Electrician

The Q-180 panel meter should only be installed by a fully qualified electrician who has

knowledge of electricity meters connected with current transformers.

It is the installer who is fully responsible for the safe installation of this meter. It must

be installed to meet the current electrical regulations concerning installation of panel

meters.

EMC Installation Requirements

Whilst this unit complies with all relevant EU EMC (electro-magnetic compatibility)

regulations, any additional precautions necessary to provide proper operation of this

and adjacent equipment will be installation dependent and so the following can only be

general guidance:

Avoid routing wiring to this unit alongside cables and products that are, or could be, a

source of interference.

The supply to the unit should not be subject to excessive interference. In some cases, a

supply line filter may be required.

To protect the product against incorrect operation or permanent damage, surge

transients must be controlled. It is good EMC practice to suppress transients and surges

at the source. The unit has been designed to automatically recover from typical

transients; however in extreme circumstances it may be necessary to temporarily

disconnect the supply for a period of greater than 10 seconds to restore correct

operation.

Screened communication leads are recommended and may be required. These and

other connecting leads may require the fitting of RF suppression components, such as

ferrite absorbers, line filters etc., if RF fields cause problems.

It is good practice to install sensitive electronic instruments that are performing critical

functions in EMC enclosures that protect against electrical interference causing a

disturbance in function.

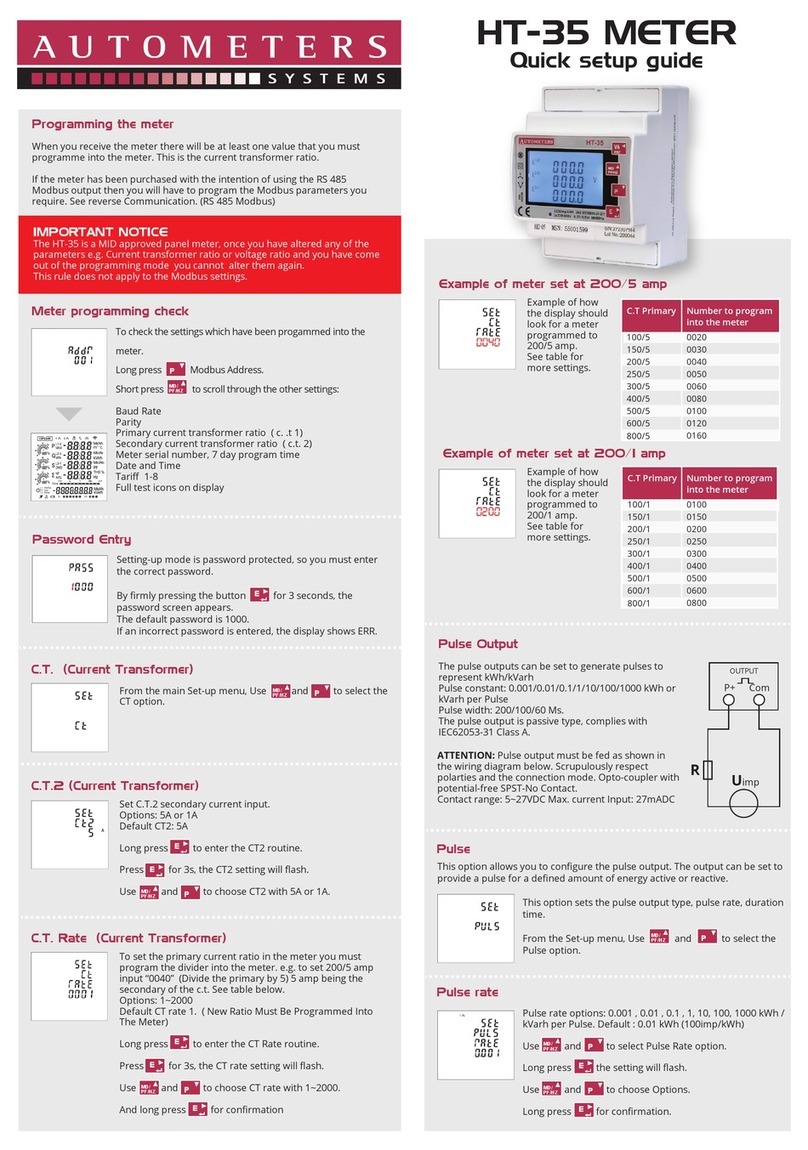

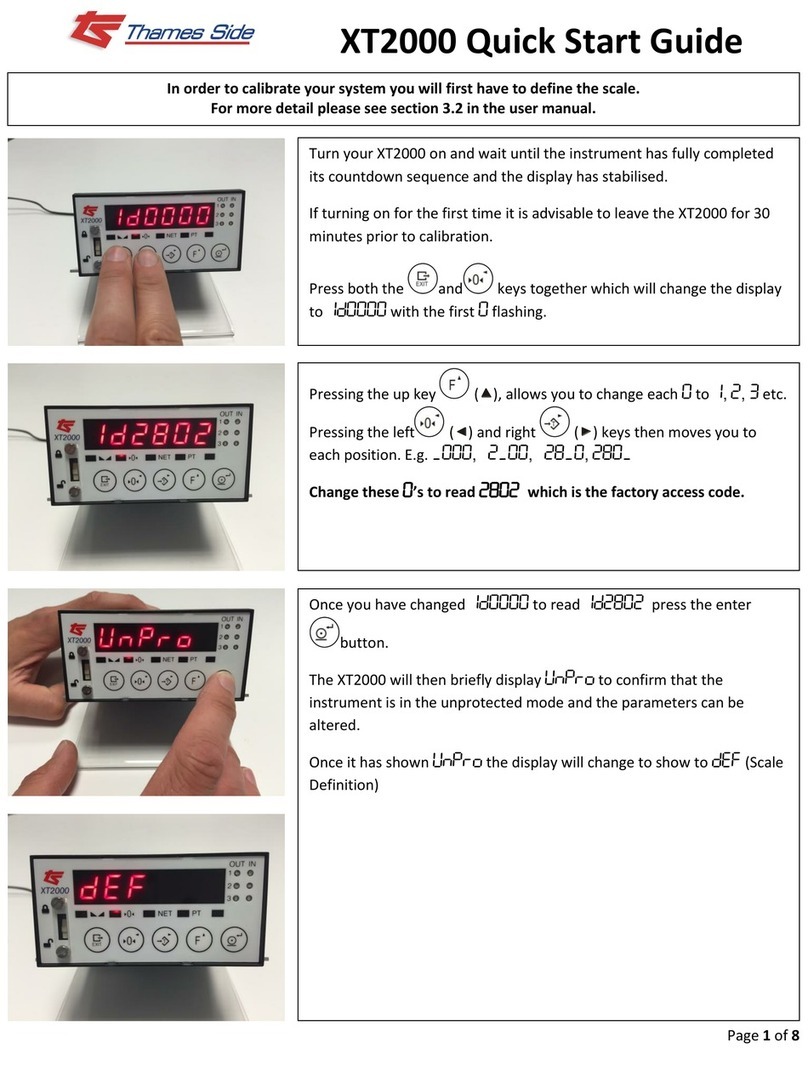

Password Entry

Setting-up mode is password protected, so you must enter

the correct password.

By firmly pressing the button for 2 seconds, the

password screen appears.

The default password is 1000.

To increment number press to 1000.

Press and hold display will change to RS485 Comm.

If an incorrect password is entered, the display shows ERR.

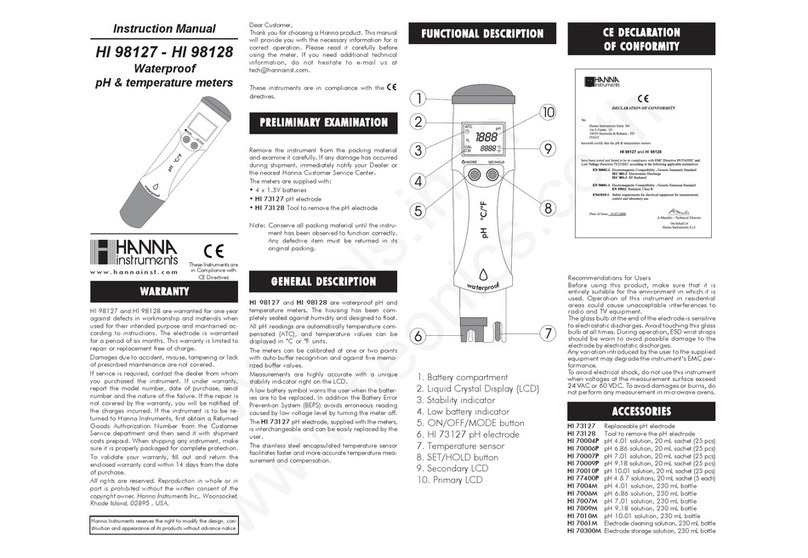

Wiring Information

Power Supply

The Q-180 requires auxilliary power to be connected

Wiring

The electrical connections of voltage, current and Pulse output are made directly to

the back of the meter. The RS 485 Modbus connections are at the top on the side of

the meter.

All terminals are green in colour and can be unplugged, The current terminals are

screwed in but can be unplugged if the screws are removed

Programming the meter

When you receive the meter there will be at least one value that you must

programme into the meter. This is the current transformer ratio.

If the meter has been purchased with the intention of using the RS 485

Modbus output then you will have to program the Modbus parameters you

require. See reverse Communication. (RS 485 Modbus)

Q-180

MULTIFUNCTION METER

Communication (RS 485 Modbus)

The RS485 port can be used for communications using

Modbus RTU protocol. Parameters such as Address, Baud

rate, Parity, Stop bit can be selected.

To adjust all other parameters press . When you find

the parameter you want to reset press and hold for 2s.

Long press to enter the Address option.

To reset Baud rate, Parity, Stop bit, press

Address

Mains

Load

Neutral

L1

L2

L3

Direction of Current

P2

P2

P2

1 Amp

Fast Blow

Fuses S2 S1 S2 S1 S2 S1

L3 L2 L1

C.T. INPUTS

TX+ TX- SHIELD

MODBUS OUTPUT

Aux Power supply

L N E

Voltage Inputs

NV3V2V1

S1

S2

S1

S2

S1

S2

3 phase 4 wire

Electrical Connections

2.5mm flexible stranded cable is recommended for all main electrical

connections. For the low voltage communication connections we recommend a

twisted shielded cable Belden 9841 2 wire or 9842 4 wire or equivalent.

Phasing and polarity of the AC current and voltage inputs and their relationship

is critical to the correct operation.

Aux

Power

Supply

E

E

An RS485 network can accommodate up to 255 different

devices, each identified by an individual address.

The Modbus address range on the Q-180 is between

001~247

Default setting from Autometers is 001

Long press to enter the selection routine.

The address setting will flash. Use and to

increment or reduce the number.

Press to move cursor to the right.

When address is correct, long press for

confirmation and press to return to the main menu.

E

E

E

PF Hz

MD P

Ph S

ESC

PF Hz

MD

E

P

E

P