Autowel DRAGON-350A User manual

THYRISTOR

THYRISTORTHYRISTOR

THYRISTOR

CO

COCO

CO

2

22

2

/MAG/MIG WELDER

/MAG/MIG WELDER/MAG/MIG WELDER

/MAG/MIG WELDER

DRAGON-350A

DRAGON-350ADRAGON-350A

DRAGON-350A

DRAGON-500A

DRAGON-500ADRAGON-500A

DRAGON-500A

DRAGON-650A

DRAGON-650ADRAGON-650A

DRAGON-650A

User

UserUser

User

Manual

ManualManual

Manual

CONTENTS

CONTENTSCONTENTS

CONTENTS◀ ▶

◀ ▶◀ ▶

◀ ▶

1. PRODUCT INTRODUCTION

2. CONFIGURATIONS and SPECIFICATIONS

3. INSTALLATION

4. HANDLING and OPERATION

5. SAFETY INSTRUCTION

6. MAINTENANCE and INSPECTION

7. TROUBLE SHOOTINGS

8. WELD CONDITION

9. SYMBOLS

10. DIAGRAMS

Before using welding machine, users have to read

the all contents described by manual to have better

quality of weld, and to reduce maintenance works.

1. Product Introduction

1. Product Introduction1. Product Introduction

1. Product Introduction

Autowel DRAGON- 350(500/ 650) sustains excellent stability under

the changes of input power or surrounding temperature by

adopting of the high responsive thyristor feedback and MICOM

type, so it is suitable in automatic welding and high- speed

welding.

2. Configurations and specifications

2. Configurations and specifications2. Configurations and specifications

2. Configurations and specifications

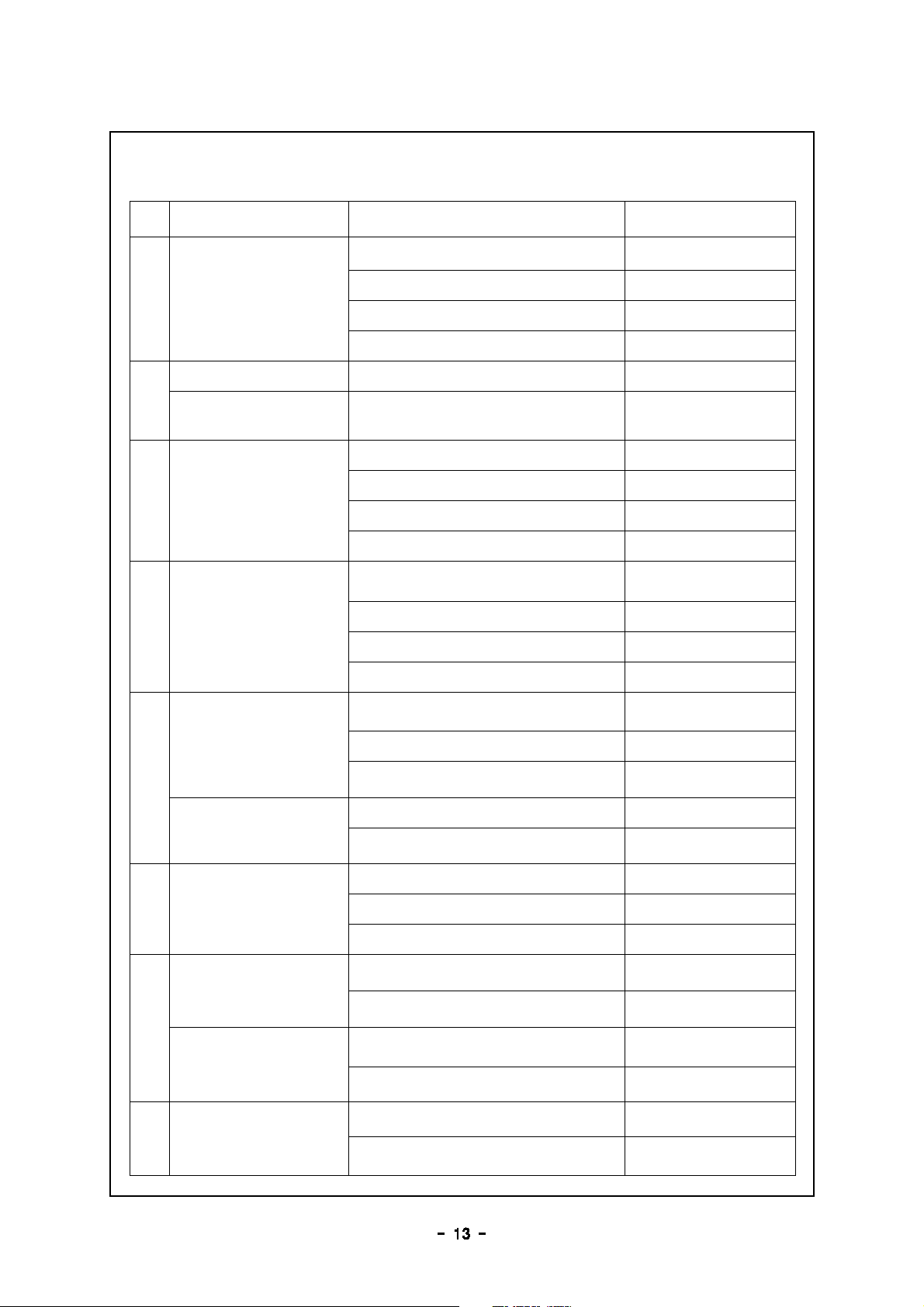

2- 1. Configuration

2- 1. Configuration2- 1. Configuration

2- 1. Configuration

Name

Type DRAGON- 350A DRAGON- 500A DRAGON- 650A Q'ty

WELDING POWER DC 350A DC 500A

(Gouging)

DC 650A

(Gouging) 1

WIRE FEEDER (0.9)1.2φ(1.2)1.4φ(1.2)1.6φ1

TORCH 350A, 3M 500A, 3M 650A, 3M 1

Gas Gage CO

2

(110V) CO

2

(110V) CO

2

(110V) 1

Welding cable 5M 5M 5M 1

Earth cable 35SQ, 3M 50SQ, 3M 70SQ, 3M 1

Tip (0.9)1.2φ(1.2)1.4φ(1.2)1.6φ3

Gas Diffuser for 350A for 500A for 500A 3

Insulator for 350A for 500A for 500A 3

Nozzle for 350A for 500A for 500A 3

2- 2. Standard Specification

2- 2. Standard Specification2- 2. Standard Specification

2- 2. Standard Specification

Item Type DRAGON- 350A DRAGON- 500A DRAGON- 650A

Input Voltage 3P, AC 220/ 380/ 440V selected

Input Power 18.5KVA 32KVA 45KVA

Frequency 50/ 60㎐

Output Current 50 350A~60 500A~80 650A~

Max. No- load Voltage 53V 65V 70V

Load Voltage 16 34V~16 42V~16 50V~

Use Rate 60 % 70% 80%

Dimension (WXDXH) 420X640X750 510X700X770 510X700X860

Weight 115kg 186kg 205kg

2- 3. Electrical Apparatus

2- 3. Electrical Apparatus2- 3. Electrical Apparatus

2- 3. Electrical Apparatus

Item Type DRAGON- 350A DRAGON- 500A DRAGON- 650A

NFB 60A 75A 100A

1st Cable 10SQ or above 16SQ or above 25SQ or above

Grounding Cable 10SQ or above 16SQ or above 25SQ or above

3. Installation

3. Installation3. Installation

3. Installation

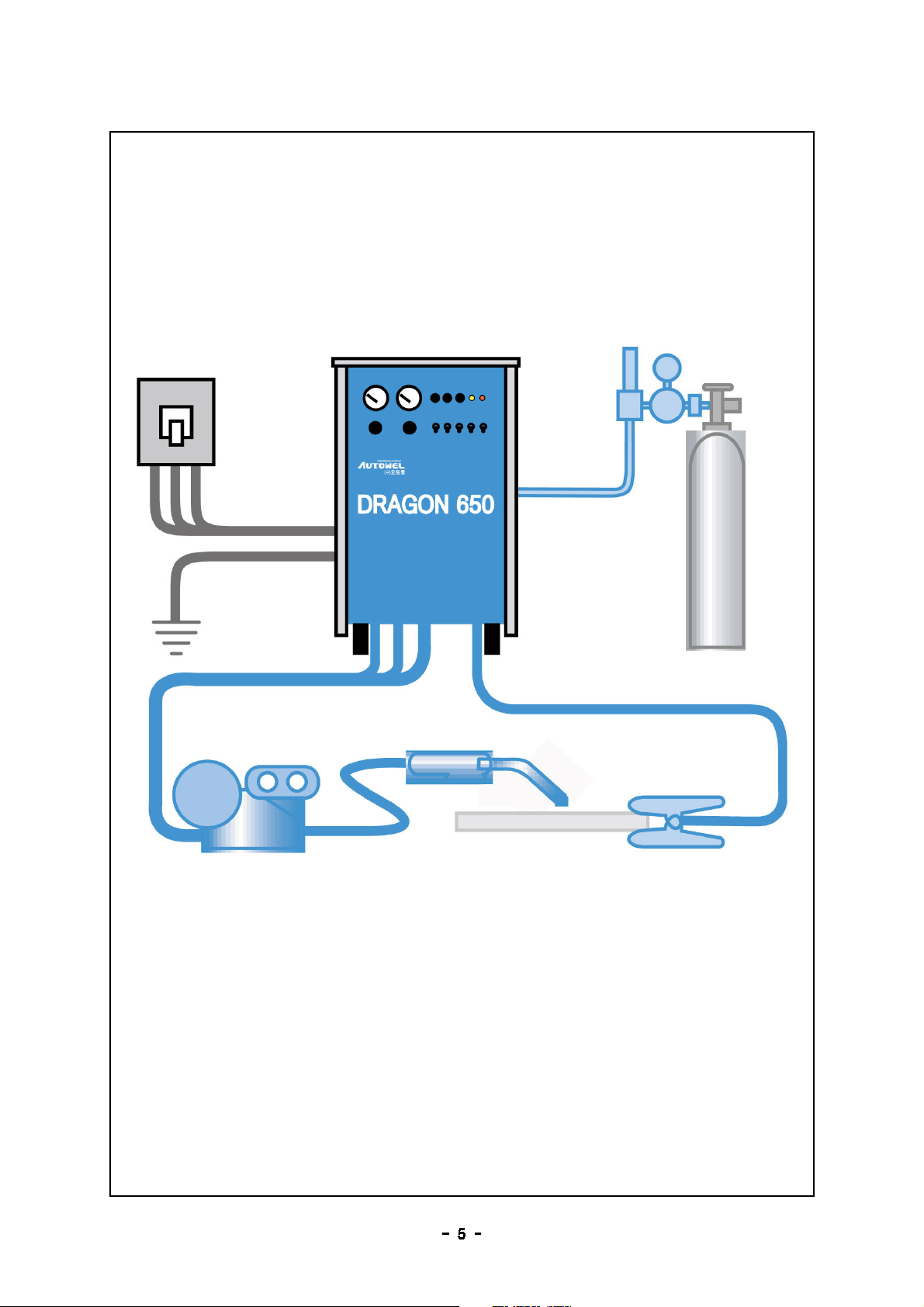

3- 1. Installation diagram

3- 1. Installation diagram3- 1. Installation diagram

3- 1. Installation diagram

Fig1. Full installation diagram

Fig1. Full installation diagramFig1. Full installation diagram

Fig1. Full installation diagram

3- 2. Location of installation

3- 2. Location of installation3- 2. Location of installation

3- 2. Location of installation

1) The inside of a house that there is a little moisture or dust.

2) The area far from each welders or wall more than 30cm.

3) The area that can avoid direct ray of sun, wind or rain.

4) The area where the surrounding temperature is in - 10 40~ ℃

range

5) The area that can install at the flat floor of stable construction

3- 3. Cautions in grounding

3- 3. Cautions in grounding3- 3. Cautions in grounding

3- 3. Cautions in grounding

1) The welder must be grounded, or electrical current of the case

causes the unstability of operation and accidents.

2) Connect grounding conductive cable which is 10SQ or more to

the grounding terminal which is marked "Grounding". During

the grounding work, make sure to off the on/ off switch in the

switch board, and afterward connect the ground cable.

3) When the base metal is placed on insulator such as wood, the

base metal must be grounded.

4) When there swimming pool or pond between the earth of

power source switch board and the earth of welder, leakage

current may flow to the pond or swimming pool. So in such

place, please connect grounding to both grounding points in

parallel so that the leakage current flow through the cable.

3- 4. Ventilation

3- 4. Ventilation3- 4. Ventilation

3- 4. Ventilation

1) Welding fume and gas are very bad for the health. They may

deal a person a fatal damage or cause death.

2) CO

2

arc- welding resolves shield gas, CO

2

in high temperature

and produces few carbon monoxide. Therefore, please ventilate

or wear the oxygen supply system or mask always when

welding is carried out in a small space.

3) If the ventilation is insufficient, please, install the dust collector

or support ventilation system.

3- 5. Movement Method

3- 5. Movement Method3- 5. Movement Method

3- 5. Movement Method

1) Separate welder and input power before moving welder.

2) Separate power unit, output, and earth cable before moving

welder.

3) No control or no contact below the equipment when it is

moved by hoist or forklift truck.

4) Use the adequate carriage to carry the welder.

3- 6. Connection of electrical sys

3- 6. Connection of electrical sys3- 6. Connection of electrical sys

3- 6. Connection of electrical sys

(

((

(Off the on/ off switch in the switch board

Off the on/ off switch in the switch boardOff the on/ off switch in the switch board

Off the on/ off switch in the switch board)

))

)

Even one point of defective connection may cause

unsatisfactory welding quality. Please tighten the connection

cables firmly with tool.

1) Connection of input power : Please connect referring to the

Fig. 1. Install NFB for your safety. When you install the electric

leafage breakers, please install the one which can detect more

than 30mA.

2) Connection of output : Referring the Fig 1, please connect

the torch to (+), base metal to (- ).

3) Connection of control cable : Connect the control cable to

remote terminal in order to control welding wire feeder and

remote control box.

4) Ground : Ground terminal is behind of the inverter welder.

The connection cable shall be 10SQ or above.

5) When it is used with engine generator, please use bigger

engine generator than the one specified in 2- 2. standard

specification. Unstable output power voltage may cause the

stop by activating the abnormal voltage detection circuit of

welder. And please start the engine generator when the power

switch of welder is off mode. An instant applying of excessive

voltage may cause malfunction of welder.

3- 7. Gas Connection

3- 7. Gas Connection3- 7. Gas Connection

3- 7. Gas Connection

1) Connect CO

2

gas to pressure regulator.

2) Connect outlet hose of gas pressure regulator to the gas inlet

behind of in the welder.

3) Connect the heat plug of gas pressure regulator to the

dedicated receptacle behind of the welder. (The receptacle is

dedicated to pressure regulator)

4) Install the gas container in the place where is no direct ray of

sun. And it is recommended to fix it to a supporter for safety.

5) For the good welding quality, please use high purity gas.

4. Handling and operation

4. Handling and operation4. Handling and operation

4. Handling and operation

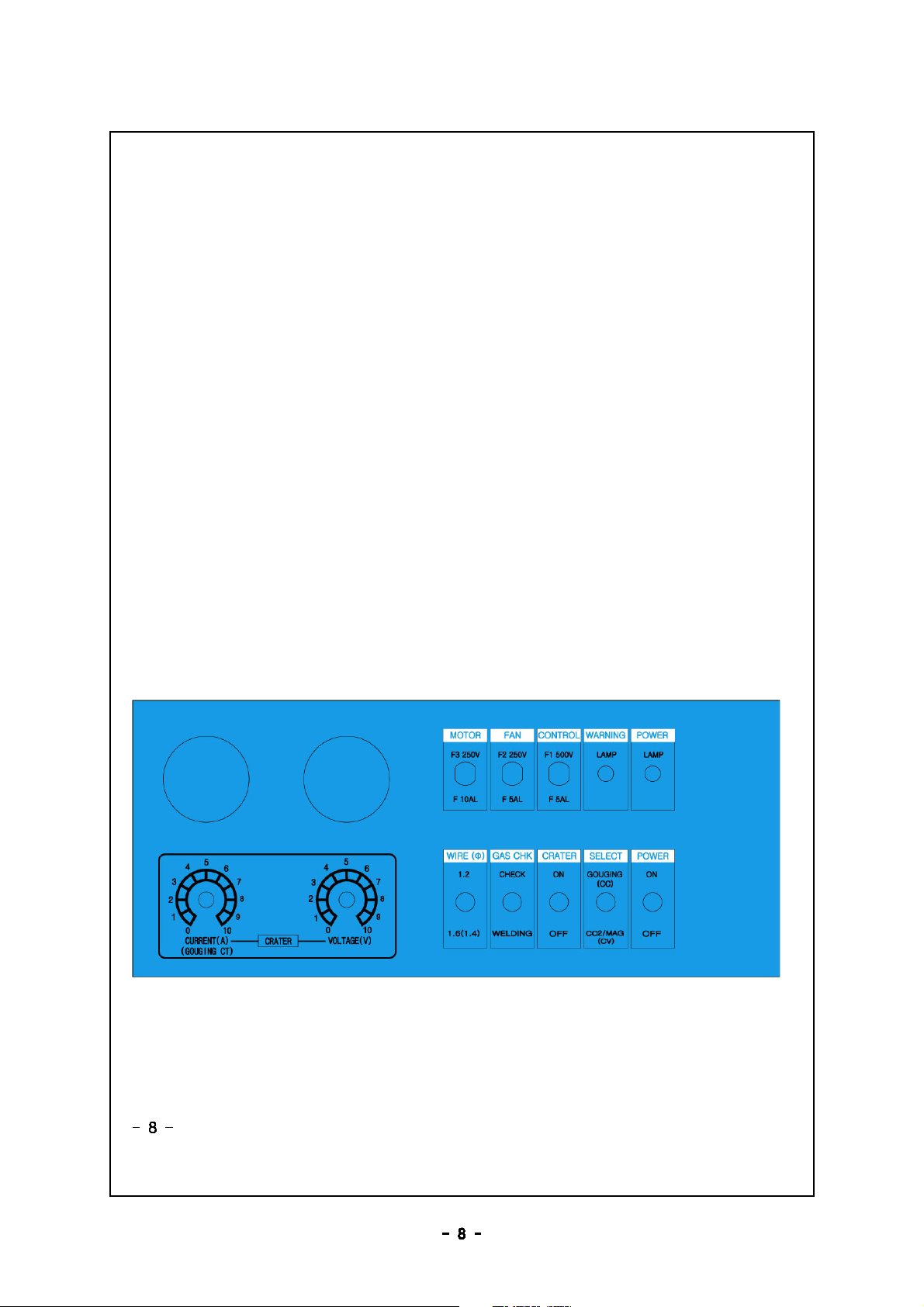

4- 1. Front panel and name

4- 1. Front panel and name4- 1. Front panel and name

4- 1. Front panel and name

DRAGON- 350A / 500A / 650A

DRAGON- 350A / 500A / 650ADRAGON- 350A / 500A / 650A

DRAGON- 350A / 500A / 650A

4- 2. Function and explanation

4- 2. Function and explanation4- 2. Function and explanation

4- 2. Function and explanation

1) POWER switch : power on/ off of welder. When on mode, fan

motor and magnetic switch is in standby mode. (power saving

function)

2) SELECT switch : Select CO2/ MAG/ M welding function (CV)

and gouging function (CC)

3) CRATER switch : self containing is activated in ON mode,

and enables to treat crater prior to completion of welding,

and the welding is available only when it is OFF and torch is

ON.

4) GAS check switch : On for checking gas volume, otherwise

select OFF.

5) WIRE (select wire diameter) switch : It balances voltage-

current according to the wire diameter for welding with same

voltage. (If the wire diameter is bigger, the feeding speed is

slow).

6) POWER LAMP : It turns on when the on/ off switch is ON.

(It indicates the welder is powered)

7) WARNING LAMP: It is turned on upon overheating and

overloading, and it stops operation. For restart, reset the

power switch.

8) CONTROL FUSE : use 5A fuse , for protection of control

circuit.

9) FAN FUSE : use 5A fuse , for protection of fan motor.

10) MOTOR FUSE(feeder motor fuse) : use 10A fuse, for

protection of feeder motor

11) CRATER C’T VOLUME(adjust crater current) :It adjusts current

value when crater switch is ON, and adjusts gouging current

value when gouging is selected.

12) CRATER VOLT VOLUME(adjust crater voltage) : When crater

switch is ON, crater voltage can be adjusted.

13) CURRENT METER : It indicates output current value in welding

( in case of no- load, it is not indicated)

14) VOLTAGE METER : It indicates output voltage in welding

(If the torch switch is ON under no- load condition, no- load

voltage value is indicated )

15) REMOTE : It connects to the feeder control box.

16) Torch terminal (+) : Connect to the torch terminal of feeder.

17) Earth terminal (- ) : Connect to the base metal.

18) Gas terminal : Connect to gas terminal of the feeder.

19) Remote control box : It is installed on the feeder.

a) Inching switch : It extrudes wire to the end of torch

quickly when welding wire is replaced.

b) Welding voltage volume : Adjust welding voltage.

c) Welding current volume : Adjust welding current.

(When gouging is selected in the feeder, it functions to

adjust gouging current)

d) Weld selection switch : Select CO2/ MAG/ MIG weld and

GOUGING function

20) Back panel:

a) 3 phase power input terminal

b) Power input switching terminal box : Select 220V/ 380V/

440V (In case of switching terminal box input power, open

the upper panel and change the terminal of single phase

auxiliary transformer)

c) HEATING power source of gas regulator : 110V

d) HEATER protection fuse of gas regulator : 2A glass tube

fuse

4- 3. Cautions in handling

4- 3. Cautions in handling4- 3. Cautions in handling

4- 3. Cautions in handling

1) Torch angle by welding direction

Incline the torch 10~ 15° toward the welding

direction, and afterward, you can weld by

"forward method", or "Backward method"

In general, "Forward method" is used considering

with the friction of arc and protection of welded

surface by gas.

2) Welding torch

If the welding torch is bent excessively, smooth wire feeding is

not available, and welding condition is damaged due to

reduced current. Please do not bend cable forcefully.

3) Standard use rate

Use rate 350A 500A 650A

60% 350A

70% A 500A

80% A A 650A

90% A A A

100% 200A 350 600A

5. Safety instruction

5. Safety instruction5. Safety instruction

5. Safety instruction

1) Power source device : Install one on/ off switch for one welder.

2) Terminal connection : Fasten the connection part for smooth

current carrying in welding. Loose fastening may cause cable

damage or wasting power.

3) Ground : Apply class 3 grounding

4) Surrounding environment : Please avoid the location where

moisture and dust is too much, and surrounding temperature is

too high. Select place where air is ventilated well. Especially,

ventilation relates to the use rate.

6. Maintenance and inspection

6. Maintenance and inspection6. Maintenance and inspection

6. Maintenance and inspection

Input power switch must be OFF when internal and external

terminal are checked. The condenser of welder internal circuit

is charged, so please wait 5 minutes after completing welding

work, and afterward open the case and check.

6- 1. Check items by time

6- 1. Check items by time6- 1. Check items by time

6- 1. Check items by time

Before

welding

1) Does the switch work well ?

2) Does the cooling fan works well according to the On

and Off mode, and is the air well ventilated to

forward?

3) Is there any abnormal vibration, noise or smell?

4) Any thing wrong in weld cable and connecting area?

5) Is there any defective insulation on cable?

3 6 month~

1) Remove dust : Remove dusts by blowing out dry

compressed air. Especially, transformer, reactor and

semiconductors shall be cleaned carefully.

2) Check of electrical contact area : Fasten bolts tightly

and remove foreign material such as rust with file or

sand paper so that sufficient contact is available

between metals.

3) Check if ground is done well.

Annual total

maintenance

1) Based on maintenance schedule, replace expendable

supplies, repair case and reinforce worn cables.

2) Insulation resistance shall be 1 mega ohm or above,

or maintenance and repair are required.

7. Trouble shootings

7. Trouble shootings7. Trouble shootings

7. Trouble shootings

Step Phenomenon Reason Remedy

1

Power lamp is not

turned on when power

switch is ON.

Poor lamp Replace lamp

Poor contact of the 1st input part Contact test

Poor fuse Replace fuse

Poor NFB Replace NFB

2

Only FAN works. Poor torch switch Replace torch switch

Power lamp is on, but

fan does not work. Poor fan motor Replace fan motor

3 Gas doesn' t come out.

No gas or no connection Check and replace

Poor solenoid valve Replace valve

Defect in control PCB Request A/ S

Poor torch switch Replace torch switch

4Gas comes out

continuously.

Gas comes out even if power is off. Remove foreign

material from valve

Poor solenoid valve Replace valve

Defect in control PCB Request A/ S

Poor torch switch Replace torch switch

5

Weld wire is not fed

even though inching

switch is pressed.

Poor motor fuse Replace fuse

Poor motor Replace motor

Poor PCB relay Replace relay

Wire is not fed when

torch switch is ON.

Poor torch switch Replace torch switch

Poor PCB Request A/ S

6Voltage and current are

not adjustable.

Poor remote contact Check and replace

Poor control volume Replace

Poor PCB Request A/ S

7

Under no- load

condition, voltage meter

does not work and no

ARC.

Poor torch switch Replace torch switch

Poor PCB Request A/ S

Under no- load

condition, voltage meter

works but no arc.

Broken torch cable Replace torch cable

Poor contact of earth able Check

8Crater is not

controllable.

Poor control volume Replace

Poor PCB Request A/ S

8. Weld condition

8. Weld condition8. Weld condition

8. Weld condition

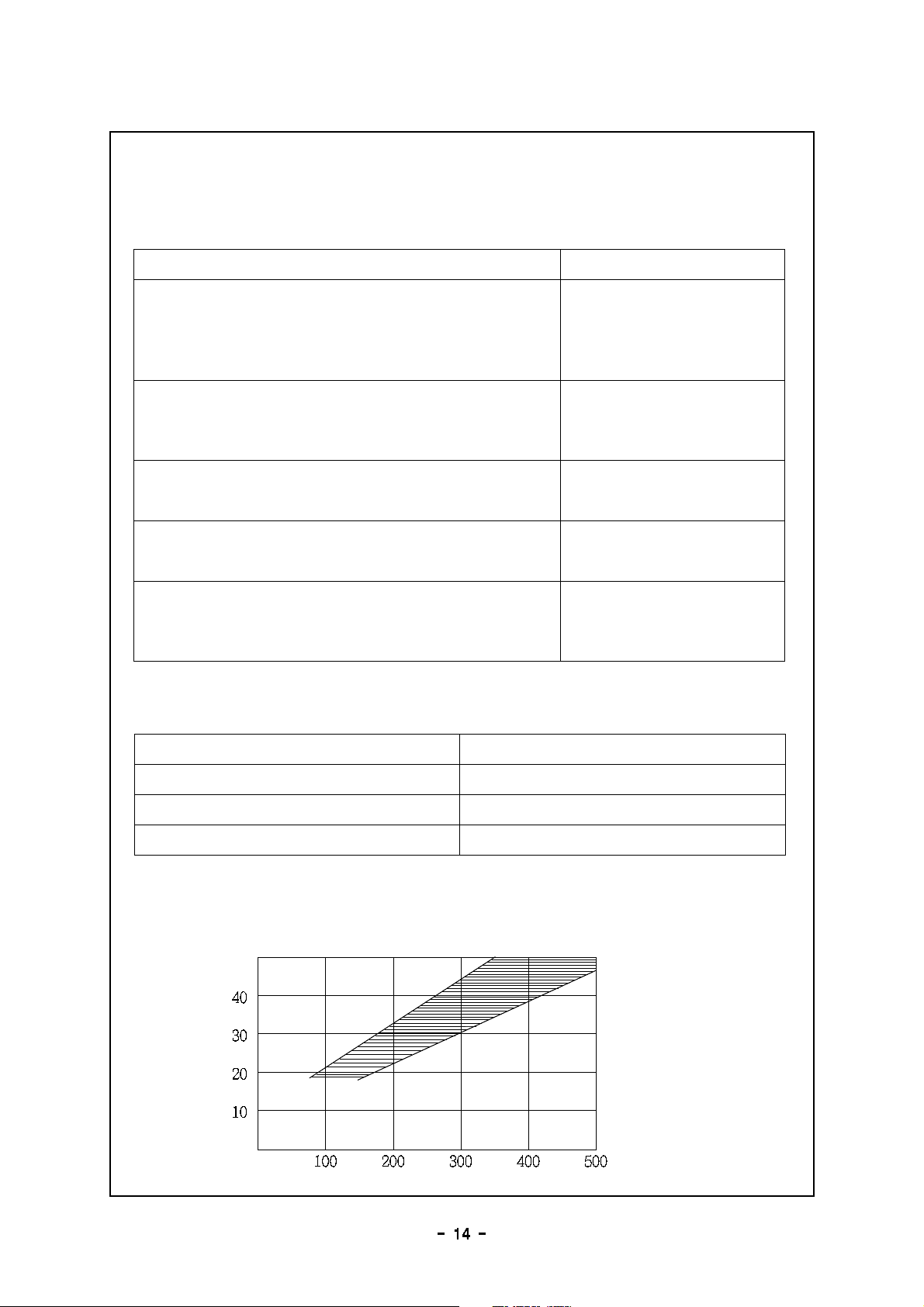

8- 1. In case of improper welding conditions

8- 1. In case of improper welding conditions8- 1. In case of improper welding conditions

8- 1. In case of improper welding conditions

8- 2. Clearance between base metal and tip

8- 2. Clearance between base metal and tip8- 2. Clearance between base metal and tip

8- 2. Clearance between base metal and tip

8- 3. Relation between weld current and voltage

8- 3. Relation between weld current and voltage8- 3. Relation between weld current and voltage

8- 3. Relation between weld current and voltage

Reason Remedy

Arc length is growing

Particle of spatter becomes bigger

Bead width is widening

The length and height of weld penetration become

smaller.

Arc voltage is too high

Wire sticks to the base metal and too many spatters.

Bead width becomes narrow.

The depth and height of weld penetration becomes

bigger.

Arc voltage is too low

Particle of spatter becomes smaller

Bead width is widening

The depth of weld penetration becomes bigger.

Welding current is too high

Bead width becomes narrow.

The length and height of weld penetration become

smaller.

Welding speed is fast.

Particle of spatter becomes smaller

the number of spatter decreases.

The depth and height of weld penetration becomes

bigger.

Current density of wire is

high.

Wire diameter (mm) Clearance (mm)

0.9 1.0~10 15~

1.2 15 20~

1.6 25 30~

8- 4. Reasons and remedy for defects of CO

8- 4. Reasons and remedy for defects of CO8- 4. Reasons and remedy for defects of CO

8- 4. Reasons and remedy for defects of CO

2

22

2

welding

weldingwelding

welding

Type

TypeType

Type Main reason

Main reasonMain reason

Main reason Remedy

RemedyRemedy

Remedy

1. Blow holes

1. Blow holes1. Blow holes

1. Blow holes

1) No feed gas comes out

2) Air mixed in feed gas

3) Insufficient coating effect due

to strong wind

4) Carbon dioxide soaked in

5) Foreign material in welding part

6) Nozzle diameter is too small

7) Arc is too long

1) Check the gas cylinder, valve and pressure

regulator

2) Check the connection part of gas tube

3) Make measure for wind in wind speed

2m/ sor more

Remove spatter from the nozzle

4) Use gas of welding purpose

5) Clean the welding area

Remove feed oil from roller and wire

6) Select proper nozzle diameter

7) Lower voltage

2. Under cut

2. Under cut2. Under cut

2. Under cut

1) Wrong grounding location

2) Welding speed is too fast

3) Arc length is long

4) Welding current is too much

1) Ground onto the first location

2) Slower the welding speed

3) Keep arc length short

4) Select proper welding current

3. Overlap

3. Overlap3. Overlap

3. Overlap

1) Too low arc voltage comparing

to welding current

2) Welding speed is low

1) Raise arc voltage

2) Speed up the welding speed

4. Curve bead

4. Curve bead4. Curve bead

4. Curve bead

1) Wire pressurizing lever does not

work

2) Distance between tip and the

base metal is too far.

3) Tip mounting is not proper

4) Wire bent

5) Tip is worn out

1) Adjust control screw of pressurizing lever

2) More than 10~ 15 times of wire diameter

3) Adjust mounting angle in order to go into

the wire guide directly

4) Straighten wire

5) Replace contact tip

5. Crack

5. Crack5. Crack

5. Crack 1) Improper welding conditions

(high current, high speed)

2) Wire approaching angle is too

small

3) Too much containing of carbon

and other metals in the base

metal

4) Too much moisture in gas

5) Quick electrical break of arc in

crater

1) Set proper condition

(Raise voltage, slow speed)

2) Increase wire approaching angle

3) Preheating and after- heating treatment

4) Use gas of welding purpose

5) Treat with crater

(add up enough deposition metal)

Blow holes

Blow holesBlow holes

Blow holes

Overlap

OverlapOverlap

Overlap

Crack

CrackCrack

Crack

Under cut

Under cutUnder cut

Under cut

8- 5. CO

8- 5. CO8- 5. CO

8- 5. CO

2

22

2

(semi)auto weld condition

(semi)auto weld condition(semi)auto weld condition

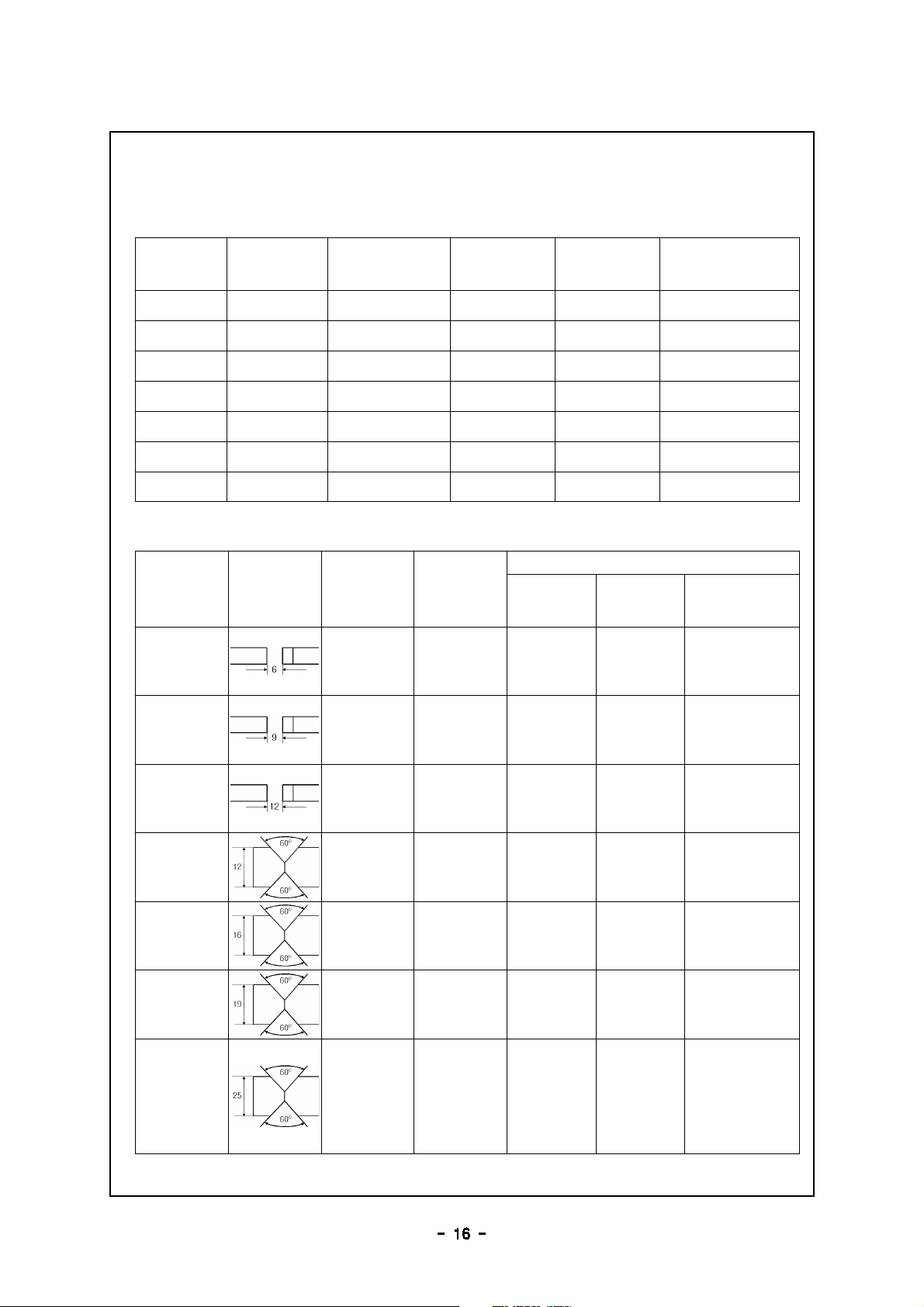

(semi)auto weld condition

1) 1form butt weld

short ARC weld①

Hi- Current②weld

Thick

(mm) gap (mm) Wire dia.

(mm) CT (A) Volt (V) weld speed

(cm/ min.)

1.6 0 0.8 1.0~90 18 45

2.0 0.5 0.8 1.0~100 18 50

2.3 1.0 0.8 1.2~120 19 55

3.2 1.2 0.8 1.2~140 19 50

4.5 1.5 1.2 160 23 50

6.0 1.5 1.2 260 26 50

8.0 1.5 1.2 320 32 50

thickness

(mm) improved pieces Wire dia.

(mm)

weld condition

CT (A) Volt (V) SP(cm/ min)

6 2 1.2

1.2

190

210

19

20 25

9 2 1.6 340

360

33.5

34 50

12 2 1.6 430

450

36

37 50

12 2 1.2 310

330

32

33 55

16 2 1.6 410

430

34.5

36 45

19 2 1.6 470

490

37

38 43

25 2 1.6 480

500

38

39 40

2) Horizontal fillet weld

3) vertical down fillet weld

4) Edge weld (Thin steel plate)

5) CO

2

ARC for welding wire (solid wire)

thickness

(mm)

weld width

(mm)

wire dia.

(mm)

weld current

(A)

weld voltage

(V)

weld speed

(cm/ min)

1.6 3.0 0.8 1.0~130 20 50

2.0 3.0 1.0 1.2~130 20 45

2.3 3.0 1.0 1.2~140 20.5 45

3.2 4.0 1.0 1.2~170 21 45

4.5 4.5 1.2 230 23 50

6.0 6.0 1.2 290 28 50

9.0 7.0 1.2 330 33 45

12.0 11.0 1.6 400 38 25

thickness

(mm)

width

(mm)

Wire dia.

(mm)

weld current

(A)

weld voltage

(V)

weld speed

(cm/ min)

1.2 3.0 0.8 1.0~100 19 50

1.6 3.0 0.8 1.2~120 20 50

2.0 3.0 0.8 1.2~130 20 50

2.3 3.5 1.0 1.2~140 20.5 50

3.2 4.0 1.0 1.2~160 21 45

4.5 4.5 1.2 230 23 55

6.0 6.0 1.2 290 28 50

8.0 8.0 1.2 320 32 55

plate thick

(mm)

wire dia.

(mm)

current

(A)

voltage

(V)

speed

(cm/ min)

Tip/ base

M

(mm)

gas

volume

( / min)ℓ

1.6 0.9 65 75~16 17~40~10 10 15~

2.3 0.9 80 100~19 20~40~10 10 15~

3.2 1.2 130 150~20 22~35~10 15~10 15~

4.5 1.2 150 180~21 23~30~10 15~10 15~

type impurities uses wire dia

(mm)

C Si Mn P S

KC- 25 0.10 0.22 0.62 0.015 0.009 mild

steel

hi- tensio

n weld

0.8, 0.9

KC- 26 0.10 0.45 0.98 0.013 0.010 1.0, 1.2

KC- 28 0.11 0.82 1.45 0.014 0.016 1.6

6) Horizontal fillet weld(thin steel plate)

8- 6. MAG (semi)auto weld condition

8- 6. MAG (semi)auto weld condition8- 6. MAG (semi)auto weld condition

8- 6. MAG (semi)auto weld condition

1) Vertical down butt weld

2) Horizontal fillet weld

plate thick

(mm)

wire dia

(mm)

current

(A)

voltage

(V)

speed

분(cm/ )

tip- base

M

(mm)

gas

volume

( / min)ℓ

0.8 0.9 60 70~16 17~40 45~10 10 15~

1.2 0.9 80 90~18 19~40 50~10 10 15~

1.6 0.9 90 110~19 20~45 50~10 10 15~

2.3 0.9 100 130~20 21~45 50~10 10 15~

2.3 1.2 120 150~20 21~45 50~10 10 15~

3.2 1.2 150 180~20 22~45 50~10 15~10 15~

4.5 1.2 200 250~24 26~40 50~10 15~10 15~

thick

(mm) gap (mm) wire dia (mm) current (A) voltage (V) weld speed

(cm/ min)

0.4 0 0.4 20 15 40

0.6 0 0.4 0.6~25 15 30

0.8 0 0.6 0.8~30 40~15 40 55~

1.2 0 0.8 0.9~60 70~15 16~30 50~

1.6 0 0.8 0.9~100 110~16 17~25 60~

3.2 1.0 1.5~0.8 1.2~120 140~16 17~25 30~

4.0 1.5 2.0~1.0 1.2~150 160~17 18~20 30~

thick

(mm) width (mm) wire dia (mm) current (A) voltage (V) weld speed

(cm/ min)

0.6 2.0 0.4 0.6~30 40~14 40 50~

1.0 2.0 2.5~0.6 0.8~40 60~14 15~40

1.6 3.0 0.6 0.8~90 100~15 16~40 55~

2.4 3.5 0.8 1.0~110 120~16 17~35 40~

3.2 4.0 0.8 1.2~135~17 18~35 35~

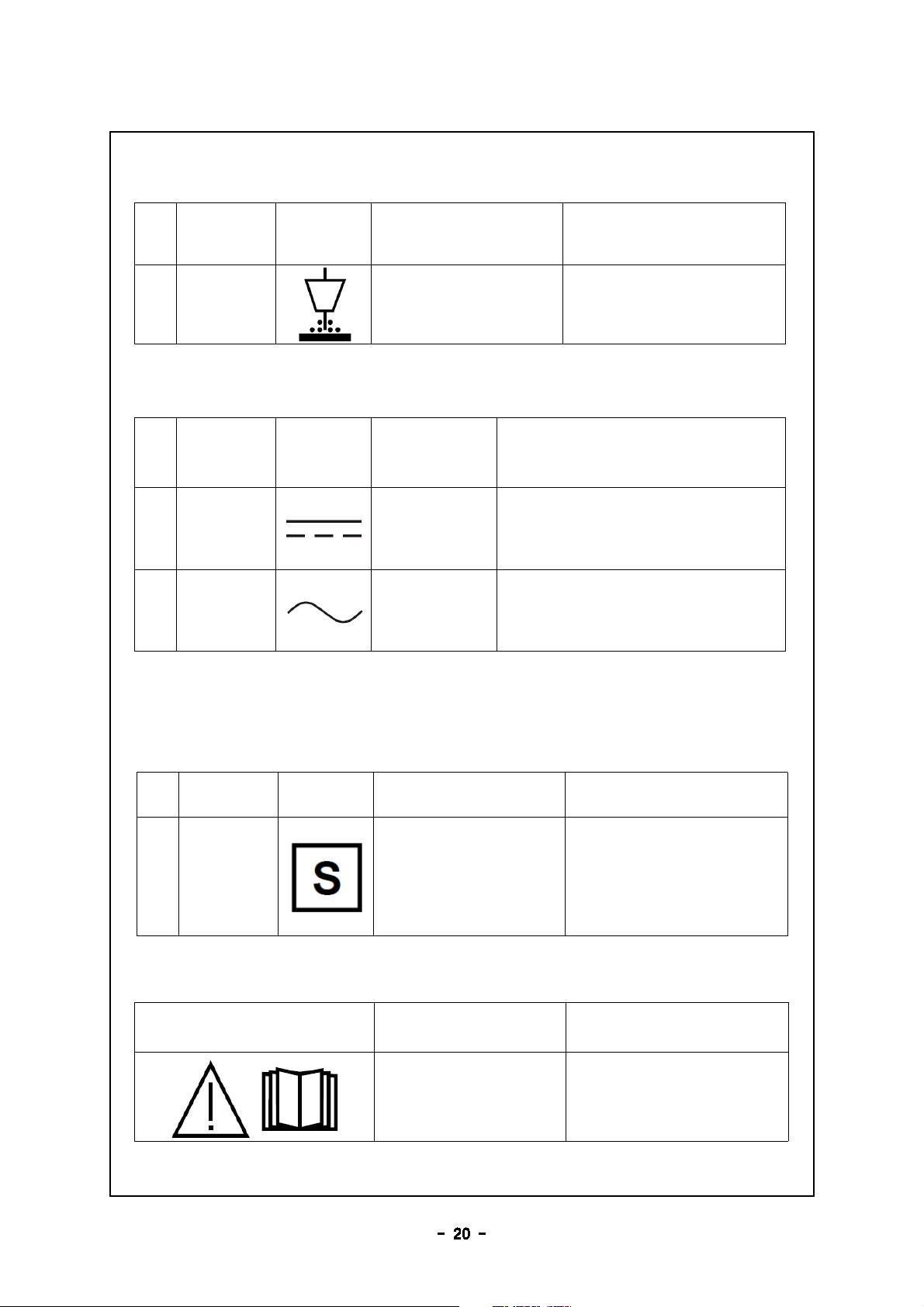

9. Symbols

9. Symbols9. Symbols

9. Symbols

9- 1. Symbols to indicate switch or control position

9- 1. Symbols to indicate switch or control position9- 1. Symbols to indicate switch or control position

9- 1. Symbols to indicate switch or control position

N°

N°N°

N° SOURCE

SOURCESOURCE

SOURCE SYMBOL

SYMBOLSYMBOL

SYMBOL

FUNCTION,

FUNCTION,FUNCTION,

FUNCTION,

KEYWORD OR

KEYWORD ORKEYWORD OR

KEYWORD OR

PHRASE

PHRASEPHRASE

PHRASE

APPLICATION

APPLICATIONAPPLICATION

APPLICATION

1. IEC

604175007 On (power)

To indicate connection to the

mains, at least for mains switches

or their positions, and all those

cases where safety is involved.

2. IEC

604175008 Off (power)

To indicate disconnection from the

mains, at least for mains switches

or their positions, and all those

cases where safety is involved.

9- 2. Symbols to indicate electrical connection

9- 2. Symbols to indicate electrical connection9- 2. Symbols to indicate electrical connection

9- 2. Symbols to indicate electrical connection

N°

N°N°

N° SOURCE

SOURCESOURCE

SOURCE SYMBOL

SYMBOLSYMBOL

SYMBOL FUNCTION, KEYWORD

FUNCTION, KEYWORDFUNCTION, KEYWORD

FUNCTION, KEYWORD

OR PHRASE

OR PHRASEOR PHRASE

OR PHRASE APPLICATION

APPLICATIONAPPLICATION

APPLICATION

1. IEC

604175005 Plus; positive polarity To signify positive polarity

2. IEC

604175006

Minus; negative

polarity To signify negative polarity

3. IEC

604175019

Protective earth

(ground)

To signify the equipment

connection point for the

protective earth (ground)

4. IEC

604175939

Power supply type of

electric device

On device or equipment

e.g. on arc welding

equipment

9- 3. Symbols to indicate type of torch

9- 3. Symbols to indicate type of torch9- 3. Symbols to indicate type of torch

9- 3. Symbols to indicate type of torch

N°

N°N°

N° SOURCE

SOURCESOURCE

SOURCE SYMBOL

SYMBOLSYMBOL

SYMBOL FUNCTION, KEYWORD

FUNCTION, KEYWORDFUNCTION, KEYWORD

FUNCTION, KEYWORD

OR PHRASE

OR PHRASEOR PHRASE

OR PHRASE APPLICATION

APPLICATIONAPPLICATION

APPLICATION

1. MIG/ MAG Torch To signify a MIG/ MAG

torch

9- 4. Symbols to indicate processes

9- 4. Symbols to indicate processes9- 4. Symbols to indicate processes

9- 4. Symbols to indicate processes

N°

N°N°

N° SOURCE

SOURCESOURCE

SOURCE SYMBOL

SYMBOLSYMBOL

SYMBOL FUNCTION, KEYWORD

FUNCTION, KEYWORDFUNCTION, KEYWORD

FUNCTION, KEYWORD

OR PHRASE

OR PHRASEOR PHRASE

OR PHRASE APPLICATION

APPLICATIONAPPLICATION

APPLICATION

1. Submerged arc

welding

To signify submerged arc

welding

9- 5. Symbols to describe the type of power source

9- 5. Symbols to describe the type of power source9- 5. Symbols to describe the type of power source

9- 5. Symbols to describe the type of power source

N°

N°N°

N° SOURCE

SOURCESOURCE

SOURCE SYMBOL

SYMBOLSYMBOL

SYMBOL

FUNCTION,

FUNCTION,FUNCTION,

FUNCTION,

KEYWORD OR

KEYWORD ORKEYWORD OR

KEYWORD OR

PHRASE

PHRASEPHRASE

PHRASE

APPLICATION

APPLICATIONAPPLICATION

APPLICATION

1. IEC

604175031

Direct current

(DC)

To signify that power source

delivers direct current

2. IEC

604175032

Alternating

current (AC)

To signify that power source

delivers alternating current

9- 6. Symbols to indicate protective component and class

9- 6. Symbols to indicate protective component and class9- 6. Symbols to indicate protective component and class

9- 6. Symbols to indicate protective component and class

of protection

of protectionof protection

of protection

N°

N°N°

N° SOURCE

SOURCESOURCE

SOURCE SYMBOL

SYMBOLSYMBOL

SYMBOL FUNCTION, KEYWORD

FUNCTION, KEYWORDFUNCTION, KEYWORD

FUNCTION, KEYWORD

OR PHRASE

OR PHRASEOR PHRASE

OR PHRASE APPLICATION

APPLICATIONAPPLICATION

APPLICATION

1. IEC

60974- 1

Suitable for welding in

an environment with

increased hazard of

electric shock

To signify a welding power

source suitable for welding

in an environment with

increased hazard of

electric shock

9- 7. Examples of combinations of symbols

9- 7. Examples of combinations of symbols9- 7. Examples of combinations of symbols

9- 7. Examples of combinations of symbols

SYMBOL

SYMBOLSYMBOL

SYMBOL FUNCTION, KEYWORD

FUNCTION, KEYWORDFUNCTION, KEYWORD

FUNCTION, KEYWORD

OR PHRASE

OR PHRASEOR PHRASE

OR PHRASE APPLICATION

APPLICATIONAPPLICATION

APPLICATION

Caution! Read the

instruction manual

To indicate a hazard and

signify that the instruction

manual should be read

This manual suits for next models

2

Table of contents

Other Autowel Welding System manuals

Popular Welding System manuals by other brands

ESAB

ESAB Caddy Mig C160i instruction manual

Bug-O Systems

Bug-O Systems STW-3000 Instructions and parts manual

Chicago Electric

Chicago Electric 68888 quick start guide

Migatronic

Migatronic PILOT 1500 HP instruction manual

Magneti Marelli

Magneti Marelli Clima-Tech Plus user manual

Miller

Miller Maxstar 300 owner's manual