IMPORTANT SAFETY INFORMATION

FOR SAND MAN OWNERS, OPERATOR EMPLOYERS

AND OPERATORS

1. Do not allow individuals to operate the Sand Man without first receiving personalized training

and ensuring that they have read this manual.

2. Before each operation of the Sand Man, make a careful visual inspection of the machine. Do

not operate if you observe damaged or missing parts, missing guards, excessive wear or

unusual noise or vibration during startup.

3. Never allow a bystander to approach the operating Sand Man.

4. Do not attempt to clear large obstacles from the path of the Sand Man. Stop the Sand Man,

turn it off and manually remove obstacles.

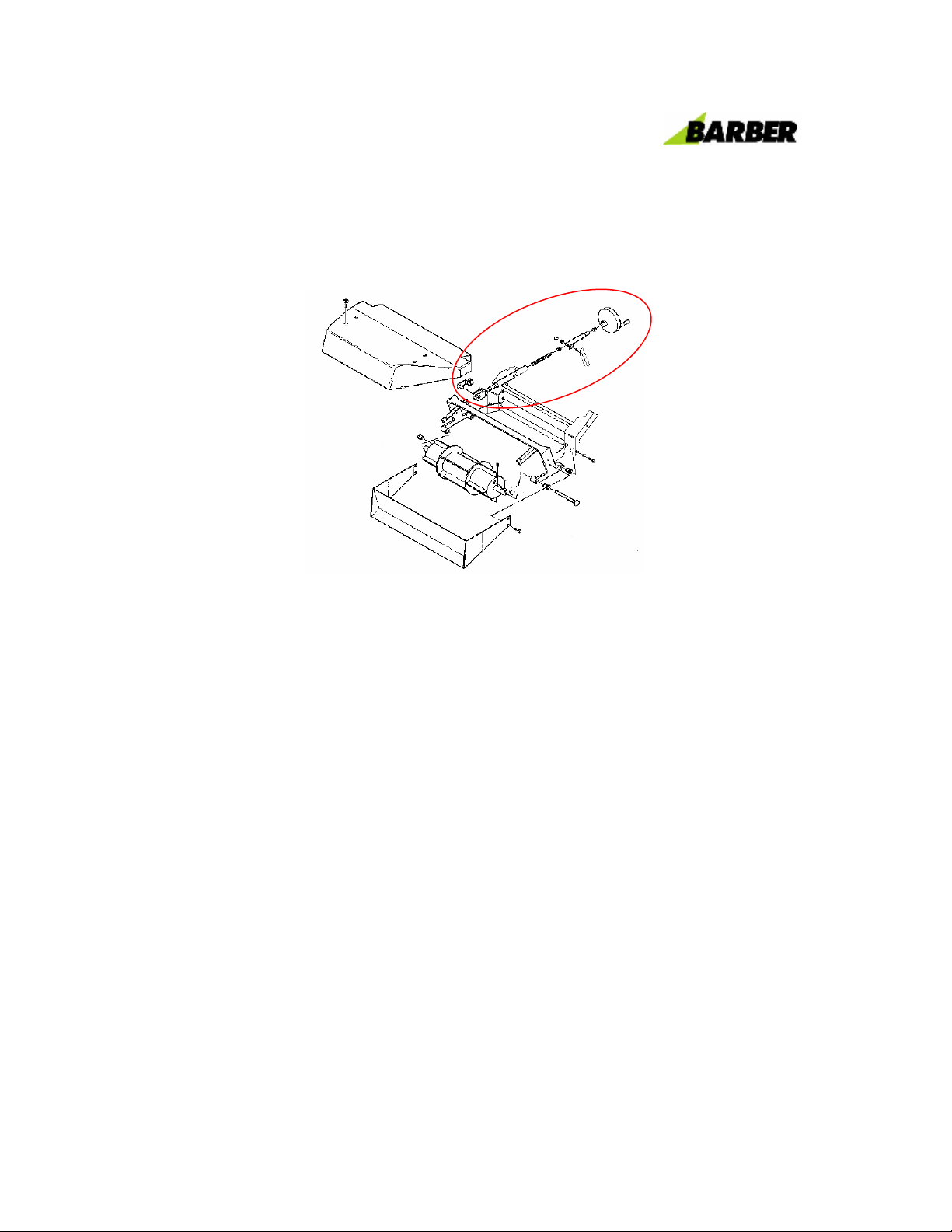

5. Never attempt to clear a jam by placing hands or any part of the body into or near the

machinery which has not been completely shut down. A jammed shaker component can

immediately jump into motion and cause serious injury to hands or other body parts in

immediate contact with the components if the engine is running.

6. Follow OSHA regulations regarding fire safety, guarding and if applicable, lock-out/tag/out

procedures.

7. Before conducting any repair or maintenance on the Sand Man, insure that the engine is OFF,

not just in neutral, and examine the machine carefully to assure that:

(a) All sources of power have been locked in the AOFF@position and tagged.

(b) No flames are present.

(c) Engine has been cooled.

8. Never allow one person to operate the controls of the Sand Man while another has any part of

their body in or near a pinch point or machinery element from which a guard has been removed.

9. Do not operate the Sand Man on a steep incline, extremely irregular surface or unstable

surface. The Sand Man can capsize and cause serious injury or death to the operator or nearby

persons.

10. Never modify any part of the Sand Man without prior approval, in writing, from the manufacturer.

11. Never replace any components of the Sand Man with one which is not manufactured by H.

Barber & Sons, Inc., or listed in this manual as a proper replacement part.