5

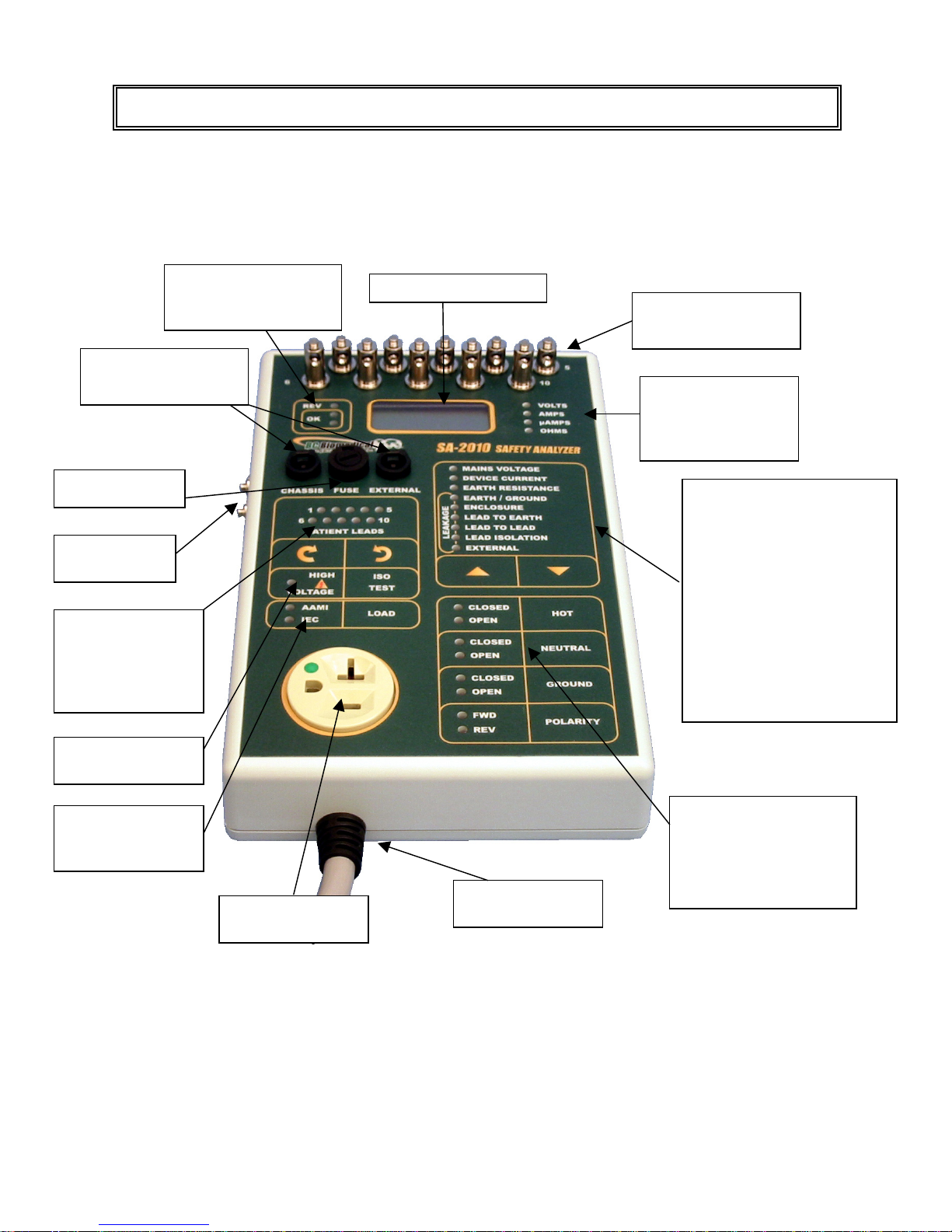

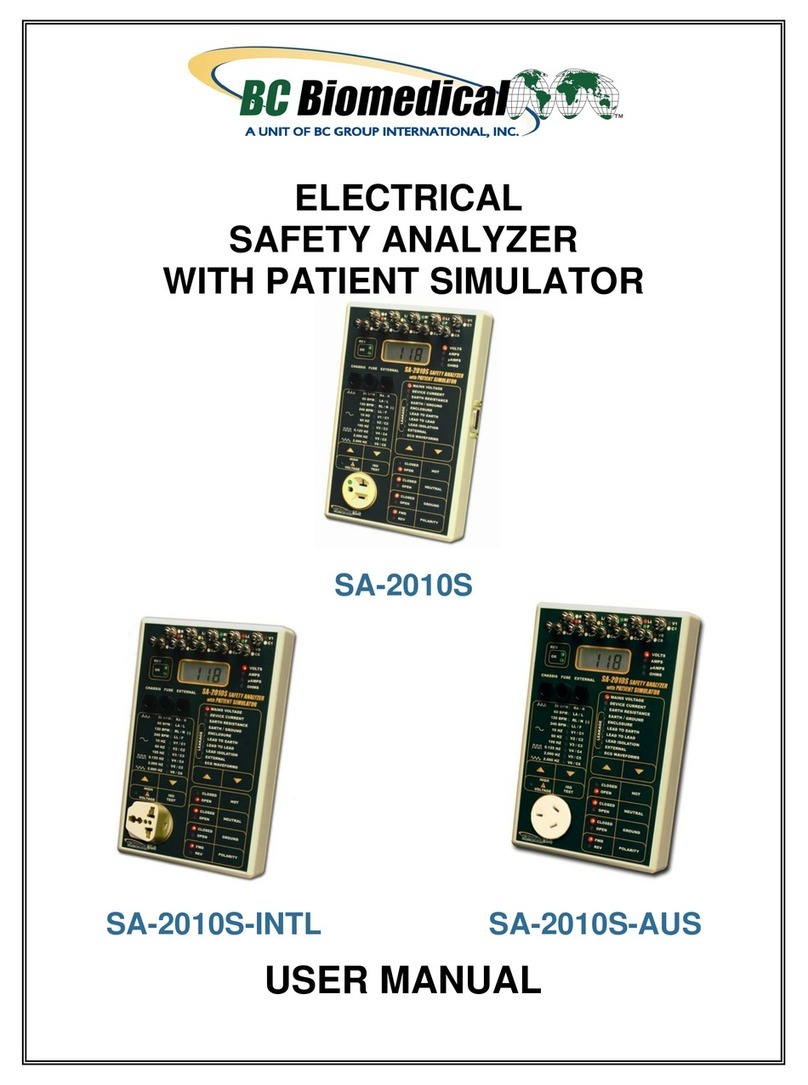

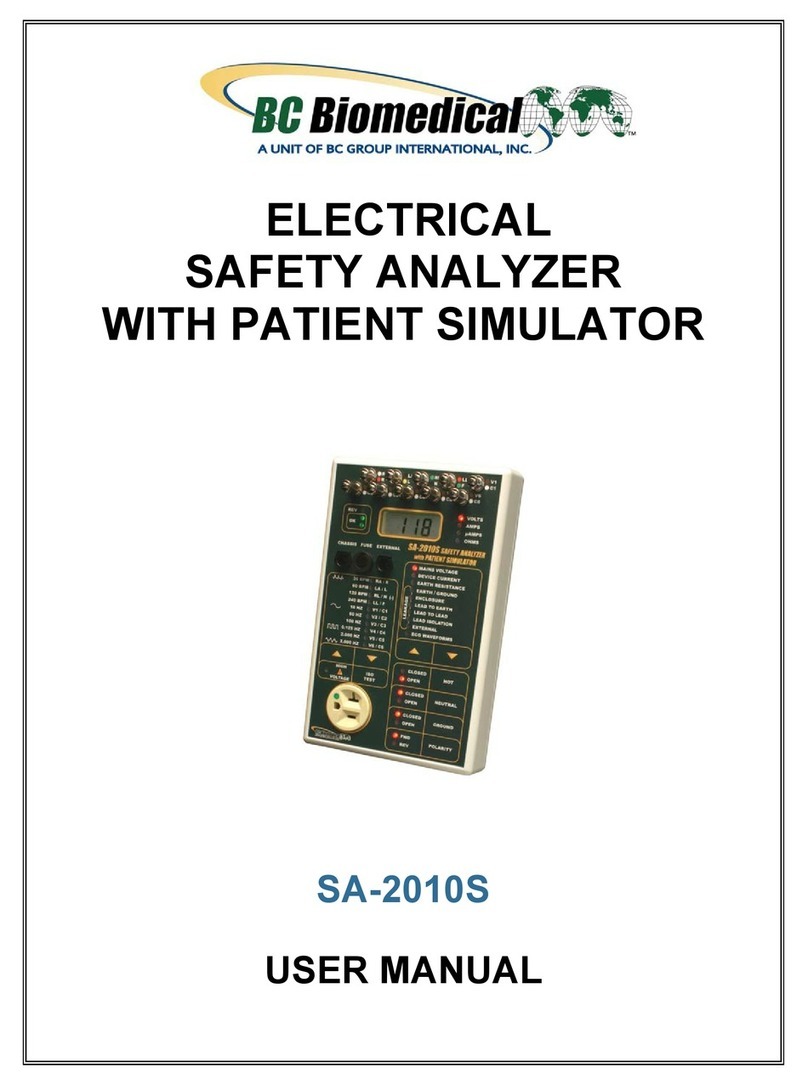

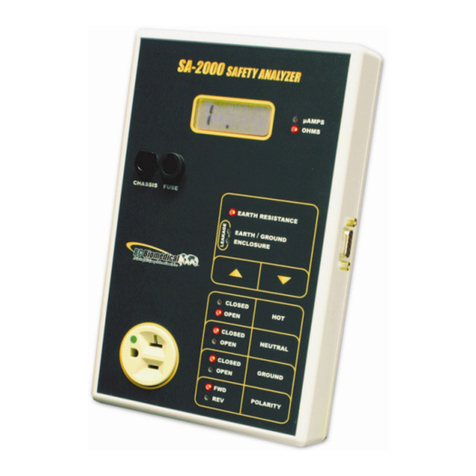

Display

The main information in the system is presented in the 3½ digit LCD display. This data is

provided as simple meter readings with the units indicated by one of the four LEDs on the

right of the display. The units LEDs will automatically change to the necessary range

based on the function selected.

Function Selection

Nine LEDs and two keys make up the Function Selection Section. The keys are up and

down arrows. When depressed, they step the Analyzer through the available options. The

LED next to the currently selected option is illuminated.

Analyzer Test Receptacle Control

There are four keys and 8 LEDs in the Analyzer Test Receptacle Control Section. They

allow the manual control of the power connections that are made to the DUT. Internally, a

series of relays are switched by the microprocessor based on the keys that are depressed.

The LEDs indicate the current state of the power connections to the Receptacle.

Note: The Forward/Reverse keys have an internal switching delay feature that first turns off

the power to the DUT, delays for a short period, reverses the lines and the turns the unit

back on. This eliminates the need for the user to remember to delay at this point or risk

damage to the Analyzer.

Load Selection

The unit may either use the AAMI ES1-1993 or IEC 601 Test load for measurements. This

is selected by the Load key and the current Load selection is indicated by the LEDs.

Patient Lead Control

In the maximum configuration, there are ten patient lead inputs. During testing, it is

necessary to select between these leads, select all of them and apply High Voltage to

them. This section provides the control keys to do these test configurations and the LEDs

to indicate the current state.

There is one LED for each input. Internally, there is a relay for each lead. The LEDs

indicate when that relay is on, thus selecting the indicated lead. The left and right arrow

keys sequentially select each lead in order and scroll through from None to 1-10 to All and

around again.

To apply High Voltage to the leads, the Isolation Test key is depressed. It is only active in

the Isolation mode. It is a momentary key, the voltage is only applied while the key is held

down.