61780 0221

HYDRAULIC RESERVOIR The reservoir tank is located across the front of the frame. It supplies hydraulic

fluid to the hydraulic pump and conveyor belt drive motor. It has a magnetic drain on the bottomforchanging

the hydraulic fluid. There is a sight gage for inspecting hydraulic fluid level on the side of the tank.

BREATHER CAP The breather cap on top of the reservoir is pressurized to keep outcontaminantsandkeep

fumes from entering the atmosphere. It has a 10 micron rating and has a 5 PSI relief valve setting.

HYDRAULIC PUMP The hydraulic pump should be placed over the PTO spline shaft at the rear of the

tractor. Slide the pump as far forward as possible. The pump bracket can be mounted directlyto the toplink

of the three point hitch. Adjust arms to keep the pump upright and as close as possible to the tractor. If this

bracket cannot be attached, use the bracket with mounting chain. To secure the pump, securethechaintoa

rigid surface of the tractor, preferably to the pin of the upper three-point hitch arm bracket, so that thetorque

arm of the pump is positioned up. The PTO spline will turn clockwise and the resulting torquewilltendtoturn

the pump clockwise also. Minimize the length of the safety chain. There is a removable link thatattachesthe

hook to the chain. This link may be repositioned along the chain to minimize the chain length and maintain

the upright orientation of the pump. It may be necessary to reduce the chain length to achieve proper

orientation of the pump. It may also be necessary to reposition the pump arm to fit up with the tractor. Be

careful not to crimp or twist the hoses. If the 1"(2.54cm) suction hose is twisted, the hose clamp on the

pump end of the hose can be loosened, the hose turned to the desired position, and the clamp re-tightened.

FLOW CONTROL The flow control is located between the pump and conveyor belt

motor. It raises or lowers the speed of the conveyor belt motor by regulating the flow of

hydraulic fluid circulated by the pump. The control arm is on the side. When the control

arm is in the up position, hydraulic fluid is completely restricted, preventing the motor

and conveyor belt from turning. As the control arm is turned down, the valve inside is

opened up and the motor and conveyor belt increase speed. There is a built-in, preset,

pressure relief valve that protects the conveyor belt assembly. If an oversized object

stops the rotation of the conveyor belt, the valve will open, relieving pressure from the

conveyor motor and bypass the hydraulic fluid back to the reservoir.

HYDRAULIC FILTER The hydraulic fluid is filtered and returned to the reservoir tank through the canister

filter.

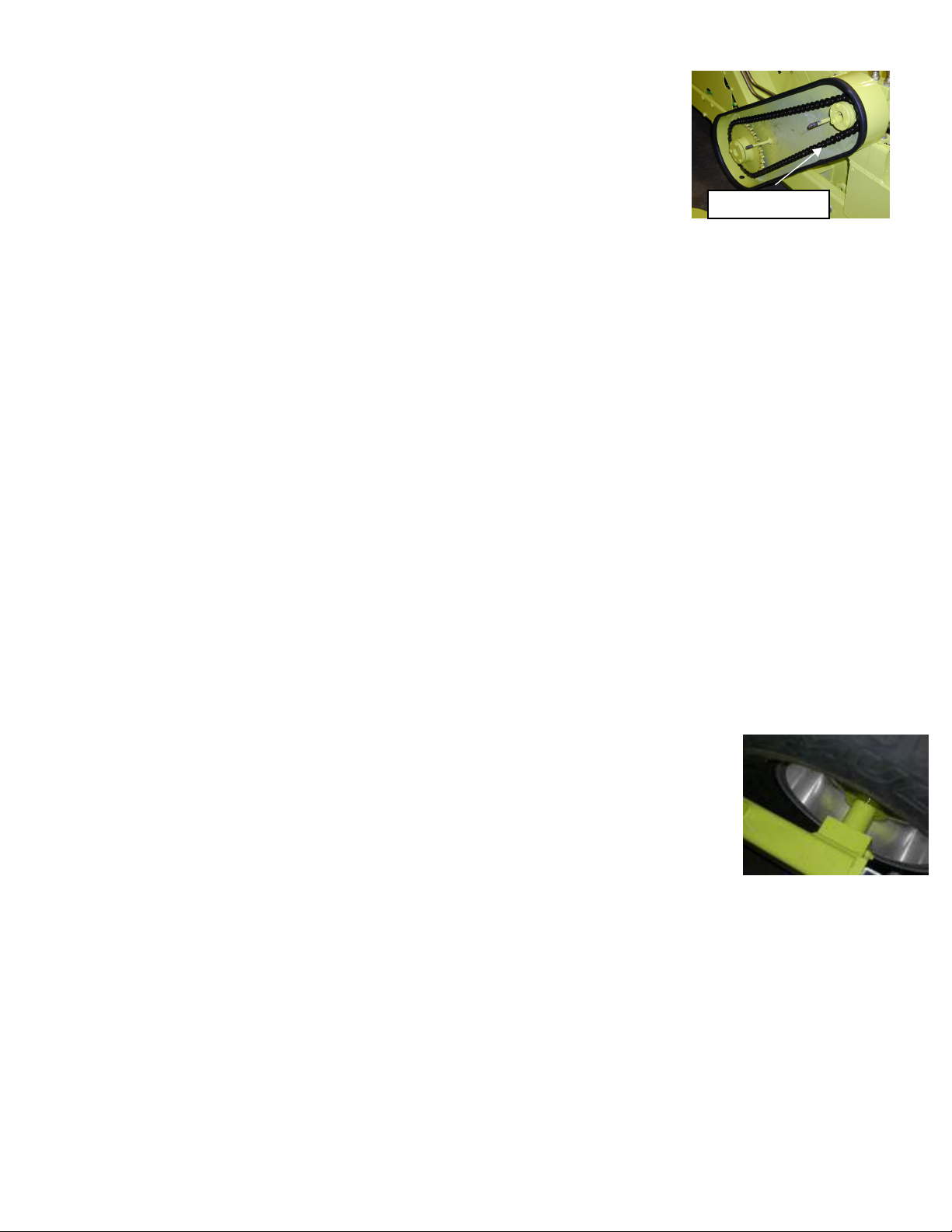

HYDRAULIC CONVEYOR BELT MOTOR The hydraulic motor drives the conveyor belt and is located next

to the chain case. The intake hose comes from the flow control and the outlet hose

returns to the reservoir. The motor does not run in reverse. There is a takeup bolt and

lock down nut at the base of the motor that moves the motor to adjust and tighten the

chain case drive chain when the chain wears.

HYDRAULIC COMPONENTS (BUCKET AND FINISHER)

The tractor’s remote valve hydraulic system is used to control both the bucket

hydraulics and the hydraulic moldboard if equipped.

Each tractor remote valve spool has a pair (2) of quick disconnects that are next to each other, positioned

either vertically or horizontally depending on brand of tractor, and independently operated from adjacent

spools. One spool (2 quick disconnect outlets) is needed for the hose for the bucket raising and lowering

operation and tripping and returning operations. Only one quick connect is utilized. No other hose or

implement can be plugged into the unused quick connect. If a hydraulic moldboard option is added, an

additional spool or second remote is required to raise and lower the moldboard. These are the onlydouble

acting cylinders on the Surf Rake®and use both the upper and lower quick disconnects of a spool. It is not

possible to share two of these operations on the same spool or set of remote valves. When connecting to

each spool use the upper remote and leave the lower remote empty.

CONTROL VALVE

CONVEYOR MOTOR