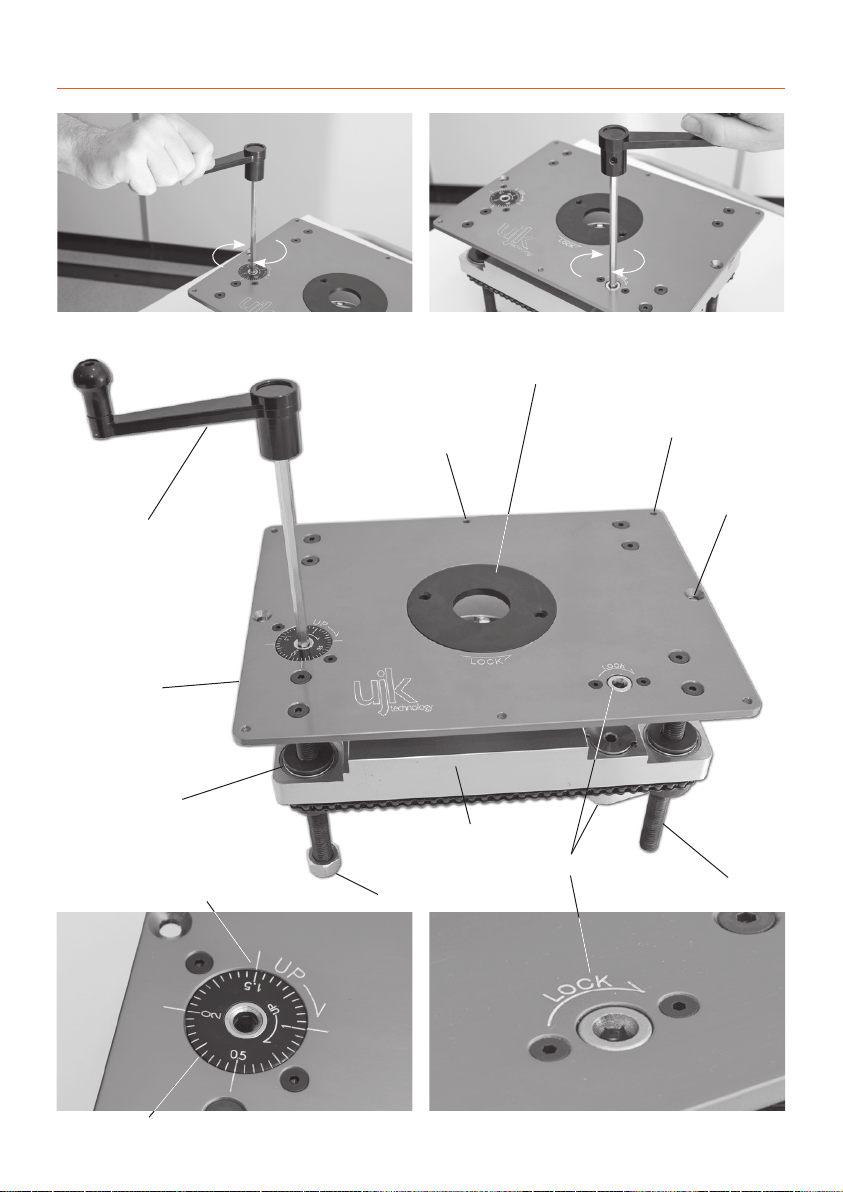

Fitting the Router and the Cutters

10

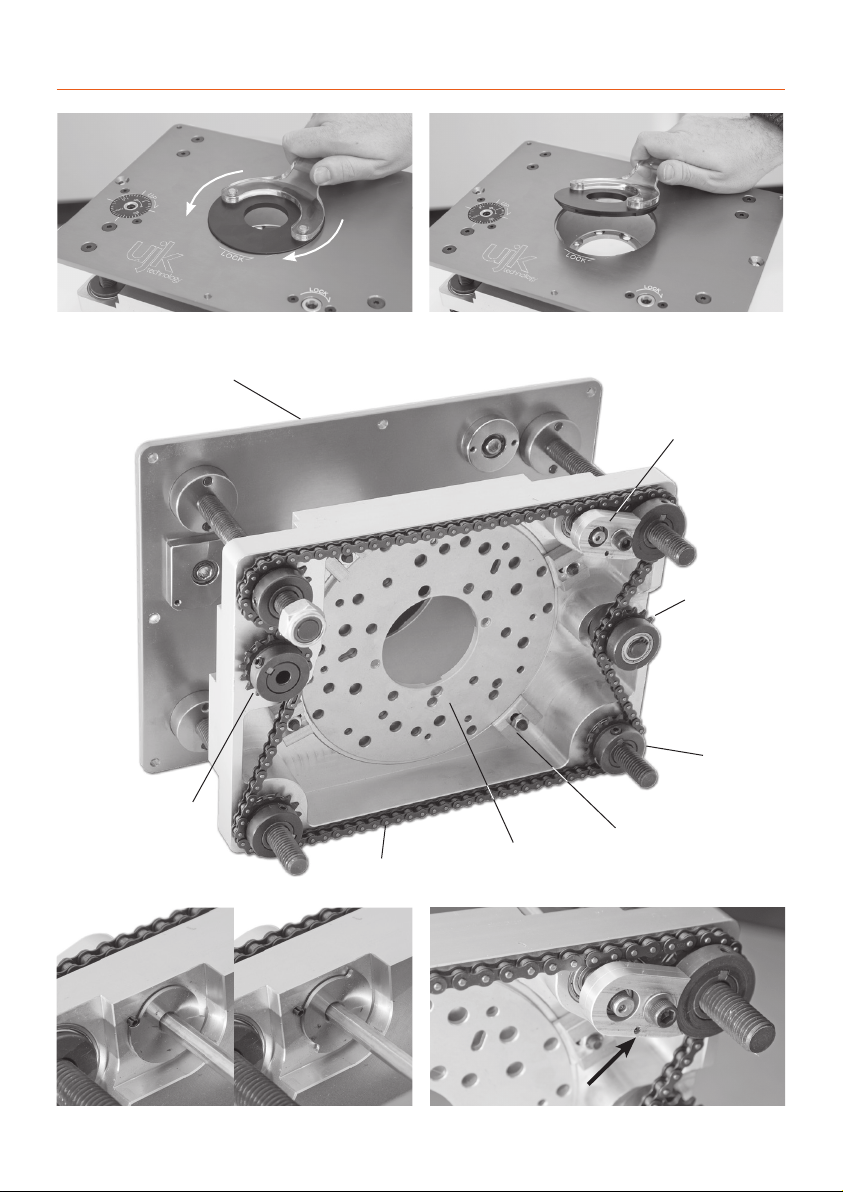

Fig 1

Fig 2

Fig 3

IN ORDER TO FIT SOME OF THE ROUTERS TO THE ELEVATOR AND ACHIEVE

UNRESTRICTED MOVEMENT, IT MAY BE NECESSARY TO REMOVE THE HANDLES;

PLUNGE THE ROUTER BODY TO DEPTH, ETC., ETC.

Lower the table to almost its fullest extent. Using the

Allen key provided loosen the bolts and therefore the lugs

holding the universal mounting plate (UMP) in position

and remove. (See Figs 1 and 2).Remove the sole plate from

your router, see illustrations 1 to 2 and secure your router

to the UMP via the appropriate holes, see pages 8-9. Insert

the requisite tool into the router and tighten securely.

Adjust the‘depth’of the router to give the slightly more

than the required exposure of the tool (to allow for

adjustment) and lock the body. Remember that you will

loose 14.5mm of the set ‘height’ of the cutter between the

lower face of the universal mounting plate and the upper

surface of the machine table. Alternatively, current practise

would indicate that the router is plunged to maximum

depth and all height adjustment is done using the elevator.

Refit the mounting plate to the rise and fall platform.(See

Fig 3)

Re-fasten the holding lugs. If the router tool diameter is

greater than 75mm, the router/mounting plate combina-

tion must be refitted to the rise and fall platform first, and

then the tooling mounted into the router. (Hint.You will

find this easier with the rise and fall platform at its highest

position and the table insert removed).

Mounting plate holding down lug

Router/mounting plate mounted in the router elevator

Please note: Removing the router handles will

prevent them from interfering with the chain.

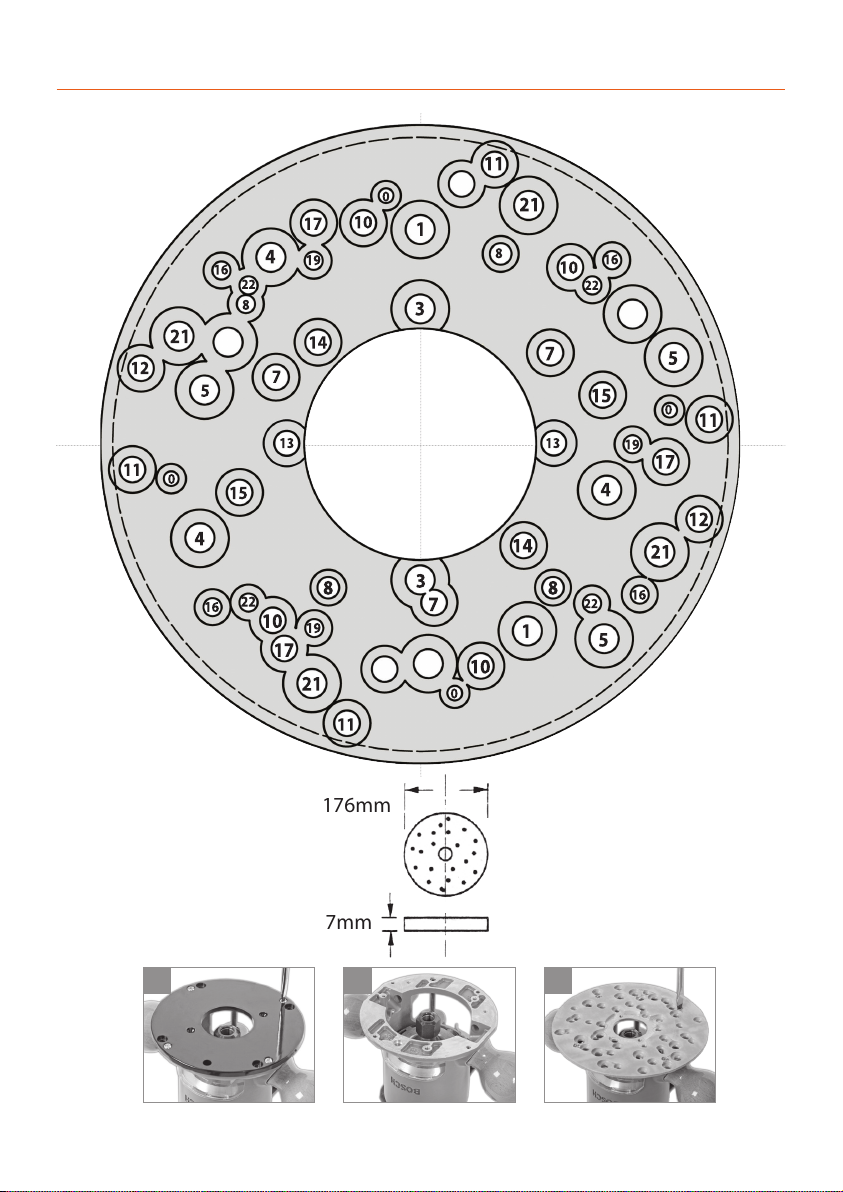

1

2

UMP (universal mounting plate)

Sole plate