E1

CP-SP-1393E

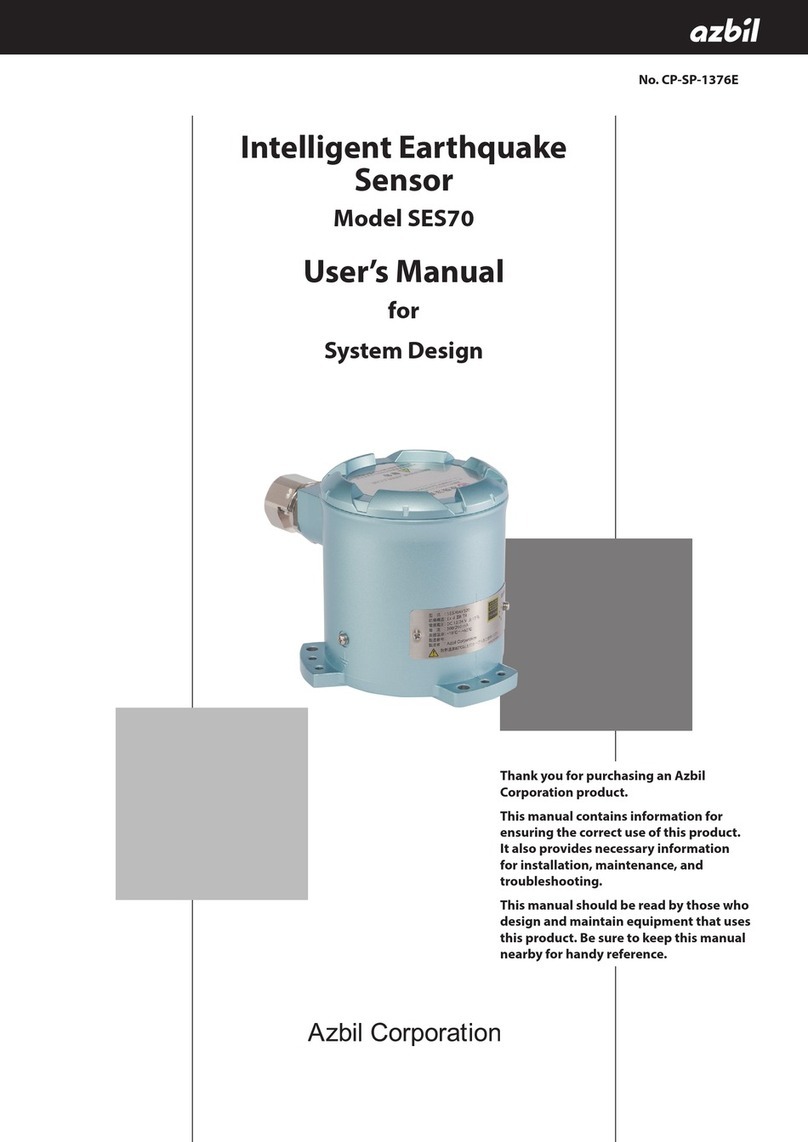

Intelligent Earthquake Sensor

Model SES70

User’s Manual

Thank you for purchasing this Azbil Corporation product.

This manual contains information for ensuring the safe and correct

use of the product. Also the manual provides necessary information

for installation, maintenance, and troubleshooting. It should be read

by those who design or maintain a control panel or other equipment

that uses this product. Be sure to keep the manual nearby for handy

reference.

For details refer to SES70 Intelligent Earthquake Sensor User’s Manual

for System Design, CP-SP-1376E.

Please read “Terms and Conditions”from the following URL before

ordering and use.

https://www.azbil.com/products/factory/order.html

NOTICE

Be sure that the user receives this manual before the product is used.

Copying or duplicating this user’s manual in part or in whole is forbid-

den. The information and specifications in this manual are subject to

change without notice.

Considerable effort has been made to ensure that this manual is free

from inaccuracies and omissions. If you should find an error or omission,

please contact the azbil Group.

In no event is Azbil Corporation liable to anyone for any indirect, special

or consequential damages as a result of using this product.

© 2015–2018 Azbil Corporation. All Rights Reserved.

Note: SES™is a trademark of Azbil Corporation.

SAFETY PRECAUTIONS

Safety precautions are for ensuring safe and correct use of this

product, and for preventing injury to the operator and other

people or damage to property. You must observe these safety

precautions. Also, be sure to read and understand the contents of

this user’s manual.

Key to symbols

WARNING

Warnings are indicated when mishandling this product might re-

sult in death or serious injury to the user.

CAUTION

Cautions are indicated when mishandling this product might result

in minor injury to the user, or only physical damage to this product.

WARNING

This device is certified as a pressure-resistant explosion-proof

construction (Ex d IIB T4). Install it in a location that complies with

this certification.

When there might be an explosive atmosphere do not open the

cover.

If you use the Smart Loader Package (sold separately), do so in a

non-hazardous area where there is no danger of explosion or fire.

Always use the cable gland and flameproof packing set supplied

with this unit. Use packing that is appropriate for the cable. If

the wrong packing is used the unit will no longer be a certified

explosion-proof product.

WARNING

Use cables with a heat resistance of 80°C or more. If a cable with

a heat resistance of less than 80°C is used the unit will no longer

be a certified explosion-proof product. Moreover fire or device

failure may result.

After wiring work be sure to firmly tighten the cover screws.

Otherwise the unit will not satisfy the conditions for a pressure-

resistant explosion-proof construction.

In Taiwan, this device cannot be used in an explosive atmosphere.

Before doing wiring work be sure to disconnect the power. Failure

to do so may result in an electric shock.

If the cover is open in a hazardous area do not turn on the

electricity.

CAUTION

Only specialists with the proper knowledge and technical skill

concerning this type of equipment and this unit should carry

out the installation, wiring, inspection, and maintenance work.

This device does not incorporate any countermeasures against

lightning. As necessary, take appropriate measures to protect

equipment from lightning.

Do not use a walkie-talkie or other transceiver within 2 m of this

unit or cables connected to this unit. Doing so might cause this

unit to malfunction.

Use shielded cables for wiring.

Be sure to carry out the wiring work properly. Incorrect wiring

may cause device failure.

Take special care that crimp terminals (etc.) are not in contact

with adjacent terminals.

For control of critical equipment (e.g. for earthquake emer-

gency shutdown), to avoid dependence on a single output use

this earthquake sensor together with another one, or use a

2-out-of-3 configuration.

If this unit malfunctions its electrical output may be incorrect.

If equipment safety might thereby be endangered, consider

having a fail-safe design for the system as a whole, with com-

partmentalization of controller and limits and with duplexing;

or use a redundant design.

Interference from a shock wave or electromagnetic wave may

activate the noise protection function of this unit preventing

vibration detection output or AO/DO output.

Do not subject this device to shock that exceeds the operating

conditions stated in the specifications. Doing do so may cause

device failure.

Handle the case and cover with care. If the threads are dam-

aged, the cover will not open and close properly.

This device is a precision instrument. Impact from a 1cm fall is

enough to damage the internal sensor.

Be sure to handle it carefully. Take care to prevent impact when

removing this unit from the box, placing it on the floor tempo-

rarily during installation, etc.

During installation, take care not to bump this device against

metal objects such as pipes.

When connecting the wiring, be sure not to hit the sensor with a

crimping tool screwdriver or other tool.

When tightening the cable gland with a wrench, do not hit the

wrench with a hammer.

If there is a risk of impact to this unit after it is mounted install a

protective cover or like.

Do not disassemble or modify this device.

Do not subject this unit to impact or shock from a wrench or the

like when removing the unit for periodic inspection, etc.

When sending this unit back to Azbil Corporation for periodic

inspection, pack it in the shipping package specially made for it.

Contact the azbil Group for the shipping box.

Handling Precautions

• Do not remove the seal from the cable gland connection

port until the wiring work is about to begin.