Barry-Wehmiller Thiele Technologies Streamfeeder Reliant... User manual

Manual

Reliant 1500

Part Number: 00900323

© 2009 Thiele Technologies, Inc. - Streamfeeder. All rights reserved.

No part of this publication may be reproduced, photocopied, stored on

a retrieval system, or transmitted without the express written consent of

Thiele Technologies, Inc. - Streamfeeder.

Thiele Technologies, Inc. - Streamfeeder

103 Osborne Road

Minneapolis, MN 55432-3120 USA

Tel:763.502.0000

Fax:763.502.0100

e-Mail: service@streamfeeder.com

Web: www.streamfeeder.com

Printed in the USA.

i

Relaint 1500 Manual

Contents

Safety Information ........................................................ii

Specications ..............................................................iv

Section 1: About the Machine .......................................................1

Section2: InstallingtheMachine ..................................................7

Section3: PreparingforOperation .............................................15

Section4: HowtoOperate ...........................................................27

Section5: Troubleshooting .........................................................31

Section6: InspectionandCare ...................................................33

Section7: AdditionalWedges .....................................................41

Section8: ElectricalSchematics.................................................43

Section9: MechanicalComponents ...........................................47

ii Reliant 1500 Manual

Message

Conventions

DANGER signies an action or specic equipment area that can result

in serious injury or death if proper precautions are not taken.

WARNING signies an action or specic equipment area that can

result in personal injury if proper precautions are not taken.

CAUTION signies an action or specic equipment area that can

result in equipment damage if proper precautions are not taken.

ELECTRICAL DANGER signies an action or specic equipment

area that can result in personal injury or death from an electrical haz-

ard if proper precautions are not taken.

TIP signies information that is provided to help minimize problems

in the installation or operation of the feeder.

NOTE provides useful additional information that the installer or

operator should be aware of to perform a certain task.

CHECK signies an action that should be reviewed by the operator

before proceeding.

IMPORTANT alerts the installer or operator to actions that can poten-

tially lead to problems or equipment damage if instructions are not

followed properly.

WARNING LABELS afxed to this product signify an action or spe-

cic equipment area that can result in serious injury or death if proper

precautions are not taken.

Before You Begin

iii

Relaint 1500 Manual

Message

Conventions

Before You Begin

Avoid injury. Do not reach around guards.

Hazardous voltage. Contact will cause electric shock or burn. Turn off

and lock out power before servicing.

Moving parts can crush and cut. Keep guards in place. Lock out power

before servicing.

Pinch point. Keep hands and ngers clear.

Moving parts can crush and cut. Keep guards in place. Lock out power

before servicing.

iv Reliant 1500 Manual

Maximum Product Size: ......................... 9.25 W x 6 L in (235 x 152 mm)

Contact us for longer insert length

Minimum Product Size: ...................... 2.125 W x 2.25 L in (54 x 57 mm)

Min/Max Product Thickness: ......................... .003-.25 in (.076-6.35 mm)

Belt Speed: ......................................................... 1000 ipm (25,400 mmpm)

Electrical Requirements: ................................................... 115/230vac, 1A

Weight: .............................................................................. 23 lbs. (10.43kg)

speCifiCations

1

Relaint 1500 Manual

1About the Machine

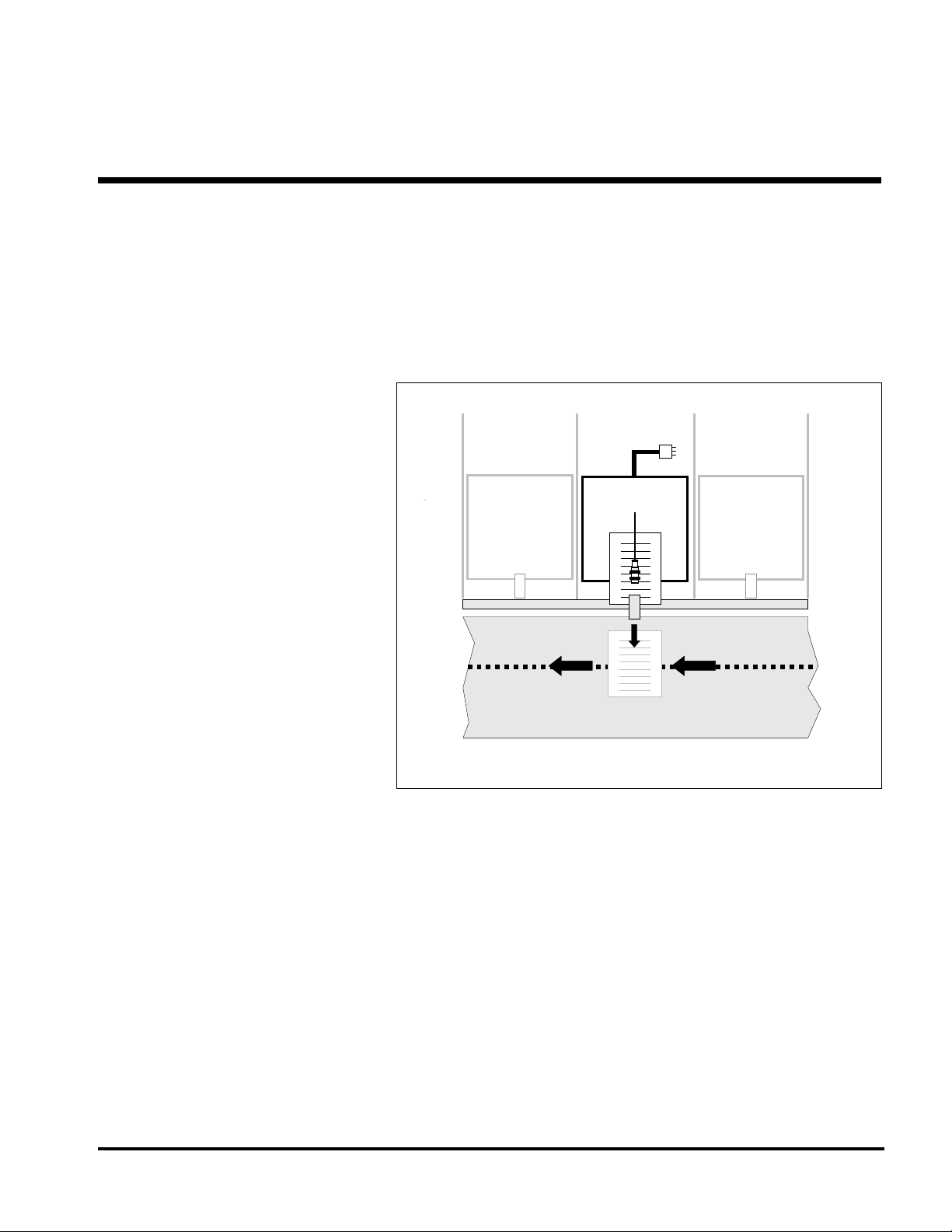

The Streamfeeder Reliant 1500 Universal Friction Feeder is designed

for use with multi-station inserters to efciently separate, singulate,

and feed a wide variety of cut sheets and non-nested material. After

material is loaded into the hopper, the rest is automatic. With photo

sensor monitoring, feed cycling is always sychronized with the in-

serter gripper jaw. Figure 1 shows a typical setup on the inserter.

Introducing the

Reliant 1500

Universal Friction

Feeder

Figure 1. Reliant 1500 Universal Friction Feeders

Mounted on an Inserter

Insert Track

Feeder x

Station x

2Reliant 1500 Manual

Product Description Section 1

One of the design features that makes the Reliant 1500 Universal Fric-

tion Feeder unique is a part called the gate assembly (Figure 2). This

patented device is the main reason the feeder can separate, singulate,

and feed individual sheets with accuracy and reliability — even at

high speeds. A single-knob adjustment allows you to easily setup the

feeder for many different types of material.

Figure 2. Standard O-Ring Gate, Horizon Adjust

Bar Gate II Horizon Adjust Assembly

The machine is entirely powered by a single AC synchronous mo-

tor that runs off of either a 120- or 240-VAC electrical power source.

Once the machine is prepared for operation, the power-up and opera-

tion of the feeder is relatively easy.

But to get the most out of your machine, you should rst become fa-

miliar with all of the features, including controls and sensors, connec-

tors, and cables.

Please read the “Main Features” subsection that follows to learn about

all controls, sensors, and connections. Once you have done this, you

should be ready to adjust and successfully run the machine with any

material within the specication parameters.

NO TE

This manual contains installation, preparation,

and operation information only.

3

Relaint 1500 Manual

Section 1 Product Description

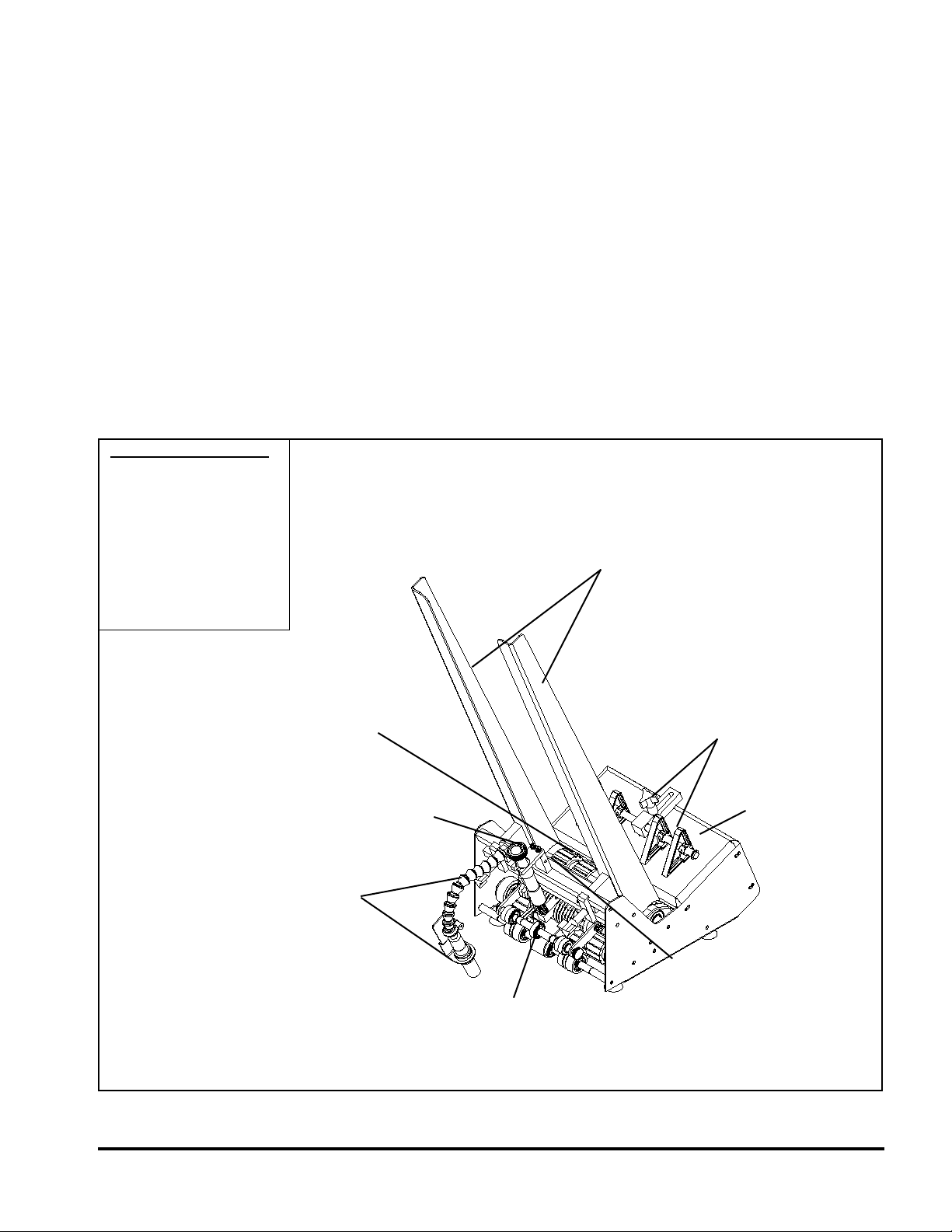

Main Features

Figure 3. Reliant 1500 Universal Friction Feeder Features

Loose Parts Supplied

• Side Guides (2)

• Hold-Down Spring

Assemblies (2)

• Side Guide

Wing-Nut Assemblies (2)

• Insert Plate Guide

• AC Power Cord

Side Guides

(Adjustable)

Back Wedge and

Adjustments

Feeder

Top Panel

(Table Top)

Gate Bracket

Assembly

Discharge

Assist

Assembly

Photo Sensor

and Flex Arm

Extension

Gate Assembly

and Adjustment

Feed Belts

The Reliant 1500 Universal Friction Feeder is designed for reliability,

exibility, and ease of use. All control, sensing, and feeding assem-

blies are combined into one compact unit.

The main components and adjustments of the feeder are shown in Fig-

ure 3. Brief descriptions of each are found in Table 1 on the following

page.

4Reliant 1500 Manual

Feature Description

Gate assembly and adjustment Mounted on a gate bracket assembly directly above the feed belts, this

device provides a curvature to help preshingle stacked material. When

properly adjusted, a clearance is created to help singulate and feed

material. (Note: For multiple page material, a 1 to 1.5 maximum thickness

is typical.)

Top panel (table top) Used to support the back wedge.

Side guides (adjustable) Holds a stack of material to be fed and helps keep it straight for proper

entry through the gate assembly area. Also referred to as “hopper”.

(Note: Loading can be performed from either the front or back of inserter.)

Back wedge and adjustment Lifts the material to keep it off the table top, reduces excessive contact

with the feed belts, and helps push the material against the curvature of

the gate assembly.

Photo Sensor and ex arm extension Controls the starting and stopping of a feed cycle by sensing the presence

or absence of material. To ensure proper alignment of the sensor, a ex

arm extension allows you adjust it for proper distance and angle to the

material.

Feed belts Provides the friction and motion necessary to pull individual material from

the bottom of the stack and through the gate assembly area.

Discharge assist assembly A series of small rollers mounted on movable brackets help to gently hold

material down on the feed belts as material exits the gate assembly area.

These brackets and rollers are part of the gate assembly and are removed

when the gate assembly is removed.

On/Off switch (not pictured) Located on the rear of the feeder, this toggle switch turns AC power On or

Off to the feeder.

Hold-down spring assemblies As a piece of material exits the feeder gate assembly area, these two

hold-down spring assemblies help keep it aligned and in proper position

for the gripper jaw. Shipped loose and mounted on inserter.

Side guide wing-nut assmblies Secures side guides to the cross-bar. Loosening each allows you to move

each side guide horizontally to accommodate various material sizes.

Insert plate guide This plate is supplied with your feeder and is to be mounted on the back

deck plate. Shipped loose and mounted on inserter (if required).

AC power cord, 8 ft. (2.44 m) IEC320 removal three-prong. Shipped loose.

Product Description Section 1

Table 1. Feature Descriptions of Reliant 1500 Universal Friction Feeder

5

Relaint 1500 Manual

Controls and

Sensors

Read the following descriptions to become familiar with the controls

and sensors. See Figure 4 for locations

ON/OFF SWITCH. This rocker switch determines whether AC power

to the feeder is “On” or “Off”. Push the horizontal line (—) to turn

“On” and push the circle (O) to turn “Off”. It is located at the rear of

the feeder.

PHOTO SENSOR. Sends signals to the relay circuit to both “start”

and “stop” the feed cycle. Also called a sheet sensor, it “looks” for

the leading edge of the bottom sheet of material to stop the machine.

When the gripper jaw removes the bottom sheet of material, the feeder

starts and then feeds the next sheet. The machine stops as the sensor

“sees” the leading edge. The sensor uses two LED indicators. A green

LED functions as the power indicator and is constantly lit during

normal operation. The second LED is amber, and indicates the pres-

ence of product staged under the sensor. Amber LED on indicates the

sensor "sees" product; off when no product is present.

Read the following descriptions to become familiar with the connec-

tors and cables. Refer back to Figure 4 for location.

AC POWER INLET/FUSE. This 3-prong connector receives incom-

ing AC power from the designated power source. One end of AC

power cord plugs into power inlet (rear of machine), while the other

plugs into a three-prong grounded and fused outlet.

Connectors and

Cables

Figure 4. Feeder (Rear)

On/Off Switch

Fuse Holder

AC Power

Inlet

Connector

6Reliant 1500 Manual

7

Relaint 1500 Manual

2Installing the Machine

Installation of the Reliant 1500 Universal Friction Feeder onto the

back deck plate of an inserter is a relatively simple procedure, with

only minor modications to the selected insert station prior to attach-

ing the feeder. The entire installation can typically be done with a hex-

head driver set and a slotted screwdriver.

To install the feeder, perform the following steps:

1: Removing rear guide assembly

2: Removing T-plate

3: Repositioning separator foot

4: Removing suction cup and closing off vacuum hose

5: Repositioning insert guide tabs

Optional step: Install insert plate guide

6: Installing feeder hold-down spring assemblies

7: Aligning feeder with insert station

8: Securing feeder to inserter

9: Initial feeder photo sensor positioning

!

!

!

When performing initial installation, always

make sure you turn Off the main power

switch and disconnect all equipment from

the electrical power source. Failure to do so

can expose you to a potential start-up, and

therefore moving parts which can cause

serious injury.

Do not attempt feeder installation while the

inserter is running. Failure to do so can expose

you to moving parts which can cause serious

injury.

Avoid turning on the feeder or making initial

adjustments until all parts are secured. Failure

to do so can cause damage to equipment.

STEP 1:

Removing Rear

Guide Assembly

At the selected insert station, remove the fasteners that hold the

inserter rear guide assembly to the inserter back deck plate. Lift rear

guide assembly off of back deck plate (Figure 5).

Figure 5. Removing Guide Assembly Rear from Inserter

Rear guide

assembly

8Reliant 1500 Manual

STEP 2:

Removing T-Plate

With the rear guide assembly removed, you can now access the in-

serter T-plate. Simply lift off of back deck plate (Figure 6).

Figure 6. Removing T-Plate from Inserter

T-plate

STEP 3:

Repositioning

Separator Foot

• Locate the separator foot at the front side of the inserter station (at-

tached to top rotating shaft).

• With a screwdriver, loosen the inserter separator foot and tilt away

slightly from insert station assembly (opposite feeder) so the foot

does not interfere with material being fed (Figure 7).

• Retighten to secure.

Figure 7. Repositioning Separator Foot at Front of Inserter

Separator foot

9

Relaint 1500 Manual

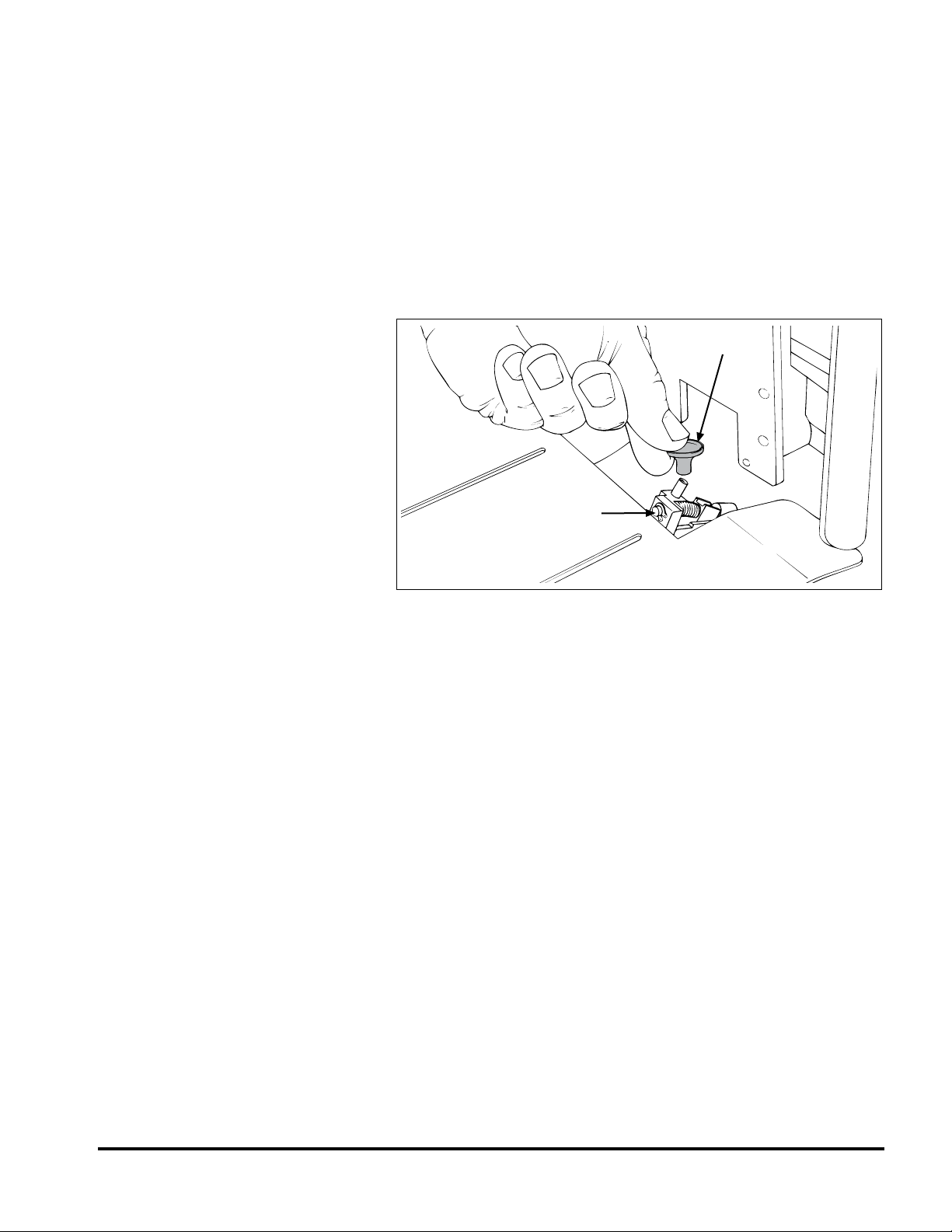

STEP 4:

Removing Suction

Cup and Closing Off

Vacuum Hose

• Locate the suction cup and hose from front side of insert station.

• Remove suction cup from vacuum assembly. See Figure 8.

• Lower and tilt the adjustable vacuum assembly forward (by turn-

ing the built-in thumbscrew). The vacuum assembly may be moved

down and to one side if it interferes with the material being fed.

• Close off the vacuum hose opening; any convenient plugging

method will do.

Figure 8. Removing Suction Cup from Vacuum Assembly

Suction cup

Vacuum assembly

10 Reliant 1500 Manual

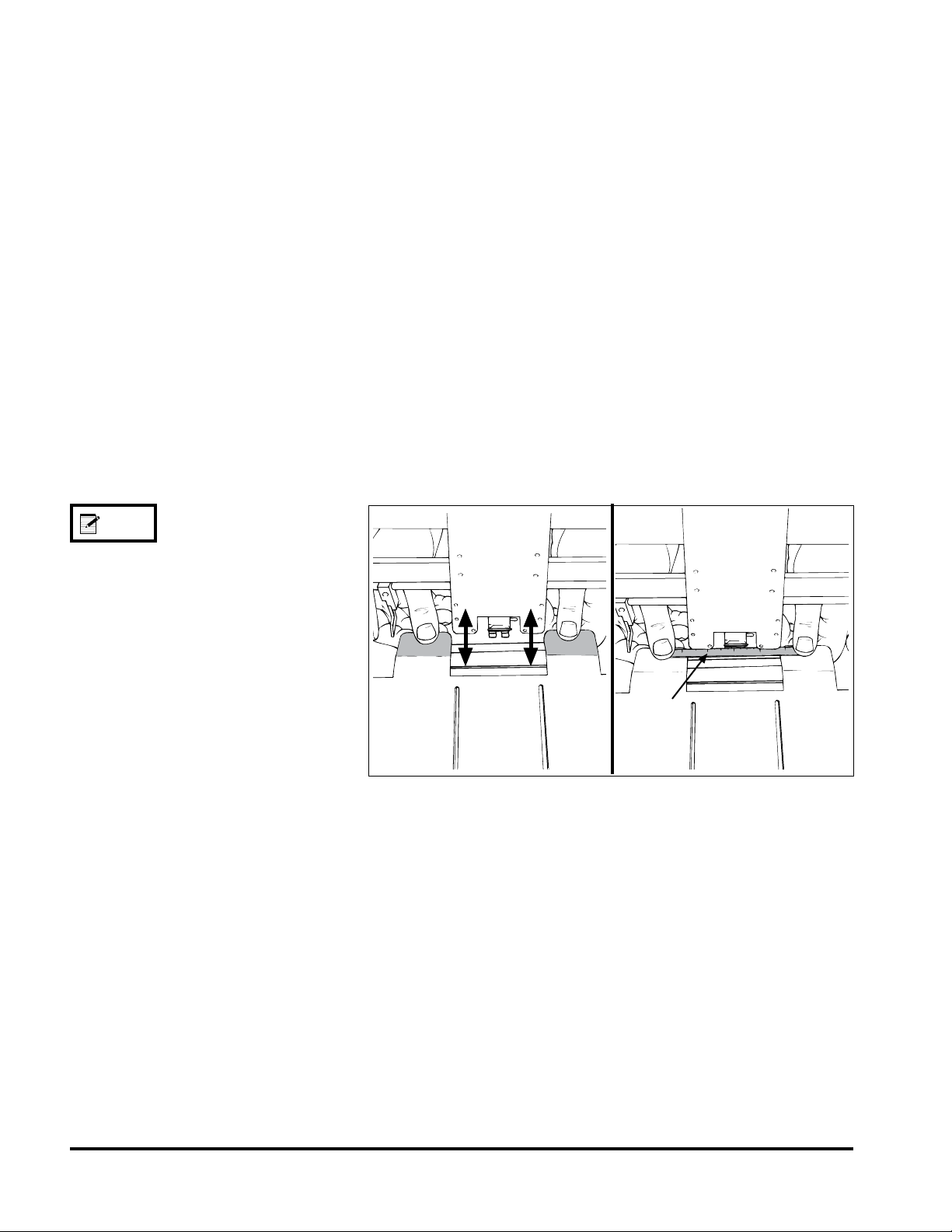

STEP 5:

Repositioning

Insert Guide Tabs

• Cycle the inserter until the gripper arm jaw is approximately 1/2 in.

(12.7 mm) from the hopper plate (leading edge of material exiting

feeder stops here).

• Locate the two insert guide tabs that protrude from under the back

deck plate. Bend these tabs as required (either up or down) until

their top surface is slightly above the bottom of the gripper arm

jaw. The material to be run will rest on these tabs. The bottom of

the gripper arm jaw must pass under the material without making

contact with it.

• As it is important that there be adequate clearance between the

guide tabs surface and the gripper jaw, use a at, thin rule (or

gauge) to test for clearance. Ideally, with the gripper jaw should be

fully open when testing.

• Center the gauge on the guide tabs and slide the gauge back and

forth on the tabs, making sure the gripper jaw does not touch the

bottom of the gauge. See Figure 9.

Figure 9. Respositioning Guide Tabs and Testing For Clearance

Inserco inserters only:

Remove the two insert guide tabs that protrude

from the back deck plate. Make a bend in each

tab approximately 1-3/8 in. (34.9 mm) from the

tip by placing the tab approximately 1-3/8 in.

(34.9 mm) into the rear guide assembly. Bend

the tab slightly and repeat same for second tab.

Reinstall insert guide tabs to back deck plate.

NO TE

Ruler or

gauge

11

Relaint 1500 Manual

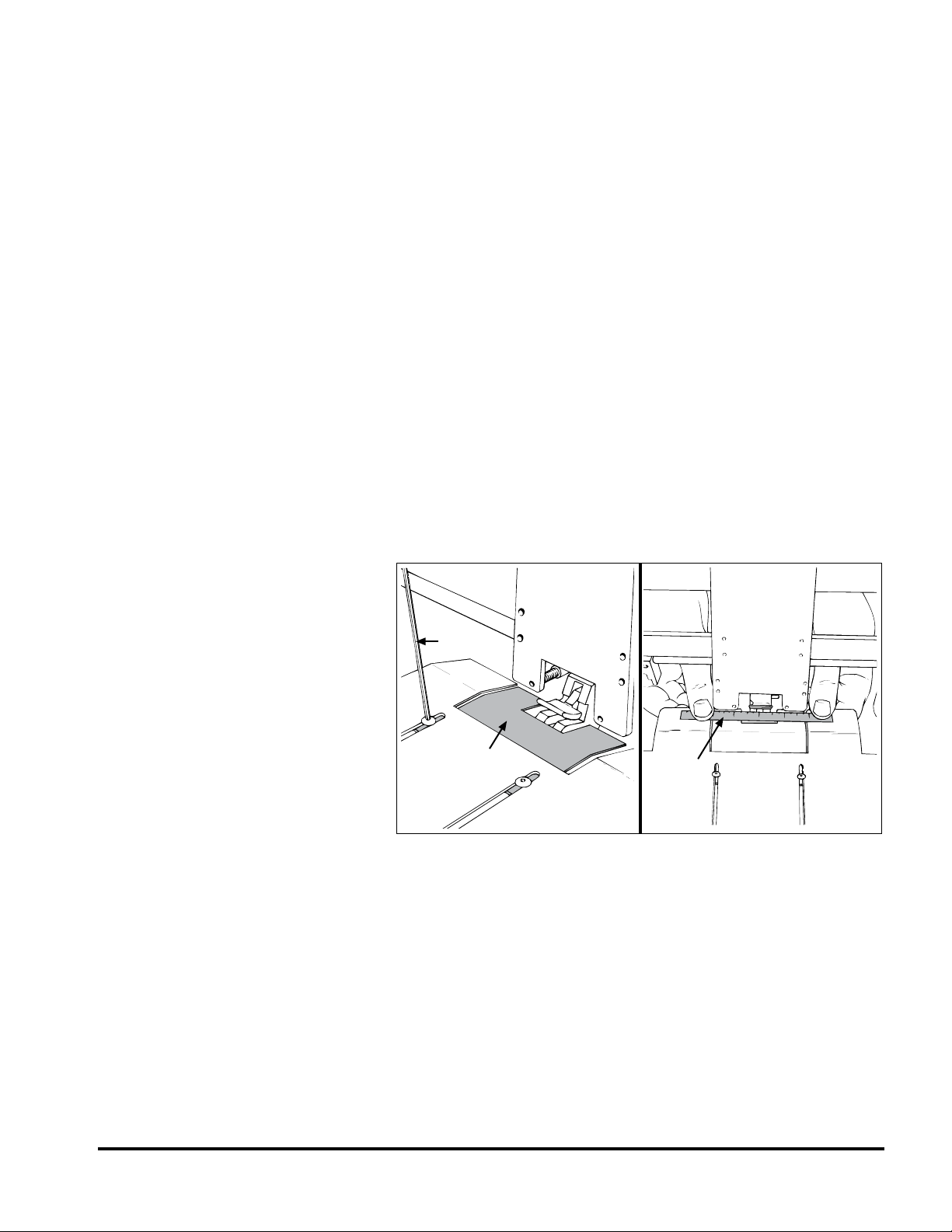

Optional Step:

Installing Insert

Plate Guide

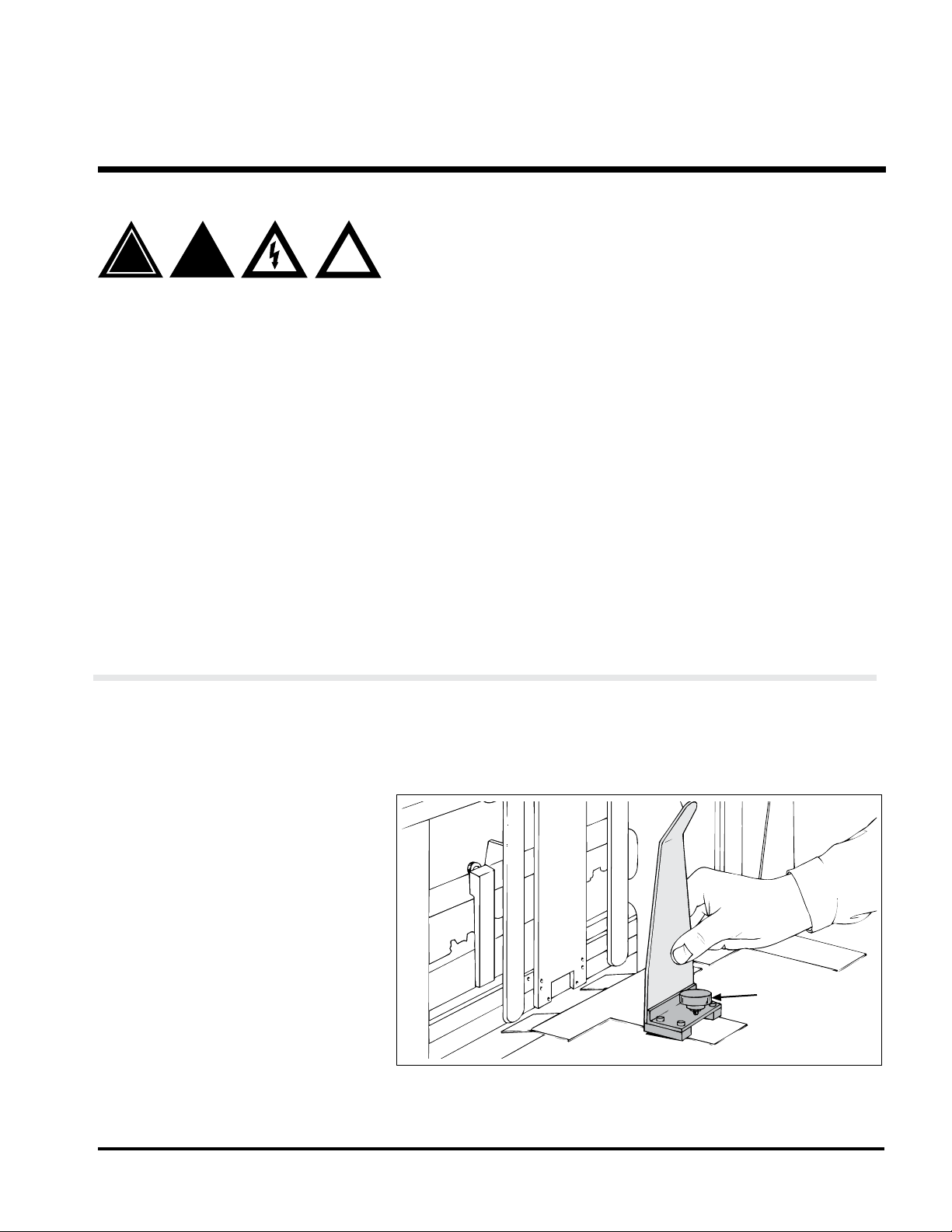

When feeding materials less than 5 in. (12.7 cm) wide, you must in-

stall the provided insert plate guide with your machine. Install it from

the underside of the back deck plate using the two provided hex-head

screws; reuse the two slots previously used for mounting the rear

guide assembly.

• Start the screws from the top side of the back deck plate, leaving

them loose so you can move insert plate guide during placement.

• Position the insert plate guide so the top surface is slightly above

the bottom of the gripper arm jaw.

• Tighten to secure.

• As it is important that there be adequate clearance between the

guide tabs surface and the gripper jaw, use a at, thin rule (or

gauge) to test for clearance. Ideally, the gripper jaw should be fully

open when testing.

• Center the gauge on the guide tabs and slide the gauge back and

forth on the tabs, making sure the gripper jaw does not touch the

bottom of the gauge. See Figure 10.

Figure 10. Installing Optional Insert Plate Guide and

Checking for Clearance

Insert plate

guide

Allen

wrench

Ruler or

gauge

12 Reliant 1500 Manual

• Using the two provided hold-down spring assemblies (with support

bars), place each on the insert station rail (feeder side of inserter).

• Position each spring support bar so that they are equally spaced

from each edge of the material to be run.

• Tighten the built-in wing nut on each to secure.

• Check for placement and pressure of the hold-down spring as-

semblies by sliding a piece of material to be run under the springs.

There should be a “slight drag” when moving the material back and

forth.

• Make adjustments as required and recheck. See Figure 11.

STEP 6:

Installing Feeder

Hold-Down Spring

Assemblies

NO TE

Figure 11. Installing Hold-Down Spring Assemblies and

Testing for Drag

Feeder

hold-down

spring

Feeder

hold-down

springs

Use this conguration

for Bell & Howell

Mailstars, and 825

models.

Knowing how far from each edge of the material

to place the hold-down spring assemblies is a

combination of intuition and testing.

TIP

With material inserted between the springs and

the insert guide tabs, test the spring tension by

sliding the material back and forth. Tension

should not be so great that it distorts the material

as it moves.

If adjustment is required, loosen the hex-head

screw for each spring and move up or down on

support bar. Retighten when optimum tension is

achieved.

TIP

Certain inserter models require hold-down spring

assemblies to mount from the bottom side of the

cross-bar (see gure below). To invert, simply

remove screw and invert L-bracket and spring.

13

Relaint 1500 Manual

Figure 12. Aligning Feeder with Insert Station

STEP 7:

Aligning and

Securing Feeder to

Insert Station

• Using your nger, turn the drive belt to advance a piece of your

material through the gate assembly area and under the feeder hold

down springs.

• Continue advancing the material until the trailing edge of material

ts between the feeder exit rollers (.25 in. to .5 in., or 6.4 mm to

12.7 mm of material).

• Carefully slide the feeder into the inserter station and center the

leading edge of your material under the inserter hold-down springs.

Ensure the front edge of the material is in-line with the front hopper

plate. See Figure 12.

• Once you are satised with the feeder alignment, press down on the

feeder top plate to secure the feeder suction cups to the inserter rear

deck plate.

T-handle

screw

S uctio n

c up

14 Reliant 1500 Manual

STEP 8:

Initial Feeder Photo

Sensor Positioning

• With the machine turned Off, position the photo sensor by sighting

along the tubular barrel. It should point exactly at the leading edge

of material being held by the hold-down springs (Figure 13).

• Use the retractable extension to maneuver the photo sensor into

position for desired height and angle.

• During the nal adjustment of the photo sensor, you need to actu-

ally load material into hopper, turn the feeder Off, and cycle the

inserter. See Section 3, “Preparing for Operation”, for more infor-

mation.

NO TE

The nal photo sensor adjustment will align

slightly to the rear of the leading edge. This is

because when the photo sensor signals the feeder

to stop, the motor will over-travel slightly.

Figure 13. Initial Photo Sensor Adjustment

Photo

sensor

A perpendicular alignment to the material is

preferred. However, in many instances you may

be limited to an angular alignment due to the

constraints of the retractable extension and

cross-bar design.

IMPOR TANT

Table of contents

Other Barry-Wehmiller Wire Feeder manuals

Popular Wire Feeder manuals by other brands

Kemppi

Kemppi KEMPOWELD WIRE 200 Operation instructions

EWM

EWM Drive 4 Basic S D200 operating instructions

RNA

RNA STS 220-4 operating instructions

LOBSTER

LOBSTER ARF-800P instruction manual

Lincoln Electric

Lincoln Electric DX7 Instructions for use

Oerlikon

Oerlikon DMU P400 Instruction for operation and maintenance