User Manual VITRO S1

- 3 -

WARNINGS ............................................................................................................................... 4

UE Declaration of Conformity ................................................................................................. 6

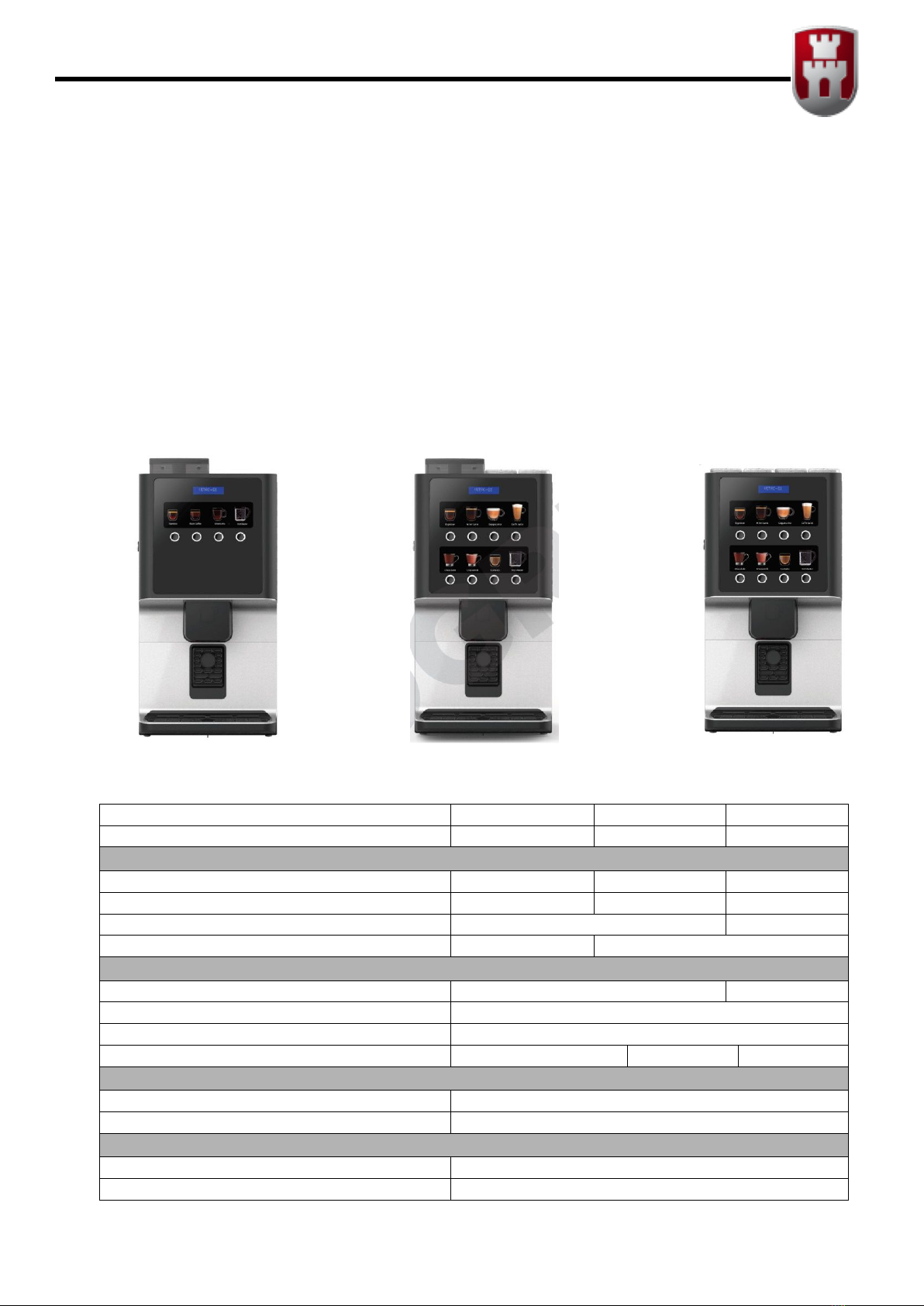

CHAPTER 1. GENERAL CHARACTERISTICS ........................................................................ 7

1.1.- Description of the machine. ........................................................................................... 7

1.2.- Description of the main components .............................................................................. 8

CHAPTER 2. INSTALLATION AND STARTING-UP ................................................................ 9

2.1.- Choice of location for the machine ................................................................................. 9

2.2.- Electrical installation ...................................................................................................... 9

2.3.- Start-up .......................................................................................................................... 9

2.4.- Water supply .................................................................................................................. 9

2.5.- Payment module .......................................................................................................... 10

CHAPTER 3. DESCRIPTION OF THE MACHINE .................................................................. 11

3.1.- Soluble product hoppers .............................................................................................. 11

3.2.- Initial loading of soluble product. .................................................................................. 11

3.3.- Loading coffee beans ................................................................................................... 11

3.4.- Initial loading of water .................................................................................................. 11

3.5.- Programming the water temperature under special conditions .................................... 12

3.6.- Bean coffee group (Espresso Machines) ..................................................................... 12

3.7.- Dismantling the coffee bean group .............................................................................. 13

3.8.- Settings and adjustments ............................................................................................. 13

CHAPTER 4. PROGRAMMING .............................................................................................. 15

4.1.- How do we communicate with the machine? ............................................................... 15

4.2.- What can be programmed? ......................................................................................... 15

4.3.- Programming menu .................................................................................................... 15

4.4.- List of functions ............................................................................................................ 16

4.5.- Customising the Programming Menu ........................................................................... 18

4.6.- Service programming. .................................................................................................. 18

CHAPTER 5 – TROUBLESHOOTING AND MAINTENANCE ................................................ 21

5.1 - Reset ........................................................................................................................... 21

5.2.- Error detected by the machine. .................................................................................... 21

5.3.- Changing the product labels ........................................................................................ 22

CHAPTER 6. CLEANING THE MACHINE. ............................................................................ 23

6.1.- Components that require regular cleaning ................................................................... 23

6.2.- Regular cleaning of the machine and maintenance operations ................................... 24

6.3.- Cleaning cycle for the group brewing chamber ............................................................ 24

6.4.- Descaling cycle. ........................................................................................................... 26

6.5.- Replacing the water filter ............................................................................................. 27

6.6.- Exterior cleaning .......................................................................................................... 27

Anexe 1. THE TREATMENT, COLLECTION, RECYCLING AND DISPOSAL OF THIS

DEVICE ................................................................................................................................... 28