3

The UJK professional router table is a solid, dependable

unit that will give many years of useful service.The benefits of

using cast iron for the manufacture of machine tables are well

known especially where vibration damping and stability are

paramount.The quality of the surface grinding on this table is

superb, offering little resistance when passing stock across the

table during use. If you have room in your workshop for a full

sized router table, you will wonder how you managed without

one.There are many complex routing operations that can only

be carried out using a table set-up.The aperture in the table

top is designed to accept our router elevator and when fitted

with this unit you will have yourself an excellent versatile set-

up.Top measures 812 x 610mm.

Introduction

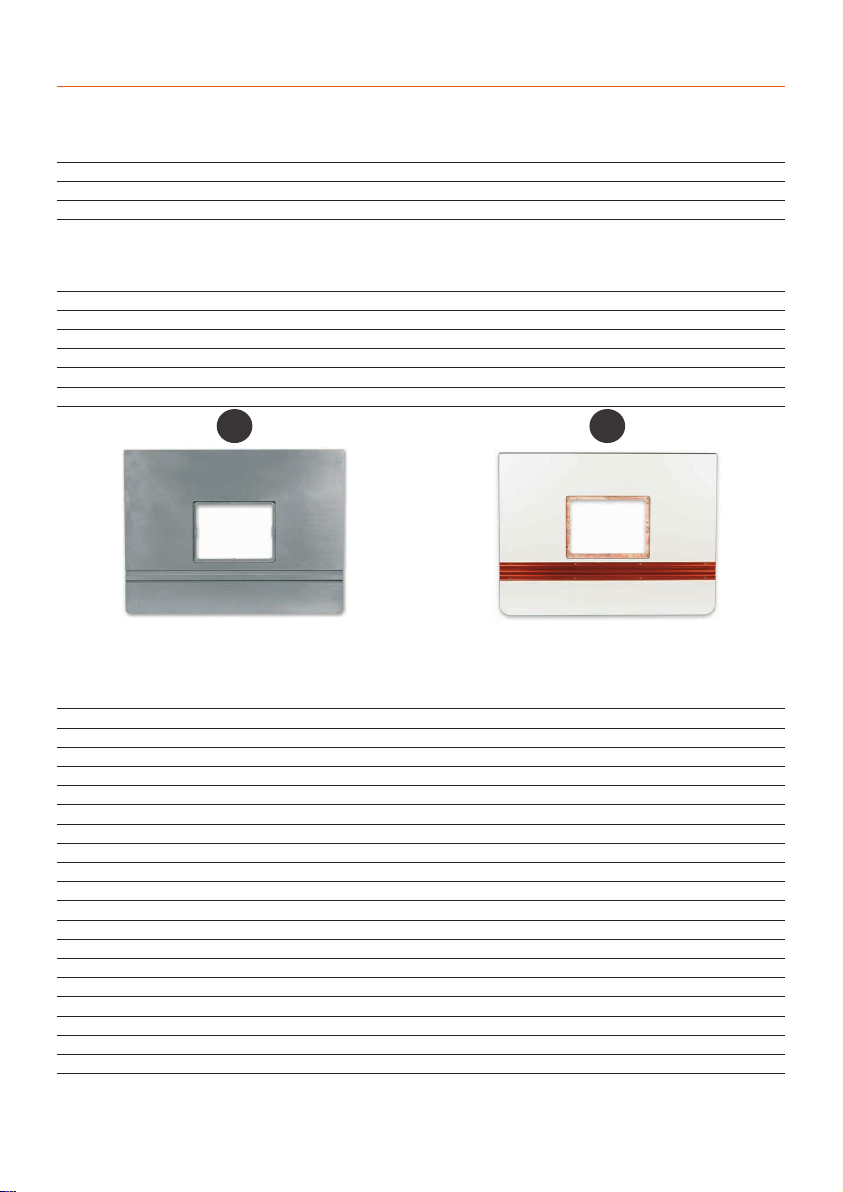

The Professional Laminated router table is high grade birch

ply with a hard wearing, low friction, phenolic laminated sur-

face.The ply core ensures the top will remain flat throughout its

working life, while the laminated top ensures workpieces glide

smoothly. An extruded aluminium track inset into the tabletop

includes a standard 19mm track for the use of a mitre fence and

a T-track slot for other jigs and accessories.The 230 x 306mm

central aperture will accept any of the UJK router table inserts

as well as the UJK router elevator.The top measures 800 x

600mm and is pre-drilled to fit the UJK Professional router table

leg stand, fence assembly or optional dust collection box

.

The fence is a superb quality single aluminium section

supplied with a transparent dust port for efficient extraction

from above the table. Provision is made for the fitting of guards

and accessories with a T-slot at both the top and front of the

fence.An adjustable transparent guard is included for your

safety. Adjustable scales are provided for attachment at either

side of the table and the fence is attached to these and locks

into place at the required position.A scale is also provided for

the top of the fence with the zero position at the centre.

Adjustable in-feed and out-feed fences attach to either side of

the aluminium section and the central aperture can be opened

and closed according to the diameter of the cutter in use.

Fence measures 904 x 90mm high.

The leg stand is of sturdy construction with a foot operated

retractable castor for excellent mobility around the workshop.

A neat rack is provided for keeping your most popular router

cutters to hand and provision is made for storage of the

supplied mitre fence assembly. Stand height including cast

iron top 930mm.