P.O.DrawerE/161GatehouseRoad/Sanford,Maine04073/USA

389D000 Rev B iii

TABLE OF CONTENTS

I – FUNCTION OF THE SterilGARDe3...................................................................................................1

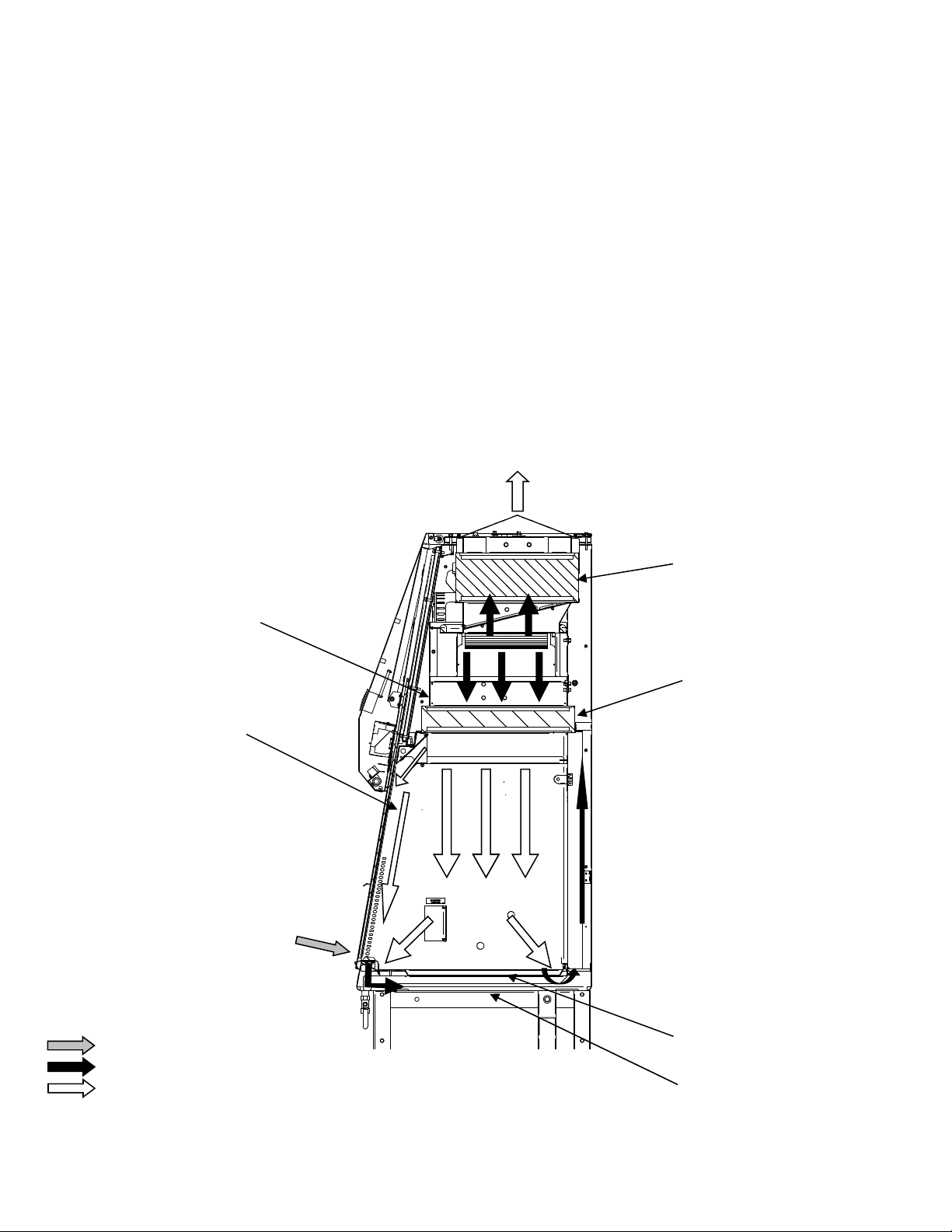

II - CABINET DESIGN...................................................................................................................................2

Standard Features....................................................................................................................................3

Cabinet Primary Function.................................................................................................................................................3

Applicable Standards........................................................................................................................................................3

Cabinet Pressure Plenums.................................................................................................................................................3

Motor/Blower Capacity, Cabinet Supply Blower.............................................................................................................3

Manual Air Balance..........................................................................................................................................................3

Cabinet Filters ..................................................................................................................................................................3

Easy Filter Access ............................................................................................................................................................3

Work Area Design............................................................................................................................................................3

Front Access High Velocity Air Slots ..............................................................................................................................3

Towel Guard.....................................................................................................................................................................4

Work Surface....................................................................................................................................................................4

Drain Pan..........................................................................................................................................................................4

View Screen......................................................................................................................................................................4

View screen Access Opening ...........................................................................................................................................4

Work Area Lighting..........................................................................................................................................................4

Electronic Ballast..............................................................................................................................................................4

Ground Fault Circuit Interrupter (115V only)..................................................................................................................4

Laboratory services...........................................................................................................................................................4

Alarms ..............................................................................................................................................................................4

Timers...............................................................................................................................................................................4

Padded Bypass Armrest....................................................................................................................................................5

UniPressure™ Plenum......................................................................................................................................................5

Motor/Blower Assembly ..................................................................................................................................................5

Cable Port.........................................................................................................................................................................5

ReadySAFE™ Mode........................................................................................................................................................5

Power/Processor Fault Alarm...........................................................................................................................................5

Optional Features.....................................................................................................................................6

Adjustable Cabinet Stand .................................................................................................................................................6

IV Bar...............................................................................................................................................................................6

UV light............................................................................................................................................................................6

Floor and Wall Seismic Anchoring ..................................................................................................................................6

FlexAIR™ Canopy Exhaust Connection (CEC) ..............................................................................................................6

Digital Display Package Option (DDP)............................................................................................................................6

Auxiliary Wiring Options.................................................................................................................................................6

III - PROPER CABINET USE.......................................................................................................................7

Operation and Controls...........................................................................................................................7

Blower..............................................................................................................................................................................7

Fluorescent Light..............................................................................................................................................................8

Auxiliary Outlets ..............................................................................................................................................................8

Ultraviolet (UV) Light [Optional] ....................................................................................................................................8

Alarm Reset......................................................................................................................................................................8

Alarm Conditions.....................................................................................................................................9

Sash Alarm .......................................................................................................................................................................9

Power/Processor Fault Alarm...........................................................................................................................................9

Double Proximity Sensor Fault Alarm .............................................................................................................................9

Low-flow Exhaust Alarm.................................................................................................................................................9

Alarm Summary Table .....................................................................................................................................................9

Cabinet Timer Functions.......................................................................................................................10