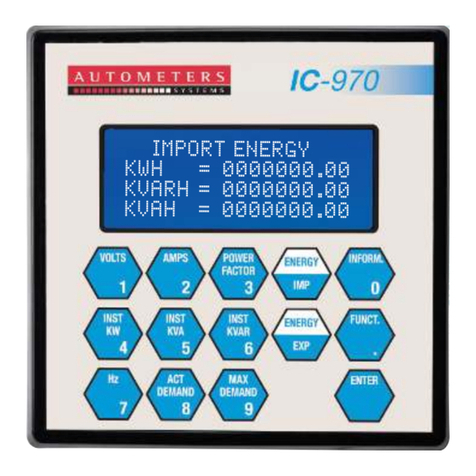

Autometers Systems ic9 User manual

installation and

operation manual

IC7-C and IC9-C

horizonrangeThe fusion of land based metering and ether based monitoring

9

Overview

The IC7-C and IC9-C meter is

230/400 volt 50 Hz, 5 amp current

transformer operated meter

designed for measuring 3 phases

in a 4 wire star configured system

and is capable of transmitting

kWh and KVAh by means of

the volt free outputs which are

standard on the basic model. The

model IC9-C is supplied with fully

programmable RS485-Modbus

communication output and is

capable of transmitting all of the

data the meter monitors.

Installation

Orientation

The meters are designed to be

fitted into a panel, normally a

switchgear cabinet. It is therefore

recommended that the front of

the meter is positioned vertically

with adequate space around and

at the back for connections.

Location

The meters should be mounted in

a dry dirt free environment away

from all heat sources and very

high electric fields. Temperatures

should not exceed 70°C or fall

below -20°C.

Installing the meter.

First remove the meter from the

packaging and check for any

damage. The meter should be in

two pieces, a Front Bezel and the

back of the meter. (See diagram

1 above) The aperture required to

fit the meter is 92 mm x 92 mm.

Holding the back of the meter

in one hand and the bezel in

the other hand, present to the

opening. Slide the back of the

meter first through the opening

on the rear side of the door and

then push the bezel from the

front side over the protruding

clear plastic and push fully

home until it locks firmly.

Please note it is extremely

difficult to remove when fitted.

Please see diagram 1.

Check Contents

Package should contain:

1. Black locking bezel

2. Main meter case

3. Top terminal cover

4. Lower terminal cover

The Information Centre ic

7

-C and ic

9

-C

Diagram 1. Meter Installation

Diagram 2. External Dimension

9216 16

124

12

75

64 12

95

150

92 4315

Communication

Sockets

Cable Channel

Cable Channel

Cable Entry

All Dimensions in mm

DILL SWITCH

Phasing and polarity of the AC

current and voltage inputs and

their relationship is critical to the

correct operation of this meter.

The connection diagram shows a

current transformer fitted to the

Neutral.

If you do not want to monitor the

neutral current it is not necessary

to connect to terminals 7 and 8.

Terminal 9 is the Neutral supply

Terminals 10,11,and 12 are the

three phase line voltages (230

volt). Terminals 14,15, and 16 are

the low voltage pulse output. (volt

free)

2

L3 N

LOAD

MAINS

L3

L2

L2

L1

L2

S2

S1

P2

P1

S2

S1

P2

P1

S2

S1

P2

P1

S2

S1

P2

P1

L1

1 Amp

230/400Volt 50Hz

0.1-5Amp

Communication

Sockets

Cable Channel

Cable Channel

Fuse

Cable Entry

DILL SWITCH

ON DIP

1234567812345678

ON DIP

1234567812345678

Wiring information

Power supply

The standard IC9 requires a 230

volt 50 Hz supply. This is powered

from the L3 phase and Neutral

internally.

Wiring

Electrical and communication

connections are made directly to

the back of the meter.

The main electrical connections are

made to terminals 1-16 at the lower

half of the meter, Communication

Modbus 485 connections are made

via the two sockets at the top of the

meter on the side. Please see dia 2.

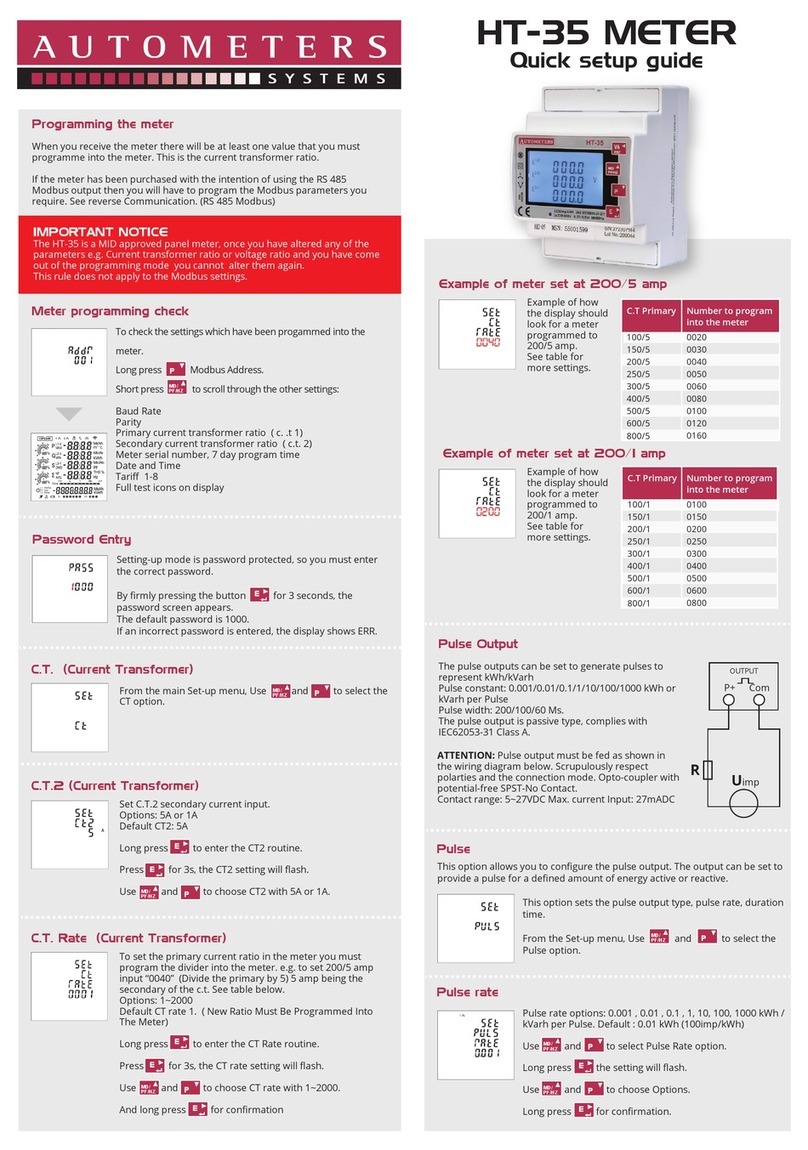

Programming

the CT Ratio '13'

To programme the CT Ratio the

dill switch number "8" on the

lower dill switch block must be in

the "On" position

See diagram 6 for position of dill

switches.

Connect power to the meter.

To programme, press the

function key on the front of the

meter, which will then take you

into the display sequences for

programming the CT Ratios.

You should now see the screen

below

Diagram 3: Programming Screen

(a) You will notice the cursor

flashing on the first "zero", by

pressing the "Energy" key the

zero will change to 1, if you press

the "Energy" key again it will

change to 2 and so on.

(b) If you go past your number

continue going through the

numbers until the number you

require reappears. Stop at your

correct number '1'.

(c) Press the "Enter" key and the

flashing cursor will move to the

right. Stop at number '3'. Press

function.

Diagram 4 : CT Setting Screens

(d) Repeat steps (a) to (c) to enter

the correct programming details

for your chosen CT ratios.

(e) When the process is complete

press the "Function" key to take

you back to the default screen.

Note: When setting CT ratios and

if you have only three digits you

must enter "0" as the first digit.

e.g. 100/5 would be entered as

0100/5.

When you have programmed the

meter, disconnect the power to

the meter and ensure dill switches

are set to the 'OFF' position.

Operating

information

Power on

After you have programmed the

meter and you have put power

onto the meter, the first screen

to appear will indicate details of

the meter and your programmed

parameter values. After 10

seconds will revert to normal

default screen. "b"

a) Power On:

b) Normal Default Display

Test Mode Display

At this stage it is advisable to check

the connection to the meter, to do

this please see page 6 function 50.

This will enable you to see if the

current transformers have been

connected correctly and the three

voltages are present.

Diagram 5: Connection Check Screen

The diagram above is showing

that the current transformers

are correct and the three phase

voltages are correct.

If the current transformers are

correct but the voltage on each

phase is missing or below 200

volts, then the screen will look as

in the diagram below:

PLEASEENTERFUNCTIONNUMBER**RATIOCTPRIMARY=****/5NTPRIMARY=****/5

3

IMPORTENERGYKWH=000000.00KVAH=000000.00KVARH=000000.00CONNECTIONL1importV1ONL2importV2ONL3importV3ONCONNECTIONL1importV1OFFL2importV2OFFL3importV3OFF

IC3P4W230/400V50HZCTRatio****:5NTRatio****:59

Screen Definitions

Below are the available screens,

which can be seen by pressing

the various keys on the front of

the meter. After 10 seconds the

meter will revert to the "IMPORT

ENERGY" screen.

By pressing the following keys the

display will show:

a) Volts

Press the key twice to view Page 2

b) Amps

c) Power Factor

d ) Actual Demand

e) Energy

Press the key twice to view Page 2

f) Harmonic

Press 'H' key, the dislay change as

below:

1. HARMONIC L1V (%)

2. HARMONIC L2V (%)

3. HARMONIC L2V (%)

4. HARMONIC L1A (%)

5. HARMONIC L2A (%)

6. HARMONIC L3A (%)

7. HARMONIC NA (%)

When it enter any harmonic

display, press 'ENTER', it will

display one kind of harmonic

data.

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

g) Instantaneous KW

h) Instantaneous KVAR

i) Instantaneous KVA

Page 2 Max Demand

4

IMPORTENERGYKWH=000000.00KVAH=000000.00KVARH=000000.00EXPORTENERGYKWH=000000.00KVARH=000000.00VOLTAGEL1=000.0L1-L2=000.0L2=000.0L2-L3=000.0L3=000.0L3-L1=000.0

FREQUENCY50.00Hz

AMPSL1=000.0L2=000.0T=000.0L3=000.0N=000.0INSTKWL1=00.0000L2=00.0000T=00.0000L3=00.0000INSTKVAL1=00.0000L2=00.0000T=00.0000L3=00.0000INSTKVARL1=00.0000L2=00.0000T=00.0000L3=00.0000ACTDEMANDKW=00.0000KVAR=00.0000KVA=00.0000MIN=00MAXDEMMANDKW=00.0000KVAR=00.0000KVA=00.0000POWERFACTORL1=0.000L2=0.000T=0.000L3=0.000HARMONIC***(%)THD=0.009th=0.003th=0.0011st=0.005th=0.0013th=0.00HARMONIC***(%)7th=0.0015th=0.0017th=0.0025th=0.0019th=0.0027th=0.00HARMONIC***(%)21st=0.0029th=0.0023th=0.0031st=0.0033th=0.0041st=0.00HARMONIC***(%)35th=0.0043th=0.0037th=0.0045th=0.0039th=0.0047th=0.00HARMONIC***(%)49th=0.0055th=0.0051st=0.0057th=0.0053th=0.0059th=0.00HARMONIC***(%)61st=0.0063th=0.00

5

viii. Press 'ENTER' Key

To see meter information

continually press to scroll down

pages.

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

2) Function operating display:

Press 'FUNCT' key. Display will

change to below.

On the screen above, you will see

two asterix, one flashing.

Type in the first number of the

required function you wish to

see by pressing the 'ENERGY'

key continually until you have

reached the correct number, then

press 'ENTER' key. Repeat for the

second asterix.

When both numbers have been

entered, press the "FUNCT' key.

This will take you to the desired

screen.

To return to the normal screen

press 'FUNCTION' key again.

If you enter an incorrect number

or a function which is not

available on this model you will

see the screen below.

METERDESCRIPTION3PHASE4WIRE230/400V5A50HzRATIOSVT230.0:230.0CT5:5NT5:5PULSESDETAILSPULSEVALUE=1kWhPULSEPERIOD=100msRESETMDFUNC-012RATIOFUNC-013CONTRASTFUNC-016CONNECTIONFUNC-050PULSE TESTFUNC-060PLEASEENTERFUNCTIONNUMBER**FUNCTIONSELECTEDIS NOT

AVAILABLEAUTOMETERSLTDIC9SERIAL No:9000001ADDRESS:00

Function Option Number

Number

12 Demand reset

13 Ratio CT ratio Primary

16 Display contrast + or - Primary

50 Connection test

60 Pulse test

List of function code as below:

6

RESET MAXIMUM DEMAND

Function 12.

To reset maximum demand enter

Function 12

(page 5 function operation

display)

press “enter” key.

Press “Funct” key to return to

normal display.

SETTING CURRENT

TRANSFORMER RATIO.

Function 13.

To set C.T. ratio see page 3.

DISPLAY CONTRAST.

Function 16.

To alter the display enter function

16.

(See Page 5 function operation

display)

The curser will flash on one of the

two signs.

To increase contrast press “enter”

key to move the curser to the

flashing “+” sign,

Display will change, press the

“Enter “key to step the contrast.

Press “Funct” key to return to

normal display.

CURRENT TRANSFORMER

AND VOLTAGE CONNECTION

SETTINGS

Function 50

To check connections enter

function 50.

(See Page 5 function operation

display)

Press “Funct” key to see

connections.

Press “Funct” key to return to

normal display.

PULSE TEST

Function 60

To test the relay output enter

function 60

(See Page 5 function operation

display)

Press “enter key”

Press “Funct” key to return to

normal display.

PRESSENTERKEYTO RESETMDRATIOCTPRIMARY=****/5NTPRIMARY=****/5DISPLAYCONTRAST+-CONNECTIONL1importV1OFFL2importV2OFFL3importV3OFFRELAYPULSETESTPULSEEVERYSECONDPRESSENTERTOEXIT

Diagram 6.

L3 N

LOAD

MAINS

L3

L2

L2

L1

L2

S2

S1

P2

P1

S2

S1

P2

P1

S2

S1

P2

P1

S2

S1

P2

P1

L1

1 Amp

230/400Volt 50Hz

0.1-5Amp

Communication

Sockets

Cable Channel

Cable Channel

Fuse

Cable Entry

DILL SWITCH

Position of Communication Sockets

ON DIP

1234567812345678

ON DIP

1234567812345678

7

Wiring Information

Power Supply

The standard IC7-C and IC9-C

requires a 230 volt, 50Hz supply.

This is provided from the L3

phase and Neutral internally.

Wiring

Electrical and communication

connections are made to

terminals 1-6 at the lower half

of the meter. Communication

Modbus 485 connections are

made via the two sockets at the

top of the meter on the side.

Please see diagram 3.

Programming the

Meter

To program the meter the dill

switch, number “8” on the lower

dill switch block must be in the

“on” position.

Programming the Modbus

Meter Register

Each meter that is connected to

a Local Area Network (LAN) must

have a unique modbus register

so that it can be identified by the

computer processor. Allocating

a meter modbus register is

accomplished using the upper

block of dill switches. The dill

switches in this block each

represent a number, in geometric

progression starting with dill

switch number “8”. Thus switch

number “8” represents register

number “1”, switch number “7”

represents register number “2”,

switch number “6” represents

register number “4”, switch

number “5” represents register

number “8” and so on.

To allocate a meter register

number the required dill switches

must be switched into the “on”

(up) position.

Thus: To allocate meter register

number “1”, only dill switch

number “8” on the upper block

of dill switches needs to be in the

“on” position.

To allocate meter register number

“14” dill switches numbers “5”,

“6” and “7” must be in the “on”

position.

To allocate meter register number

“39” dill switches numbers “3”,

“6”, “7” and “8” must be in the

“on” position. Etc.

Programming the

Meter Functions.

The operating functions of the

meter, such as baud rate, data

format etc are programmed using

the lower block of dill switches,

as follows:

Baud Rate

Programming the Baud rate

utilises dill switches numbered

“1” and “2” on the lower dill

switch block, as follows:

Baud Rate Dill Switch Dill Switch

1 2

9600 Off Off

19200 On Off

38400 Off On

1200 On On

Wire Mode

Programming wire mode utilises

switch number “3”, as follows:

Two wire mode: switch Off

Four wire mode: switch On

Modbus Type

Programming the modbus type

utilises switch number “4”, as

follows:

RTU: switch Off

ASCII: switch On

Parity Type

Programming the parity type

utilises switch number “5”, as

follows:

Even: switch Off

Odd: switch On

Data Format

Programming data type utilises

switch number “6”, as follows:

ASCII string: Off

Floating point: On

Floating Point Format

Programming the floating point

format utilises switch number

“7”, as follows:

High word first: switch Off

Low word first: switch On

LED Mode

Programming the LED mode and

CT ratio utilises switch number

“8”, as follows:

Calibration 1000 impulses per

Kwh: switch On

Kwh impulse with output relay:

switch Off

ON DIP

1234567812345678

TOP SWITCH

MODBUS

ADDRESS

ON DIP

1234567812345678

LOWER SWITCH

MODBUS

PARAMETERS

Performance and data

Overview

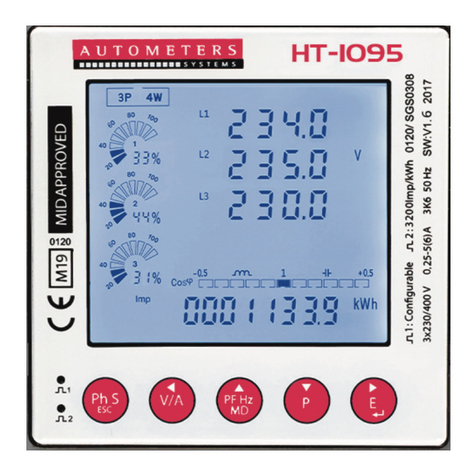

The IC7-C and IC9-C meters are 230/400 volt 50 Hz, 5 amp

current transformer operated meter designed for measuring

3 phases in a 4 wire star configured system and is

capable of transmitting kWh and kVAH by means of the

volt free outputs which are standard on the basic model.

The model IC9-C is supplied with a fully programmable

RS485-communication output and is capable of

transmitting all of the data the meter monitors.

Technical Parameters

Meter Standard BS EN 61036

Accuracy Active 1.0, Reactive 2.0

Reference Voltage 3 x 230 /400 v

Basic Current 5 Amp

Maximum Current 6 Amp

Frequency 50/60 Hz

Pulse Constant (LED strobe) 1000 imp/kWh,

1000 imp/ kVAH

Range of Voltage 200- 250 volt

Operating Temperature -30°C – +70°C

Storage Temperature -30°C – +80°C

Power Consumption 0.01VA @5A; 0.8W,

8VA @230V

Pulse Output IEC 62053-31

Red L.E.D. Pulse Indication.

Display 20 x 4 character LCM with

background light.

Output Details 2 – Opto isolated Mosfet

devices: 400 ACV, 100ma

KWh, KVAH

Pulse Duration 80-100 ms closure

Pulse Value C.T. Value less than 1000/5A

= 1 kWh/imp

C.T. Value 1000/5A or more

than = 10 kWh/imp

0.4

0.3

0.2

0.1

-0.1

-0.2

-0.3

-0.4

0.1 1.0 2.0 3.0 4.0 5.0 6.0

IC9Load Curve

0.5 Lag 1.0

Unity 0.5

Lead

8

Current transformer selection

For accurate monitoring, correct selection

of the current transformers is critical.

Always select the current transformers suitable

for the load you are actually monitoring.

DO NOT automatically select current

transformers to the breaker size

in case the load is significantly lower.

Main Function

Measurement and Information available from

Keypad.

1. Active, Reactive, Apparent import energy

2. Active, Reactive export energy

Real Variables

1. Voltage: 3 phase voltages, 3 line voltages

2. Current: 3 phase current and neutral

current

3. Active instant (kW): 3 phase and total

power

4. Reactive instant (KVAR): 3 phase and total

power

5. Apparent (KVA): 3 phase and total power

6. Power factor: 3 phase and total power

factor

7. Frequency

Demand (Demand period 30 minutes)

1. Current Demand: Active, Reactive,

Apparent demand

2. Maximum demand: Active, Reactive,

Apparent Maximum demand

Performance characteristics

Diagram 9: Typical load curve with

balanced load at 50 Hz.

Autometers Systems Limited

4b Albany Road, Chorlton-cum-Hardy, Manchester M21 0AW

Tel: +44 (0)161 861 9056 Fax: +44 (0)161 881 3745

Important

The meter must be fitted by a competent person and

must be fitted in accordance to the latest edition of

electrical regulations concerning electricity meters.

The attention of the specifier, purchaser, installer and

user is drawn to the special measures and limitations

to use, which must be observed when this product

is taken into service to maintain compliance with

the CE directives currently in force. Details of these

special measures and limitation to use are available

from HMSO.

Ref: IEC1000-5-1 (BS195/210788DC), IEC1000-

5-2 (BS195/214642DC), IEC1000-5-6 (BS195/

210789DC).

Dedicated customer service

Customer service is the cornerstone of the company’s

success. A positive service policy is observed

throughout every specialist area of operation.

The personal involvement of the directors at every

level, a highly trained and motivated staff, fully

computerised systems and in depth stock holding,

combine to provide a level of service which has

earned the appreciation of customers across the

spectrum of the UK and export markets.

Computerised distribution systems are geared to

consistent 24-hour despatch of products, with 20-

minute despatch being possible in respect to urgent

demand for small orders.

Product range

Metering and monitoring equipment ranges from

single and three phase kWh meters to a sophisticated

range of fully programmable information centres.

Also available are Electronic meters capable of

monitoring over 400 individual parameters with full

memory backup for in depth graphical analysis of

power usage, together with a range of devices which

enables data to be transferred utilising leading-edge

telephone technology, thus enabling the information

to be sent directly to the web and viewed via a PC,

a laptop computer or even a mobile ‘phone. The

information can also be sent to a dedicated internal

server if preferred.

Product development is continuous and Autometers

Systems Ltd reserves the right to make alterations

in specifications and manufacture without notice.

Products as delivered may therefore differ slightly

from the description and illustrations contained in

this publication.

Publication No. IC9. 03.06

This manual suits for next models

2

Table of contents

Other Autometers Systems Measuring Instrument manuals

Autometers Systems

Autometers Systems HORIZON HT-400 User manual

Autometers Systems

Autometers Systems HORIZON HT-1095 User manual

Autometers Systems

Autometers Systems IC 970 Installation instructions

Autometers Systems

Autometers Systems HORIZON HT-35 User manual

Autometers Systems

Autometers Systems HORIZON HT-35 User manual

Autometers Systems

Autometers Systems Q-180 User manual

Autometers Systems

Autometers Systems A-35M User manual

Autometers Systems

Autometers Systems HORIZON HT-1095 User manual

Autometers Systems

Autometers Systems A-45 Series User manual

Autometers Systems

Autometers Systems ADP3-80C User manual