Normal temperature range

Most standard transducers will operate from 0∞F to 180∞F.

High temperature measurements

Special transducers and couplants are available for temperatures above 180∞F up to 650

with intermittent contact. It is necessary to cool the transducer, by submerging the trans-

ducer in water between readings, when measuring high temperatures.

Modes and temperature errors

In addition to errors caused by velocity changing with temperature, some modes (measu

ment techniques) are affected more than others. For example, dual element mode has lar

errors due to changes in temperature of the delay line. However, in multi-echo technique

auto temperature helps to minimize these errors.

4.6 Measurement Modes

In this section we will discuss the different measurements modes the TI-CMX is capable

operating in, the transducers required, and the reasons for using specific modes:

Pulse-Echo Mode (Flaw & Pit detection) – Coating Off (P-E)

Pulse-echo mode measures from the initial pulse (sometimes referred to as an artificial

zero) to the first echo (reflection). In this mode, either an automatic or manual zero can

performed depending on the zero probe function setting. If the manual mode has been

selected, the transducer is placed on a reference disk, located on top of the TI-CMX, and

key is pressed to establish a zero point for the particular transducer. If the Auto Zero fea

ture is enabled, a simple key press will perform an electronic zero to establish the same

zero point.

In this mode errors result from surface coatings and temperature variations.

Since pulse-echo only requires one reflection, it is the most sensitive mode for measurin

weak reflections (flaws) typically found when measuring heavily corroded metals.

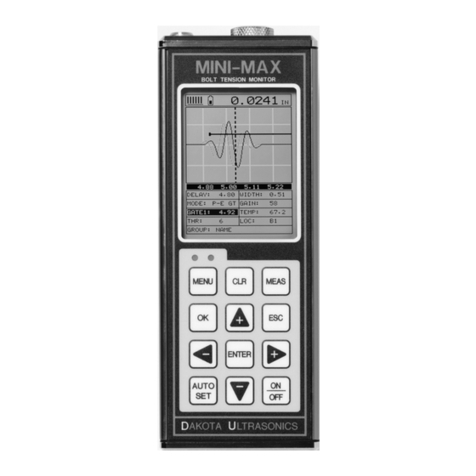

V-Path Correction

Dual element delay line transducers have two piezoelectric elements

mounted at an angle on one end of the delay line. One element is used

for transmitting sound, while the other element only receives sound.

The two elements and their delay lines are packaged in a single housing

but acoustically isolated from each other with a sound barrier. This

allows the transducer the ability to achieve very high sensitivity for

detecting small defects. Also, the surface of the test material does not

have to be as flat in order to obtain good measurements.

Dual element transducers are normally used in pulse-echo mode for

finding defects, and in echo-echo mode for through coating measurements.

Dual element delay line transducers are usable over a range of 0.025 inches to 20 inches

depending on the material, frequency, and diameter.

A limitation of dual element delay-line transducers is the V shaped sound path. Because

sound travels from one element to another, the time versus thickness relationship is non-

linear. Therefore, a correction table in the instruments software is used to compensate fo

this error.

-19-

Dual Element

Transducer

showing

V-path of sign

9.0 PULSE-ECHO COATING & COATING TECHNIQUES

9.1 Introduction to Pulse-Echo Coating Measurement (PECT)

In the previous sections we’ve discussed the need for detecting pits and flaws (pulse-echo)

in materials, along with the requirement to measure through and eliminate errors caused by

coated materials (echo-echo). Until now, both modes were needed in order accomplish both

tasks. Pulse-echo mode was used for flaw detection, and echo-echo mode was used to elim-

inate the coating thickness and provide a nominal material thickness only. With this in

mind, it often became cumbersome toggling between both modes respectively.

In a majority of applications involving coated materials, inspectors are often interested in

monitoring both the thickness of the material, as well as the thickness of the coating.

Therefore, the TI-CMX has been designed to provide the user with the ability to measure

the material and coating thicknesses simultaneously, while maintaining the ability to detect

flaws and pits all in a single mode called Pulse-Echo Coating (PECT). This is accom-

plished by using a custom hybrid combination mode utilizing properties from the basic

modes along with a group of special techniques and theoretical wave phenomena’s.

The TI-CMX is preset to a coating velocity of 0.0850 in/µsec (2159 m/sec) from the facto-

ry. This velocity is a very close approximation of the common coating velocities found in

the field. However, the TI-CMX also has a built-in one and two point calibration options to

calibrate to coating samples with a known thicknesses.

There are two coating modes built into the TI-CMX:

1. Pulse-Echo Coating (PECT) – used during inspections where both the material

and coating thicknesses are required.

2. Coating Only (CT) – used during inspections where only the coating thickness is

required.

9.2 Enabling Pulse-Echo Coating Mode (PECT) & Coating (CT)

When the TI-CMX is initially powered up, the gauge will automatically check to see if the

transducer plugged into the gauge can be recognized. All Dakota Ultrasonics coating

enabled transducers are equipped with the auto recognition feature. If the TI-CMX doesn’t

recognize that a special coating enabled transducer is plugged into the gauge, the coating

feature will be disabled entirely. There are a number of coating enabled transducers avail-

able from Dakota. Please contact us with your application requirements for additional

information on frequencies and diameters currently offered.

The coating modes can be enabled in three different ways:

1. On Power up and probe recognition.

2. By pressing MULTI MODE keypad.

3. From the tabbed menus under TUNE, MEASURE MODE.

The steps that follow will demonstrate all three methods in the order listed above.

-38-