Contents

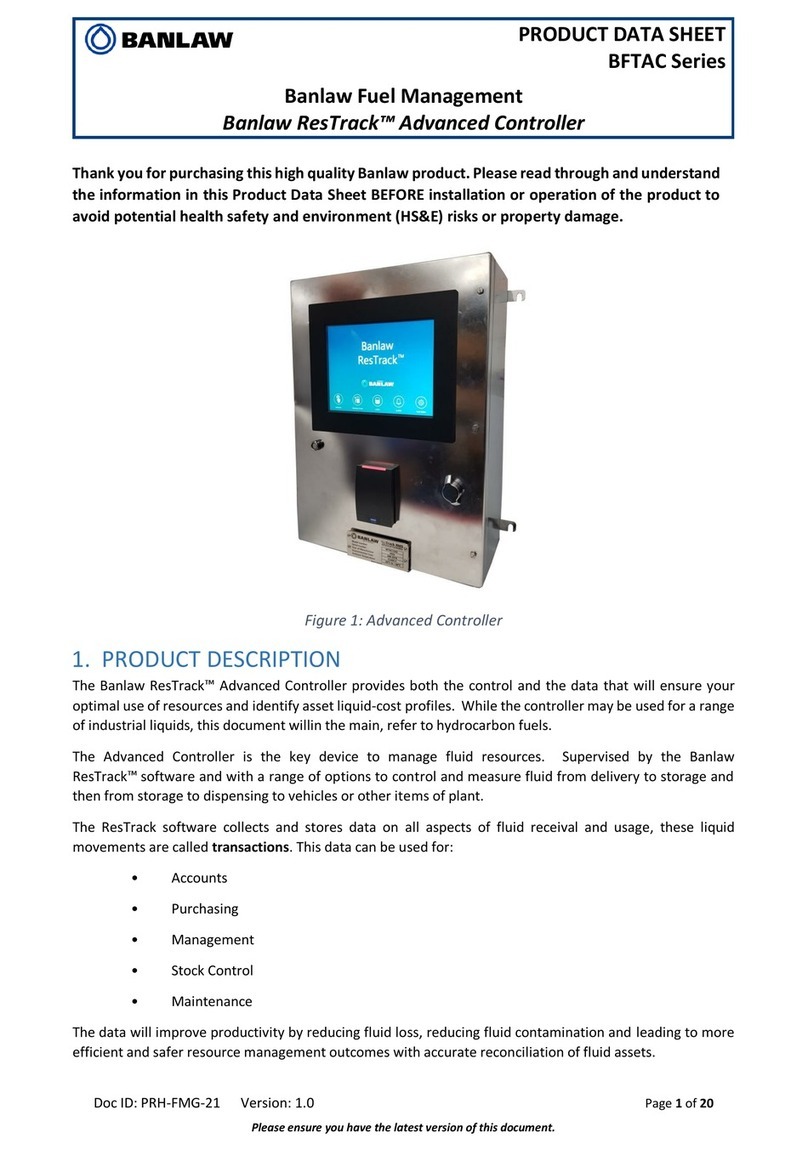

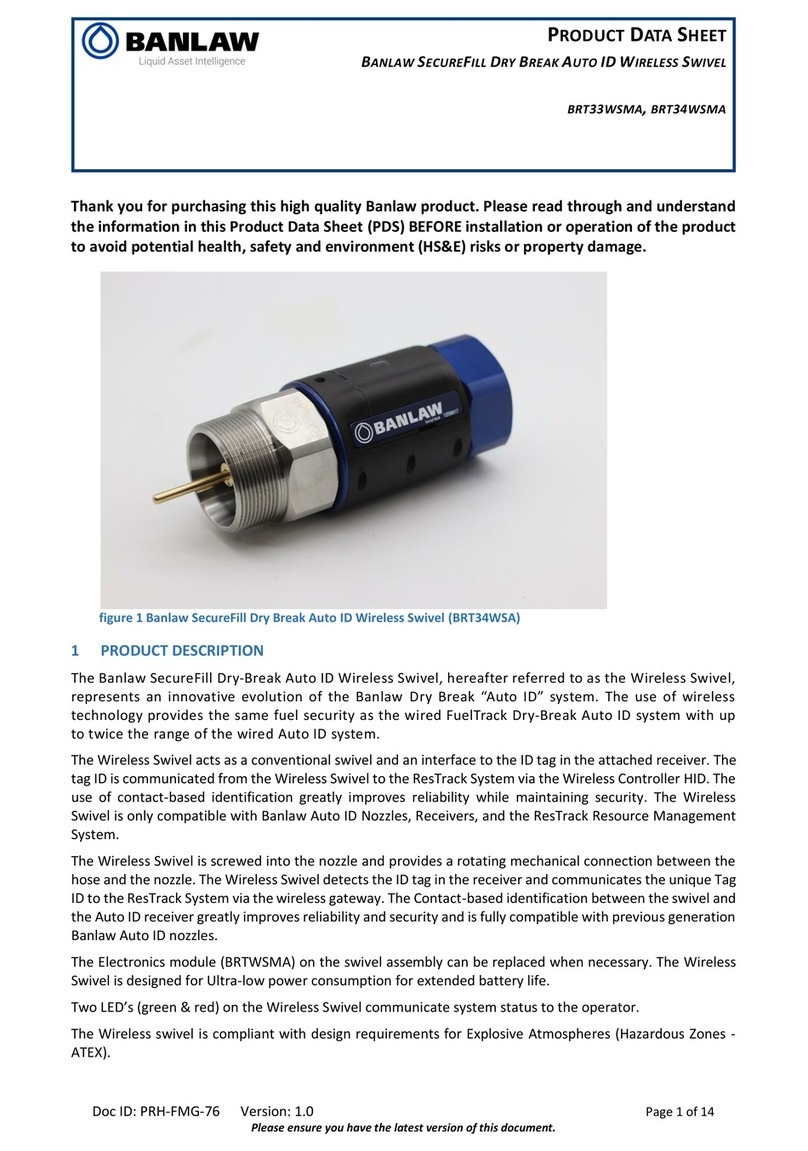

1PRODUCT DESCRIPTION..............................................................................................................................................................................1

1.1 Glossary of Terms ....................................................................................................................................................................................3

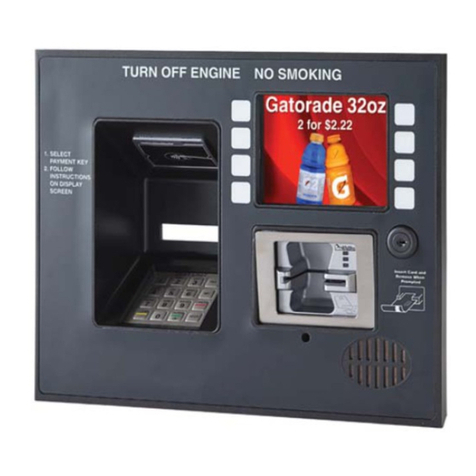

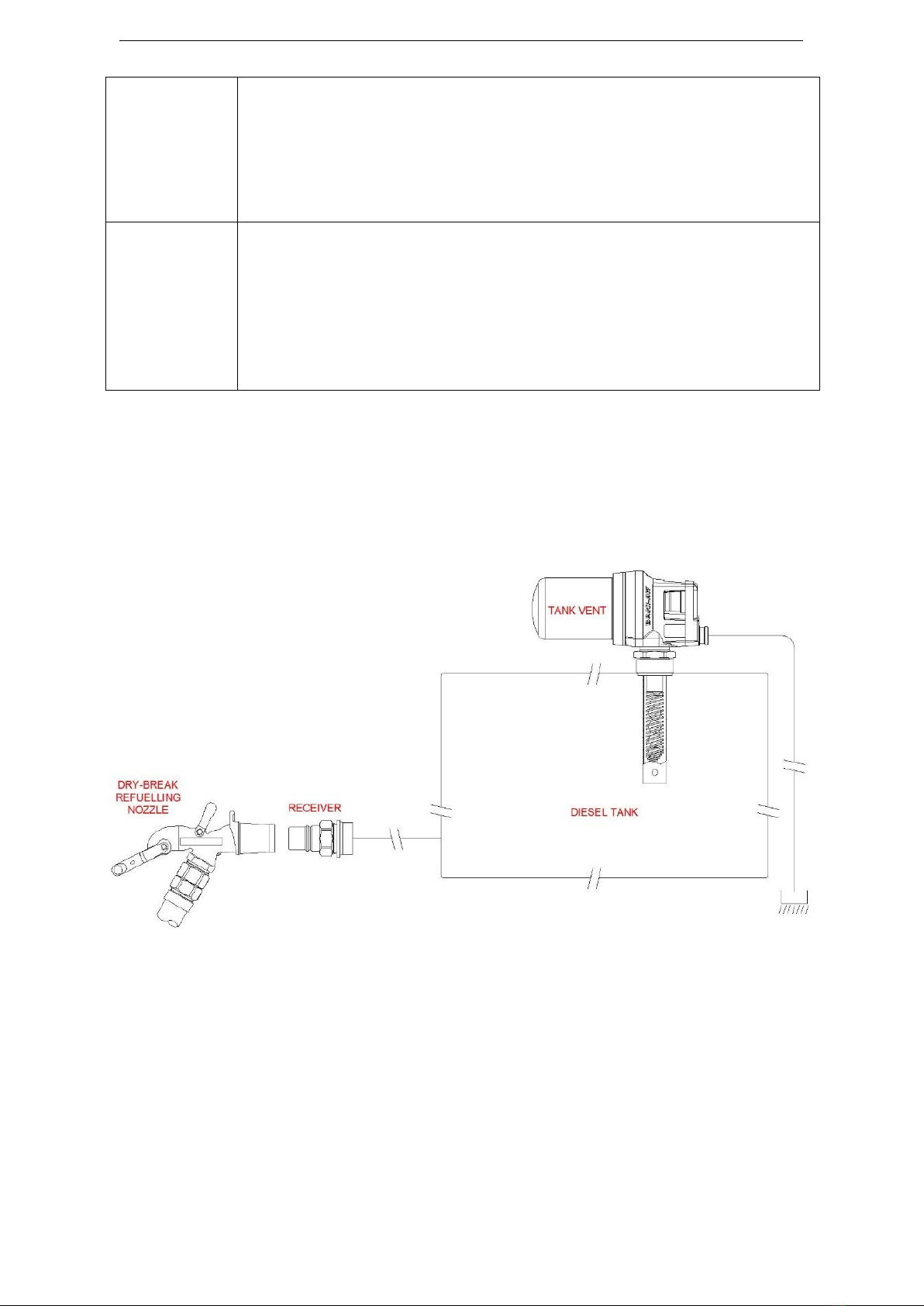

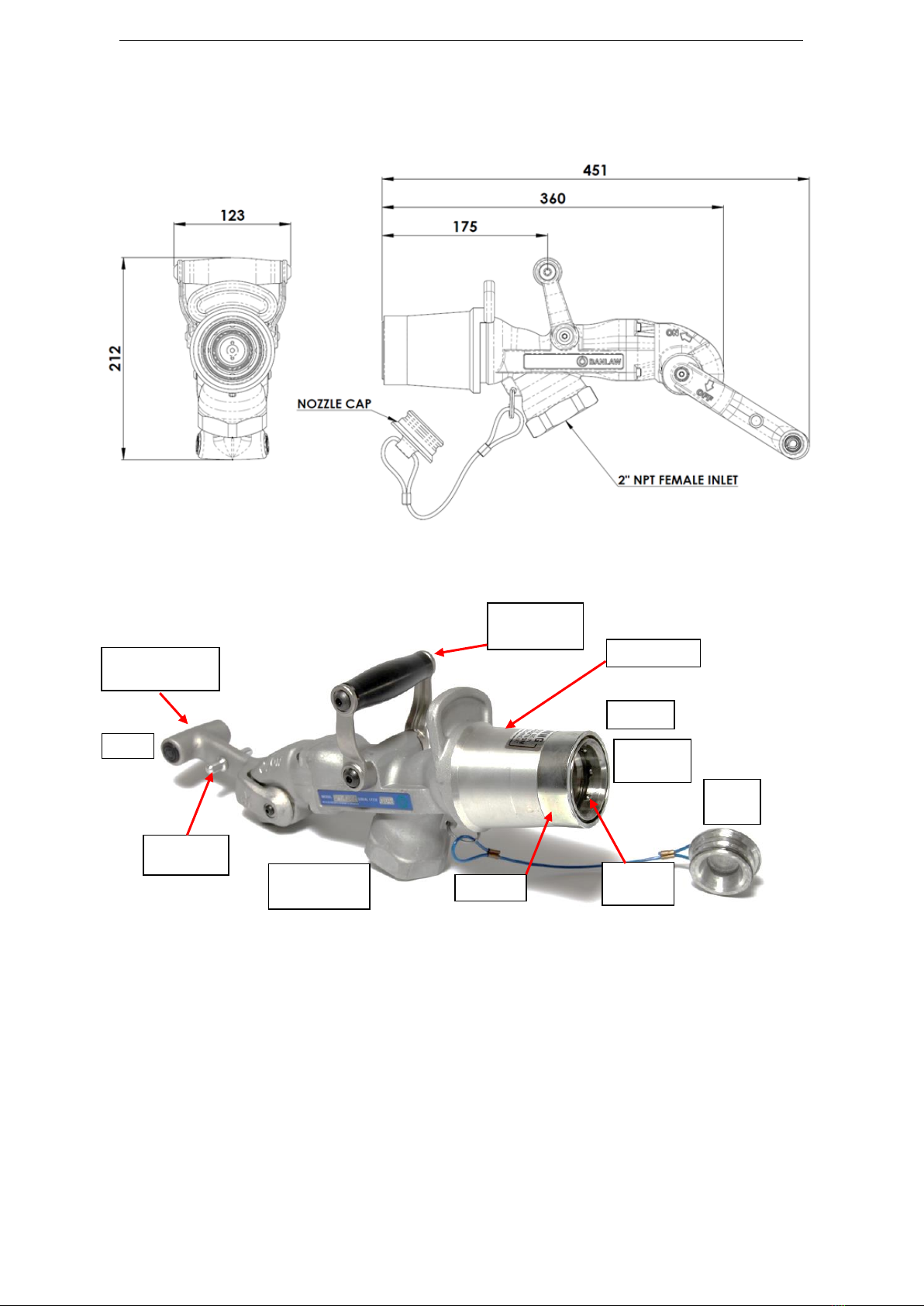

1.2 System Overview .....................................................................................................................................................................................4

1.3 Key Features.............................................................................................................................................................................................5

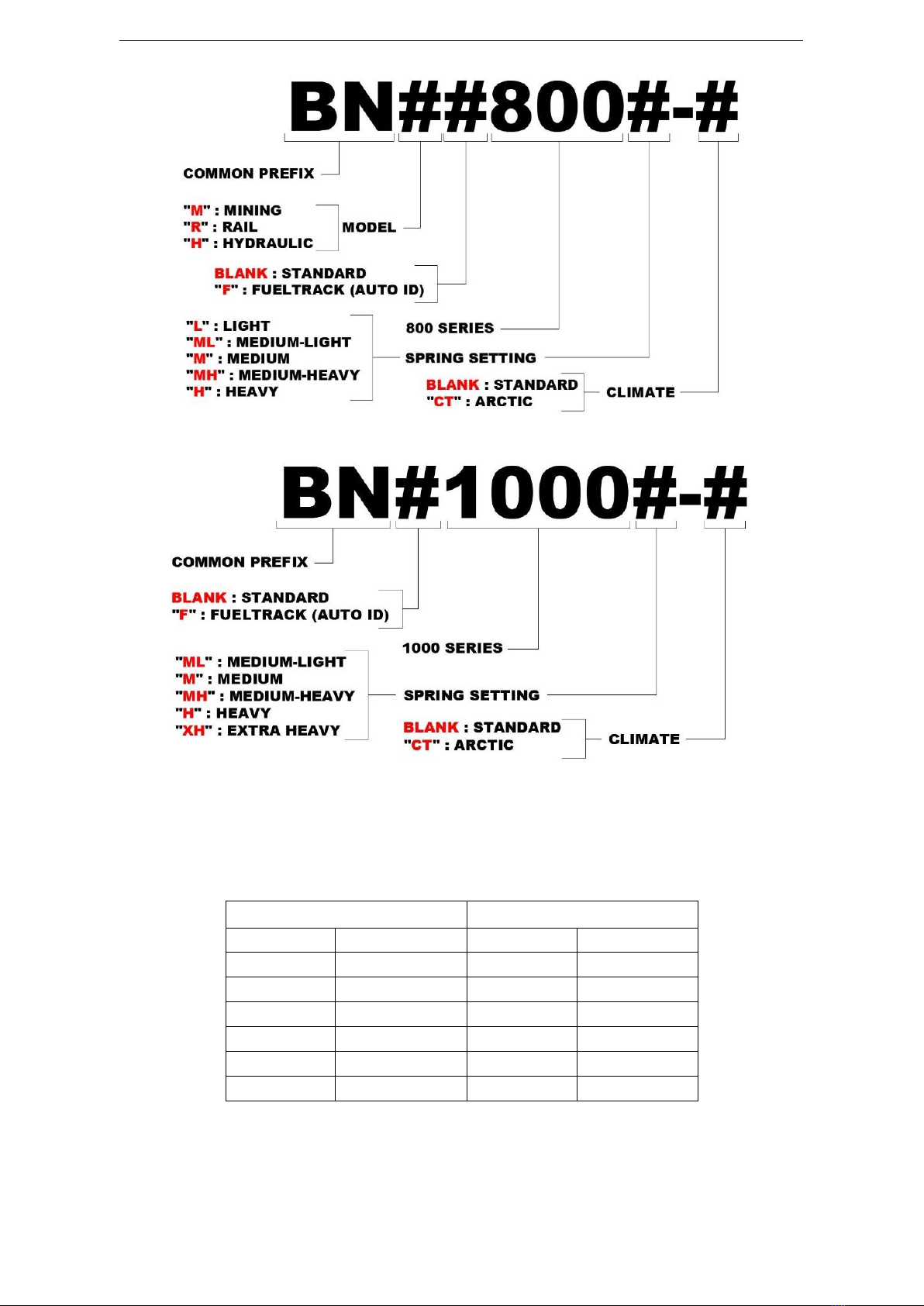

1.4 Part Numbering........................................................................................................................................................................................ 6

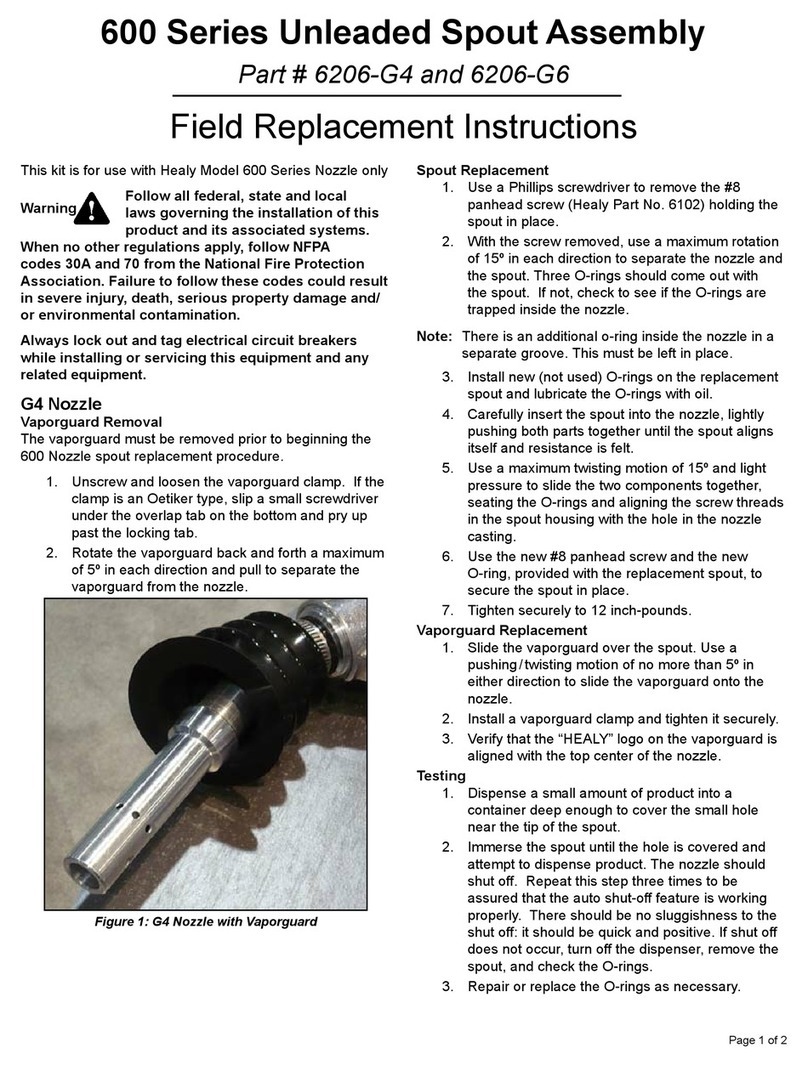

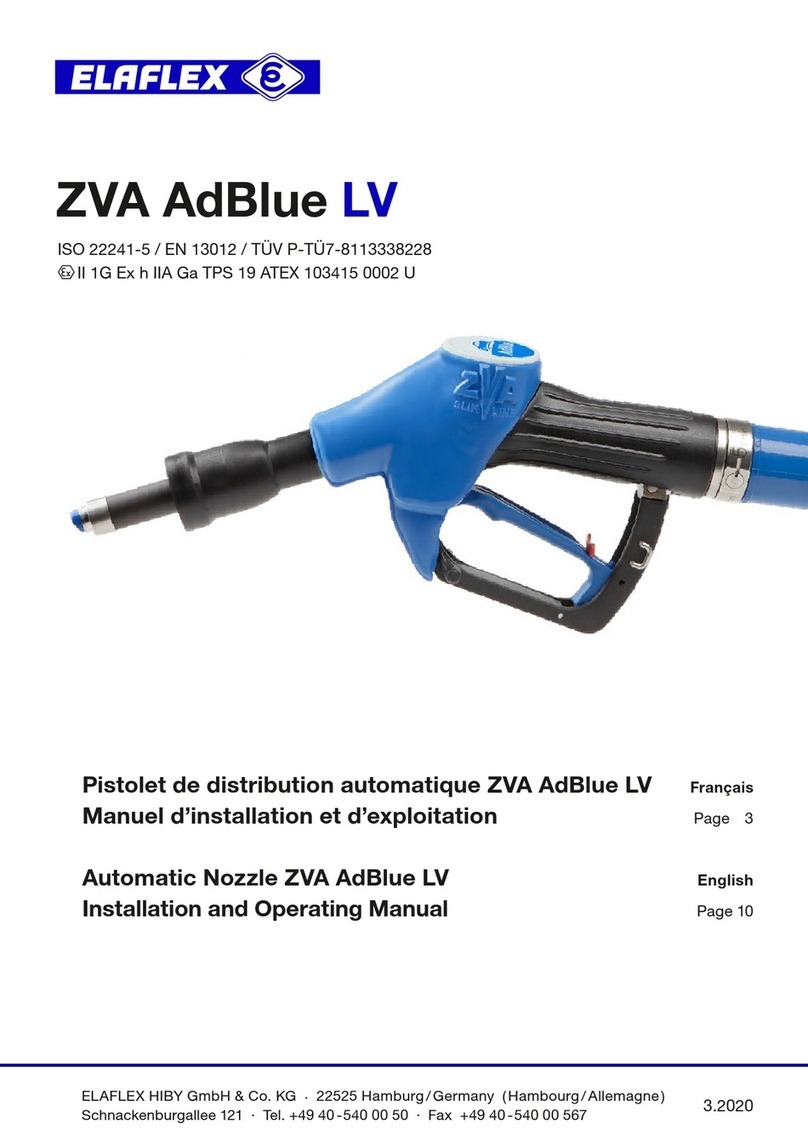

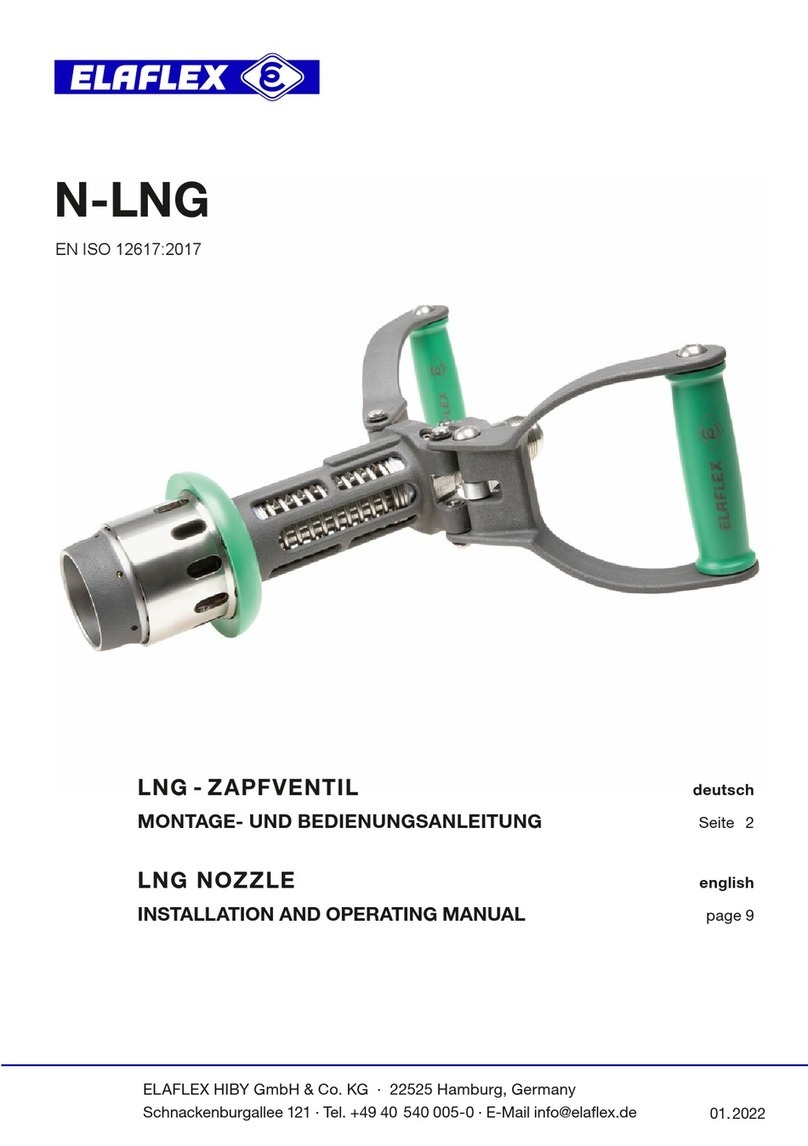

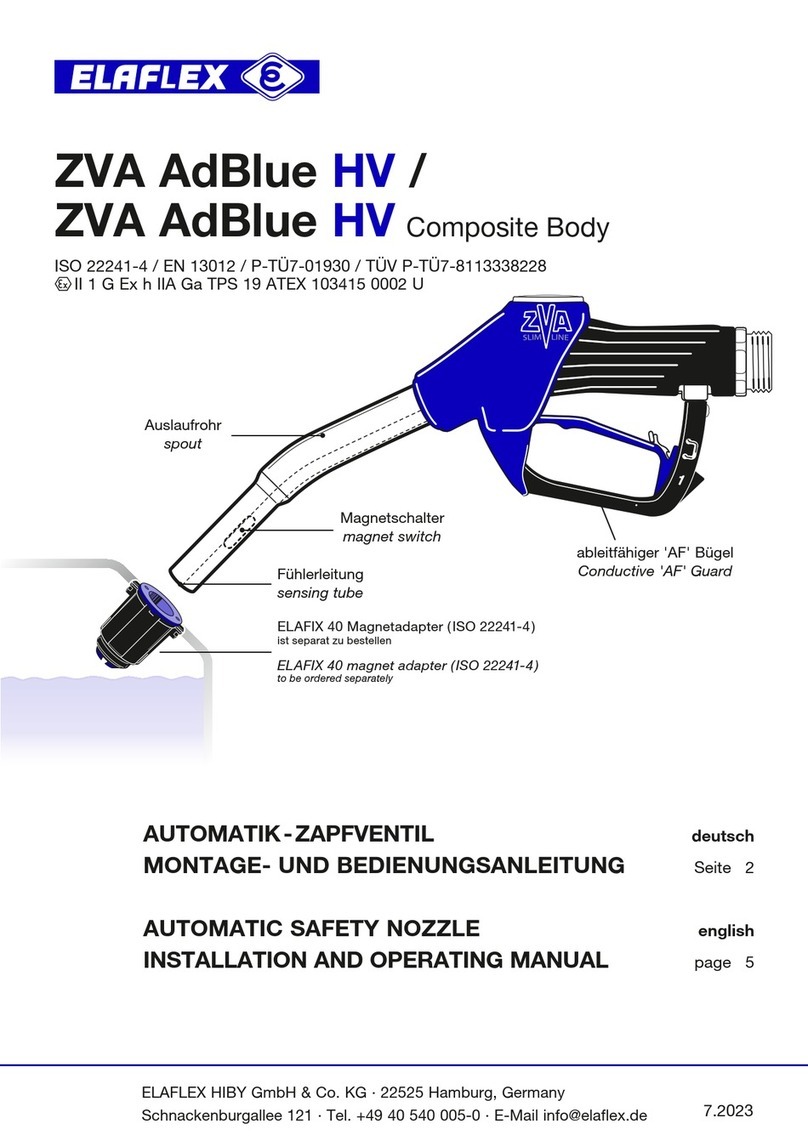

1.5 Available Nozzle Models.......................................................................................................................................................................... 7

1.6 Nozzle Spring Settings.............................................................................................................................................................................. 8

1.7 FuelTrack Nozzle Variants...................................................................................................................................................................... 10

1.8 Nozzle and Receiver Compatibility ........................................................................................................................................................ 11

2IMPORTANT RESTRICTIONS ON THE USE OF THIS PRODUCT...................................................................................................................12

3PRODUCT SPECIFICATIONS .......................................................................................................................................................................13

3.1 Nozzle Flow Performance...................................................................................................................................................................... 14

4INSTALLATION & COMMISSIONING GUIDELINES .....................................................................................................................................15

4.1 Pre-Installation Guidelines..................................................................................................................................................................... 15

4.1.1 Nozzle –Ergonomics....................................................................................................................................................................16

4.1.2 Nozzle –Storage..........................................................................................................................................................................18

4.2 Installation Guidelines ........................................................................................................................................................................... 19

4.2.1 Banlaw FuelTrack Nozzles ...........................................................................................................................................................20

4.3 Commissioning Guidelines..................................................................................................................................................................... 21

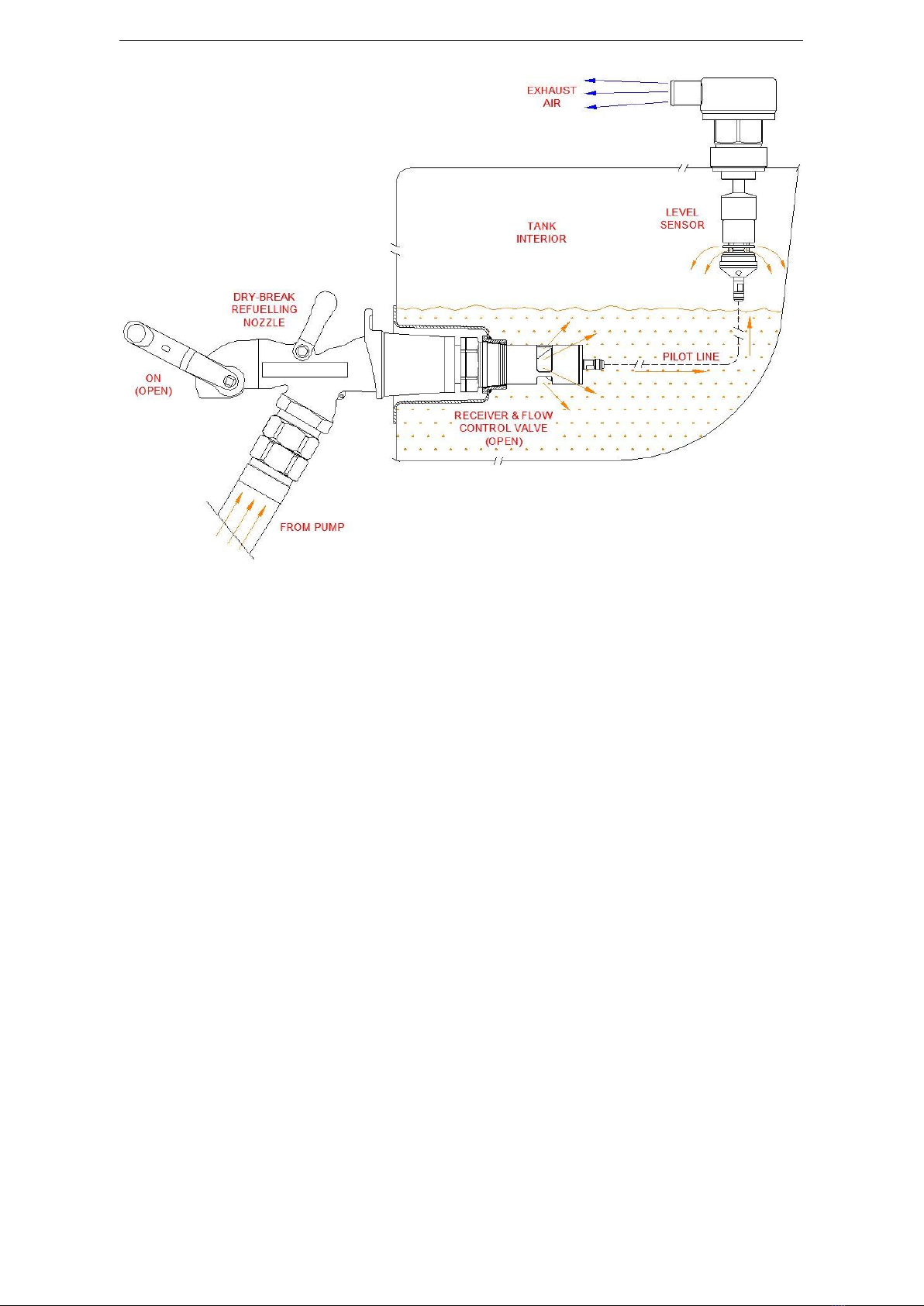

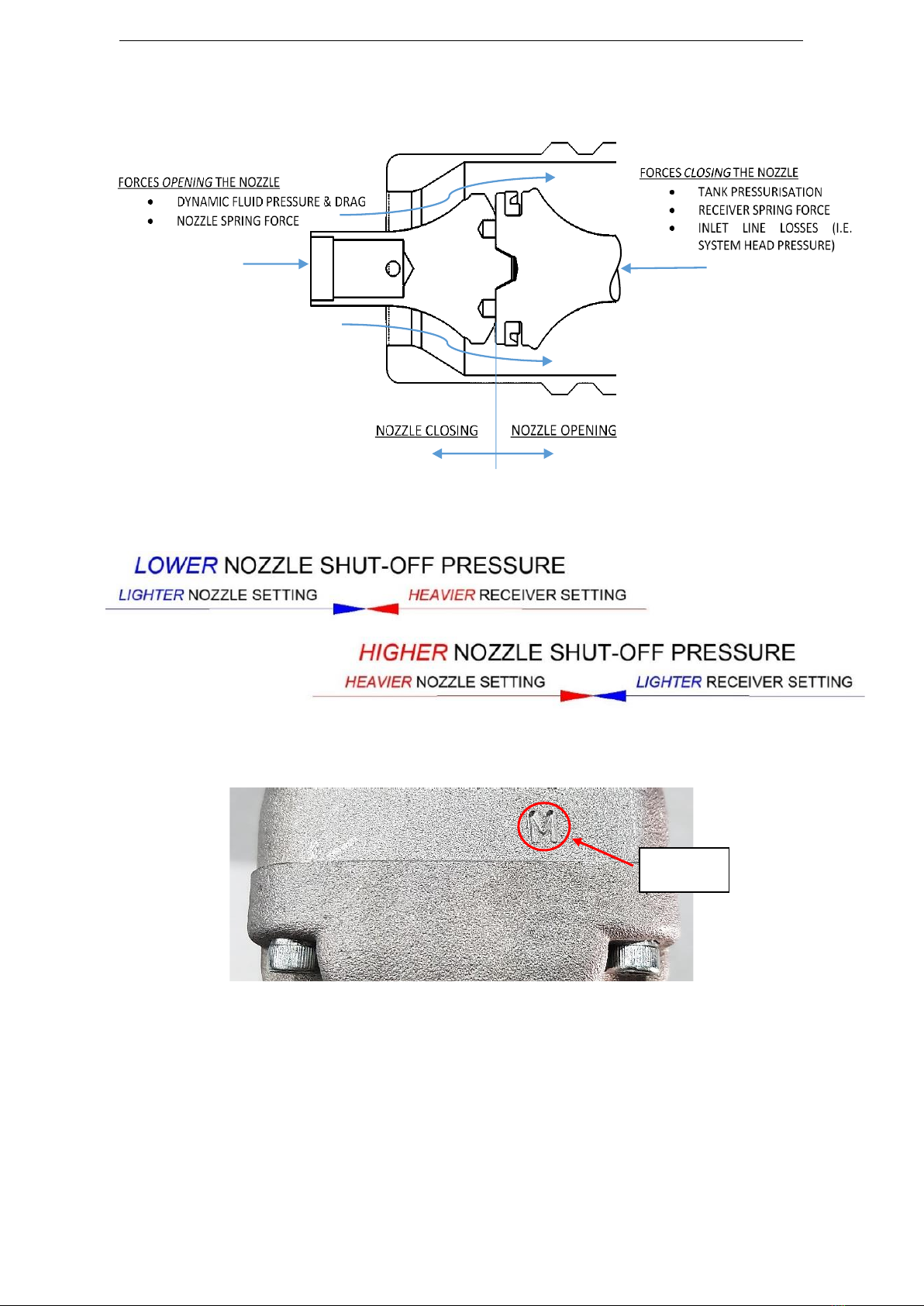

5PRINCIPLES OF OPERATION ......................................................................................................................................................................21

6MAINTENANCE & SPARE PARTS................................................................................................................................................................26

6.1 Preventative Maintenance .................................................................................................................................................................... 26

6.2 Banlaw Onsite Maintenance..................................................................................................................................................................28

7TROUBLESHOOTING..................................................................................................................................................................................29

8PRODUCT RECYCLING & DISPOSAL...........................................................................................................................................................31

9PRODUCT WARRANTY...............................................................................................................................................................................31