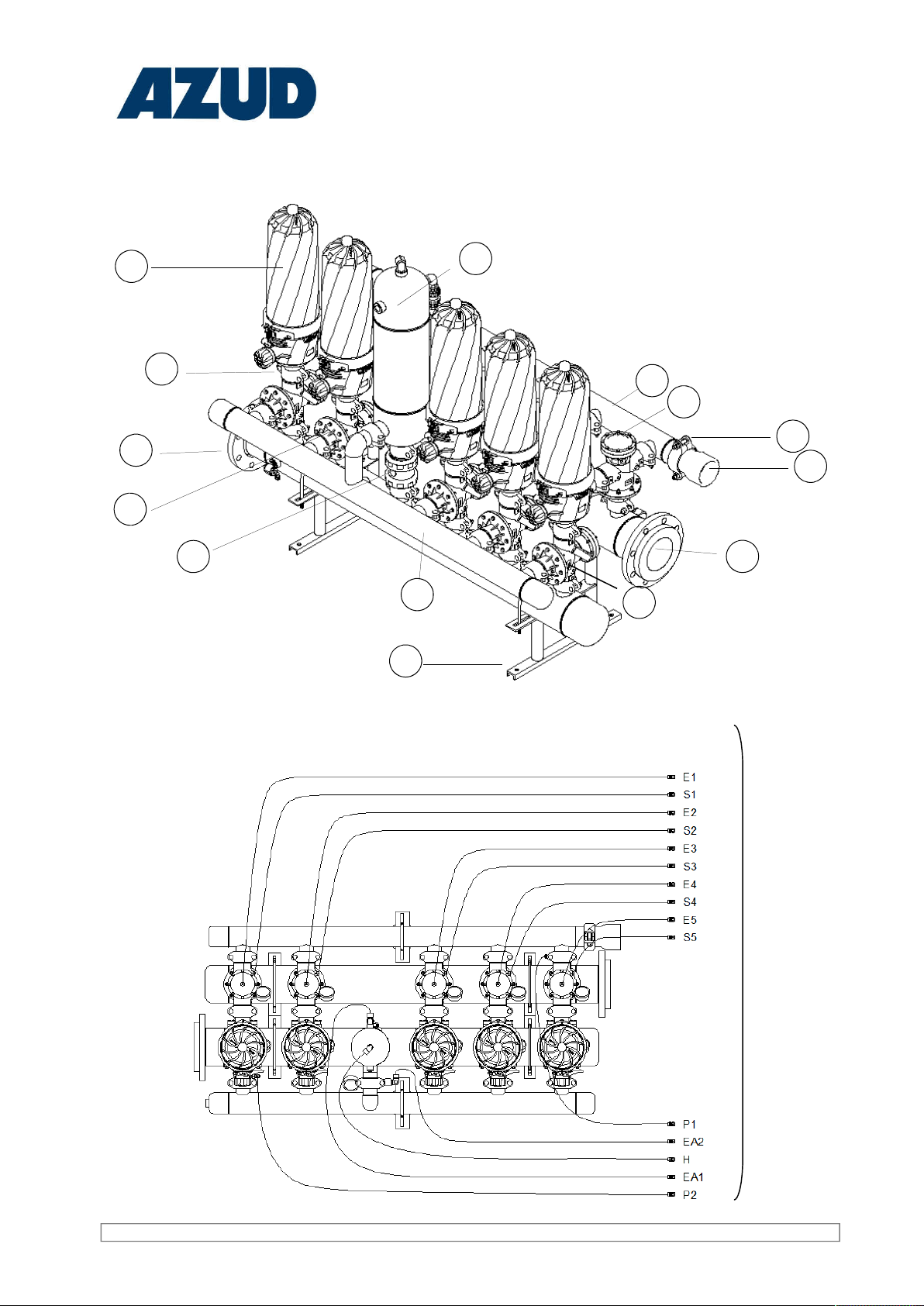

Water Filtration Solutions

10

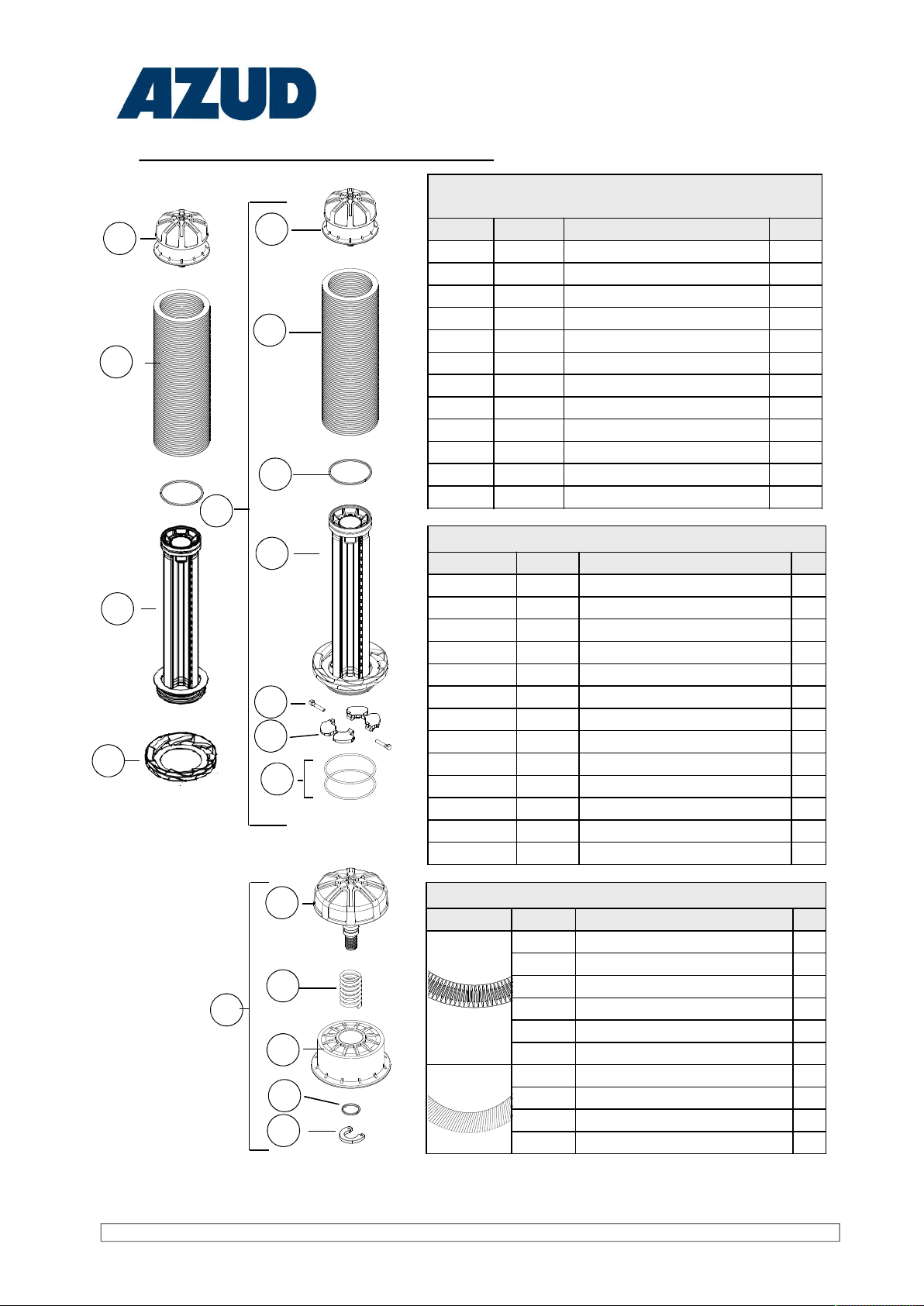

FILTERING ELEMENT SPARE PARTS

NUMBER CODE DESCRIPTION un

21 PISTON FRAME AZUD HELIX AUTOMATIC 1

22 --- DISCS KIT AZUD HELIX AUTOMATIC 1

23 18R60037 PISTON OGASKET92,6 x 100 x 4 mm 1

24 ---------- FRAME WIITHOUT CHECK VALVE 1

25 ---------- CHECK VALVE 1

26 ---------- STEM CLAPETA 1

27 18R60026 O-RING 103X4 2

28 ---------- A PISTON COMPONENT 1

29 ---------- SPRING 1

30 ---------- B PISTON COMPONENT 1

31 ---------- O-RING 13X2 2

32 ---------- CLIP 1

AZUD HELIX AUTOMATIC FILTERING ELEMENT

SPARE PARTS KITS

NUMBER CODE DESCRIPTION un

23-27x2-31-32 18R60116 O-RINGS KIT AUTOMATIC FILTER 3.0 1

23-31-32 18R60117 PISTON SET OF O-RINGS AUTOMATIC FILTER 3.0 1

23-27x2-29-31-32 18R60118 MAINTENANCE KIT AUTOMATIC FILTER 3.0 1

20 18R60119 FRAME AUTOMATIC FILTER DEP 3.0 1

25x2-26x2 18R60120 CHECK VALVE AUTOMATIC FILTER 3.0 1

26 ---------- STEM CLAPETA 1

27 18R60026 O RING 103X4 2

28 ---------- A PISTON COMPONENT 1

29 ---------- SPRING 1

30 ---------- B PISTON COMPONENT 1

31 ---------- O RING 13X2 2

32 ---------- CLIP 1

33 17RXP020 HELICAL ELEMENT 1

AZUD HELIX AUTOMATIC DISCS KIT

NUMBER CODE DESCRIPTION un

22

18R60033 S-DISC KIT AUTOMATIC FILTER 130 MICRON 1

18R60039 S-DISC KIT AUTOMATIC FILTER 100 MICRON 1

18R60034 S-DISC KIT AUTOMATIC FILTER 50 MICRON 1

18R60035 S-DISC KIT AUTOMATIC FILTER 20 MICRON 1

18R60038 S-DISC KIT AUTOMATIC FILTER 10 MICRON 1

18R60036 S-DISC KIT AUTOMATIC FILTER 5 MICRON 1

22

18R60040 DISC KIT AUTOMATIC FILTER 400 MICRON 1

18R60012 DISC KIT AUTOMATIC FILTER 200 MICRON 1

18R60011 DISC KIT AUTOMATIC FILTER 130 MICRON 1

18R60010 DISC KIT AUTOMATIC FILTER 100 MICRON 1

28

29

30

32

31

21

21

22

23

24

25

26

27

17

21

22

20

33