4

8. ELECTRICAL INSTALLATION ......................................................................................................................................................20

8.1. Electrical installation for fitting assembly, wall assembly, valve assembly or rail assembly

models ...................................................................................................................................................................................20

8.2. Electrical installation of the control cabinet model .......................................................................................24

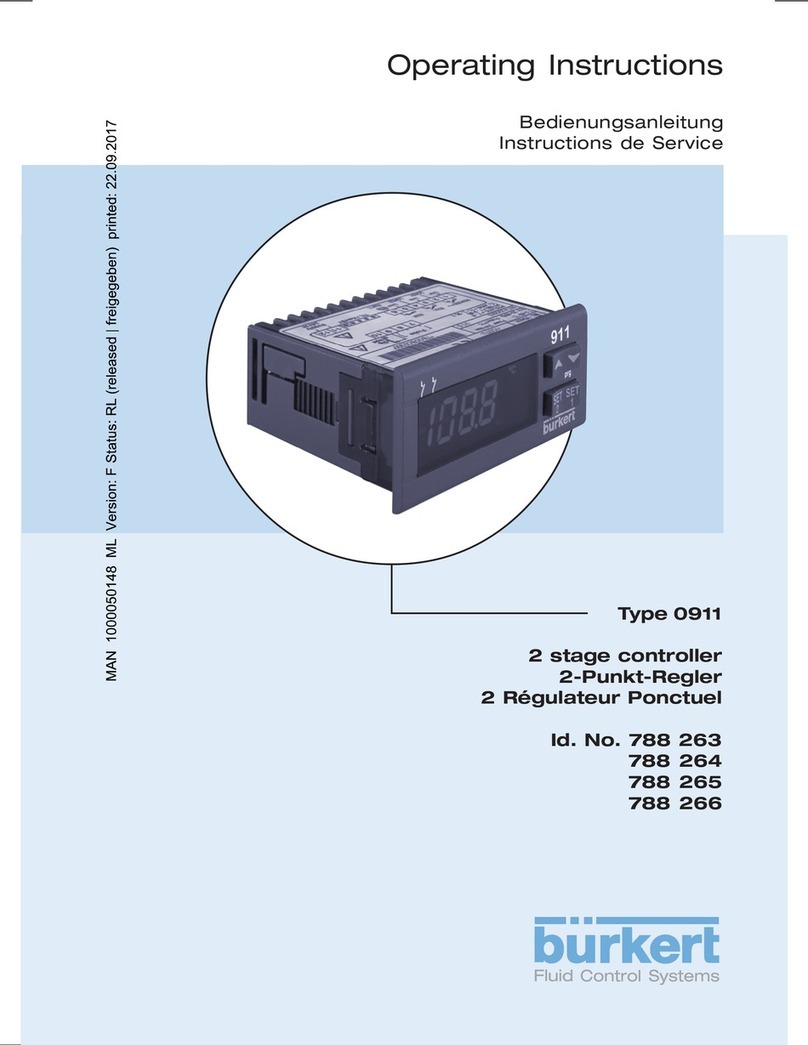

9. OPERATION AND FUNCTION ....................................................................................................................................................27

9.1. Control and display elements ....................................................................................................................................27

9.2. Operating levels and operating states .................................................................................................................28

9.3. Function of the keys .......................................................................................................................................................29

10. OPERATING STRUCTURE ............................................................................................................................................................30

10.1. Operating structure of the process operating level in MANUAL operating state .........................30

10.2. Operating structure of the configuration level .................................................................................................31

11. FUNCTIONS OF THE PROCESS OPERATING LEVEL ...................................................................................................37

11.1. Operating state AUTOMATIC .....................................................................................................................................37

11.2. Operating state MANUAL .............................................................................................................................................38

11.3. Specific menu options of process and ratio control .....................................................................................38

11.4. Menu options in the MANUAL operating state .................................................................................................38

11.5. SET - Set-point value default for process control .........................................................................................39

11.6. RFAC - Ratio factor default for ratio control ......................................................................................................39

11.7. TEST – Display of the analog inputs and outputs and the digital inputs ..........................................40

11.8. PARA – Display and optimization of the controller parameters .............................................................41

11.9. VALV – Manual opening and closing of the connected actuating elements ....................................42

12. FUNCTIONS OF THE CONFIGURATION LEVEL ...............................................................................................................44

12.1. General Description ........................................................................................................................................................44

12.2. Menu options of the configuration level ..............................................................................................................45

12.3. MODE - Selection of control variable, actuating element and process value input ....................46

12.4. UNIT - Selection of measuring units and decimal places .........................................................................59

12.5. SETP / RFAC - Selection and scaling of set-point value default / entry of ratio factor ............62

12.6. S_IN - Scaling of sensor input signal

english

Type 8611