7

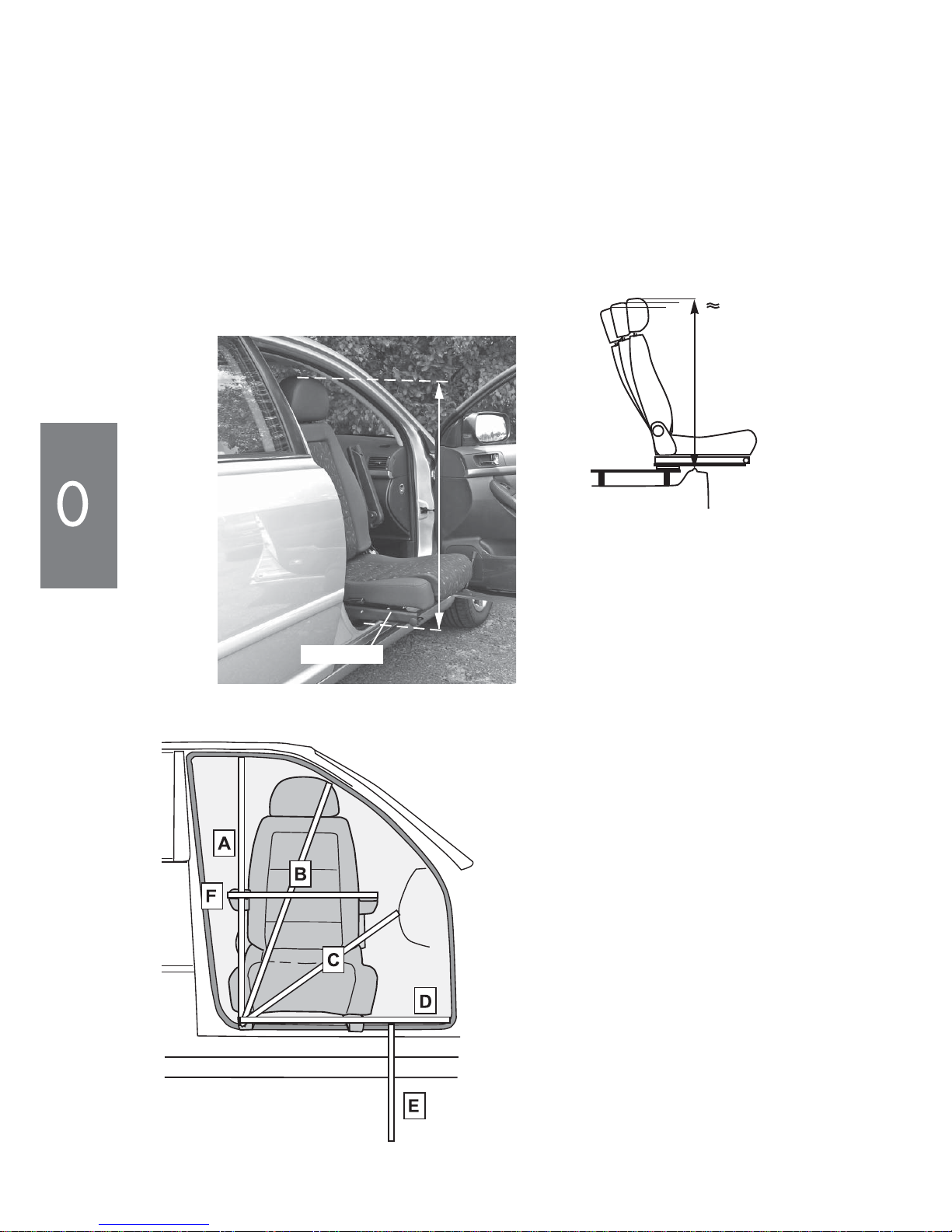

0:1 Technical data

General

Seat angle 17º

Depth of seat 493 mm

Seat width 408 mm

Height of seat surface in front 510 mm

Backrest inclination -19º till 23º

Backrest height 653 mm

Backrest width 435 mm

Distance of headrest in front of backrest 34 mm

Height of backrest above seat 775 mm

BEV seat specifications

Total width, with air tyres 62 cm

Total width, puncture free wheels 60,9 cm

Length 75 cm

Length with anti-tip and foot rests 108 cm

Height without seat 38 cm

Height with seat 115 cm

Total weight 93 kg

Weight of wheel unit with batteries 75 kg

Clearence beneath wheelchair 65 mm

Adjustable seat height 42-55 cm

Dimension front wheels 200x50 mm

Tyre pressure front wheels 2,6 bar

Dimension rear wheels 315x50 mm

Tyre pressure rear wheels 2,8 bar

Range 25 km

Max speed 6,5 km/h

Max reverse speed 3 km/h

Braking distance 0,8 m

Obstacle clearence 6 cm

Turning space180 degrees 150 cm

Hill-climbing ability 6 grader

Max user weight 120 kg

Battery type AGM; 1245

Batteriy max dimension 198x 165x170

Main fuse 50 A

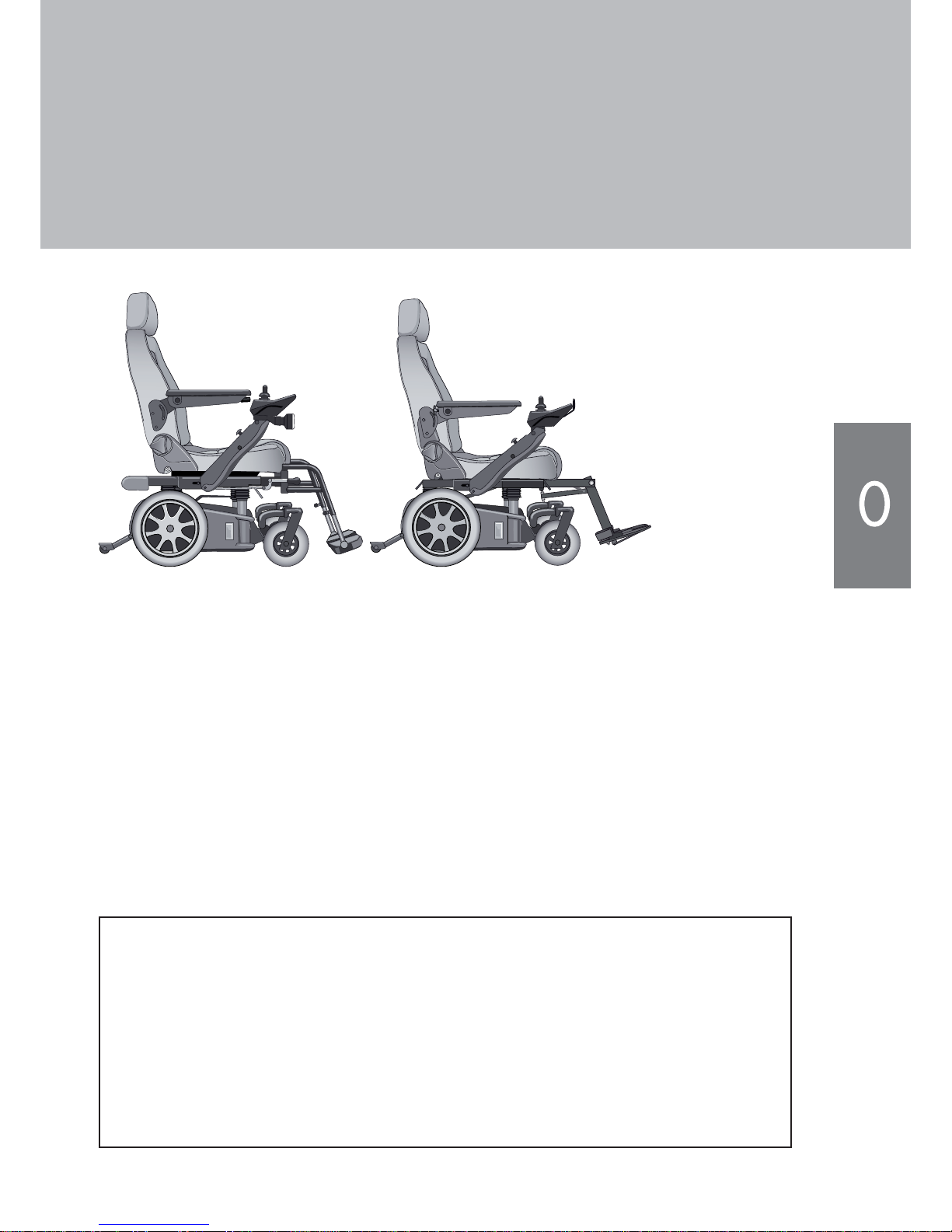

Carony Go/ Drive

Go: Drive:

110-122 cm

33,5 cm

112-126 cm

110 kg

92 kg

65 mm (35 mm)

37-51 cm

Distance from footplate to seat 404-550 mm in 8 steps

Length of footplate 129 mm

Footplate angle variable

Angle of legrest to seat surface 104º

Armrest height 285 mm

Distance to backrest from front edge

of armrest 335 mm

Armrest length 356 mm

Armrest width 57 mm

Armrest angle -38º to 10º

Distance between armrests 438 mm

Carony Go Carony Drive