4 AB-5965

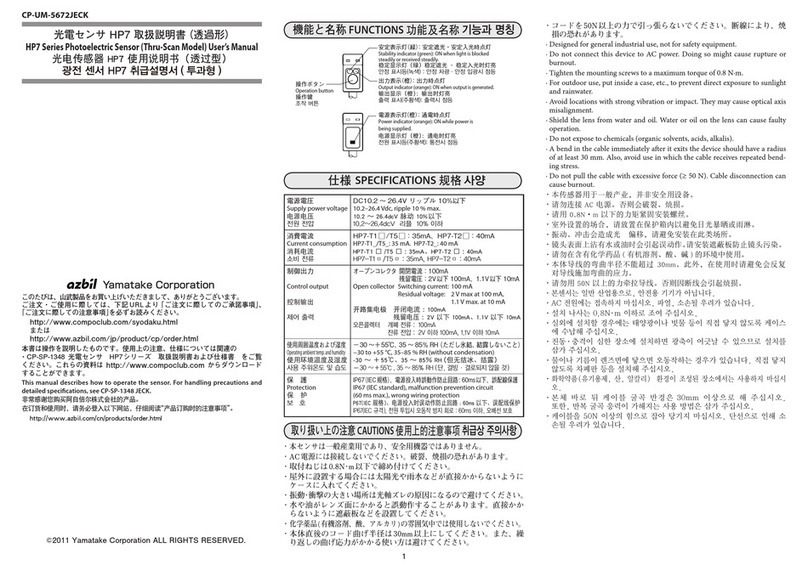

Cautions on wiring

Use shielded multi conductor cable (CVV-S) of 1.25 mm²

for humidity output. IV cable of min. 1.25 mm² may also

be used. Be sure to ground the shielded cable at the

controller side.

Maximum wiring length is 100 m.

Do not connect power supply to temperature output.

Always check the wiring before power is supplied.

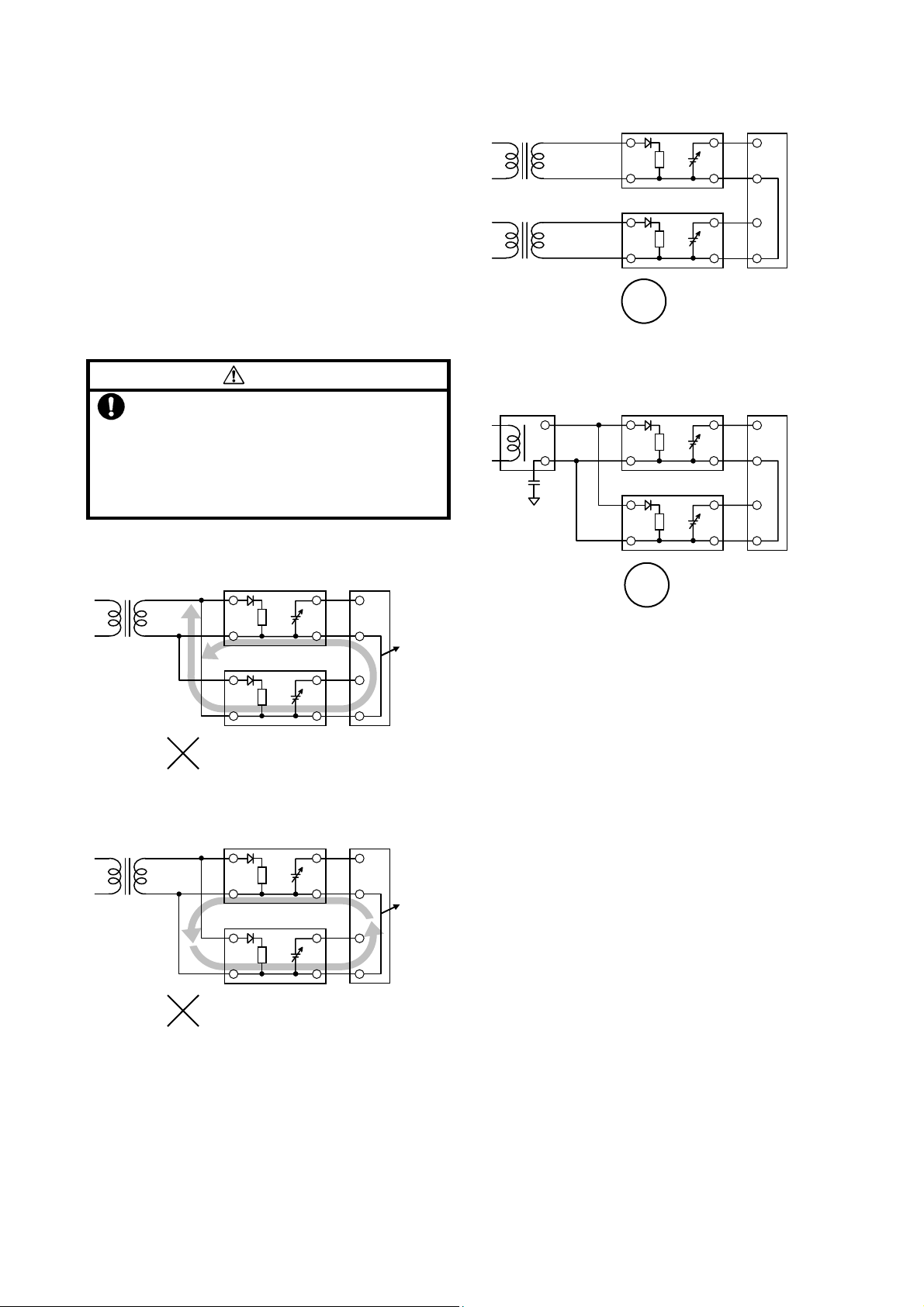

Never share 24V AC transformer with other equipment.

Connect Separate Fransformers

CAUTION

Use insulated transformer to supply 24V AC

power supply voltage.

Never share 24V AC power supply with other

equipment.

If a transformer is shared with other equipment,

loop will be formed at common and the sensor

may be damaged.

•Transformer (24V AC power supply) shared

•Separate transformer (24V AC power supply)

•24V DC power supply shared

Follow the next instructions to prevent an induction cur-

rent flowing from the humidity sensor to the controller

input circuit, or to prevent an influence on the generating

noise due to inadequate time constant of the controller

input.

•Use a controller with a low pass filter with a removal

ratio of 40dB or higher (normal mode).

•Connect an isolator to the controller input circuit if a

removal ratio is unknown.

•If you use a Azbil Corporation cotnroller, no problem

will occur.

Maintenance

Since the temperature/humidity sensor have been in-

spected and adjusted accurately before shipment, they

need no adjustment at the site. However, follow the

maintenance instructions below :

1) Periodical inspection

Determine the periodical inspection intervals according

to the amount of suspended dust and other

contaminants in the environment. Regulary check the

sensor’s accuracy and the condition of its cover.

2) Troubleshooting

If any problem occurs during operation, refer to the

following table for appropriate solutions.

Common loop formed

Not Good

24V

C

+

⊥

+

-

+

-

+~

⊥

~

-

-

Humidity/temperature

senso

Humidity/temperature

senso

Multi-loop

controlle

Common

share

The transmitter will be

shorted if miss-wired.

Not Good

24VAC

Multi-loop

controlle

Common

share

+

⊥

+

-

+

-

+~

⊥

Temperature/humidity

senso

~

-

-

Temperature/humidity

senso

No common loop formed

Good

Common loop formed, however, not

so affected by common mode noise.

Good

24VAC

+

-

+

-

~

⊥

24VAC

~

⊥

+

-

+

-

Multi-loop

controlle

Temperature/humidity sensor

Temperature/humidity sensor

24VDC

⊥

+

-

+

-

~

⊥

~

+

-

+

+

-

-

Multi-loop

controlle

Temperature/humidity sensor

Temperature/humidity sensor