Bartec Varnost 07-5103 Series Quick start guide

Operational Instruction (Original) Distribution box Type 07-5103-…./…., 07-5105-

…./…., 07-5106-…./…. and 07-5107-…./….

BARTEC

Varnost d.o.o.

Cesta 9.avgusta 59

1410 Zagorje o Savi

Slovenia

Tel.: +386 59 221 471

Fax: +386 59 221 470

info@ artecvarnost.si

www. artecvarnost.si

Reservation Technical data su ject to change without notice. Changes, errors and

misprints may not e used as a asis for any claim for damages.

EN 1/3

Explosion protection

Technical data

ATE

Ex type of protection

II 2G Ex e ia/i IIA, IIB, IIC T6, T5 G

II 2G Ex ia/i IIA, IIB, IIC T6, T5 G

For type 07-5103-…./…. and 07-5105-…./….

also:

II 2D Ex t IIIC T80

°C,T95

°C D

IP65/IP66

For type 07-5105-…./…. also:

II 2D Ex ia/i IIIC T80 °C D

Certification

PTB 08 ATEX 1064

IECEx

Ex type of protection

Ex e ia/i IIA,IIB,IIC T6,T5 G

Ex ia/i IIA,IIB,IIC T6,T5 G

For type 07-5103-…./…. and 07-5105-…./….

also:

Ex t IIIC T80°C,T95°C D IP66

For type 07-5105-…./…. also:

Ex ia/i IIIC T80°C D

Certification

IECEx PTB 09.0009X

Working temperature ranges

With EPDM gasket:

-

20 °C to +95 °C

(

-

4 °F to +203 °F)

With inspection windows:

-

25 °C to +95 °C

(

-

13 °F to +203 °F)

With silicone gasket:

-

55 °C to +100 °C

(

-

67 °F to +212 °F)

Ambient temperature ranges

Depending on the temperature class:

By T95 °C, T5 and for the Ex ia/i IIC T6 G

version, silicone gasket:

-

55 °C to +55 °C

(

-

67 °F to +131 °F)

T6 and T80 °C, silicone gasket:

-

55 °C to +40 °C

(

-

67 °F to +104 °F)

T6 EPDM gasket and inspection window(s):

-

20 °C to +40 °C

(

-

4 °F to +104 °F)

Approved for zones

1 and 2

21 and 22

Protection class

Max. IP66

Rated voltage (U

e

)

AC/DC 1000 V

Mechanical strength

Impact energy: 7 Joule

Enclosure material/manufacturing

process

Type 07-5103-…./…. and 07-5105-…./….

–

Glass

-

fi er reinforced polyester

–

Surface resistance <10

9

–

RAL 9005 lack

Type 07-5106-…./…. and 07-5107-…./….

–

Glass

-

fi er reinforced polyester

–

Surface resistance

>

10

12

–

RAL 9000/RAL 7001 grey

Lid screws

Stainless Steel, cross-head (+-)

Recommended tightening torque

M4 screw:

ca. 1.2 Nm

M6 screw:

ca. 1.4

Nm

Terminals

Certified connecting and/or rail-mounted

terminals with a maximum rated voltage of

1100 V AC/DC and a maximum rated cross

section of 300 mm².

For information a out the tightening torque

of the terminal screw, Tightening torques,

see manufacturer`s instructions.

Dimensions in mm (in)

From 80 x 75 x 55

(3.1 x 3 x 2.2)

to 600 x 250 x 120

(23.6 x 9.8 x 4.7),

see also Bartec catalogue

VS

– 11 01 301 (issue No I / 2.11.2016)

Note on instructions

When working in hazardous areas, the safety of

personnel and equipment depends on compl

i-

ance with the relevant safety regulations. The

people in charge of installation and maint

e-

nance ear a special responsi ility. It is esse

n-

tial that they have an exact knowledge of the

applica le rules and regulations.

The instructions provide a summary of the most

important safety measures and must e read

y everyone working with the product so that

they will e familiar with the correct handling of

the product.

The instructions have to e kept for future

reference a

nd must e availa le throughout the

expected life of the product.

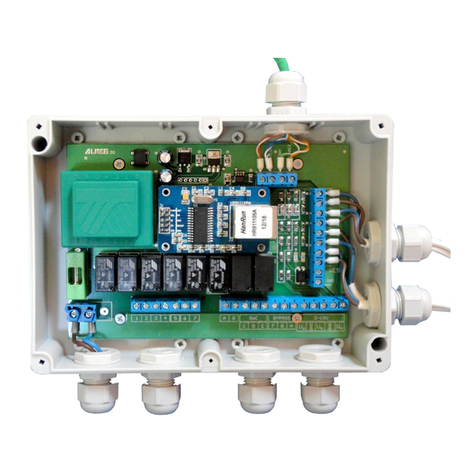

Description

The BARTEC Varnost distri ution oxes, t

ype

07-5103-…./…., 07-5105-…./…., 07-5106

-

…./…. and 07-5107-…./…., are used for co

n-

nections and distri ution of incoming and

outgoing ca les and wires with certified co

n-

necting and/or rail-mounted terminals.

The

distri ution oxes are used for connecting

lights, devices and signals.

The enclosure is made of glass-

fi re reinforced

polyester. The lid and ase are fastened with

stainless steel captive screws (+/- crosshead).

A grooved spring system with inserted sealing

chord in etween the lid and the ase provides

for the high protection type IP66.

The distri ution oxes are

mounted y means

of fixing holes outside of the sealed space.

The

distri ution oxes are also suita le for

intrinsically safe electric circuit’s connections. In

this case, a special marking is required.

The distri ution oxes can e used in hazar

d-

ous areas of oth zone 1 and 2 with certified

explosion su groups II and t

he temperature

class T5/T6 and as well as in zone 21 and 22

with certified max. surface temperature.

Operational Instruction (Original) Distribution box Type 07-5103-…./…., 07-5105-

…./…., 07-5106-…./…. and 07-5107-…./….

BARTEC

Varnost d.o.o.

Cesta 9.avgusta 59

1410 Zagorje o Savi

Slovenia

Tel.: +386 59 221 471

Fax: +386 59 221 470

info@ artecvarnost.si

www. artecvarnost.si

Reservation Technical data su ject to change without notice. Changes, errors and

misprints may not e used as a asis for any claim for damages.

EN 2/3

VS

– 11 01 301 (issue No I / 2.11.2016)

Safety

i

nstructions

The distri ution ox

may e used within the

specified temperature class and the tempera-

ture range indicated for it (see type la el).

The distri ution ox

may e operated only if it

is clean and not damaged in any way. Dust

deposits > 5 mm (> 0.2 in) must e removed.

As for distri ution

oxes used in flamma le

dust, the ignition temperatur

e of the dust/air

mixture and the glowing temperature of the

dust concerned must e greater than the

maximum surface temperature of the distri u-

tion ox taking into account of the given safe

ty

factor specified in EN 60079-0.

Utilization in areas other than

those specified or

the modification of the product y anyone other

than the manufacturer is not permitted and will

exempt BARTEC Varnost

from lia ility for

defects and any further lia ility.

The generally applica le statutory rules and

other inding direc

tives relating to workplace

safety, accident prevention and environmental

protection must e o served.

O serve the applica le laws and directives

when commissioning or restarting operation.

Always follow the safety instructions on the

operating equipment.

Marking

Particularly important points in these instruc-

tions are marked with a sym ol:

DANGER indicates a hazardous situation

which, if not avoided, will result in death

or

serious injury.

WARNING indicates a hazardous

situation

which, if not avoided, could

result in death or

serious injury.

CAUTION indicates a hazardous situation

which, if not avoided, could result in minor

or

moderate injury.

NOTICE is used to address practices not

related to personal injury.

Note

Important instructions and information on

effective, economical and environmentally

compatible handling.

Standards conformed to

2014/34/EU

as well as

EN 60079-0:2012/IEC 60079-0:2011

EN 60079-7:2007/IEC 60079-7:2006-07

EN 60079-11:2007/IEC 60079-11:2006

EN 60079-31:2009/IEC 60079-31:2008

as well as

EN 62208:2011/IEC 62208:2011

EN 60445:2010/IEC 60445:2010

EN 60529:1991 + A1:2000

Transport, storage

Risk of injury due to heavy loads.

Use an appropriate carrying aid or an

appropriate means of transport (e.g. a fork-

lift) with an adequate load-carrying a ility.

Ensure that the lifted load will not tip over

or slip off.

Damage through incorrect transport or

incorrect storage.

Transport the distri ution ox

in original

packaging, handle with

care, and do not

drop.

Store the distri ution ox

dry in original

packaging.

Assembly, installation, and

commissioning

Risk of serious injury due to incorrect

proceedings.

Only qualified personnel who are

authorized and trained to assem le electri-

cal

components in hazardous (potentially

explosive) areas may do any of the as-

sem ly, disassem ly, inst

allation and

commissioning work.

For assem ly and operation of explo

sion

protected electrical equipment, relevant in-

stallation and operating regulations are

to

adhere (e.g. Betr.SichV, IEC/EN 60079-

14

and series DIN VDE 0100).

The data on the la el and the EEC design

test data are to e o served. Further tech-

nical information is

provided in the Bartec

catalog and on the product itself.

User may not drill holes in the

distri ution

oxes and add terminals

Do not open the distri ution ox

when

energized.

Assembly / disassembly

Death or serious injury because of a miss-

ing protective earth connection.

Metallic conductor entries must e con-

nected to the ground. With plastic enclo-

sures, BARTEC Earth loc or appropriate

ground plates serve the similar purpose.

Risk of serious injury due to incorrect pro-

ceedings.

The assem ly with connecting and/or rail-

mounted terminals must e implemented

under the consideration o

f the EEC design

inspection certificate.

Check when assem ling:

• Use suita le tools.

•

Pay attention to the type of mounting

required (for fitting into enclo-

sure/attachment with distri ution ox).

• For distri ution ox

es placed in outdoors,

steps must e tak

en to ensure smooth

operation, for example rain protected

roofs, and if necessary, sufficient enclo-

sure protection.

Installation

Risk of injury due to incorrect proceedings.

Extensions or modifications to the distri u-

tion ox are only permissi le if the manu-

facturer’s approval is o tained first.

The IEC/EN60079-14 must e o served.

Installations for the highly com usti le rang

e

must exhi it an EEC design inspection certifi-

cate.

Installation of these components must

take place in such way, so that at lea

st the

enclosure remains IP54.

Connection of ca les and conductors to equip-

ment in hazardous areas require Ex

certified

entries, which are suita le for re

spective ca le

and conductor types. They must possess the

protection type e” and contain a suita le se

aling

gasket, so that the prote

ction class of the

enclosure remains at least IP54.

Unused holes for ca le en

tries have to e

sealed with Ex-

certified plugs. Connection of

ca les and conductors of zone 21 and 22

equipment require at least the protection cla

ss

IP 66.

Operational Instruction (Original) Distribution box Type 07-5103-…./…., 07-5105-

…./…., 07-5106-…./…. and 07-5107-…./….

BARTEC

Varnost d.o.o.

Cesta 9.avgusta 59

1410 Zagorje o Savi

Slovenia

Tel.: +386 59 221 471

Fax: +386 59 221 470

info@ artecvarnost.si

www. artecvarnost.si

Reservation Technical data su ject to change without notice. Changes, errors and

misprints may not e used as a asis for any claim for damages.

EN 3/3

VS

– 11 01 301 (issue No I / 2.11.2016)

Connecting conductors

Risk of serious injury due to incorrect

proceedings.

All terminal positions, including the unused

ones, are to e tightened firmly.

The connectio

ns must e secured against

self-loosening.

Take care when connecting conductors:

• Remove approx. 6 mm (0.24 in) conduc-

tor insulation from the cores.

• Prepare the ends of fine-

stranded and

multi-

stranded conductors: Crimp wire

end sleeves with suita le crimping tools in

order to achieve

a constant pressure

quality.

NOTICE!

Take care not to damage

the individual wires.

• Release terminals.

• Put the wire in the terminals.

•

Tight the terminals with a maximum

permissi le torque depending from the

size of the screws. For information a o

ut

tightening torque of the terminal screw,

see the manufacturer´s catalogue.

Commissioning

Before commissioning, check that:

• The distri ution ox

has een installed in

compliance with regulations.

• The distri ution ox is not damaged.

• The connection has een esta lis

hed

properly.

• The ca les have een laid correctly.

• All screws have een tightened securely.

• The distri ution ox functions perfectly.

Note

Electrical equipments, before putting into

operation, and at certain ti

me intervals, are to

be subjected and to examination by an electri-

cal expert.

Operation

Death or serious injury through improper

use.

The distri ution ox

may e operated only

within the technical limits that apply to it

(see page 1).

Maintenance and

f

ault

c

learance

Risk of serious injury due to incorrect

proceedings.

Only authoriz

ed qualified personnel are

allowed to do any of the work relating to

maintenance and fault clearance.

IEC/EN 60079-17 must e o served.

Do not open the distri ution ox wh

en

energized.

Risk of serious injury due to damaged parts.

If any part of the equipment is damaged, it

should e exchanged only with original

parts (e.g. sealing gasket/ca le glands/

terminals).

Maintenance

Risk of serious injury due to electrostatic

charging.

For type 07-5106-…./…., 07-5107-…./….

,

and for windows with surface resistance of

>10

9

potential electrostatic

charging

hazard exist. Only wet cleaning is allowed.

The operator of the distri ution ox

must keep

it in good condition, monitor it

and clean it

regularly. He has to determine

the maintenance

intervals depending on the conditions of use.

Within the scope of maintenance:

• Check distri ution ox,

ca le entries,

sealings, and ca les regularly for cracks

and damage.

• Make sure that they are properly esta -

lished.

Fault clearance

The distri ution ox is defective if the encapsu-

lation is damaged and/or if one of the compo-

nents does not function any longer.

In this case:

• Replace defective parts in the encapsula-

tion with original parts immediately.

• Replace or repair the defective compo-

nents with original parts.

Note

Follow the components mounting instruc-

tions operating instructions to replace or repair

the components.

Accessories,

s

pare

p

arts

For accessories and spare parts, s

ee BARTEC

catalogue.

Disposal

The distri ution ox and its components

contain

metal and plastic parts.

Therefore the statutory requirements for dispos-

ing of electronic scrap must e o served (e.g.

disposal y an approved disposal company).

Note

Ensure environmentally friendly disposal

of all

components according to legal regulations.

Service Address

BARTEC VARNOST d.o.o.

Cesta 9.avgusta 59

1410 Zagorje o Savi Slovenia

Tel.: +386 59 221 471

Fax: +386 59 221 470

This manual suits for next models

3