3

Rev (29-AUG-97) • Module Driver v4.7 © 1995-97 Automated Logic Corporation

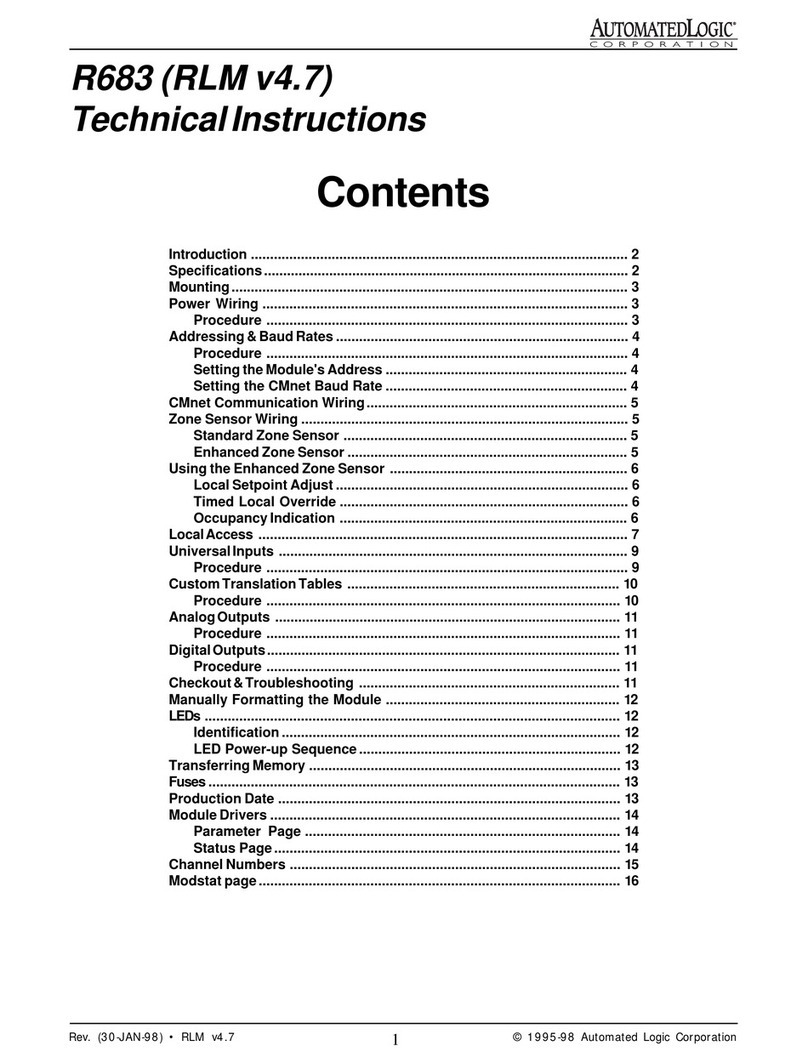

Addressing and Baud Rates

NOTES:

1. Before setting the address, remove power from the

module.

2. After setting the address, you must download memory

to the module.

Setting the Address

The address DIP switch (see Figure 2) is configured with

eight individual sliding ON or OFF switches. Only the

first seven switches, counting from right to left, are used

for addressing. The value of each switch is indicated

directly above the individual switch. The module's

address is found by taking the sum of the switch values in

the on position. As shown in the example, switches one

and three are in the ON position. Therefore, this module's

address is five.

1. Turn the G4106's power switch OFF.

2. Set the G4106's address and baud rate using the

8-position dip switch (see Figure 1 for location).

3. Turn the G4106 module's power ON. If the address

has been changed, the module's Error LED will turn

ON.

4. To begin communication and to turn the Error LED

OFF, download memory to the module as described

later in this document.

Example:

Power Wiring

CAUTION: GX-Line controllers are Class 2 devices (less

than 30VAC). Take appropriate isolation measures when

mounting the GX-Line in a control panel where Class 1

devices (120 VAC) or wiring are present.

NOTE: Whenever possible, terminate and verify power

and communications to all modules before terminating

any inputs and outputs.

Multiple modules can be powered from the same

transformer as long as the proper polarity is observed. The

number of modules that can be hooked up to a single

transformer is based on the VA rating of the transformer

and on the VA requirements of the modules. For example,

if the transformer is rated for 50 VA and it is connected to

a G8102e (rated for 25 VA) and a X4106p (rated for 40

VA), then the transformer has been exceeded by 15 VA (25

VA + 40 VA = 65 VA). The size of the transformer would

have to be increased by at least 15 VA in order to properly

drive the modules under all circumstances. Measuring the

voltage level at the power terminals is not an accurate

method of determining accurate power because it could

result in selecting a transformer that is undersized for the

worst case scenario (i.e. all inputs and outputs driven to

maximum), resulting in a module brownout.

Automated Logic products are rated at 24 VAC ±10%.

This gives an operating range of 21.6 VAC to 26.4 VAC

RMS. Functional operation of the module is not

guaranteed if the voltage drops below 21.6 VAC or goes

above 26.4 VAC at the power input terminals to the

module (not the transformer).

NOTE: Pilot relays should NOT be powered from

thesametransformerwhichpowerstheGXboards.

1. Verify that the G4106 is addressed correctly (see

Figure 2).

2. Turn the G4106's power switch OFF. This prevents

the module from being powered up until proper

voltage is verified.

3. Make sure that the power source is OFF.

4. Terminate the two power wires to the screw terminals

indicated in Figure 5.

NOTE: Multiple boards(G or X) poweredfromthe

same transformer should observe the same polarity.

5. Terminate power to the transformer.

6. Turn the power source ON.

Figure 2: Setting the Modules Address

Setting the CMnet Baud Rate

The baud rate for the CMnet is set using the same DIP

switch as with setting the address. As shown in Figure 2,

only the first switch position, counting from left to right,

is used for the baud rate. As shown in the example, switch

number one is in the ON position. Therefore, the module's

CMnet baud rate is set at 38.4k bps.

The G4106 module has the capability of communicating

with the CMnet at a baud rate of 9600 or 38.4k bps.

Baud 64 32 16 8421

Switch values

for ON Position

38.4k bps

9600 bps

O

N