ii

Safety Precautions

Safety precautions are intended to ensure the safe and correct use of this product, to prevent injury to the operator

and others, and to prevent damage to property. Be sure to observe these safety precautions. Please make sure you un-

derstand the safety guidelines before reading the rest of this manual.

The use of this product in a manner not specified by the manufacturer will impair its built-in safety features.

WARNING

For explosion-proof instrumentation, install and wire this unit in accordance with the National

Institute of Industrial Safety's "User's Guidelines for Electrical Installations for Explosive Gas

Atmospheres in General Industry" (Tokyo, 1994 [in Japanese]).

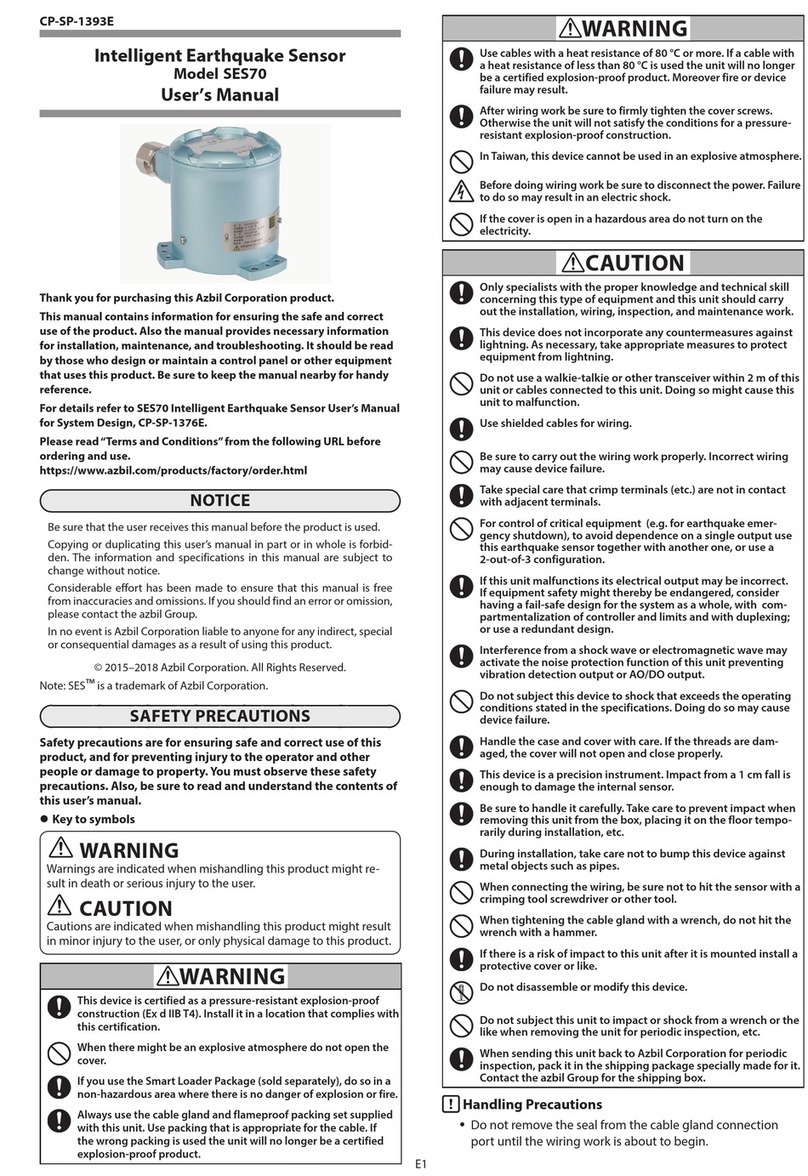

This device is certified as a pressure-resistant explosion-proof construction (Ex d IIC T4). Install

it in a location that complies with this certification.

In Taiwan, this device cannot be used in an explosive atmosphere.

If there might be an explosive atmosphere, do not open the cover. Doing so may cause

explosion or fire.

If you use the Smart Loader Package (sold separately), do so in a non-hazardous area where

there is no danger of explosion or fire.

Always use the cable gland and flameproof packing set supplied with this unit. In addition,

use packing that is appropriate for the cable. If the wrong packing is used, the unit will no

longer be a certified explosion-proof product.

Use cables with a heat resistance to temperatures of 80 °C or more. If a cable with a heat

resistance of less than 80 °C used, the unit will no longer be a certified explosion-proof

product. Moreover, fire or device failure may result.

After wiring work, be sure to firmly tighten the cover screws. Otherwise the unit will not satisfy

the conditions for a pressure-resistant explosion-proof construction.

Before doing wiring work, be sure to disconnect the power. Failure to do so may result in an

electric shock.

If the cover is open in a hazardous area, do not turn on the electricity. Doing so may cause

explosion or fire.

CAUTION

Only specialists with the proper knowledge and technical skill concerning this type of

equipment and this unit should carry out the installation, wiring, inspection, and maintenance

work.

This device does not incorporate any countermeasures against lightning. As necessary, take

appropriate measures to protect equipment from lightning.

Do not use a walkie-talkie or other transceiver within 2 m of this unit or cables connected to

this unit. Doing so may cause this unit to malfunction.

Use shielded cables for wiring.