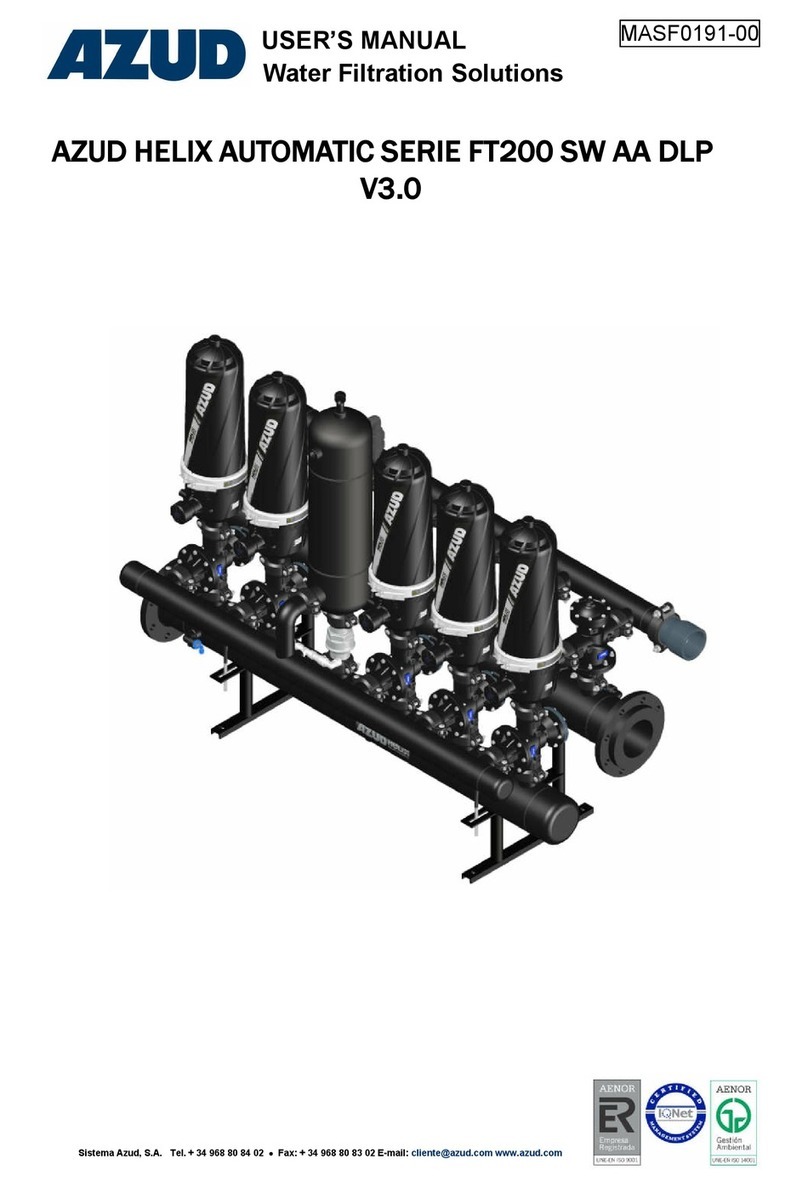

Water Filtration Solutions

3

AZUD FBC Control Unit is able to control the automatic backflushing of the filtration equipments with

different possibilities of start and actuation. AZUD FBC Control Unit integrates the detection, control and

activation systems of the backflushing cycle of the filtration systems.

Electronic control system. Integrated controller to control all the detection and activation functions. It is

assembled on an electric cabinet with degree of protection IP 55.

Detection system. Easy reading differential pressure gauge.

Activation system. 24 V NC three-way electrovalves

All these is completely assembled and contains the auxiliary elements which complete the electric and

hydraulic system and which turns the Control Unit into an independent and automatic system.

2.1 Introduction.

1. Introduction

2. Characteristics of the Control Unit.

2.2. Identification of the product.

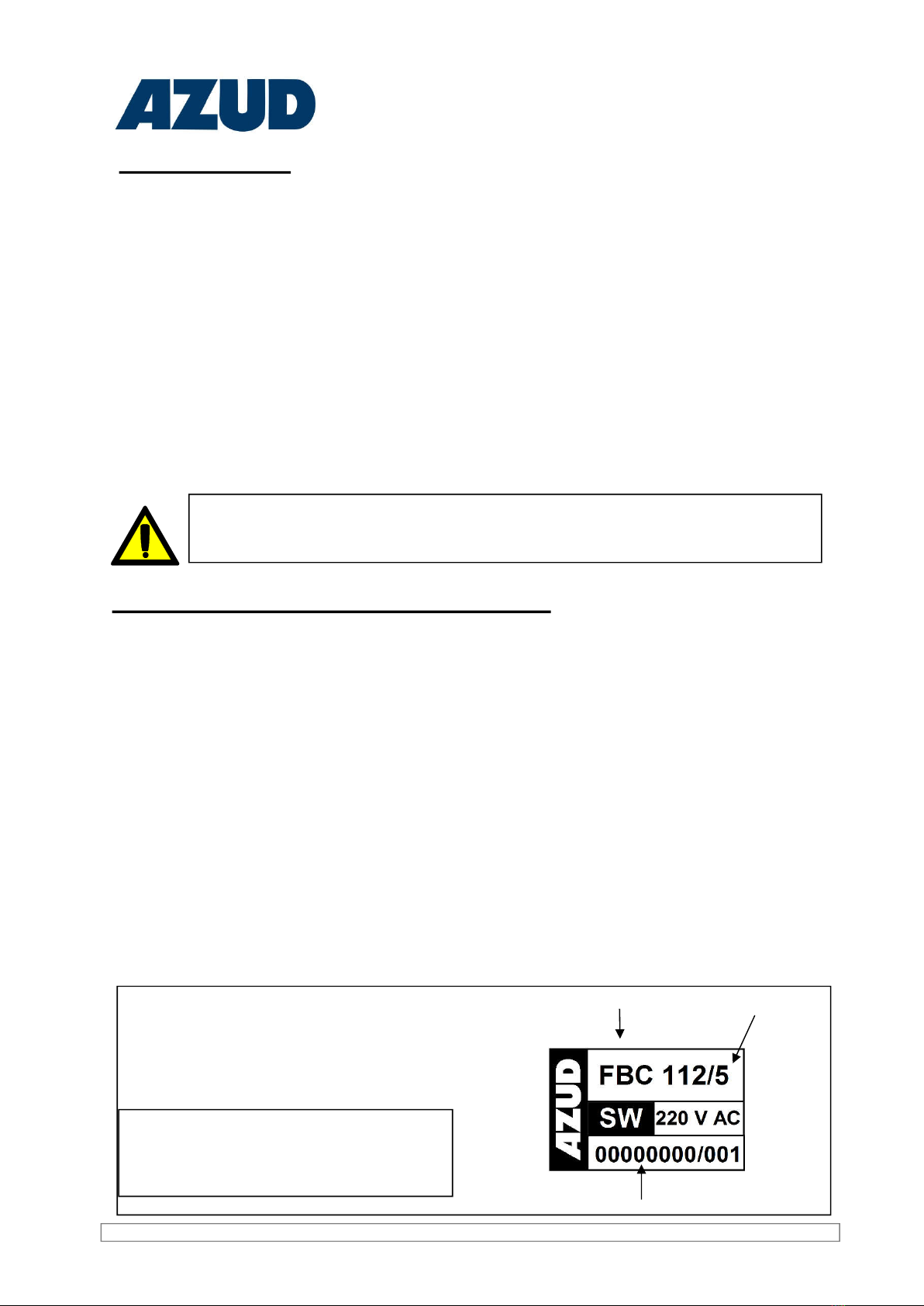

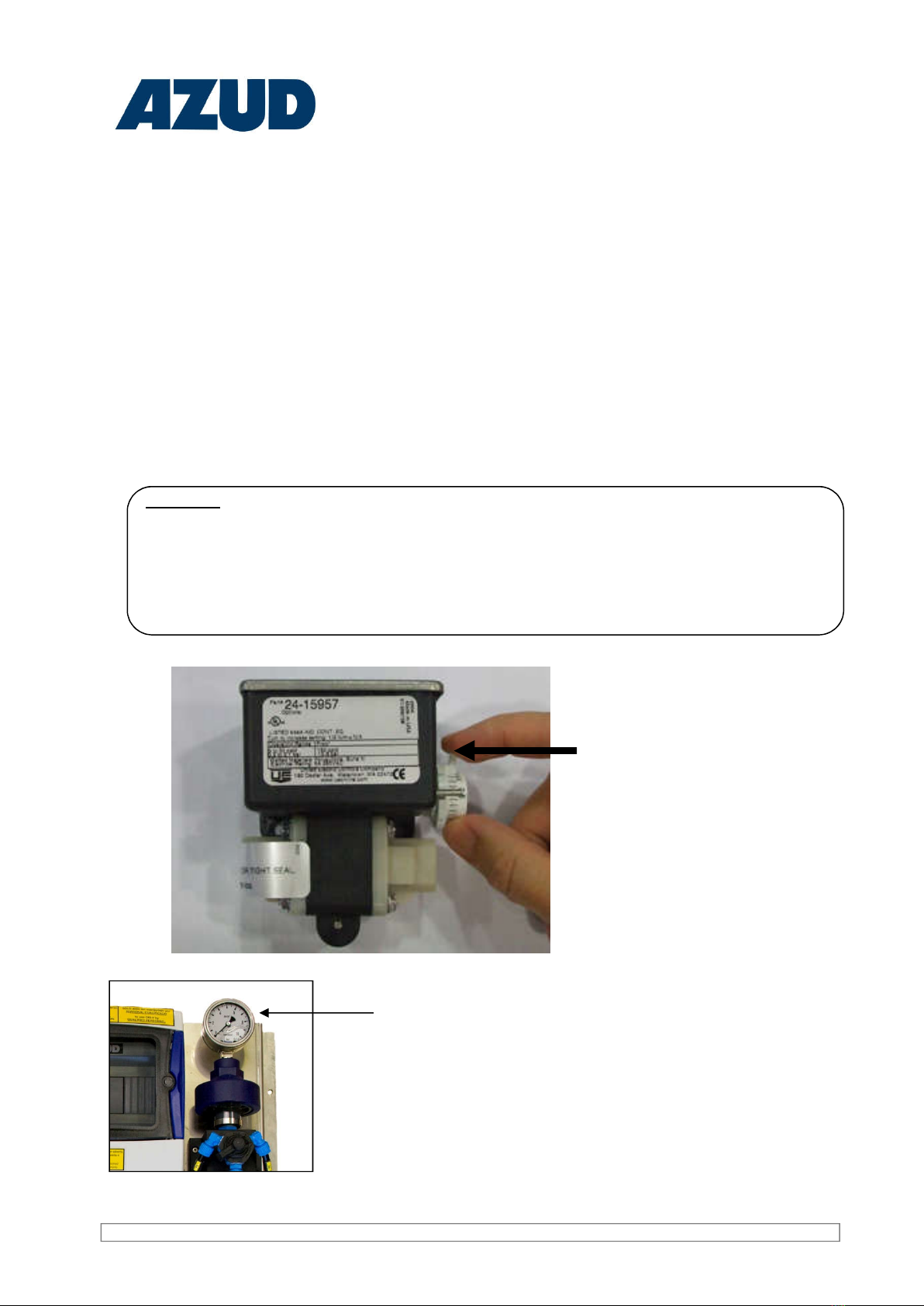

In AZUD we identify each Control Unit with an industrial label with a unique serial number. The

factory identifies the different control units with these labels.

The modification or elimination of the

label cancels any warranty; and so

impedes the identification of the

Equipment.

The industrial label indicates: the model of

the equipment, the number of stations, the

year of manufacture and the serial

number.

NUMBER OF STATIONS

SERIAL NUMBER

MODEL

Thank you very much for your confidence in AZUD FBC control units to solve your Filtration

Equipments Automation needs. Please, read carefully this manual and you will find the answer to most

of your questions.

However, IF YOU HAVE ANY DOUBT OR NEED ADDITIONAL INFORMATION, PLEASE CONTACT

All the control units manufactured in SISTEMA AZUD, S.A are subject to strict quality control tests and

are manufactured under a productive process which meets the requirements of the standard ISO

9001/2000.

Sistema AZUD is also committed with the environment, and is certified under the Environmental

Management System of the standard ISO 14001.

This Manual contains some instructions and warnings which should be observed

to obtain a correct installation, operation and subsequent maintenance of the

Control Unit.