User Manual

- 3 -

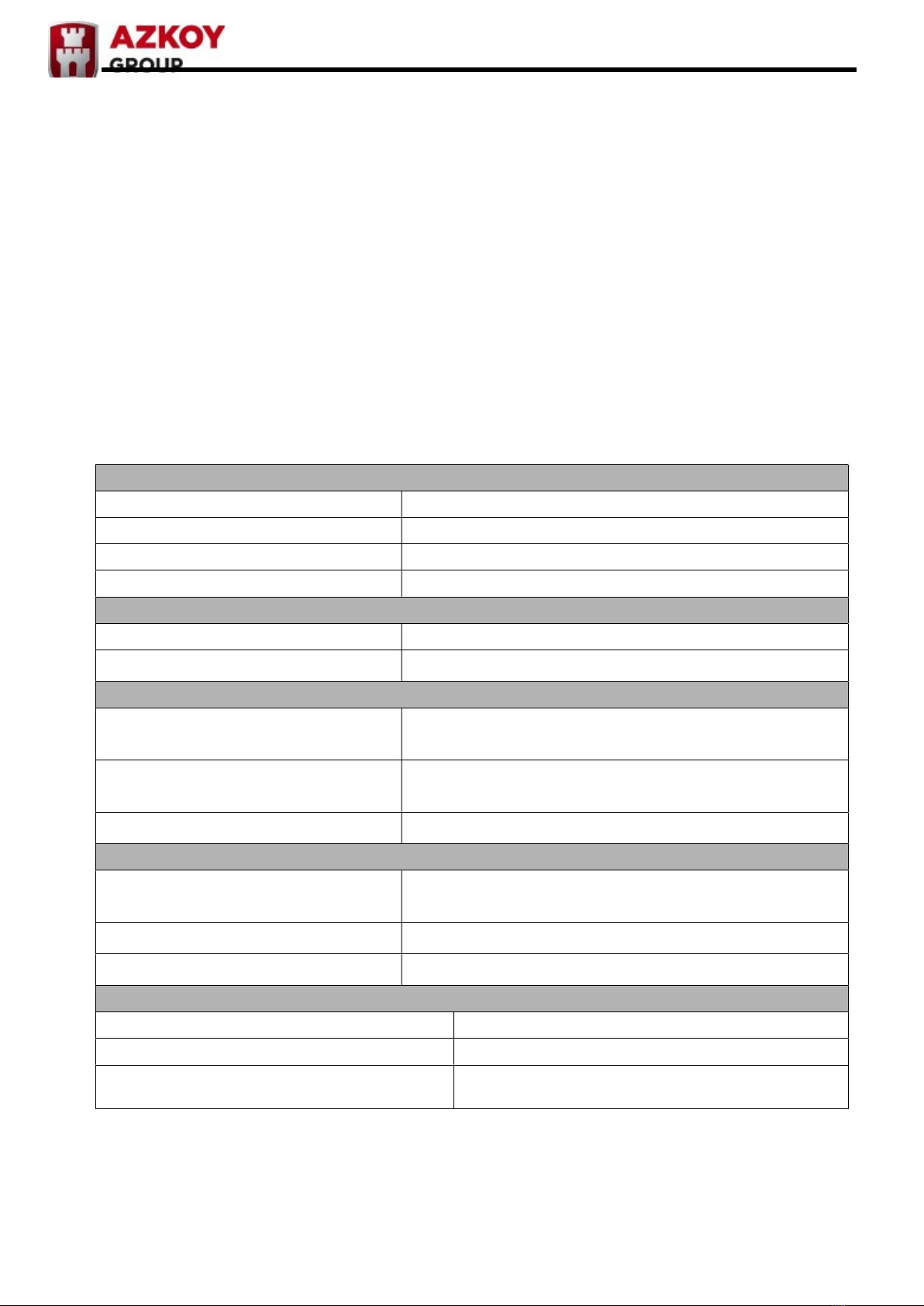

INDEX

CAUTIONS ................................................................................................................................ 4

CHAPTER 1. GENERAL CHARACTERISTICS ........................................................................ 7

1.1.- Description of the VITRO S5 line. .................................................................................. 7

1.2.- Main characteristics ....................................................................................................... 7

1.3.- Description of the main components .............................................................................. 8

CHAPTER 2. INSTALLATION AND START-UP .................................................................... 11

2.1.- Choosing a machine location ....................................................................................... 11

2.2.- Levelling ....................................................................................................................... 11

2.3.- Electrical installation .................................................................................................... 11

2.4.- Water inlet .................................................................................................................... 11

2.5.- Machine installation on a STAND. ............................................................................... 11

2.6.- Changing the product and price sign ........................................................................... 14

2.7.- Start-up ........................................................................................................................ 14

2.8.- Load level labels of the hoppers .................................................................................. 15

CHAPTER 3. FILLING THE MACHINE ................................................................................... 17

3.1.- Initial filling with soluble product ................................................................................... 17

3.2.- Filling with coffee beans ............................................................................................... 17

3.3.- Initial filling with water .................................................................................................. 17

3.4.- Initial programming ...................................................................................................... 17

CHAPTER 4. CONFIGURATION AND PROGRAMMING ...................................................... 19

4.1.- What is programming? ................................................................................................. 19

4.2.- Programming control unit ............................................................................................. 19

4.3.- Direct access to a function. .......................................................................................... 20

4.4.- List of functions ............................................................................................................ 20

4.5.- Service programming. .................................................................................................. 22

CHAPTER 5. ANOMALY CONTROL AND MAINTENANCE ................................................. 25

5.1.- Reset ........................................................................................................................... 25

5.2.- Possible incidents during a service. ............................................................................. 25

5.3.- Service Meters ............................................................................................................. 25

5.4.- Disassembly of the coffee bean unit ............................................................................ 26

5.5.- Adjustments and regulation ......................................................................................... 26

CHAPTER 6. CLEANING THE MACHINE. ............................................................................. 29

6.1.- Components that require regular cleaning ................................................................... 29

6.2.- Cleaning cycle for the group brewing chamber ............................................................ 30

6.3.- Exterior cleaning .......................................................................................................... 31