23

22

Supplied

As Standard

Function 09 - Min/Max Volts Reset to Zero

Function 10 - Min/Max Amps Reset to Zero

Function 11 - Min Max Neutral Amps Reset to Zero

Function 12 - Peak Maximum Demand Reset to Zero

Function 13 - C.T and N.T current transformer setting Programmable

Function 21 - Pulse value Programmable

Function 22 - Pulse Duration Programmable

Function 30 - Display contrast Programmable

Function 31 - Back light Duration Programmable

Function 50 - Connection details View only

Function 51 - Relay test mode View only

Function 52 - Binary switch positions View only

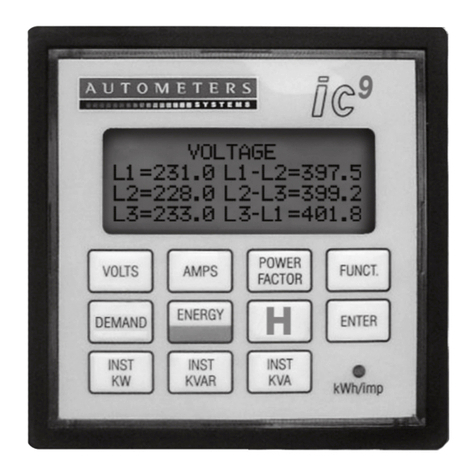

Dimensions (mm)

W96mm x H96mm x D 89mm (with comms module 103mm). Weight with communication module

and fixing clips: 0.64 kilos. Packing weight individually boxed in polyfoam box: 0.65 kilos

Field Service Considerations

In the unlikely event that a unit should fail, it will generally be serviced by exchanging the unit

for a replacement unit. The initial installation should be done in a way which makes this as

convenient as possible.

1. It is good practice that a current transformer shorting block is fitted, this enables the meter to

be disconnected without open circuiting the current transformers. The shorting block should be

wired so that the protective relays are not affected.

2. All wiring should be routed to allow easy removal of the connection to the terminals.

Disconnect From Supply

A suitable isolator for both voltage and current terminals shall be included in the wiring

installation, close to the meter with easy access and marked as the meters disconnect device.

If the equipment is used in a manner not specified by the manufacturer the protection provided

by the equipment may be impaired. Current measuring terminals are not intended to be

connected to voltages to earth above 50Vac.

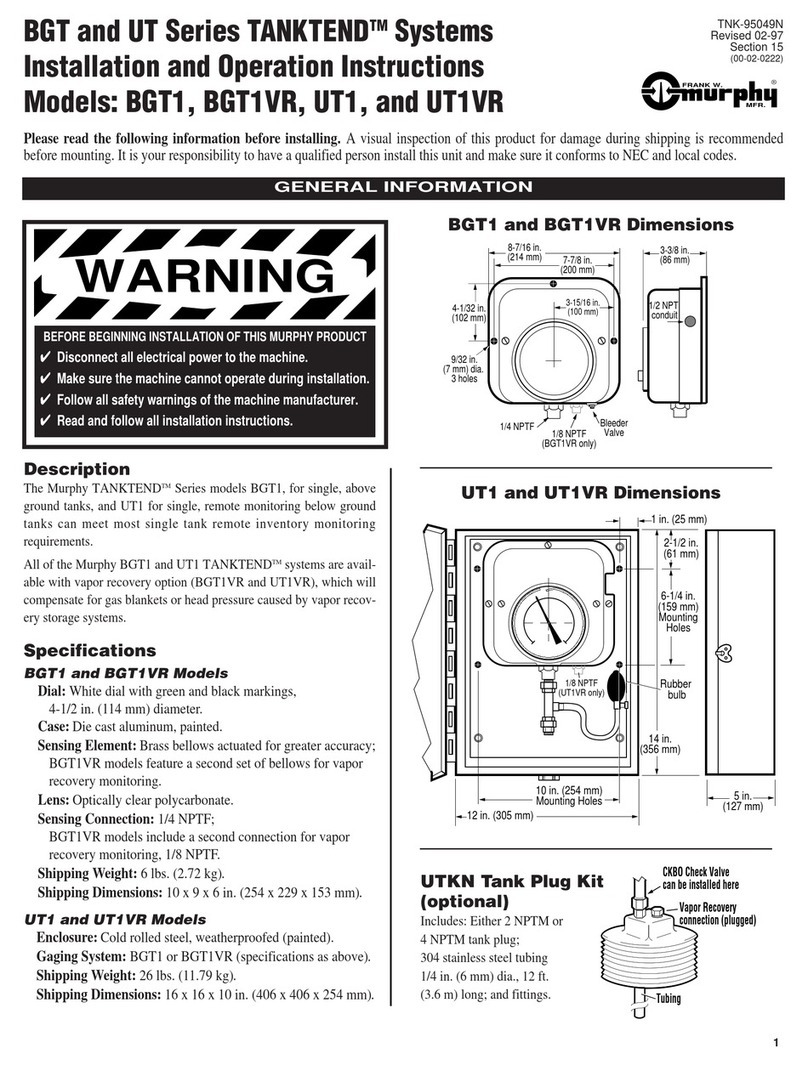

Performance Characteristics - Typical load curve with balanced load at 50 Hz

0

0 1 2 3

Amps

Pf 0.5L

Pf 1.0

% Error

4 5 6

0.1

0.2

0.4

0.3

0.246

0.223

0.189

0.105

0.069

0.102

0.068 0.048 0.055

0.046

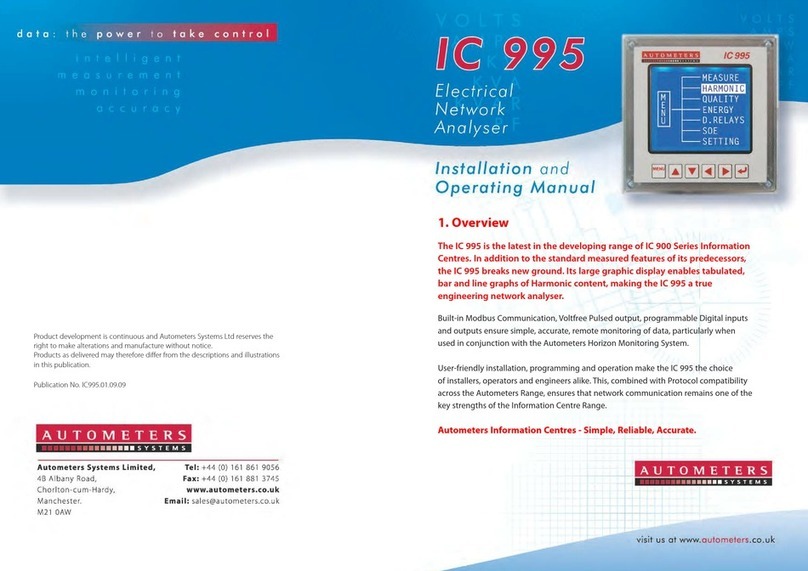

Customer care is the cornerstone of the company’s success. A positive service policy is observed

throughout every specialist area of operation.

The personal involvement of all the directors at every level, a highly trained and motivated staff,

fully computerised systems and in depth stockholding combine to provide a level of service

which has earned the appreciation of customers across the spectrum of the UK and overseas

markets. Computerised distribution systems are geared to a consistent 24 hour despatch of

products, with 20 minute despatch being possible in response to urgent demand for small orders.

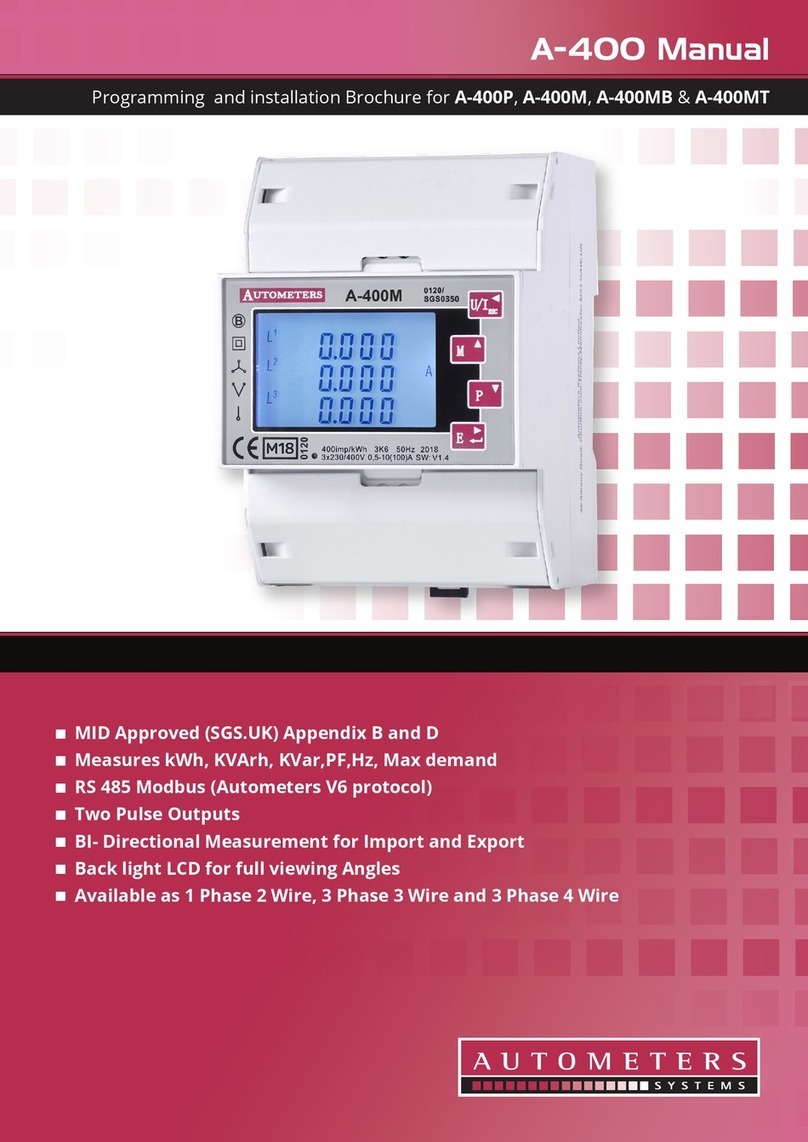

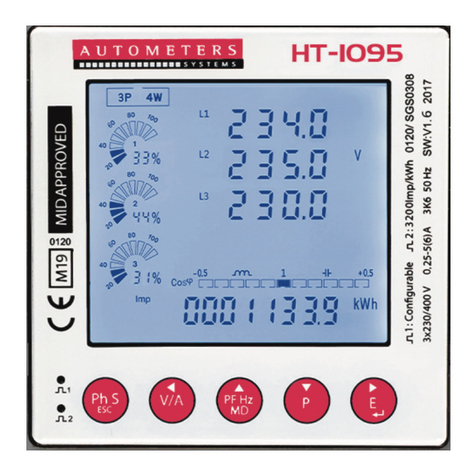

Metering and monitoring equipment ranges from single phase and Polyphase kWh

electromechanical meters to a sophisticated range of fully programmable information centres.

Also available are Electronic Meters, Panel Mounted Meters, Maximum Demand Meters, DIN Rail

Meters and Current Transformers.

CE Approval.

The IC 970 has been fully examined and tested in accordance with the standards listed and meets

the specified requirements defined in BS EN 61326:1997 inc A1, A2, A3 - Electrical equipment for

measurement, control and laboratory use - EMC requirements.

1. BS EN 61326:1997 inc. A1, A2 & A3 Conducted Emissions

2. BS EN 61326:1997 inc. A1, A2 & A3 Radiated Electricity Field Emissions

3. BS EN 61000-4-2:1995 inc. A1 & A2 Electromagnetic Compatibility

4. BS EN 61000-4-3:2002 inc. A1 & A2 Electromagnetic Compatibility

5. BS EN 61000-4-4:1995 inc. A1 & A3 Electromagnetic Compatibility

Safety Standards: BS EN 61010-1:2001

Important.

The attention of the specifier, purchaser, installer or user is drawn to special measures and

limitations to use which must be observed when these products are taken into service to

maintain compliance with the CE directives. Details of these special measures and limitations

of use are available from HMSO.

REF: IEC 1000-5-1(BS195/210788DC) IEC 1000-5-2 (BS 195/214642DC)

IEC 10000-5-6 (BS 195/210789DC).

Functions

Physical

Maintenance and service

Dedicated customer service

Product range

WARNING DO NOT MEGGAR TEST