Computer Programs and Documentation

All Gilbarco Inc. computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gilbarco

Inc. Such computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gilbarco Inc.

Federal Communications Commission (FCC) Warning

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modifications not expressly

approved by the manufacturer could void the users authority to operate this equipment.

Approvals

Patents

Gilbarco Inc. products are manufactured or sold under one or more of the following US patents:

Dispensers

Point of Sale/Back Office Equipment

Trademarks

4,566,504 4,556,927 4,570,686 4,687,033 4,728,788 4,748,846 4,799,940 4,805,453 4,876,653 4,890,210 4,913,813 4,930,655 4,934,565 4,938,054

4,938,251 4,939,730 4,967,366 4,986,445 5,040,577 5,098,179 5,134,548 5,156,199 5,269,353 5,228,084 5,325,706 5,345,979 5,355,915 5,363,988

5,384,850 5,407,115 5,417,256 5,448,638 5,450,883 5,464,466 5,501,246 5,535,130 5,542,458 5,543,849 5,546,981 5,557,084 5,571,310 5,602,745

5,626,649 5,630,528 5,708,580 5,719,779 5,719,781 5,720,325 5,724,067 5,734,851 5,755,854 5,782,275 5,794,667 5,798,931 5,803,136 5,843,212

5,857,500 5,868,179 5,871,651 5,890,520 5,954,080 5,956,259 5,969,691 5,971,042 5,979,705 5,980,090 6,026,866 6,052,629 6,073,840 6,078,888

6,078,896 6,082,415 6,085,775 6,087,954 6,089,284 6,092,410 6,098,879 6,102,085 6,109,477 6,112,134 6,113,039 6,116,505 6,119,110 6,123,118

6,149,033 6,167,923 6,176,421 6,184,846 6,185,307 6,185,893 6,196,065 6,227,227 6,244,310 6,250,151 6,253,779 6,263,319 6,275,746 6,296,148

6,302,165 6,313,737 6,325,112 6,326,934 6,336,479 6,338,369 6,347,649 6,352,176 6,357,493 6,360,137 6,363,299 6,364,206 6,380,853 6,381,514

6,386,246 6,418,983 6,421,616 6,422,464 6,431,226 6,438,452 6,460,579 6,463,389 6,466,842 6,470,233 6,493,440 6,499,516 6,505,134 6,522,947

6,523,744 6,529,800 6,532,999 6,535,726 6,546,882 6,571,151 6,571,201 6,573,884 6,574,603 6,578,145 6,618,362 6,644,360 6,681,814 6,685,089

6,690,275 6,697,705 6,704,774 6,708,797 6,710,701 6,712,101 6,721,669 6,736,313 6,741,909 6,745,104 6,761,190 6,763,974 6,766,949 RE35,238

D262,971 D265,092 D306,719 D309,144 D316,471 D413,124 D413,311 D413,336 D413,337 D413,610 D413,901 D413,902 D414,192 D414,501

D414,778 D414,779 D414,780 D414,781 D414,782 D415,166 D415,167 D415,168 D415,169 D415,170 D415,171 D415,172 D415,501 D415,777

D416,915 D416,916 D417,226 D418,523 D420,684 D421,612 D422,285 D422,604 D426,555 D428,424 D428,897 D429,739 D429,740 D431,039

D431,252 D431,573 D432,140 D432,141 D432,548 D432,552 D433,031 D433,032 D433,033 D433,034 D433,035 D433,036 D433,037 D433,420

D433,421 D433,422 D433,423 D433,424 D433,685 D433,686 D433,687 D433,688 D434,424 D434,780 D435,051 D440,579 D443,624 D456,820

D457,084

4,967,366 5,228,084 5,448,638 5,798,931 5,980,090 5,708,580 5,719,779 5,719,781 5,724,067 5,734,851 6,073,840 6,078,888 6,116,505 6,185,307

6,263,319 6,275,746 6,326,934 6,360,137 6,363,299 6,364,206

Gilbarco is an ISO 9001:2000 registered company.

Underwriters Laboratories (UL):

U L File# Products listed with U L

MH1941 All Gilbarco pumps and dispensers that bear

the UL listing mark.

MH8467 Transac System 1000 and PAM 1000

E105106 Dell DHM Minitower

E165027 G-SITE and Passport Systems

National Conference of Weights and Measures (NCWM) - Certificate of Compliance (CoC):

Gilbarco pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model # CoC# Product Model #

02-019 Eclipse Exx 02-026 H111B Series AC, RAC 02-034 External Mount CRIND CECXXXXXXX

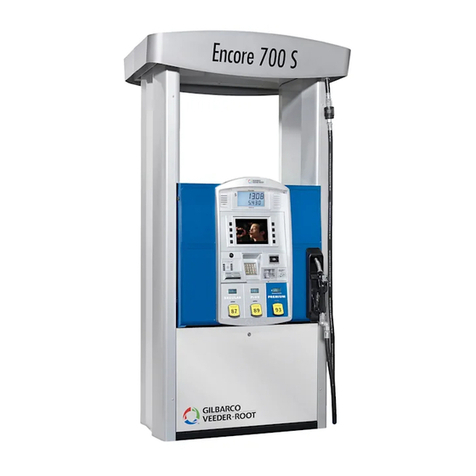

02-020 Encore Nxx

02-027

MPD-1 Series AN, RAN 02-035 Dimension Dxx

02-021 T-12C Console PA0188, RA0188 Fixed Blender AF, RAF, AG,

RAG 02-036 Legacy Jxxx

T-12C Console PA0203, RA0203 Dispenser - Low Profile AR, RAR

02-037

G-SITE Printer (Epson) PA0307

02-022 T-12G Console PA0180, RA0180 02-028 Indoor Card Q11640 G-SITE Distribution Box PA0306

02-023

T-15 Console PA0189 Outdoor Card Q11891 G-SITE Keyboard PA0304

T-15 Controller C2 PA0211 02-029 CRIND G-SITE Mini Tower PA0301

T-15 Controller PA0190

02-030

TS-1000 Console PA0240 G-SITE Monitor PA0303

02-024

ProBlender AU, RAU TS-1000 Controller PA0241 G-SITE Printer (Citizen) PA0308

Precision Blender AE, RAE Distribution Box PA0242 02-038 C+ Meter T19976

Dispenser - Standard AK, RAK Micro-T Console PA0250 02-039 Passport PA0324

Dispenser - Low Profile AL, RAL Meter - EC Series PA024EC10 02-040 Ecometer T20453

Fixed Blender AP, RAF VaporVac Kits CV

02-025 Meter - C Series PA024NC10 02-031 The Advantage Series Bxx, RBxx

Meter - C Series PA024TC10 02-032 Trimline Series AA, RAA

Salesmaker ProBlender AB, RAB 02-033 Meter - C Series PA024XC10

99-165 Salesmaker Series 2/2H/4/4A AM MPD-A3 Series AD, RAD

New York City Fire Department (NYFD):

NYFD C of A # Product

4805 The Advantage Series and

Legacy Series

4986 Encore and Eclipse

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

Registered trademarks

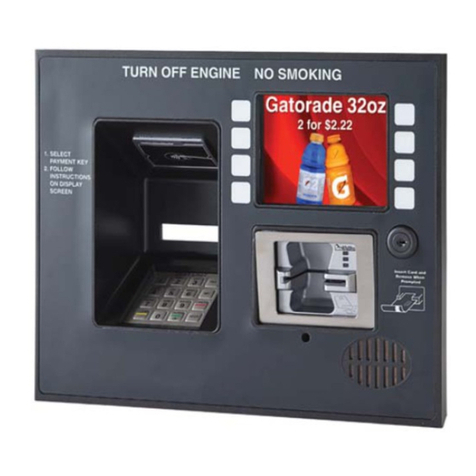

CRIND®InfoScreen®Transac® System 1000

Dimension® Series Legacy®Trimline®

e-CRIND®Making Things Better®TRIND®

Eclipse®MPD®VaporVac®

Encore®Passport®

G-SITE®Performer®

Gilbarco®The Advantage® Series

GOLD®Transac®

Additional US and foreign trademarks pending.

Other brand or product names shown may be

trademarks or registered trademarks of their

respective holders.

Non-registered trademarks

C-PAMHighlineSMART Meter

CIMMultiLineSmartPad

ECROptimum Series Surge Management System

EMCPAM 1000 Tank Monitor

G-CATPAMTCR

GilbertSMART ConnectUltra-Hi

G-SITE® LinkSMART CRINDValueLine

G-SITE® LiteSMART Merchandising

This document is subject to change without notice. · For information regarding Gilbarco Inc. Literature, call (336) 547-5661

E-mail: literature@gilbarco.com · Internet: http://www.gilbarco.com

2006 Gilbarco Inc. · All Rights Reserved

Additional US and foreign patents pending.