .Store in well-ventilated, dry room.

.Protect against floor dampness by storage on a shelf or on

a wooden pallet.

.Cover to protect against dust and dirt.

.Apply suitable corrosion protection agent to uncoated surfaces.

If multi-turn actuators are to be stored for a long time (more than 6 months), in

addition, the following points must imperatively be observed :

.Prior to storage: Protect uncoated surfaces, in particular the output drive parts

and mounting surface, with long-term corrosion protection agent.

.Check for corrosion approximately every 6 months. If first signs of corrosion

show, apply new corrosion protection.

After mounting, connect actuator immediately to electrical system,

so that the heater prevents condensation.

4.3 Packaging Our products are protected by special packaging for the transport ex works. The

packaging consists of environmentally friendly materials which can easily be

separated and recycled.

7

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

Operation instructions AUMA NORM

85°

Figure A-1 Figure A-2

We use the following packaging materials: wood, cardboard, paper and

Polyurethane foam. For the disposal of the packaging material, we recommend

recycling and collection centers.

5. Mounting to valve/gearbox .Prior to mounting the multi-turn actuator must be checked for

damage. Damaged parts must be replaced by original spare

parts.

.After mounting, check multi-turn actuator for damage to paint

finish. If damage to paint-finish has occurred after mounting, it

has to be touched up to avoid corrosion.

Mounting is most easily done with the valve shaft/gearbox shaft pointing vertically

upward. But mounting is also possible in any other position.

The multi-turn actuator leaves the factory in position CLOSED (limit switch

CLOSED tripped).

.Check if mounting flange fits the valve/gearbox.

Spigot at flanges should be loose fit!

The output drive types B1, B2, B3 or B4 (figure A-3) are delivered with bore and

keyway (usually according to ISO 5210) and are sometimes shipped with bore and

keyway according to customer request.

For output drive type A (figure B-1), the internal thread of the stem nut must match

the thread of the valve stem. If not ordered explicitly with thread, the stem nut is

unbored or with pilot bore when delivered. For finish machining of stem nut refer to

next page.

.Check whether bore and keyway match the input shaft of valve/gearbox.

.Thoroughly degrease mounting faces at multi-turn actuator and valve/gearbox.

.Apply a small quantity of grease to input shaft of valve/gearbox.

.Place actuator on valve/gearbox and fasten. Fasten bolts (quality grade 5, refer

to table 2) evenly crosswise.

8

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

AUMA NORM Operation instructions

Figure A-3

Output drive type B1/B2

Plug sleeve (option) Output drive type B3/B4

Bore with keyway (standard)

UNC threads TA(ft lbs)

516- 18 19

38- 16 33

12- 13 78

58- 11 155

34- 10 255

1 - 8 590

114- 7 1,2000

Conversion factor: 1 Nm corresponds to 1.3529 ft lbs.

Table 2: Standard dry fastening torques for bolts

Finish machining of stem nut (output drive type A):

The output drive flange does not have to be removed from the actuator.

.Remove spigot ring (80.2, figure B-1) from mounting flange.

.Take off stem nut (80.3) together with thrust bearing (80.01) and thrust bearing

races (80.02).

.Remove thrust bearing and thrust bearing races from stem nut.

.Drill and bore stem nut and cut thread.

When fixing in the chuck, make sure stem nut runs true!

.Clean the machined stem nut.

.Apply Lithium soap EP multi-purpose grease to thrust bearing and races, then

place them on stem nut.

.Re-insert stem nut with thrust bearings into the mounting flange. Ensure that

dogs are placed correctly in the slots of the hollow shaft.

.Screw in spigot ring until it is firm against the shoulder.

.Press Lithium soap EP multi-purpose grease on mineral oil base into the grease

nipple with a grease gun (for quantities, refer to table below):

Protection tube for rising valve stem

.Protection tubes may be supplied loose. Seal thread with hemp, Teflon tape, or

thread sealing material.

.Screw protection tube (1) into thread (figure B-2) and tighten it firmly.

.Push down the sealing (2) to the housing.

.Check whether cap (3) is available and without damage.

9

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

Operation instructions AUMA NORM

Figure B-1

80.3

80.2

Output drive type A

Stem nut

80.01/80.02

Output drive A 07.2 A 10.2 A 14.2 A 16.2 A 25.2 A 30.2 A 35.2 A 40.2 A 48.2

Qty1) in g 1.5 g 2 g 3 g 5 g 10 g 14 g 20 g 25 g 30 g

1) For grease with a density ρ= 900 g/dm3; conversion factor: 1 oz corresponds to 28.35 g

Table 3: Grease quantities for lubricating bearings

Figure B-2: Protection tube for rising valve stem

3

1

2

6. Manual operation The actuator may be operated manually for purposes of setting and

commissioning, and in case of motor failure or power failure.

Manual operation is engaged by an internal change-over mechanism.

Engaging manual operation: .Lift up change-over lever in the center of the handwheel to approx. 85°, while

slightly turning the handwheel back and forth until manual operation engages

(figure C).

Manual force is sufficient for operating the change-over lever. It is

not necessary to use an extension. Excessive force may damage

the change-over mechanism.

.Release change-over lever (should snap back into initial position by spring

action, figure D), if necessary, push it back manually.

Operating the change-over lever while the motor is running

(figure E) can lead to increased wear at the change-over

mechanism.

.Turn handwheel in desired direction (figure F).

Disengaging manual operation:

Manual operation is automatically disengaged when the motor is started again.

The handwheel does not rotate during motor operation.

10

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

AUMA NORM Operation instructions

Figure DFigure C

Figure E Figure F

7. Electrical connection Work on the electrical system or equipment must only be carried

out by a skilled electrician themselves or by specially instructed

personnel under the control and supervision of such an electrician

and in accordance with the applicable electrical engineering rules.

7.1 Connection with AUMA plug/socket connector

.Check whether type of current, supply voltage, and frequency correspond to

motor data (refer to name plate at motor).

.Loosen bolts (50.01) (figure G-1) and remove plug cover.

.Loosen screws (51.01) and remove socket carrier (51.0) from plug cover (50.0).

.Insert cable glands or conduit fittings suitable for connecting cables.

(The enclosure protection stated on the name plate is only ensured if properly

sealed connections are made).

.Seal cable entries which are not used with sealed threaded plugs.

.Connect cables according to order-related terminal plan.

.The terminal plan applicable to the actuator is placed inside the terminal

compartment, the operation instructions are attached to the handwheel in a

weather-proof bag.

A special parking frame (figure G-2) for protection against touching the bare

contacts and against environmental influences is available.

11

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

Operation instructions AUMA NORM

Figure G-1: Connection

50.0

50.01

51.0

51.01

Technical data Power terminals1) Protective earth Control pins

No. of contacts max. 6 (3 are used) 1 (leading contact) 50 pins/sockets

Marking U1, V1, W1, U2, V2, W2 according to VDE 1 to 50

Voltage max. 750 V – 250 V

Nominal current max. 25 A – 16 A

Type of customer connection Screws Screw for ring lug Screws

Cross section max. 6 mm2(10 AWG) 6 mm2(10 AWG) 2.5 mm2(12 AWG)

Material: Pin/ socket carrier Polyamide Polyamide Polyamide

Contacts Brass (Ms) Brass (Ms) Brass, tin plated or gold plated (option)

1) Suitable for copper wires. For aluminium wires it is necessary to contact AUMA.

From size SA(R) 25.1, the motor connection is realised via a separate terminal board

Table 4: Technical data AUMA plug/socket connectors

Figure G-2: Parking frame (accessory)

Parking frame

7.2 Motor connection for the sizes SA(R) 25.1/SAR 30.1 – SA 48.1.

From the size SA(R) 25.1, the power for the motor is connected to separate

terminals. For this, the cover at the motor connection compartment has to be

removed.

The control contacts are connected to the AUMA plug/socket connector.

Cross section motor terminals:

16 mm² to 70 mm² (6 to 2/0 AWG), depending on the actuator size

7.3 Motor connection for

special motors

For versions with special motors (e.g. DC motors), the connection is

performed directly at the motor (figure G-4).

7.4 Delay time The delay time is the time from the tripping of the limit or torque switches to the

motor power being removed. To protect the valve and the actuator, we recommend

a delay time < 50 ms. Longer delay times are possible provided the output speed,

output drive type, valve type, and the type of installation are taken into

consideration.

We recommend to switch off the corresponding contactor directly by the limit or

torque switch.

7.5 Controls made by AUMA In case the required reversing contactors are not to be installed in the control

cabinet, the controls AUMA MATIC or AUMATIC for the sizes SA(R) 07.1 – SA(R)

16.1 can be easily mounted to the actuator at a later date.

For enquiries and more information, please state our commission no. (refer to

actuator name plate).

7.6 Heater AUMA multi-turn actuators have a heater installed as standard. To prevent

condensation, the heater must be connected.

7.7 Motor protection In order to protect against overheating and extreme high temperatures at the

actuator, PTC thermistors or thermoswitches are embedded in the motor winding.

The thermoswitch is tripped as soon as the max. permissible winding temperature

has been reached.

Failure to integrate PTC thermistors or thermoswitches into the control circuit voids

the warranty for the motor.

7.8 Remote position transmitter For the connection of remote position transmitters (potentiometer, RWG) shielded

cables must be used.

12

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

AUMA NORM Operation instructions

Figure G-4: Connection special motor

Figure G-3: Connection to SA(R) 25.1

Cover motor connection compartment

AUMA plug/socket connector

7.9 Limit and torque switches

Only the same potential can be switched on the two circuits (NC/NO contact) of a

limit or torque switch. If different potentials are to be switched simultaneously,

tandem switches are required.

To ensure correct actuator indications, the leading contacts of the tandem switches

must be used for that purpose and the lagging contacts for motor switching off.

7.10 Fitting of the cover After connection:

.Insert the socket carrier (51.0) into the plug cover (50.0) and fasten it with

screws (51.01).

.Clean sealing faces at the plug cover and the housing.

.Check whether O-ring is in good condition.

.Apply a thin film of non-acidic grease (e.g. Vaseline) to the sealing faces.

.Replace plug cover (50.0) and fasten bolts (50.01) evenly crosswise.

.Fasten conduit connections with the specified torque to ensure the required

enclosure protection.

13

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

Operation instructions AUMA NORM

Mechanical

lifetime = 2 x 106starts

Type of current Switch rating Imax

30 V 125 V 250 V

1-phase AC

(ind. load) cos phi = 0,8 5 A 5 A 5 A

DC

(resistive load) 2 A 0,5 A 0.4 A

with gold plated

contacts min. 5 V, max. 50 V

Current min. 4 mA, max. 400 mA

Table 5: Technical data for limit and torque switches

NO NC

NC N

O

RD

BK

RD

BK

BK 2

RD 2

BK

RD

BK 2

RD 2

BK

RD

TSC 1 / TSO 1

LSC 1 / LSO 1 TSC / TSO

L

SC /

L

SO

DSR 1 / DÖL 1

WSR 1 / WÖL 1 DSR / DÖL

WSR / WÖL

Figure G-5

II Tandem switch

SPDT

DPDT

ISingle switch

8. Opening the switch

compartment

To be able to carry out the following settings (sections 9. to 15.), the switch

compartment must be opened and, if installed, the indicator disc must be removed.

These settings are only valid for “clockwise closing”, i.e. driven shaft turns

clockwise to close the valve.

Work on the electrical system or equipment must only be carried

out by a skilled electrician themselves or by specially instructed

personnel under the control and supervision of such an electrician

and in accordance with the applicable electrical engineering rules.

8.1 Removing the switch

compartment cover .Loosen 4 bolts and take off the cover at the switch compartment

(figures H) .

8.2 Pulling off the indicator disc (option)

.If installed, pull off indicator disc (figure J). Open end wrench

may be used as lever.

14

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

AUMA NORM Operation instructions

Fig. H-2: Cover without indicator glass

DSR

WDR

Figure J: Pulling off the indicator disc

Indicator disc

Fig. H-1: Cover with indicator glass

Bolts

9. Setting the limit switching

9.1 Setting the end position CLOSED (black section)

.Turn handwheel clockwise until valve is closed.

.After having reached the end position, turn back handwheel by approximately ½

a turn (overrun). During test run, check overrun and, if necessary, correct setting

of the limit switching.

.Press down and turn setting spindle A (figure K-1) with a flat blade

screw driver in direction of arrow, thereby observe pointer B.

While a ratchet is felt and heard, the pointer B moves 90° every time.

When pointer B is 90° from mark C, continue turning slowly. When pointer B has

reached the mark C, stop turning and release setting spindle. If you override the

tripping point inadvertently (ratchet is heard after the pointer has rotated),

continue turning the setting spindle in the same direction and repeat setting

process.

9.2 Setting the end position OPEN (white section)

.Turn handwheel counterclockwise until valve is open, then turn back by

approximately ½ a turn.

.Press down and turn setting spindle D (figure K-1) with a flat blade screw driver

in direction of arrow, thereby observe pointer E.

While a ratchet is felt and heard, the pointer E moves 90° every time.

When pointer E is 90° from mark F, continue turning slowly. When pointer E has

reached the mark F, stop turning and release setting spindle. If you override the

tripping point inadvertently (ratchet is heard after the pointer has rotated),

continue turning the setting spindle in the same direction and repeat setting

process.

9.3 Checking the limit switches The red test buttons T and P (figure K-1) are used for manual operation of the limit

switches.

.Turning T in direction of the arrow LSC (WSR) triggers limit switch CLOSED.

.Turning P in direction of the arrow LSO (WÖL) triggers limit switch OPEN.

15

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

Operation instructions AUMA NORM

Figure K-1: Control unit

A

T

B

C

D

P

E

F

10. Setting the DUO limit switching (option)

Any application can be switched on or off via the two intermediate position

switches.

For setting, the switching point (intermediate position) must be

approached from the same direction as later during

electrical operation.

10.1 Setting the direction CLOSE (black section)

.Move valve to desired intermediate position.

.Press down and turn setting spindle G (figure K-2) with a flat blade

screw driver in direction of arrow, thereby observe pointer H.

While a ratchet is felt and heard, the pointer H moves 90° every time.

When pointer H is 90° from mark C, continue turning slowly. When pointer H has

reached the mark C, stop turning and release setting spindle. If you override the

tripping point inadvertently (ratchet is heard after the pointer has rotated),

continue turning the setting spindle in the same direction and repeat setting

process.

10.2 Setting the direction OPEN (white section)

.Move valve to desired intermediate position.

.Press down and turn setting spindle K (figure K-2) with a flat blade

screw driver in direction of arrow, thereby observe pointer L.

While a ratchet is felt and heard, the pointer L moves 90° every time.

When pointer L is 90° from mark F, continue turning slowly. When pointer L has

reached the mark F, stop turning and release setting spindle. If you override the

tripping point inadvertently (ratchet is heard after the pointer has rotated),

continue turning the setting spindle in the same direction and repeat setting

process.

10.3 Checking the DUO switches The red test buttons T and P (Figure K-2) are used for manual operation of DUO

limit switches.

.Turning T in direction of the arrow TSC (DSR) triggers DUO limit switch CLOSED. The

torque switch CLOSED is actuated at the same time.

.Turning P in direction of the arrow TSO (DÖL) triggers DUO limit switch OPEN. The

torque switch OPEN is actuated at the same time.

16

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

AUMA NORM Operation instructions

Figure K-2: Control unit

G

T

H

C

K

P

L

F

11. Setting the torque switching

11.1 Setting .The set torque must suit the valve!

.This setting should only be changed with the consent of the

valve manufacturer!

Setting CLOSED Setting OPEN

.Loosen both lock screws O at the torque dial (figure L).

.Turn torque dial P to set it to the required torque.

Examples:

Figure L shows the following setting:

35 ft lbs for direction CLOSE

25 ft lbs for direction OPEN

.Tighten lock screws O again

.The torque switches can also be operated in manual

operation.

.The torque switching acts as overload protection over full travel,

also when stopping in the end positions by limit switching.

11.2 Checking the torque switches

The red test buttons T and P (figure K-2) are used for manual operation of the

torque switches:

.Turning T in direction of the arrow TSC (DSR) triggers torque switch CLOSED.

.Turning P in direction of the arrow TSO (DÖL) triggers torque switch OPEN.

.If a DUO limit switching (optional) is installed in the actuator, the intermediate

position switches will be operated at the same time.

17

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

Operation instructions AUMA NORM

Ft. Lbs

Ft. Lbs

15

35

45

25

45

25

15

35

Figure L: Torque switching heads

indication in ft lbs

O

P

12. Test run

12.1 Check direction of rotation .If provided, place indicator disc on shaft.

The direction of rotation of the indicator disc (figure M-1) indicates the direction

of rotation of the output drive.

.If there is no indicator disc, the direction of rotation can also be observed on the

hollow shaft. For this, remove screw plug (no. 27) (figure M-2).

.Move actuator manually to intermediate position or to sufficient distance from

end position.

.Switch on actuator in direction CLOSE and observe the direction of rotation:

If the direction of rotation is wrong, switch off immediately

Then, correct phase sequence at motor connection. Repeat test run.

12.2 Check limit switching .Move actuator manually into both end positions of the valve.

.Check if limit switching is set correctly. Hereby observe that the appropriate

switch is tripped in each end position and released again after the direction of

rotation is changed. If this is not the case, the limit switching must first be set, as

described from page 15.

If no other options (sections 13. to 15.) require setting:

.Close switch compartment (see page 23, section 16.).

18

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

AUMA NORM Operation instructions

Figure M-1: Indicator disc

CLOSED OPEN

Figure M-2: Opening the hollow shaft

27

S1/S2

Direction of rotation of the indicator disc:

counterclockwise correct

Direction of rotation of the hollow shaft:

clockwise correct

Table 6:

13. Setting the potentiometer (option)

– For remote indication –

.Move valve to end position CLOSED.

.If installed, pull off indicator disc.

.Turn potentiometer (E2) clockwise until stop is felt.

End position CLOSED corresponds to 0 %, end position OPEN to 100 %.

.Turn potentiometer (E2) back a little.

Due to the ratio of the reduction gearings for the position

transmitter the complete resistance range is not always utilized for

the whole travel. Therefore, an external possibility for adjustment

(setting potentiometer) must be provided.

.Perform fine-tuning of the zero point at external setting potentiometer (for remote

indication).

19

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

Operation instructions AUMA NORM

Figure N: Control unit

E2

14. Setting the electronic position transmitter RWG (option)

– For remote indication or external controls –

After mounting the multi-turn actuator to the valve, check setting by measuring the

output current (see sections 14.1 or 14.2) and re-adjust, if necessary.

The position transmitter board (figure P-1) is located under the cover plate

(figure P-2).

20

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

AUMA NORM Operation instructions

Terminal plans KMS TP_ _ 4 / _ _ _

3- or 4-wire system

KMS TP _ 4 _ / _ _ _

KMS TP _ 5 _ / _ _ _

2-wire system

Output current Ia0 – 20 mA, 4 – 20 mA 4 – 20 mA

Power supply Uv24 V DC, ± 15 %

regulated

14 V DC + (I x RB),

max. 30 V

max. input

current

I 24 mA at 20 mA

output current

20 mA

max. load RB600 Ω(Uv - 14 V) /20 mA

Table 7: Technical data RWG 4020

Figure P-1: Position transmitter board

This manual suits for next models

4

Table of contents

Other AUMA Controllers manuals

AUMA

AUMA SAExC Series User manual

AUMA

AUMA SQ 05.2-F05 User manual

AUMA

AUMA SVM Series User manual

AUMA

AUMA SA 07.1 - SA 30.1 User manual

AUMA

AUMA NORM Series User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA SGM 04.1 User manual

AUMA

AUMA SQEx 05.2 User manual

AUMA

AUMA PROFOX PF-M100X User manual

AUMA

AUMA TIGRON TR-M30X Manual

AUMA

AUMA SQEx 05.2 User manual

AUMA

AUMA Profibus PBD 100 User manual

AUMA

AUMA Aumatic AC 01.1 User manual

AUMA

AUMA GSTI Series User manual

AUMA

AUMA SA 16.1 User manual

AUMA

AUMA SAI 6 User manual

AUMA

AUMA SQ 05.2 User manual

AUMA

AUMA SBA 12 User manual

AUMA

AUMA SAVEx 07.2 User manual

AUMA

AUMA SQ 05.2 User manual