B&K 230 User manual

E

&.::E-t:

INSTRUMENTS

.

INC

.

May

1972

OPERATING MANUAL

for

MODEL

230

CALIBRATION

CONTROL

OSCILLATOR

SECTION

I

SECTION

II

SECTION

III

SECTION

IV

TABLE

OF

CONTENTS

General

Description

1.1

1.2

Description

.

Specifications

Installation

Theory

of

Operation

3.1

3.2

Oscillator

Circuit

Impedance

Head

Circuits

Operation

4.1

Calibration

of

.B &K

Model 4930

Artificial

Mastoid

4.1.1

General

4.1.2

Equipment

Hook-Up

4.1.

3

Calibration

Set-Up

Procedure

4.1.4

Setting

the

Mass

Compensation

4.1.5

Calibrating

the

Model 4930

Mastoid

i

1

1

1-2

3

5

5

6

7

7

7

7-8

8-11

11

11-13

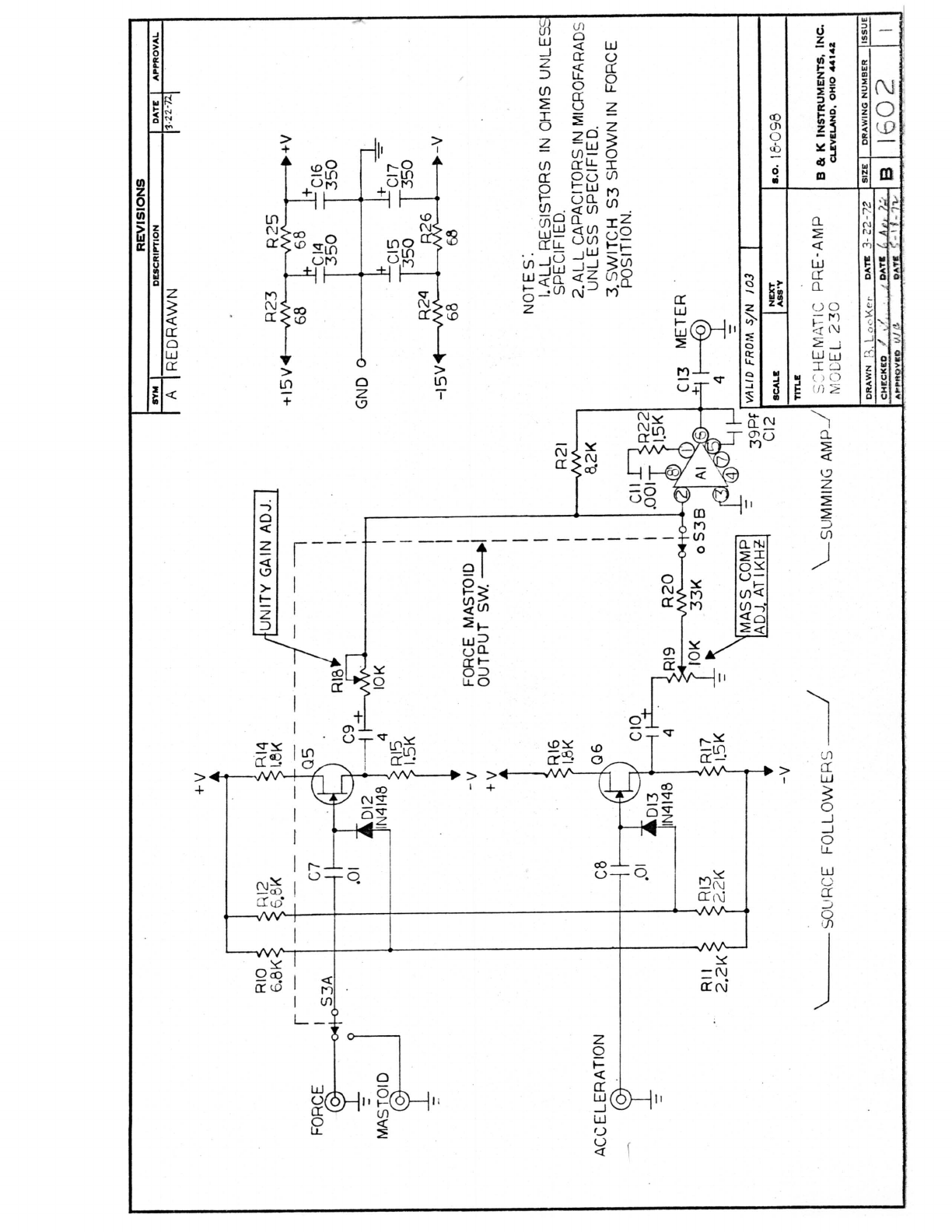

Figure

1.

Figure

2.

Figure

3.

Figure

4.

Drawing

A-1604

Drawing

A-d605

Drawing

C-1603

Drawing

B-1602

Drawing

A-1601

ILLUSTRATIONS

Picture

of

Model 230

Calibration

Control

Oscillator

Simplified

Diagram

-Model 230

Instrument

Interconnections

-

4930

Calibration

Periodic

Calibration

of

Model

4930

Artificial

Mastoid

(B

& K Form

#2-358)

Oscillator

Block

Diagram

Model 230

Preamplifier

Block

Diagram

Model 230

Schematic,

Oscillator

for

Model 230

Schematic,

Preamplifier

for

Model 230

Schematic,

Power

Supply

for

Model 230

ii

4

5

10

14

SECTION

I

GENERAL

DESCRIPTION

1.1

Description

The B & K Model 230

Calibration

Control

Oscillator

and

the

B & K

Model

4931

Artificial

Mastoid

Calibrator

are

used

together

to

calibrate

the

frequency

response

and

force

sensitivity

of

the

B & K Model

4930

Artificial

Mastoid.

The Model 230

Calibration

Control

Oscillator

has

eleven

pushbutton-selected

variable

level

test

tones

in

the

range

from

125

to

8000

Hz,

in

accordance

with

the

ANSI

1)

and

IEC2)

audiometer

test

standards.

The

calibration

control

oscillator

also

contains

the

signal

conditioners

for

transducer

signals

from

the

Artificial

Mastoid

and

the

force

and

acceleration

outputs

of

the

Impedance

Head

Model

8000.

A

mass

compensation

circuit

is

included

to

cancel

out

the

residual

mass

below

the

force

sensing

element.

Mass

compensation

at

1000

Hz

reduces

the

effect

of

residual

mass

to

below

0.2

%

of

the

true

force

signal

level

at

all

test

tone

frequencies.

An

external

rms

volt-

meter

is

used

with

the

Model 230

to

read

both

the

force

applied

and

the

mastoid

output.

1.2

Specifications

Oscillator

Output

Frequencies:

Frequency

Accuracy:

Output

Level

(Filter

Out)

:

Output

Impedance:

Distortion:

Filter

Characteristics:

125,

250,

500,

750,

2000,

3000,

4000,

+~

1000,

6000,

1.3

V rms

into

6

Ohm

load

10

Ohms

2%

at

0.1

V rms

1500,

8000

Hz.

High

pass,

0.5

dB

at

3 kHz

and

-10

dB

at

125

Hz.

1)

-

ANSI

Stand

ar

d

S3.13-1972:

An

Artificial

Head-Bone

for

the

calibration

of

Audiometer

Bone

Vibrators.

2) -IEC

Draft

Document

29C

(Cent

r

al

Office)9.

1.2

Specifications

(Cont'd)

Signal

Circuits

Inputs:

Input

Impedance:

Frequency

Response:

Noise:

Maximum

Input:

Output

Impedance:

Gain:

Mastoid

-

Force

Acceleration

Power:

Size:

.

Weight:

Rack-Mounting

Adapters

Single

Unit:

Dual

Units

Accessories:

-2-

3

(Acceieration

and

Force

from

Model

8000

Impedance

Transducer

and

Force

from

4930

Mastoid)

5 M-ohms

30 -

10,000

Hz

+0.5

dB

100

~V

with

respect

to

the

input

with

1000

pF

input

capacitor

3 V

peak

200

Ohms

o

dB

o

dB

o

to

-40

dB

prior

to

summing

115/230

V;

50-400

Hz;

15

watts

8

Tf

wide

x

3%-Tf

high

X

l3

Tf

deep

8

lbs

KS

1-1001

KS

1-2001

1 Power

Cord

1

3-ft.

Signal

Cord

BNC

to

B&K

1

Signal

Cord

Microdot

2.1

Inspection

SECTION

II

INSTALLATION

Remove

the

Model 230

Calibration

Control

Oscillator

from

its

packing

and

inspect

the

instrument

for

damage.

(Make

certain

that

the

power

and

signal

cords

are

-

not

discarded

with

the

carton.)

2.2

Installation

The B & K Model 230

Calibration

Control

Oscillator

may

be

operated

as

a

bench-top

instrument.

A

bail

on

the

lower

cover

tilts

the

instrument

fo

r

convenient

use.

For

rack-mounting,

adaptor

KS

1-1001

attaches

to

the

instrument.

Mounting

instructions

are

included

with

the

rack

adaptor.

Before

applying

power,

check

the

line

voltage

selector

at

the

rear

of

the

instrument

and

make

sure

the

switch

is

in

the

correct

position

(115

or

230).

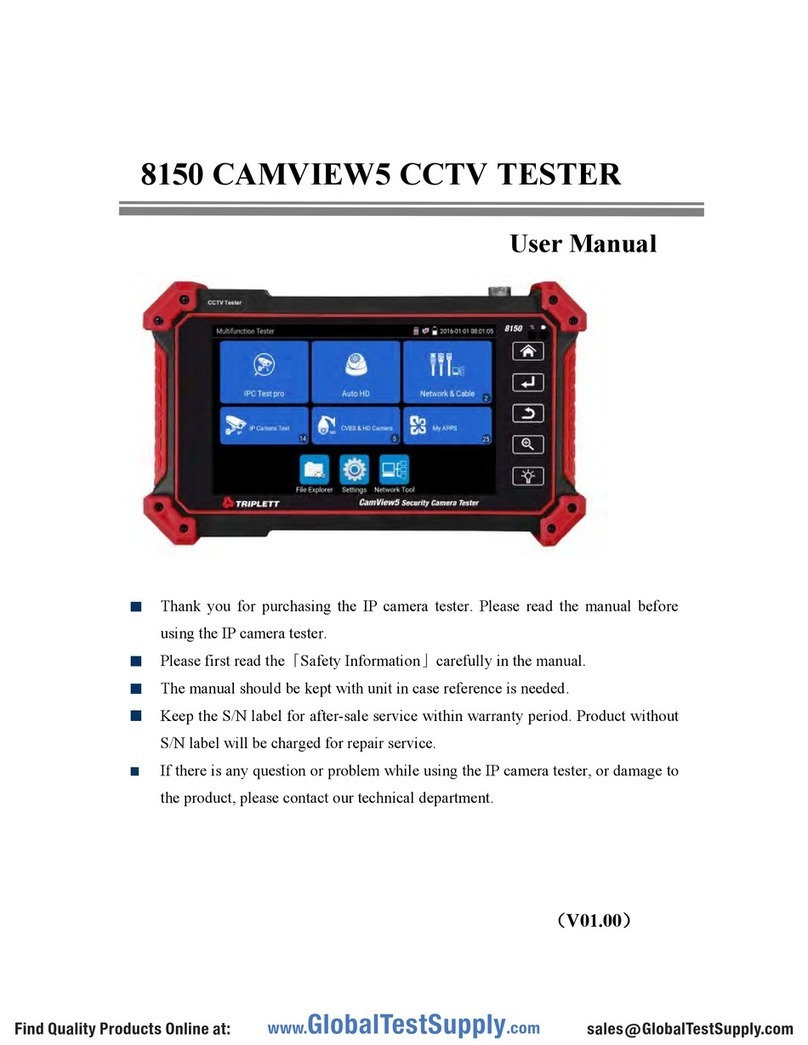

See

Figure

1.

(Picture

of

the

Model 230

showing

front

controls.)

-3-

.

~,

.::t2~

~

~·

~

-.:

._

~;'Io-

A

(5)

F

(Q)

~

M

(6)

"

Osc:

®

;1 Output

~

~

.."ll:

230 CALIBRATION

CONTROL

OSCILLATOR

"'-

Mcidol

'd o.c;c ll!vel

Il'I

-

Moifr;,id

fiI,

..

D

Out

-

Oth

~

,.

rry

O

·

O l

.tput

Qu

-

otUt

•

Adjust Moss Compensation

[[[[]]TI]]

n

125

250 500

75,0

IK I.SK

21.

3K

;fK

6K

8K

Oscillator Frequen

cy

@

Po·

....

er

o

,

t":::;;

~

l

~I

.'

:

:

C

~

~

-"

j;

"

~

.,

~

~

"

.

;

;

.

:

./

'/

O u

tput

to

Mef

e r

.

".

t

'.

:..:..,-!

.

';:

.':':

;" -~

_

-":':"'::'

_'

_ _

-.-

.' • •

.o...-:

..

_

;",,_-

.__ , t.

...

~

..

~

~

.\'

1,

1

""""

.

:;

,

~

:~

I \ '

~1

~

~;

",

~

,

i!

1

~~---

\

~'IP~

·

~~,.j;..<o

..

-

·

~"':t~

L

~

.

,

~,-<,

~~

_,u.

.

~

___

.---_~-:.;

..

....,~

.•

""_,

..;t1

'J'

~~

_

~

.

~

:::-:::!

-;

7-=.

-~

~

~--"~~~"'lI

'

d

,!.

"

Y':1I

'-

~

.

..

.

--

...

~

-

-:::::~

.

~:

/

~

Fi~

Ul:'El.

h

I

+

I

3.1

Oscillator

Circuit

SECTION

III

THEORY

OF

OPERATION

-5-

A

simplified

block

diagram

is

shown

in

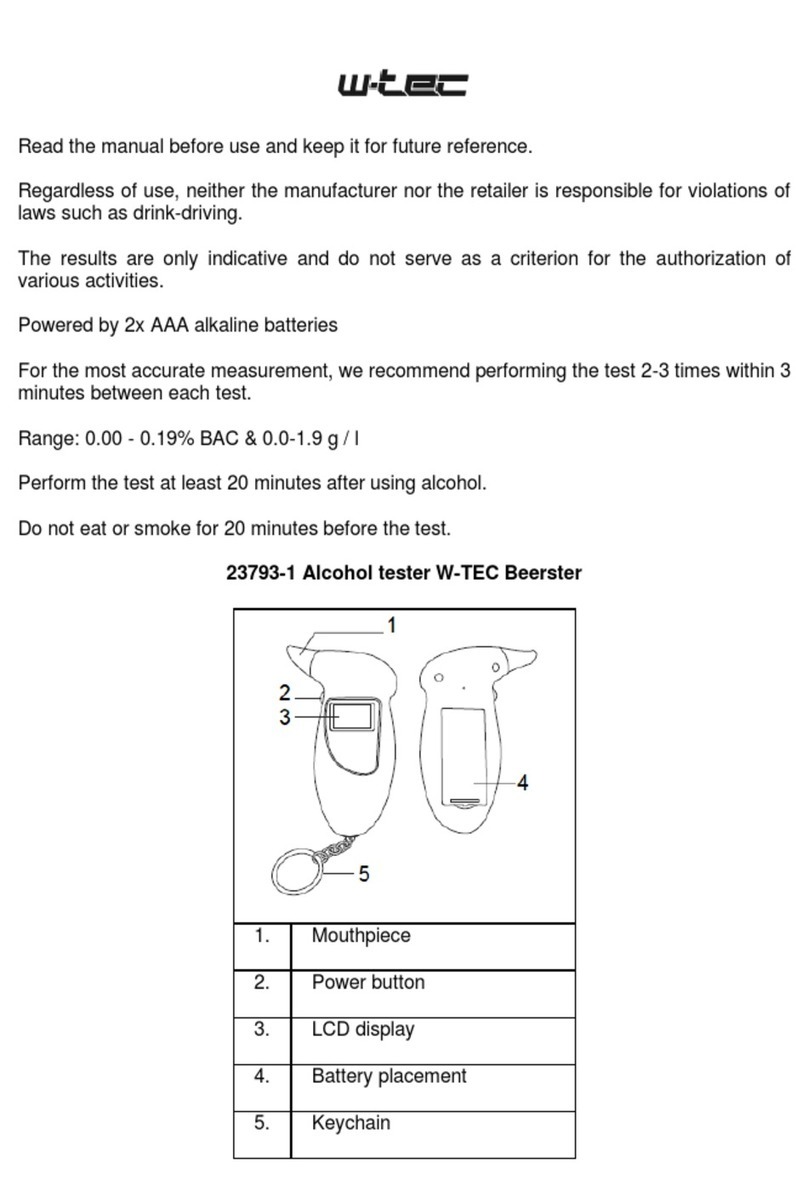

Figure

2.

The

frequency

selector

pushbuttons

S.4

select

the

frequency

of

an

RC

oscillator.

'

Eleven

frequencies

at

125,

250,

500,

750,

1000, 1500,

2000,

3000,

4000,

6000

and

8000

Hz

are

provided.

The

oscillator

output

connects

either

directly

to

the

output

amplifier

or

through

a

high-

To

Rcm

lout

F

-

--,

• I

I

I

5

Ing

le

I

(-

l

ass

.

COIll

(l.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

_J

Frequency

,

Sclector

IIR1

0

Nini

-

Sh(1kcr

5.5

230

C.C.O.

5.

11

(~lot1el

3000 Impcdnnce H

ead

)

~lodcl

'

II')30

Artificial

Nastoid

Figure

2.

Simplificd

Dingram -Hodel 230

Calibration

Control

Osci

ll

at

or

pass

filter

F.l.

Pushbutton

switch

S.5

inserts

the

high-pass

filter

into

the

circuit.

The

output

voltage

characteristic

of

this

filter

approx-

imates

the

inverse

of

the

mechanical

impedance

character-

istic

of

the

Model 4930

Mastoid.

Hence,

the

oscillator

output

to

the

Mini-

shaker

matches

the

impedance

of

the

driven

tlload

tl

(the

mastoid).

With

the

filter

switched

in,

adjustment

of

the

oscillator

level

control

is

minimal.

-6-

3.2

Impedance

Head

Circuits

The B & K Model 8000

Impedance

Head

has

a

force

output

and

an

accelera-

tion

output.

Both

transducers

are

piezoelectric

and

are

connected

to

high

input

impedance

amplifiers

A.2

and

A.3.

The

Minishaker

Model

4810

applies

force

to

the

Artificial

Mastoid

through

the

Impedance

Head

contact

surface,

a

beryllium

disc

of

1.75

cm

2,

as

specified

by

IEC-29C.

The

force

level

applied

is

read

from

the

force

gage

output

of

the

Impedance

Head.

For

applications

in

the

United

States,

the

Model 4930

Mastoid

is

calibrated

in

force

(mV/Newton). The

disc

which

bears

on

the

Model 4930

Mastoid

has

a

mass

of

about

1.1

grams.

This

mass

loads

the

lower

side

of

the

force

transducer

and

creates

an

acceleration

signal

when

in

motion.

This

signal

adds

to

the

force

signal

and

results

in

an

error.

To

eliminate

this

undesired

signal,

there

is

an

accelerometer

built

into

the

Impedance

Head.

The

output

of

this

accelerometer

is

in

opposite

phase

to

the

force

output.

By

mixing

a

portion

of

the

accel-

erometer

output

with

the

force

gage

output,

the

effects

of

the

residual

mass

are

cancelled.

To

effect

complete

cancellation,

the

Impedance

Head

and

Minishaker

are

lifted

clear

of

contact

with

the

top

of

the

Artificial

Mastoid

and

a

1000

Hz

tone

is

applied

to

the

Impedance

Head.

Since

there

is

no

load

on

the

force

gage,

the

only

signal

generated

in

the

force

gage

is

the

undesired

acceleration

signal.

The

amount

of

the

out-of-phase

acceleration

signal

added

is

set

with

the

mass

compensation

screwdriver

adjustment

so

that

a minimum

voltage

reading

(max.

cancellation)

is

obtained

at

the

output

jack

(Output

Switch

S.3

in

"FORCE"

position)

.

The

mass

compensation

screwdriver

adjustment

is

on

the

front

panel.

Mass

compensation

performe

d

at

100

0

Hz

serves

all

other

test

tones

as

well.

Error

will

be

less

than

0.2

%.

Switch

S.3

selects

the

output

of

the

mass

compensated

force

signal

or

the

Mastoid

output.

The t wo

signal

levels

can

be

measured

on

any

external

voltmeter

our

sound

level

meter.

-7-

SECTION

IV

OPERATION

4.1

Calibration

of

B & K Model 4930

Artiticial

Mastoid

4.1.1

General

The B & K Model 4930

Artificial

Mastoid

is

a

force

measuring

load

cell

with

an

elastic

sensing

face.

The

mechanical

impedance

is

similar

to

the

human

mastoid.

The Model

4930

measures

the

mechanical

output

of

the

bone

conduction

transducers

when

driven

from

audiometers.

Mastoid

calibration

establishes

the

'

transfer

function

of

the

Model

4930;

i.

e.

what

electrical

output

is

obtained

for

a known

input

force

at

each

test

frequency.

Because

of

the

differences

between

U.S.

and

European

equipment

and

standards

for

bone

conduction

calibration,

this

manual

will

show a

different

complement

of

equipment

and

some

procedure

differences

from

those

in

the

Bruel

&

Kjaer

manual

for

the

Model 4930

Mastoid.

For

U.S.

applications,

this

.

manual

should

take

precedence

using

the

Model 4930

manual

for

supplementary

data.

4.1.2

Eguipment

Hook-Up

The

instruments

to

perform

a Model 4930

Artificial

Mastoid

calibra

tion

are:

- 1 230

Calibration

Control

Oscillator

with

microcable

set

and

output

cable

4810

Minishaker

8000

Impedance

Head

Calibration

Loading

Arm

Static

Adjuster

550 gram Mass

Bubble

Balance

-8-

4.1.2

Equipment

Hook-Up (ContTd)

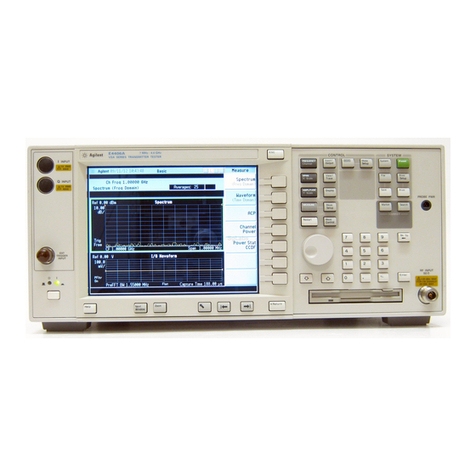

The

measuring

amplifier

or

voltmeter

which

is

normally

used

with

the

Model 4930

Mastoid

can

be

used

for

the

calibration.

Suitable

types

include:

4.1.3

2203 Sound

Level

Meter

2204

Sound

Level

Meter

2209

Sound

Level

Meter

2603

Microphone

Amplifier

2604

Microphone

Amplifier

2606

Microphone

Amplifier

2607

Microph0ne

Amplifier

.c-2608

Microphone

Amplifier

2107

Analyzer

2112

Analyzer

2113

Analyzer.

Calibration

Set-Up

Procedure

A. Remove

the

bone

conductor

loading

arm

from

the

Model

4930.

Install

the

calibration

loading

arm

for

supporting

and

positioning

the

Minishaker,

as

illustrated

below.

Calibration

Loading

Arm

~

Minishaker

Install

the

compression

type

static

load

adjuster

on

the

base

plate

containing

the

Mastoid.

Mount

the

Impedance

Head

to

the

Minishaker

and

position

and

secure

the

combination

in

the

4.1.3

-9-

Calibration

Set-Up

Procedure

(Cont'd)

loading

arm.

As

with

the

bone

vibrator,

it

is

important

to

have

the

correct

static

load

applieo

to

the

Mastoid

and

to

have

proper

positioning.

The

Impedance

Head

center

should

rest

on

the

highest

point

of

the

domed

top

of

the

Mastoid.

To

effect

this

centering,

rotate

the

loading

arm

horizontally

in

its

post

and,

by

loosening

the

knurled

nut

securing

the

mounting

post

to

the

platform,

shift

the

loading

arm

assembly

in

the

platform

slot

for

vertical

centering.

Retighten

the

knurled

nut.

The

Impedance

Head

should

be

as

vertical

as

possible

and

the

loading

arm

as

level

as

possible.

The

small

bubble

balance

included

with

the

Mastoid

may

be

placed

on

top

of

the

loading

arm

for

ease

of

leveling.

The

brass

static

loading

mass

should

not

be

installed

at

this

time.

Counterbalance

the

combined

weight

of

the

Minishaker

and

loading

arm

with

the

compression-type

static

load

adjuster.

To

perform

this

adjustment,

place

a

thin

piece

of

paper

(chart-

paper)

between

the

domed

top

of

the

Hastoid

and

the

contact

surface

of

the

Impedance

Head

and

rotate

the

static

load

adjuster

counter-~lockwise

to

pick

up

the

loading

arm

weight.

Correct

adjustment

is

obtained

when

there

is

a

light

drag

on

the

piece

of

paper

as

it

is

pulled

between

the

Impedance

Head

and

Mastoid.

If

leveling

now

needs

re-adjustment~

the

counter-balancing

should

be

touched-up

afterwards.

See

that

a

10-32

mounting

stud

is

screwed

into

the

back

of

the

Minishaker

to

provide

centering

for

the

loading

mass.

But

do

not

install

the

loading

mass

yet.

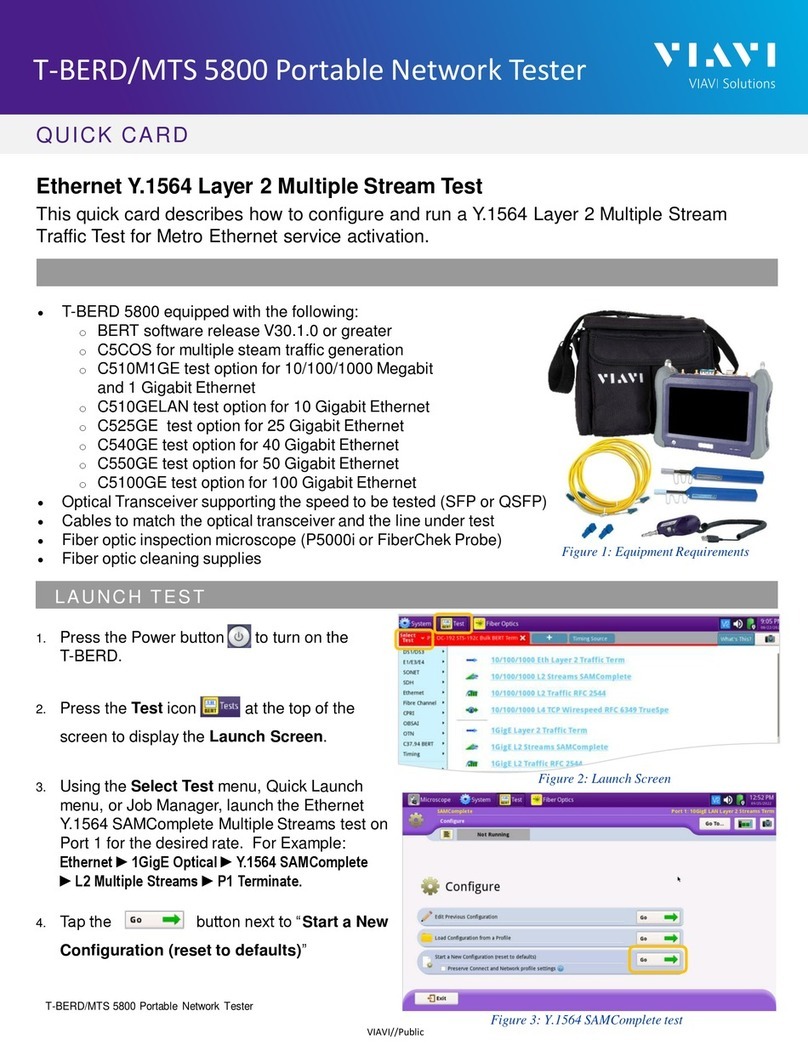

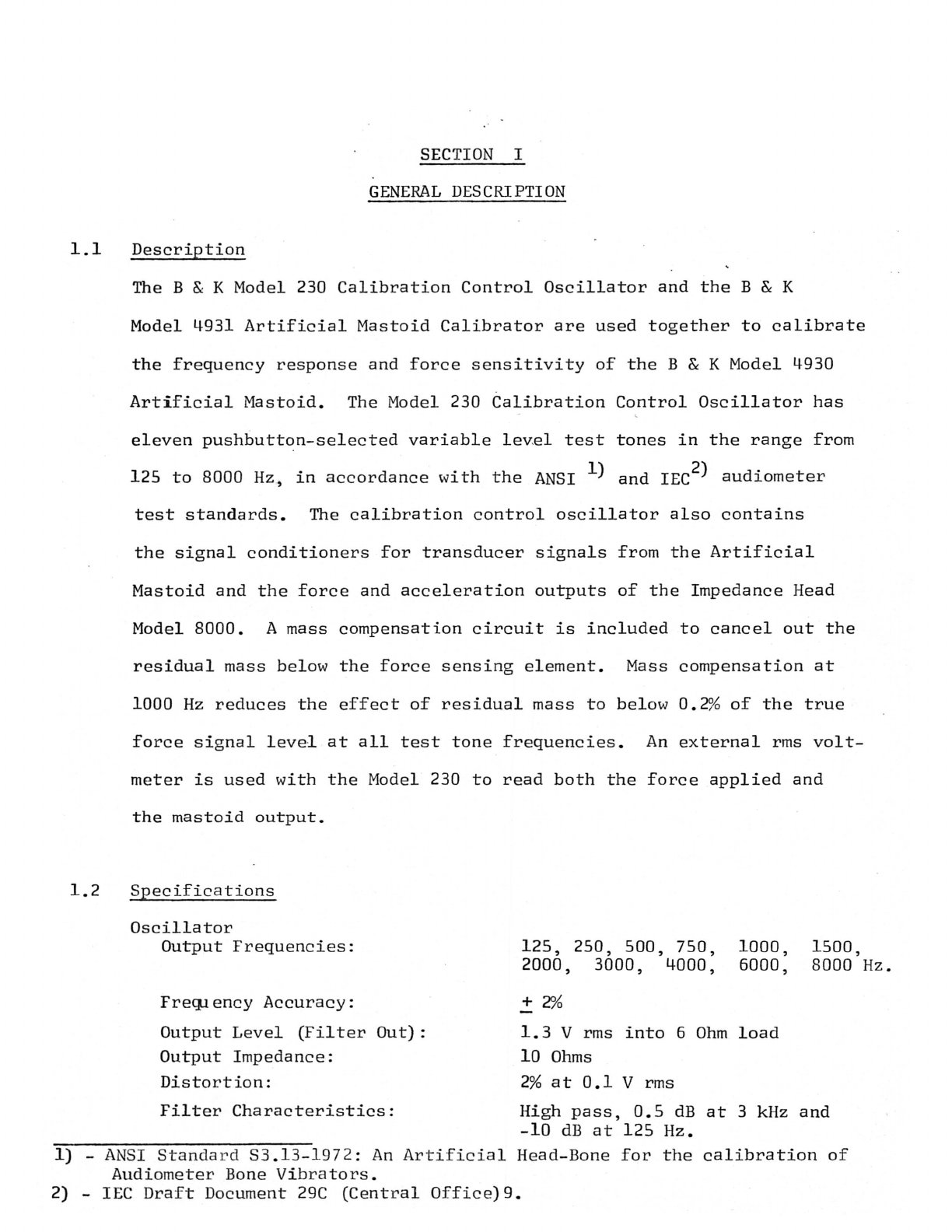

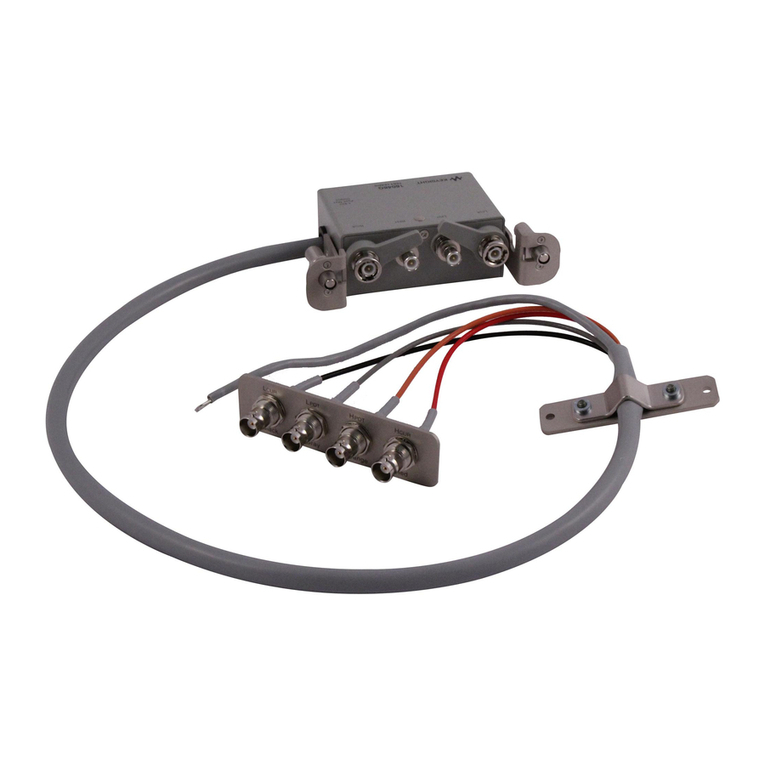

B.

Connect

the

microdot

cable

harnes~

as

shown

in

Figure

3.

Each

end

of

the

cables

is

coded

to

assure

ease

of

correct

connection.

The

cable

for

connection

between

the

Model 230

and

the

readout

instrument

has

a

BNC

connector

for

the

230

on

one

end

and

a

Bruel

&

Kjaer

connector

on

the

other

end

for

the

instruments

listed

under

4.1.2.

If

any

of

the

sound

level

-10-

4.1.3-B

Calibration

Set-Up

Procedure

(ContTd)

I.

-

_~

,,,

._

"-

..

l!2

•.

~

Jl

..

M

~

r-------t----t-----ir---;::;;::-;;t-~

tr[[t'[[rC[CI

(

~H---,

Ou

tpu

t

II

'

no

toO

"tO

o

.,

;,

;...::",

,

:.....:.

U

50<

,.

to

230

Cal.Control

Oscillator

'I'

Meter

4930 '

Arti

f

icial

Mastoid

.1

Figure

3.

Measuring

Amplifier

OR

I

I

I

L-_

Instrument

Interconnections;

4930

Calibration.

Sound

g

Level

~

M

eter

meters

or

the

Model

159

Audiometer

Calibrator

are

used

as

the

readout

instrument,

replace

its

microphone

with

the

B & K

Socket

Adapter

JJ-2612

for

the

models

2203

and

159,

and

JJ-2614

for

the

models

2204

and

2209,

to

accept

the

B & K

cable

connector.

-11-

4.1.3

Calibration

Set-Up

Procedure

(ContTd)

4.1.4

4.1.5

C.

Turn

on

the

Model 230

Calibration

Control

Oscillator

and

the

measuring

amplifier

and

allow

to

stabilize

for

15

minutes.

Set

Filter

Switch

S.5

TTIN-MASTOIDfT.

Setting

the

Mass

Compensation

A.

Raise

the

loading

arm

with

Minishaker

and

Impedance

Head

clear

of

the

Mastoid

and

block

it

in

this

up

position

by

placing

an

object

such

as

an

eraser

as

a

spacer

between

the

loading

arm

and

the

plungsr

of

the

static

load

adjuster.

B.

On

the

Model 230

select

the

1000

Hz

test

frequency,

set

TTOSC.

LEVELTT

mid-position,

and

set

the

output

switch

S.3

in

TTOUT-FORCE

TT

position.

C.

Adjlist

the

screwdriver

TTMASS

COMPENSATION

TT

control

on

the

Model 230

(above

theTTIOOO

HzTT

button)

for

minimum

deflection

of

the

readout

instrument.

This

completes

the

mass

compensation

operation.

D.

Remove

the

block

holding

the

Impedance

Head

up

and

lower

onto

the

Mastoid.

Now,

place

the

550

gram

static

loading

mass

over

the

mounting

stud.

(The

unthreaded

end

of

the

hole

in

center

w

ill

f

it

over

the

mounting

stud.)

The

Mastoid

arrangement

is

now

ready

for

calibration.

Calibrating

the

M

odel

4930 M

astoid

The

frequency

response

of

the

force

gage

in

the

Impedance

Head

is

flat

well

beyond

the

operating

range

of

the

Mastoid

• .

This

force

gage,

therefore,

serves

.

as

the

calibration

reference.

By

holding

the

force

gage

readings

constant

"

for

eaph

test

tone,

'.

4.1.5

-12-

Calibrating

the

Model 4930

Mastoid

(Contfd)

the

Mastoid

response

curve

is

generated

by

measuring

the

difference

between

the

force

gage

and

Mastoid

outputs.

Since

all

measurements

are

in

dB

ratios,

exact

calibration

of

the

readout

meter

is

unnecessary.

The

exact

voltage

values

relate

to

the

sensitivity

of

the

force

gage.

Amplitude

linearity

of

the

Mastoid

is

extremely

high,

so

that

the

calibration

level

is

not

critical

as

long

as

the

level

is

well

above

the

electrical

noise

level.

Therefore,

choose

a

level

that

is

convenient

and

makes

best

use

of

the

oscillator

level

range

of

the

Model

230.

With a B & K

Sound

Level

Meter,

set

up

for

a

I-inch

microphone,

set

the

attenuator

to

the

70

dB

range

making

full

scale

on

the

meter

80

dB

(about

10

mV).

Using

a B & K

microphone

amplifier,

use

the

10

mV

setting

but

read

the

dB

scale

(1) •

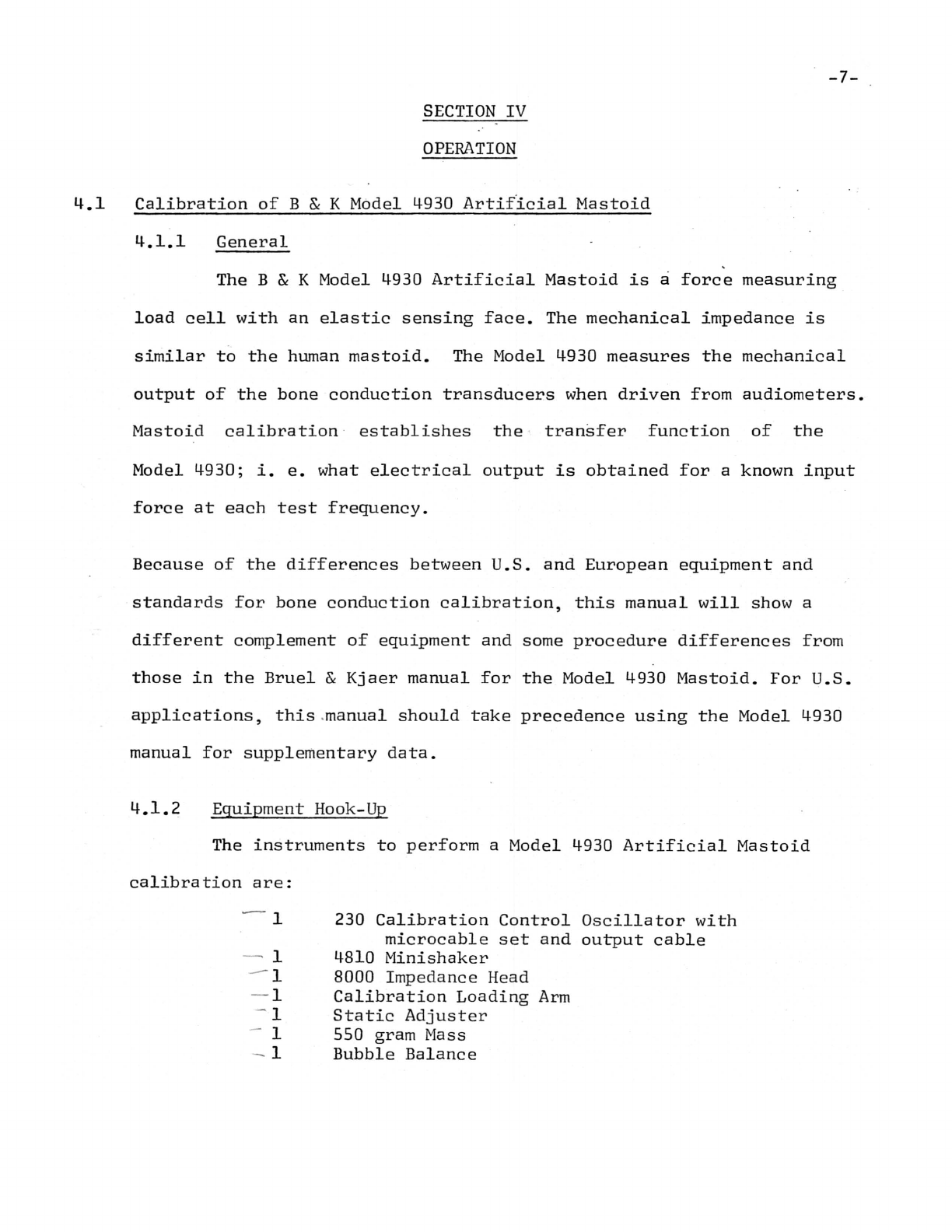

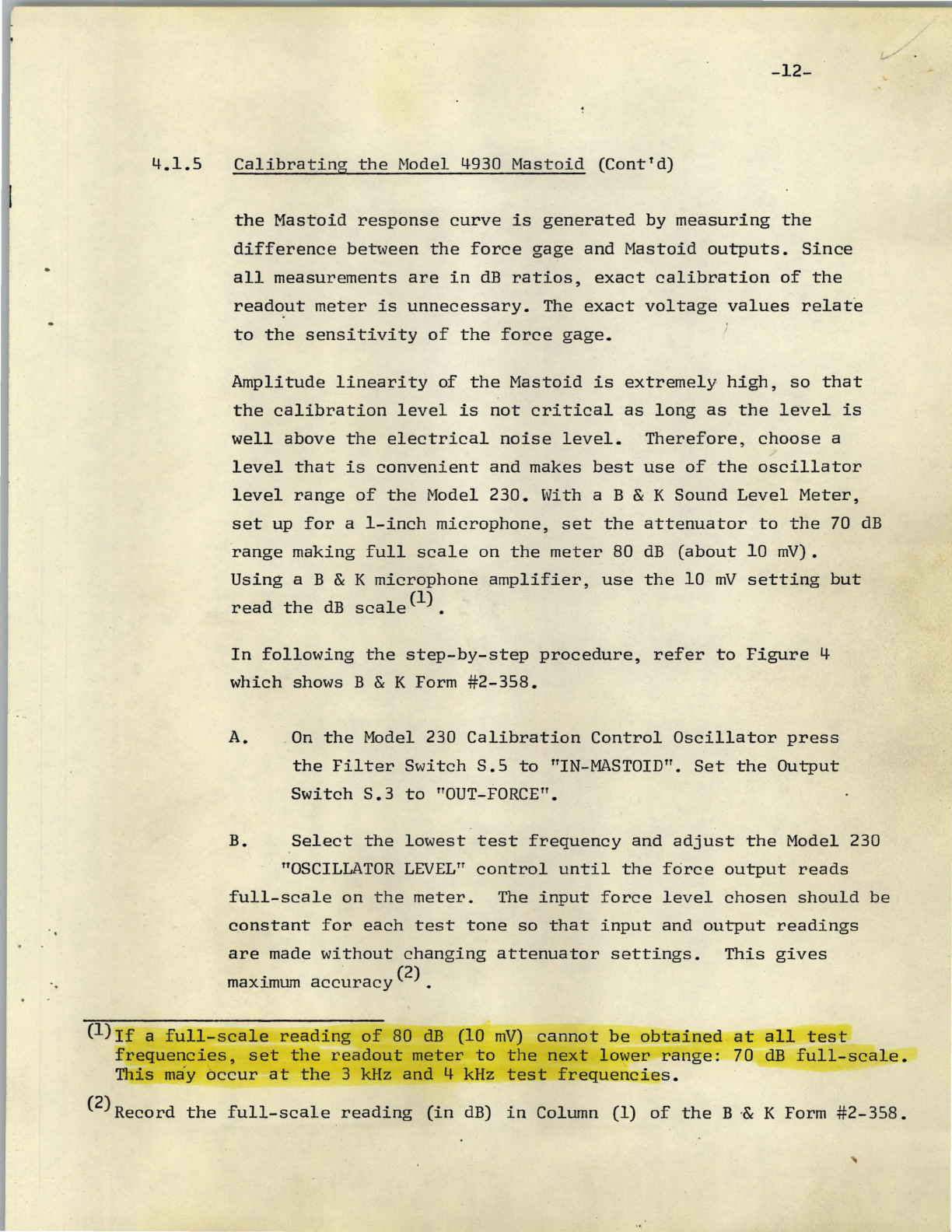

In

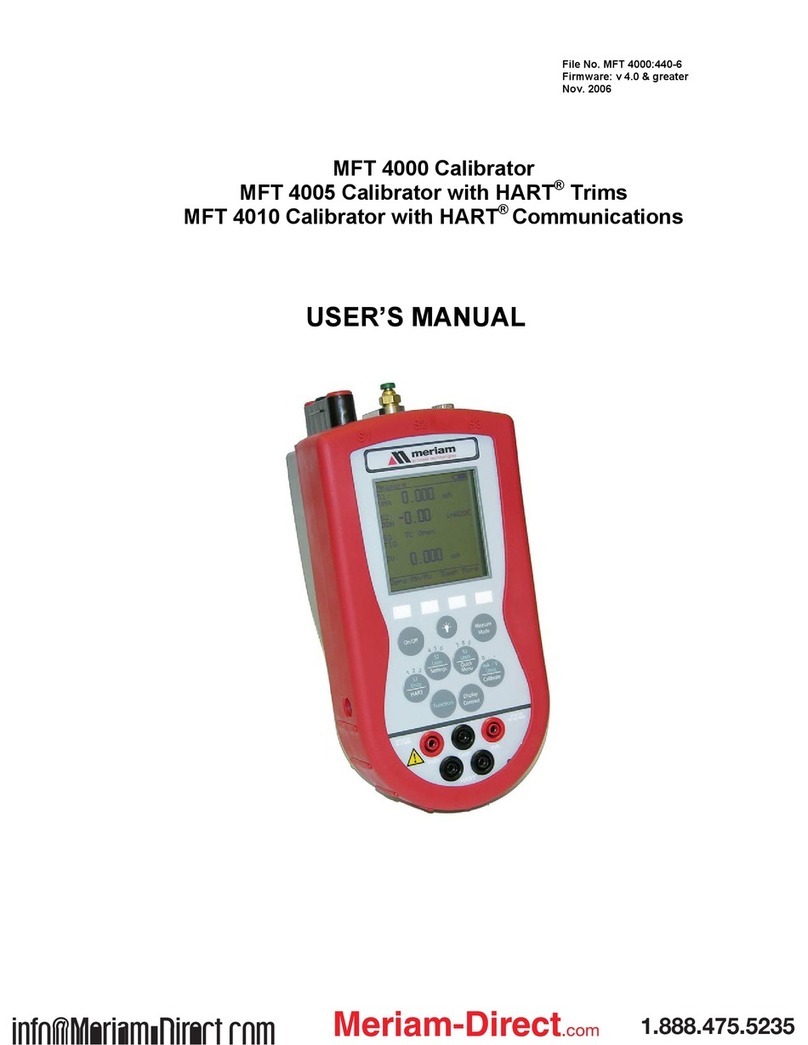

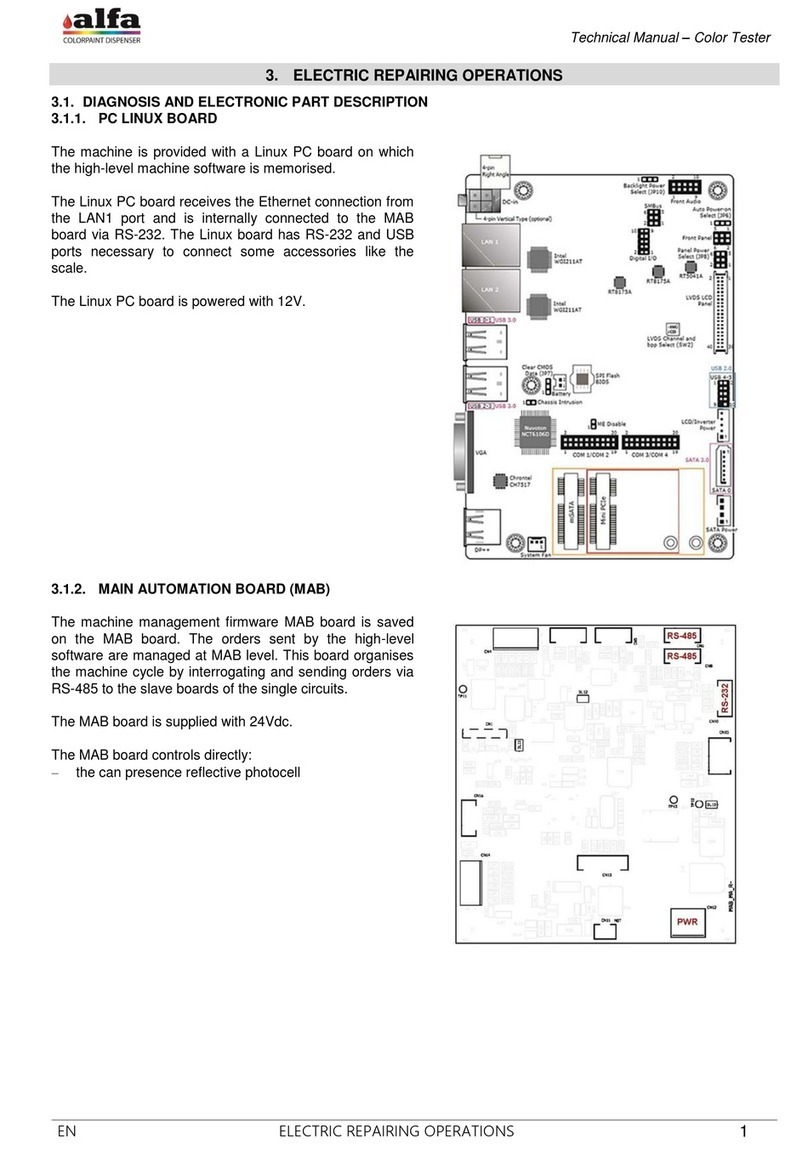

following

the

step-by-step

procedure,

refer

to

Figure

4

which

shows B & K Form

#2-358.

A. .

On

the

Model 230

Calibration

Control

Oscillator

press

the

Filter

Switch

S.5

to

"IN-MASTOIDTT.

Set

the

Output

Swi

tch

S.

3

to

"OUT-FORCE".

B.

Select

the

lowest

test

frequency

and

adjust

the

Model 230

"OSCILLATOR

LEVEU'

control

until

the

force

output

reads

full-scale

on

the

meter.

The

input

force

level

chosen

should

be

constant

for

each

test

tone

so

that

input

and

output

readings

are

made

without

changing

attenuator

settings.

This

gives

maximum

accuracy

(2) •

(l

)

If

a

full-scale

reading

of

80

dB

(10

mV)

cannot

be

obtained

at

all

test

frequencies,

set

the

readout

meter

to

the

next

lower

range:

70

dB

full-scale.

This

ma

·y

occur

at

the

3 kHz

and

4 kHz

test

frequencies.

(2)

Record

the

full-scale

reading

(in

dB)

in

Column (1)

of

the

B

.&

K Form

#2-358.

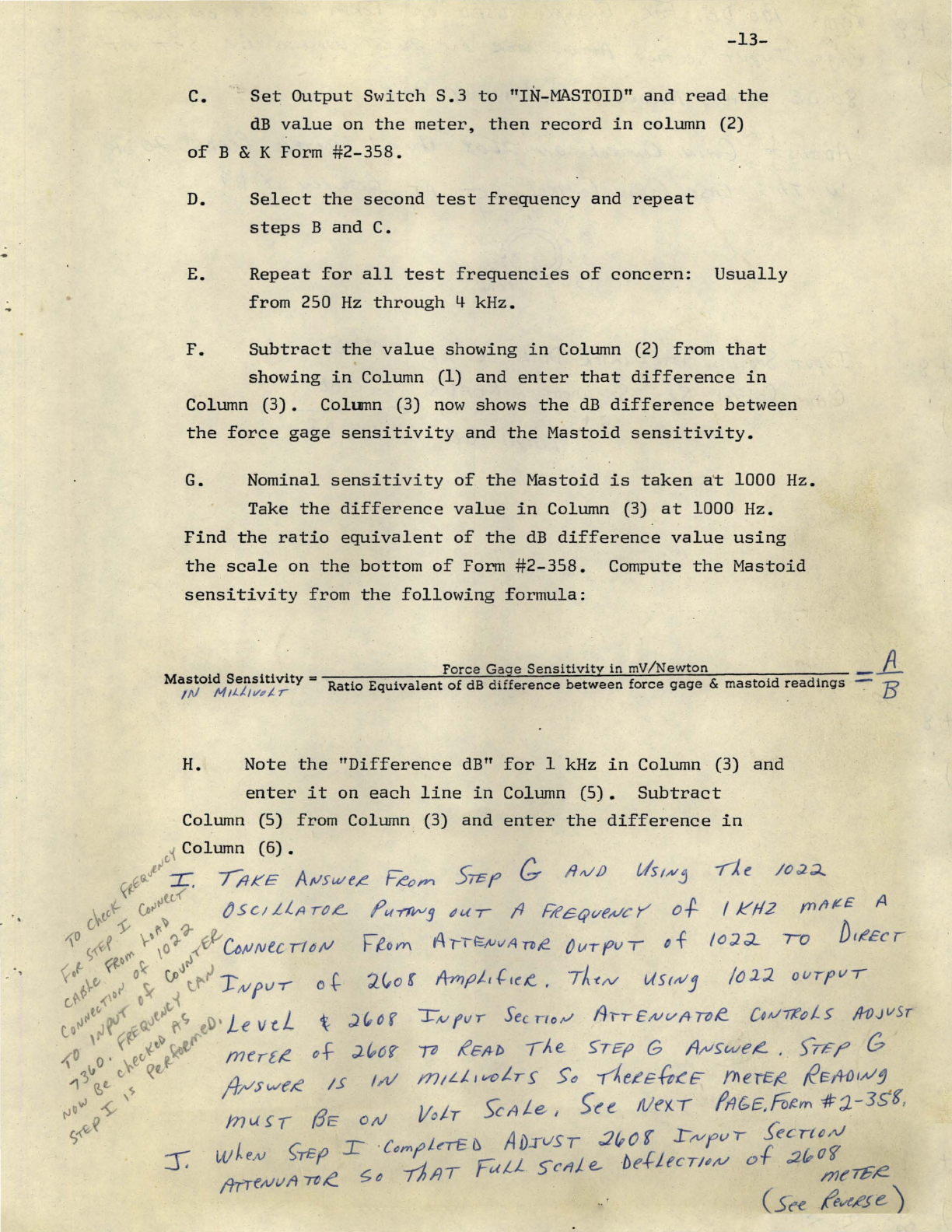

-13-

C.

Set

Output

Switch

S.3

to

"IN-MASTOID"

and

read

the

dB

value

on

the

meter,

then

record

in

column

(2)

of

B & K Form #

2-358.

D.

Select

the

second

test

frequency

and

repeat

steps

Band

C.

E.

Repeat

for

all

test

frequencies

of

concern:

Usually

from

250

Hz

through

4

kHz.

F.

Subtract

the

value

showing

in

Column (2)

from

that

showing

in

Column (1)

and

enter

that

difference

in

Column

(3).

Column (3)

now

shows

the

dB

difference

between

the

force

gage

sensitivity

and

the

Mastoid

sensitivity.

G.

Nominal

sensitivity

of

the

Mastoid

is

taken

a~

1000

Hz.

Take

the

difference

value

in

Column (3)

at

1000

Hz.

Find

the

ratio

equivalent

of

the

dB

difference

value

using

the

scale

on

the

bottom

of

Form

#2-358.

Compute

the

Mastoid

sensitivity

from

the

following

formula:

Force

Gage

Sensitivity

in

mV/Newton

_.A

Mastoid

Sensitivity

=

Ratio

Equivalent

of

dB

difference

between

force

gage

&

mastoid

r.

ead1ngs

-

7::?

/N

MIJ.tl

wl-

r V

H.

Note

the

"Difference

dB"

for

1 kHz

in

Column (3)

and

enter

it

on

each

line

in

Column

(5).

Subtract

::r.)

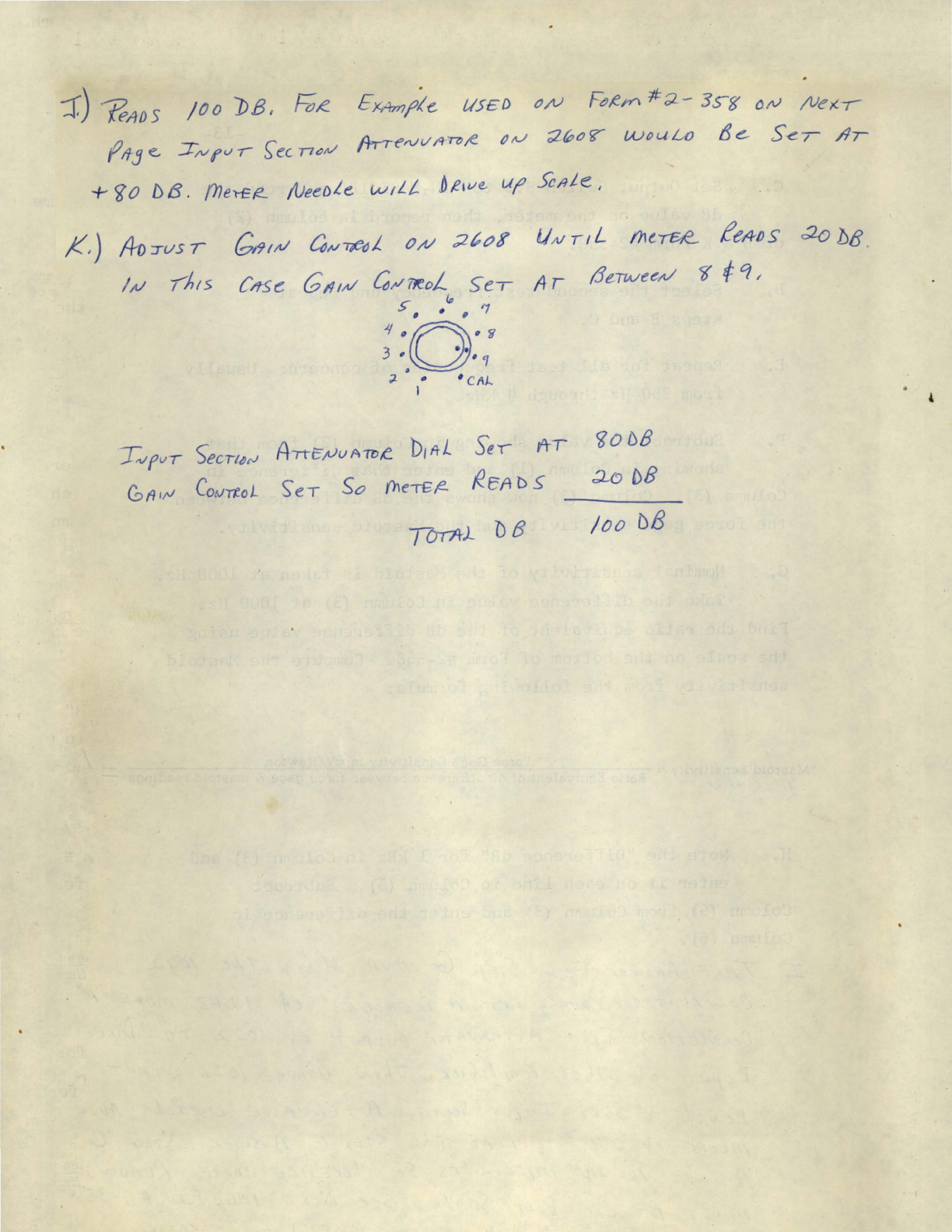

reA{)S

/tJO

PB

I

F;,e

Ex.4mjJle.

lIS£D

tJ/V

FCl,e;n

#;2-

3s-g

()N

/VeK-{

fll-Je

J"vrv-r

S;ecn",v {h--reN

l/fr'T7J/!.

()tt./

;2«:;olT

woufA)

te...

S-er

/1r

+

<60

/)

13.

(nen:F!-

NeeDLe

w/LL

.D

til/€-

uf1

Sc~Le

I

,1(,)

,40

'ILlS

T

T',vfvr

)ecT"tPrJ

Anc,.,vuAilI,e

b,A-L

Se,

frT

GfI,;J

CotJTtoL

S'eT

So

(heTEF?-

l!..eA

D S

/00

DB

..

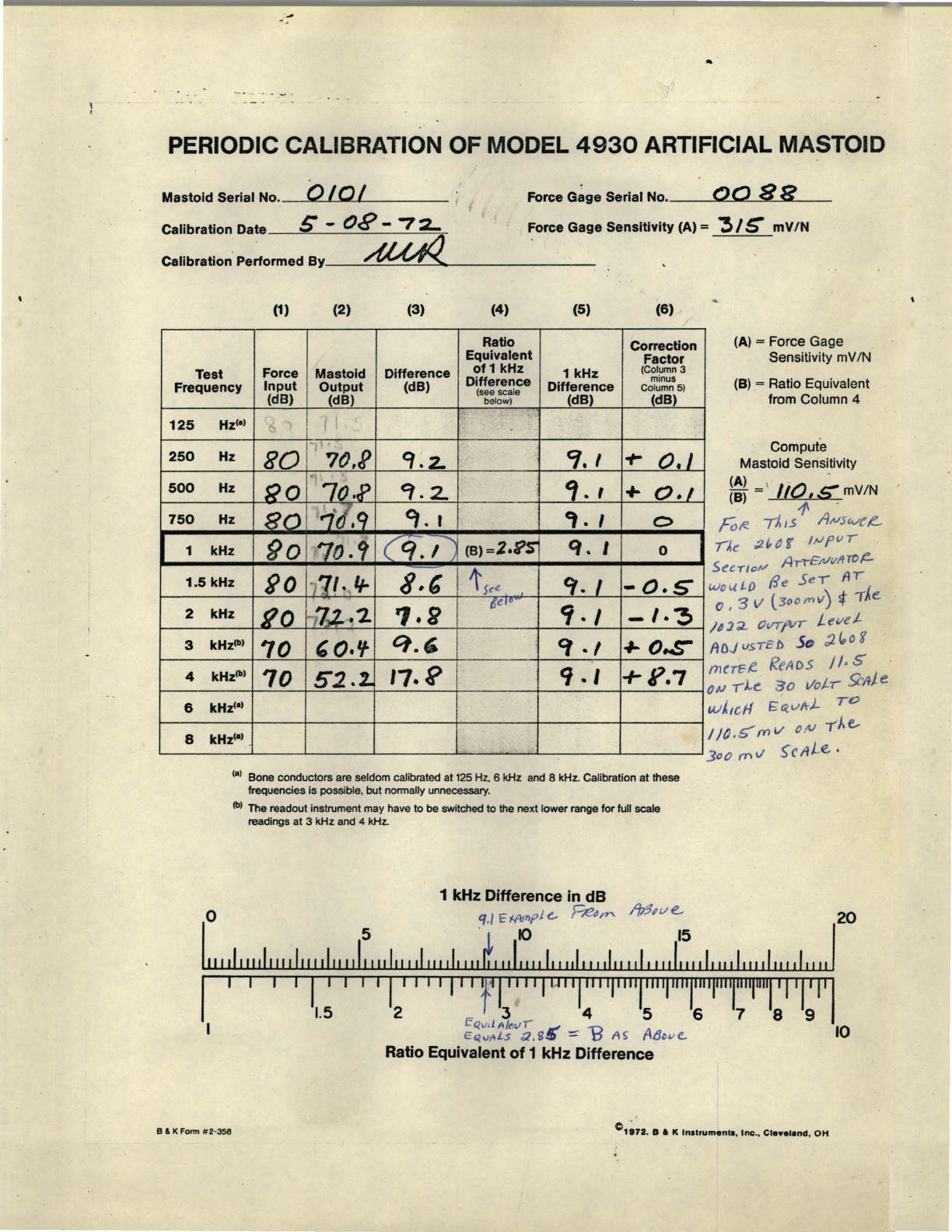

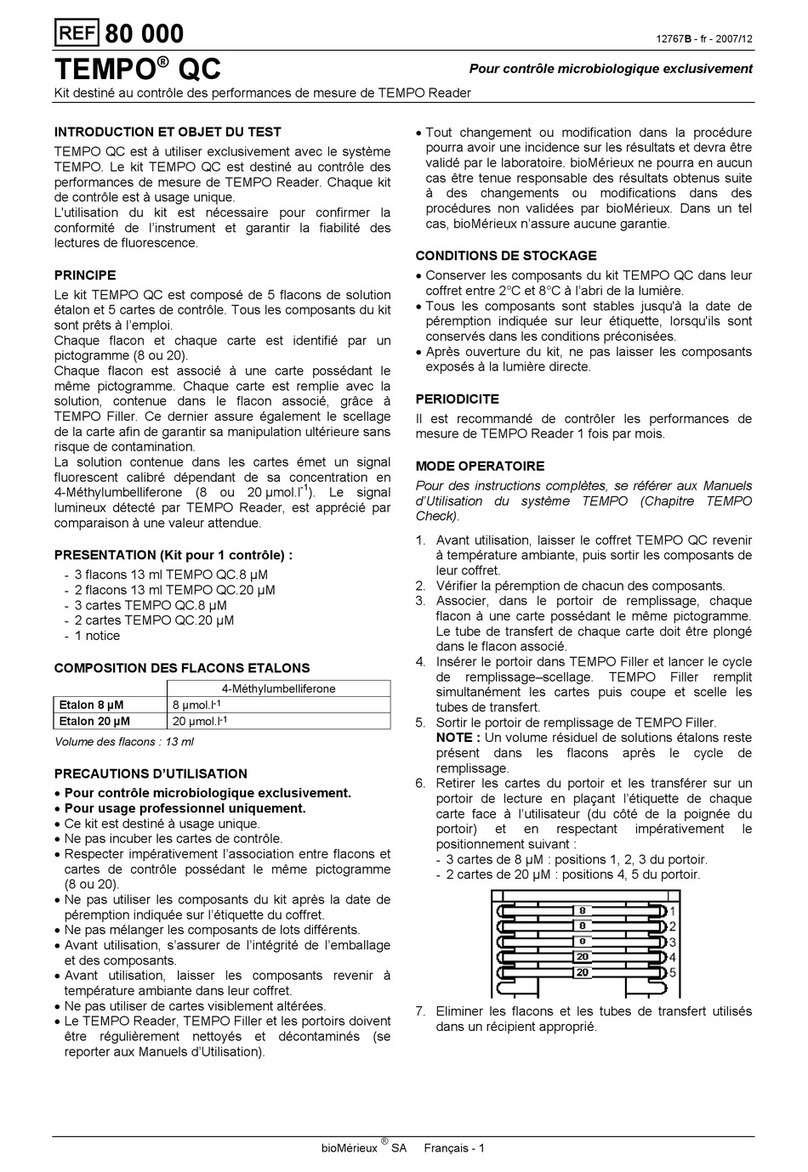

PERIODIC CALIBRATION OF MODEL

4930

ARTIFICIAL MASTOID

Mastoid

Serial No. 0

to

I Force

Gage

Serial No.

__

....!oo~o~~8~RL-_

Calibration

Date._~S-~----:()=---=e~------.:7~2...=.-

Force

Gage

Sensitivity

(A) =

:!>

I

S"

mV

IN

Calibration

Performed

By_---"AUA.'--='---=~__.30._

______

_

(1)

(2)

(3)

(4)

Ratio

Equivalent

Test

Force

Mastoid

Difference

of1

kHz

(5)

1 kHz

(6)

Correction

Factor

(Column 3

minus

(A) = Force Gage

Sensitivity mV/N

Frequency

Input

(dB)

Output

(dB) Difference

(see scale

Difference

Column 5)

(B)

= Ratio Equivalent

from Column 4

(dB) below) (dB) (dB)

125

Hz")

!)

"1

250

Hz

80

7(),R

'i.

2-

CJ.

, of-

0.

I Compute

Mastoid Sensitivity

500

Hz

(;0

'70.P

~.2.

CJ

• I +

0.1

750

Hz

80

"i

t.9

C}.

t

,.

, 0

(A) \ I 0 .

(

B)

= L,.s=mV/N

.

1"

Fote

TJ,

IS

AtUswel!.-

1 kHz

eO

70.9

(

q.,

""

(B)=2.n

q.

I 0

1.5

kHz

90

/

11.

Ir

8.'

t

5~<!C

Cf.

I

-O.S

IA~

:t(,tJ

1

IJJ!'v,

SU'r/o!o/

Arr£;t/I//Ht;~

Wol.(

Lf)

fie

SeT

AT

0,

3\1

(300J1'1V)

st

-rAe.

2

3

4

6

8

kHz

Ro

,-,

7,2..2-

'1.a

8

e1O

·

9·

I

-I.~

kHzlb)

70

, 0.'1

q.~

Cf

•,

~

O.s-

kHz'b)

70

52.%.

'7o~

<1

.,

+1?7

kHz")

kHz")

(.) Bone conductors are seldom calibrated at

125

Hz,

6 kHz and 8 kHz. Calibration at Itlese

frequencies

is

possible, but nonnally unnecessary.

(b) The readout instrument may have to

be

switched to the next lower range for full scale

readings at 3 kHz and 4 kHz.

1 kHz Difference in

dB

)4:1;1..

OVTfIIT

Lel/et

!toJ

V5Tcb 50

;J.

foo

8

m(TEI!.

ReADS /

/.

S" .

0'"

-rl-e

30

Vot,

YAle

v..J!.,cH

£

fRyltJ.-

TO

Ij().S'm

v o/V

-rAe,

300

(TIV

~cllLe,

o

'1./

'E

f.fIf7Ipi

t:.-

F,e4""

fb:1.w

e.,

20

I 5

.

~

~

~

I

11111111111111111111111111111111111111111111111111111111111111111111111111111111111111

I1111111111

," ,,,

I'

,r

'"

,,I0

",""1"

11

1""1""1""1"'1"

"1'''1'

1'1'

1'1

2 3 4

56789

EClv,lll/rllll

~

EQ.v!'tLs

<2,

g

:J)

:::

13

II

~

AtJtw

c.

10

Ratio Equivalent

of

1 kHz Difference

B & K Form #2·358

C1~72

.

B • K

Inllrumonll

, Inc

.•

Clne'.nd

,

OH

FORCE

MASi'D

J

ACCELERATION

RIO

5.8K

r--

I

S3A

RII

2.2K

RI2

6.BK

RI3

2.2K

+v

-v

+v

-v

\ -0 /

~--

S URCE

FO

LL

O

WE

RS

---.I

10K

UNITY GAIN ADJ.

---,

I

I

I '

I

I

I

I

FORCE

MASTOID

II

OUTPUT

Sw.

~

R20

33K

I

I

I

MASS

COMP

ADJ.

AT

IKH~

R21

8.2K

REVISIONS

BY

...

DESCRIP'TION

AP'I"ROVAL

A I REDRAWN

R23

+15V

+V

58

I~~t

GND

0

~

=b-

CI7

/'

• V

-15V

68

NOTES'.

I.ALL

RE

SISTORS

IN

OHMS

UNLE

SPECIFIED.

2.ALL

CAPACITORS

IN

MICROFARAD

S

UNLESS

SPECIFIED.

3. S

WITCH

S3

SHOWN

IN

FORCE

POSITION.

(13

METER

+~~

3~t~f

1"

'-'-

...

-

...

-/,"

.

--

SCALI:

•.

0·1

8-0 98

TITLE

"-S

UMMING

AM

P-.l

1

S:

HEM

ATIC

PR

E-AMP

MOG

EL

23

0 B & K INSTRUMENTS,

INC.

CLEVELAND.

OHIO

~1.2

SIZE'

DRAWING

NUMSER

I

CHECK

eD "

.•

:' •

..

'. '

DAn

~

41i

'

!f

l e I 16

02

REVISIONS

SYM I

DESCRIPTION

I

DATE

I

APPROVAL

I

I

r

-L

_

01

11

~

J2:

P2

2ooo~;T

J-

_

;;~

;>

r>1

-'-

-.

:

"-

04

.

, NOTE:

I.ALL

RESISTORS IN

OHMS

UNLESS

SPECIFIED

.

2.ALL

CAPACITOR S IN MICROFARADS

UN

LES

S SPECIFIED.

R2

820

1+

(

C2

-

L.:.

2000Uf

'02

VALID FROM SiN

103

SCALE

TITLE

NEXT

ASS'Y

±!5V

PO

WER SUPPLY

M

OD

E L

230

5.0·1

8

-098

B & K

INSTRUMENTS,

INC.

CLEVELAND,

OHIO

44142

IbOI

DATE

3-24-

72.

I

SIZE

I

DRAWING

NUMBER

tiSSUE

CHECKED

./,

' .'

.

:~

/

":"

DATE

~

/)

~r

·

.....

/;;

IA

APPROVED

l\;

()

DATE

:J

-I

~

) "

/ '2

Table of contents

Other B&K Test Equipment manuals

Popular Test Equipment manuals by other brands

POSITECTOR

POSITECTOR RTR manual

Agilent Technologies

Agilent Technologies E4406A VSA Series Programmer's guide

Keysight Technologies

Keysight Technologies 16048G Operation and service manual

Alfa Network

Alfa Network Color Tester Technical manual

bioMerieux

bioMerieux TEMPO QC quick start guide

Bacharach

Bacharach PUR-CHEK Operation and maintenance guide