P. O. Drawer E / 161 Gatehouse Road / Sanford, Maine 04073 / USA

800-992-2537 / 207-324-8773 / Fax: 207-324-3869 / bakerco@bakerco.com / bakerco.com

TABLE OF CONTENTS

I - FUNCTION AND DESCRIPTION OF THE CHEMOSHIELD

.....................................................................1

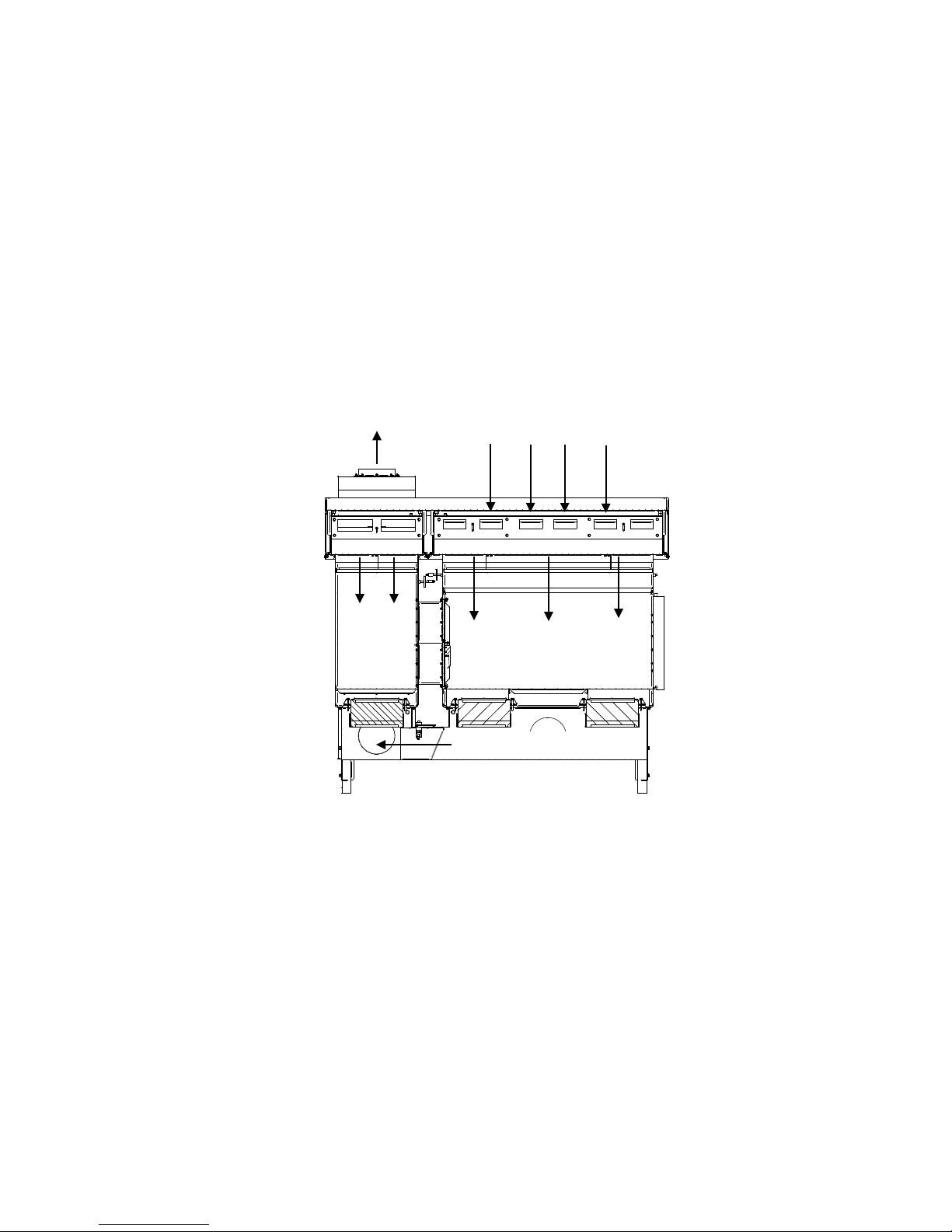

CHEMOSHIELD AIRFLOW AND BASE FEATURES .......................................................................................................1

Fig. 1: Airflow Inside Cabinet..............................................................................................................................1

CABINET PRESSURE AREAS ........................................................................................................................................2

ACCESS TO THE WORK CHAMBER ..............................................................................................................................2

DESIGN DETAILS.........................................................................................................................................................2

Performance assurance.........................................................................................................................................2

Building exhaust requirement................................................................................................................................3

Chamber walls and tunnel construction................................................................................................................3

All-metal plenums..................................................................................................................................................3

Stainless steel work surfaces..................................................................................................................................3

Cabinet exterior panels..........................................................................................................................................3

Tested HEPA filters ...............................................................................................................................................3

Viewscreens...........................................................................................................................................................3

Work chamber and pass-through lighting.............................................................................................................3

Chamber base pan construction and clean ability ................................................................................................3

Cabinet air balance adjustments...........................................................................................................................3

Easy filter access ...................................................................................................................................................4

Telescoping stand..................................................................................................................................................4

Mechanical interlock between pass-through door & inter-chamber door ............................................................4

Pressure monitoring of chambers..........................................................................................................................4

Airflow monitor – AFM .........................................................................................................................................4

Auxiliary switch (Optional) ...................................................................................................................................4

Electrical duplex....................................................................................................................................................5

Lift system (Optional) ............................................................................................................................................5

SPECIFICATIONS FOR CHEMOSHIELD®-MODEL CS500............................................................................................5

Weight....................................................................................................................................................................5

Electrical Specifications........................................................................................................................................5

Environmental Conditions.....................................................................................................................................6

Symbols and Terminology .....................................................................................................................................6

II - PREPARING THE CHEMOSHIELD® FOR USE.............................................................................................7

CHECKING THE CABINET UPON ARRIVAL...................................................................................................................7

THE USES OF A CHEMOSHIELD®CABINET................................................................................................................7

LOCATION WITHIN THE LABORATORY........................................................................................................................7

INSTALLING THE CABINET ..........................................................................................................................................7

FINAL CONNECTIONS AND TESTS................................................................................................................................8

III - PROPER CABINET USE...................................................................................................................................9

OPERATOR CONTROLS................................................................................................................................................9

START-UP PROCEDURE ...............................................................................................................................................9

LOADING MATERIALS AND EQUIPMENT....................................................................................................................10

RECOMMENDED WORK TECHNIQUES .......................................................................................................................10

UNLOADING AND WIPE DOWN ..................................................................................................................................10

REACTING TO SPILLS ................................................................................................................................................10

DECONTAMINATION..................................................................................................................................................10

CLEANING AND DISINFECTING STAINLESS STEEL......................................................................................................11

Simple Cleaning...................................................................................................................................................11

Disinfection..........................................................................................................................................................11

351D700 Rev H iii