BANLAW ResTrack BFTAC Series User manual

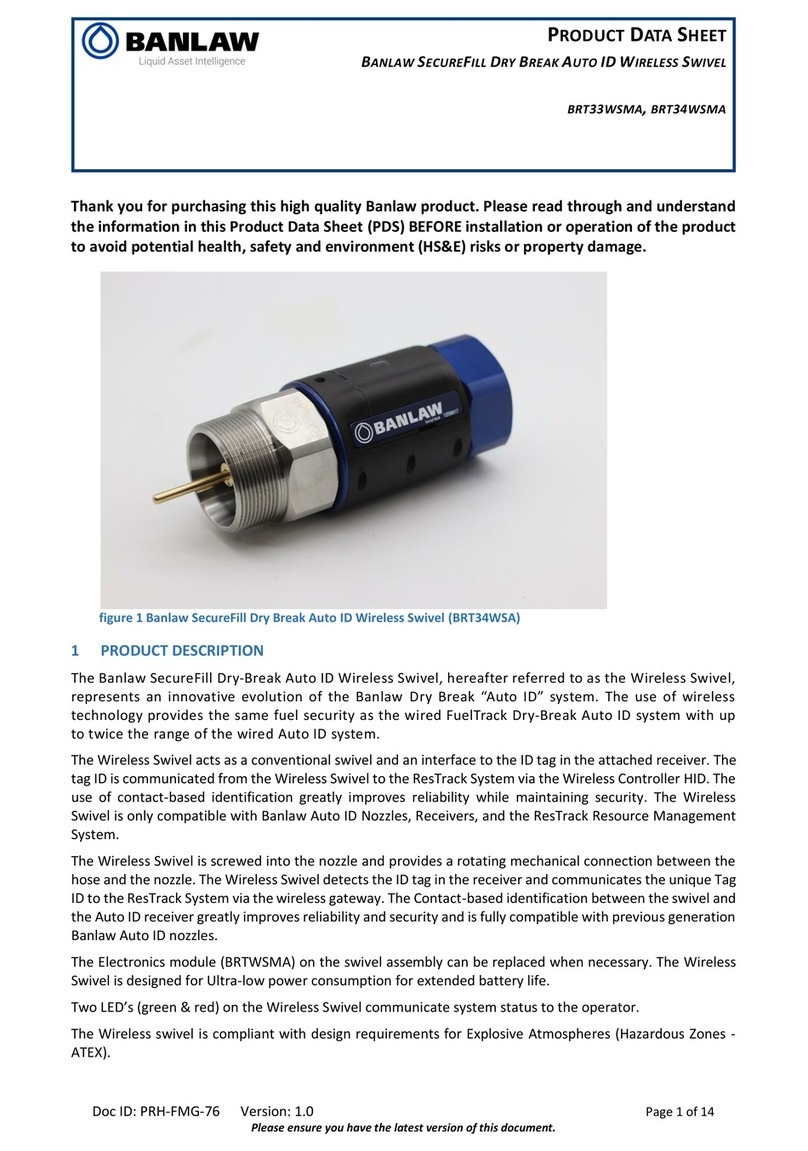

Other BANLAW Petrol Station Equipment manuals

Popular Petrol Station Equipment manuals by other brands

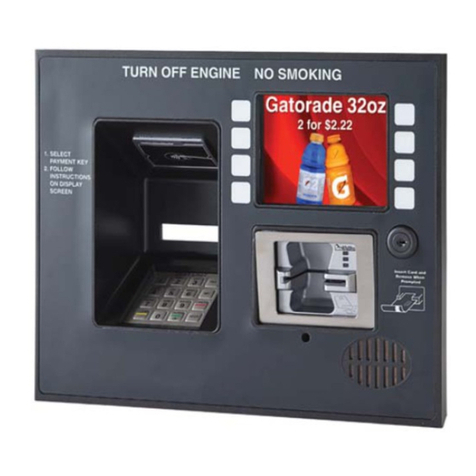

GILBARCO VEEDER-ROOT

GILBARCO VEEDER-ROOT FlexPay IV CRIND Advantage Series installation instructions

Tokheim

Tokheim Quantium 310 Maintenance manual

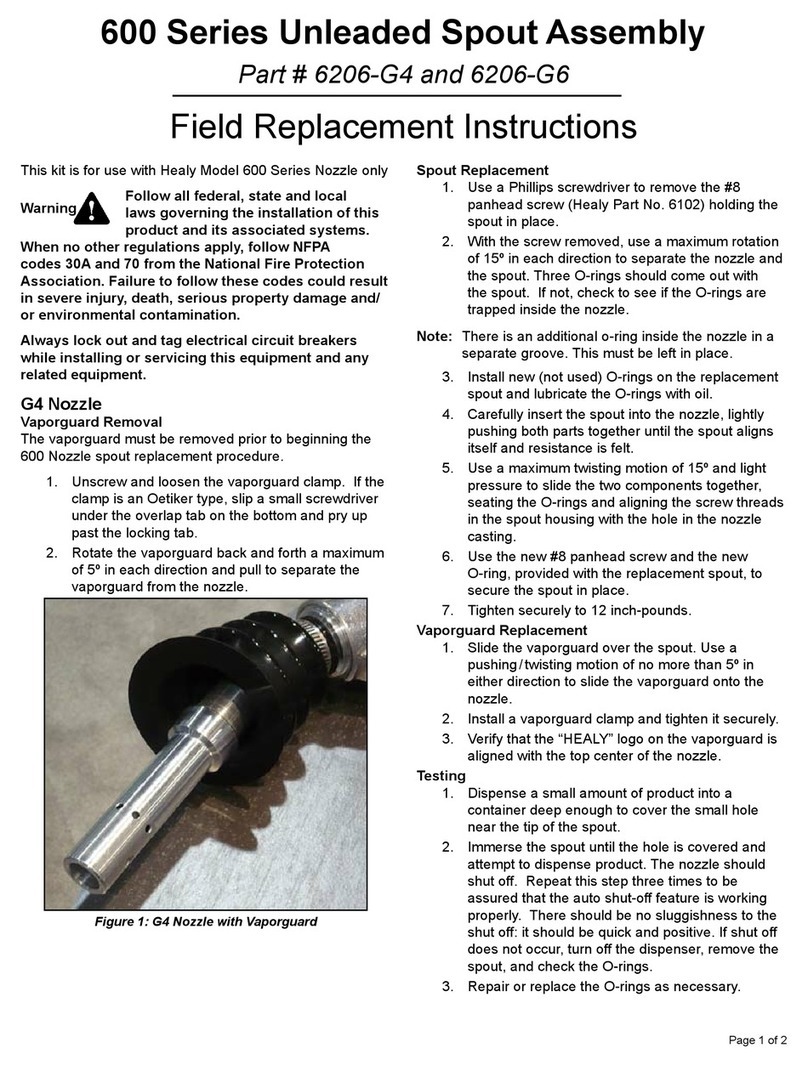

Franklin Fueling Systems

Franklin Fueling Systems 600 Series Field Replacement Instructions

Tokheim

Tokheim TQM manual

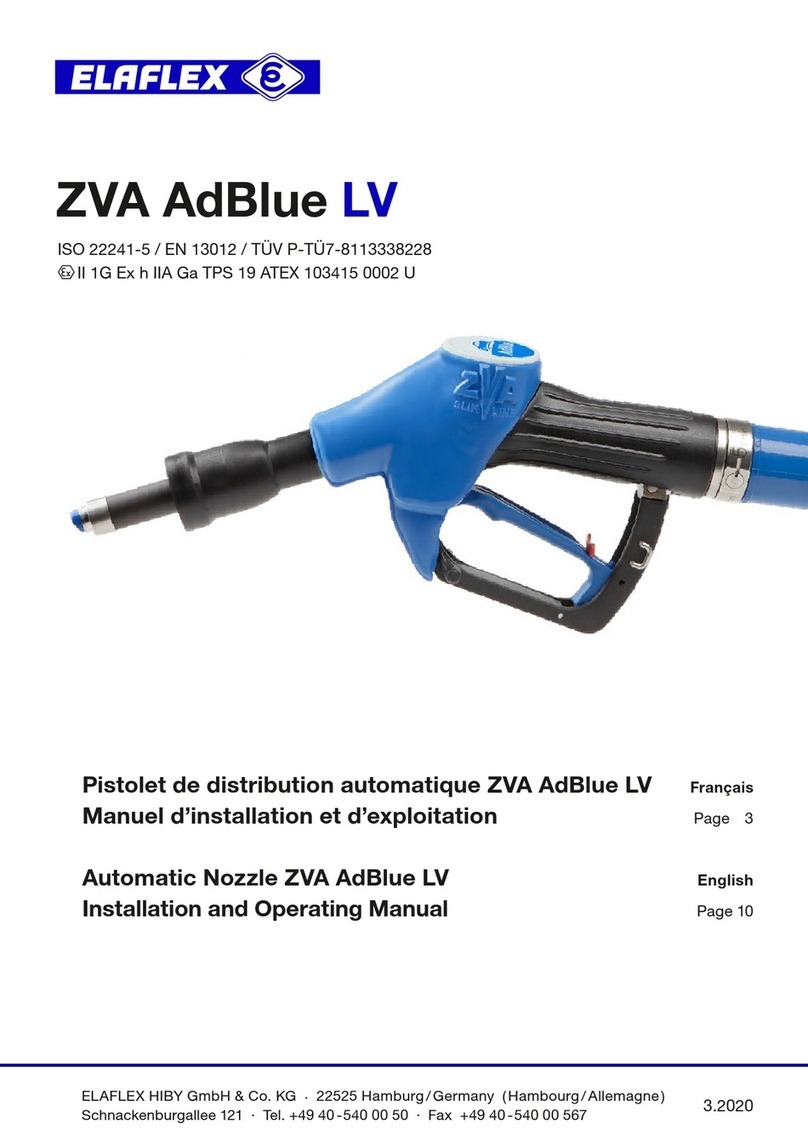

Elaflex

Elaflex ZVA AdBlue LV Installation and operating information

Elaflex

Elaflex ZVA AdBlue LV Installation and operating manual

GILBARCO VEEDER-ROOT

GILBARCO VEEDER-ROOT FlexPay EPK ECIM RF manual

GILBARCO VEEDER-ROOT

GILBARCO VEEDER-ROOT Encore 700 S Start-up and service manual

Elaflex

Elaflex SB-LNG Installation and operating manual

Dover

Dover OPW SiteSentinel Nano M2012 Operator's guide

Gespasa

Gespasa PA-60 Instruction manual and warranty

Elaflex

Elaflex N-LNG Installation and operating manual

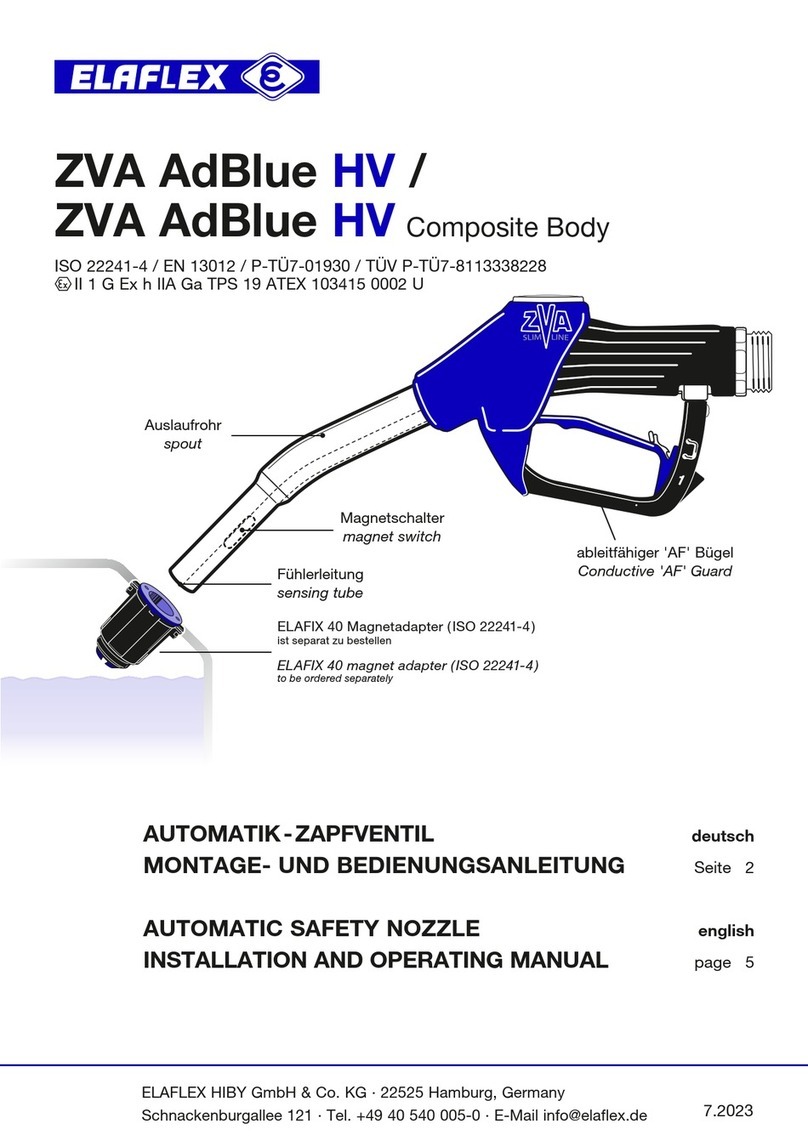

Elaflex

Elaflex ZVA AdBlue HV manual

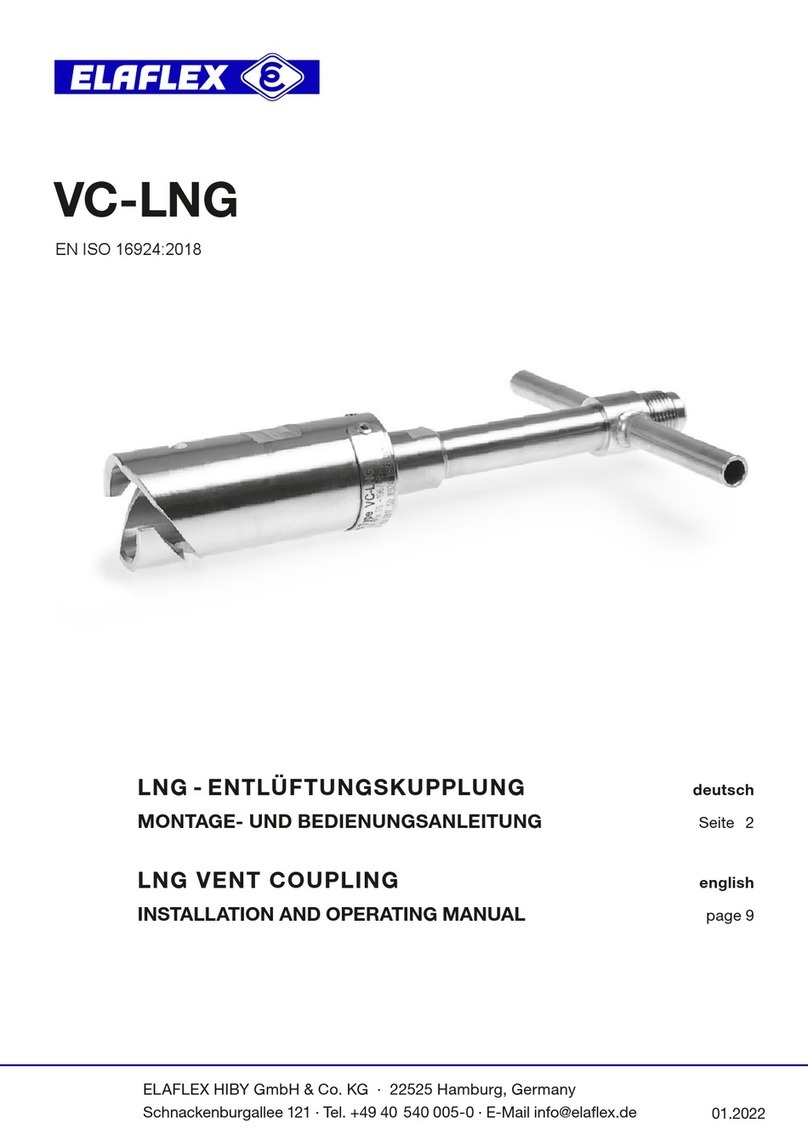

Elaflex

Elaflex VC-LNG Installation and operating manual

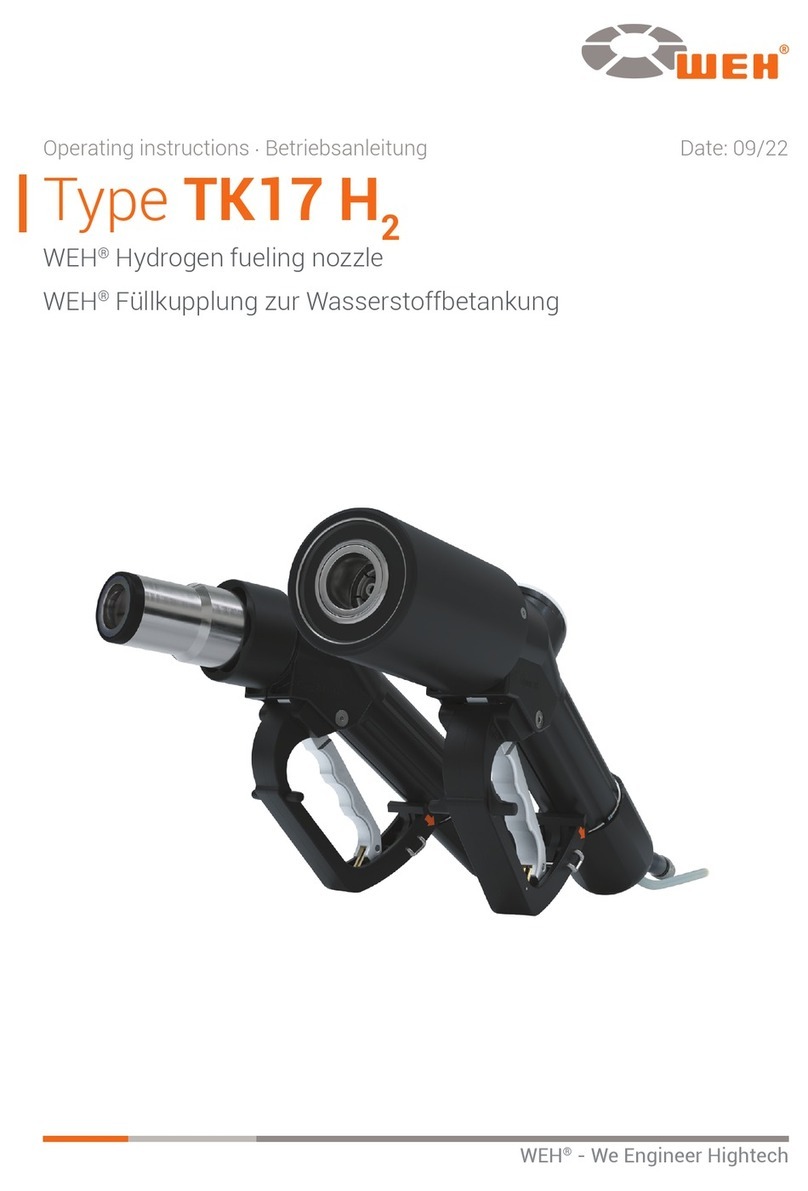

Weh

Weh TK17 H2 operating instructions

GILBARCO VEEDER-ROOT

GILBARCO VEEDER-ROOT Latitude LS-100 installation manual

GILBARCO VEEDER-ROOT

GILBARCO VEEDER-ROOT Latitude LS-100 owner's manual

GILBARCO VEEDER-ROOT

GILBARCO VEEDER-ROOT FlexPay IV Insite360 Encore Programming and Service Manual