IFM ecomat 100 R 360 Series User guide

Other IFM Controllers manuals

IFM

IFM CR720S User manual

IFM

IFM AE1300 User manual

IFM

IFM EC2121 User guide

IFM

IFM AC1433 Application guide

IFM

IFM SmartPLC DataLine AC1423 Application guide

IFM

IFM Ecomat 300 AS-i Series Application guide

IFM

IFM Ecomat 200 S 200 User manual

IFM

IFM Ecomat 300 AC1318 Application guide

IFM

IFM ecomatController User manual

IFM

IFM ecomat100 CS0015 User manual

IFM

IFM CR7132 User manual

IFM

IFM Ecomat 300 AC1355 Application guide

IFM

IFM CR1200 User manual

IFM

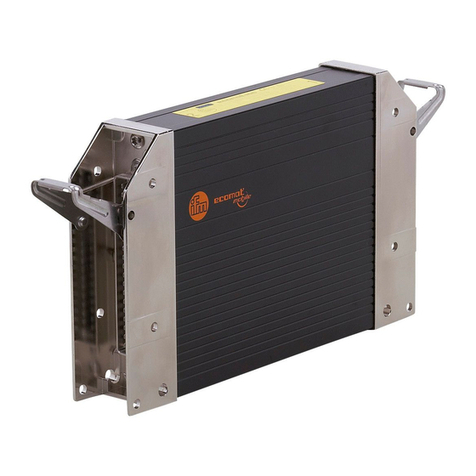

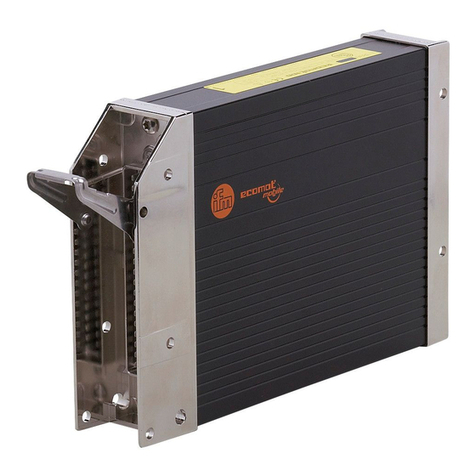

IFM ecomatController CR0708 User manual

IFM

IFM DX2011 User manual

IFM

IFM Ecomat 300 AC1307 Application guide

IFM

IFM Ecomat 100 CR0303 Application guide

IFM

IFM CR720S User manual

IFM

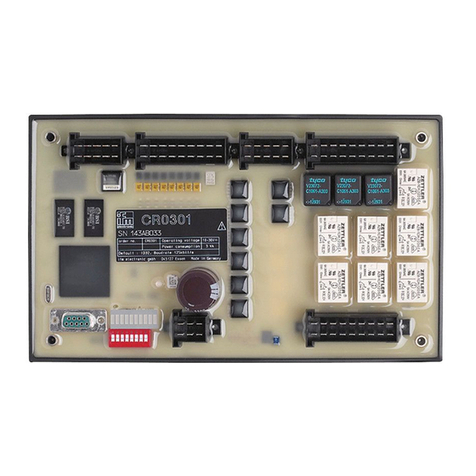

IFM Ecomat 100 Mobile CR0301 Owner's manual

IFM

IFM CR7032 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions