BC Biomedical SA-2500 User manual

Operating Instructions

BC Biomedical SA-2500

Automated Safety Analyzer

User Manual

Standard Equipment

Contacts

Standard Accessories (included with Unit)

Product Support

Technical Questions

If required please contact:

1

1

SA-2500 Safety Analyzer

16 A country specific power cable for SA-2500,

not DUT, BC20-20400

Kelvin Coiled Chassis Cable, BC20-20150

Plug-on alligator clip, BC20-20152

CD-ROMwithremotecontrol software

USB Cable, BC20-41352

1

1

1

1

BC Biomedical

BC Group International, Inc.

Product Support Hotline

Phone:

E-Mail

Optional Accessories

•

•

•

•

•

ECG adapters, accepts 3&4 mm plugs, BC20-17024

ECG adapters, accepts 3mm plugs only, BC20-17025

International DUT

Test socket adapter, BC20-20200

Carrying case, BC20-30108

Replacement Fuses, BC80-00829

The accessories available for your instrument are checked for

compliance with currently valid safety regulations at regular inter-

vals, and are amended as required for new applications. Currently

up-to-date accessories which are suitable for your measuring in-

strument are listed at the following web address along with photo,

order number, description and, depending upon the scope of the

respective accessory, data sheet and operating instructions:

www.bcgroupstore.com

2

BC Biomedical

ContactPersons

Calibration Service

We calibrate and recalibrate all instruments supplied by BC

Biomedical, as well as by other manufacturers, at our

service

center.

Competent Partner

BC Biomedical is certified in accordance with

ISO

9001:2008.

Our calibration lab is accredited in accordance with

ISO/IEC 17025:2005 under registration number L2299 .

We offer a complete range of expertise in the field of metrology:

from testreports and factorycalibrationcertificates, right on up to

ISO-

17025 calibrationcertificates.Our spectrumofofferingsisrounded

out with test equipment management. Iferrorsarediscovered

during

calibration, our specialized personnel are capable of completing

repairs using original replacement parts. As a full service

calibration

lab, we can calibrate instruments from other manufacturers as

well.

Services

Repair and Calibration Center*

If required please contact:

BC Biomedical

Service Center

3081 Elm Point Industrial Drive

St. Charles, MO 63304

Phone:

E-Mail

1-800-242-8428

1-314-638-3800

service@bcgroupintl.com

•

•

•

•

•

•

Device and software updates to current standards

Replacement parts and repairs

Help desk

Calibration lab per ISO/IEC 17025:2005

Service

Contracts and test equipment management

Disposal of old instruments

*

accreditedinaccordancewithISO/

IEC 17025

Accredited quantities: AC/DC voltage, AC/DC current, resistance,

alternating voltage, alternating current value, capacitance, frequency,

force, pressure, and temperature

BC Biomedical

3

Table of contents

Contents

Page

Contents

Page

1

1.1

1.1.1

1.1.2

Applications .................................................................. 5

Classification of Devices Under Test .................................... 6

ProtectionClasses ............................................................. 6

Applied Parts (electrical medical devices) ............................ 6

8

Index .............................................................................. 37

2

Safety Features and Precautions ..................................... 7

3

Terminals ........................................................................ 9

4

4.1

4.1.1

4.2

4.3

Initial Start-Up ................................................................ 10

Connection to the Mains (90 to 240 V,50 to 400 Hz) ....................10

Automatic Recognition of Mains Connection Errors ........................10

Switching the Measuring Instrument On ............................. 10

Configuring Device Parameters –Setup Menu ................... 10

5

5.1

5.2

Manually Triggered Measurements .............................. 11

General Procedure ........................................................... 12

Overview .........................................................................12

6

Technical Data .............................................................. 30

7

7.1

7.2

7.3

7.4

7.5

Maintenance and Calibration ......................................... 34

Housing Maintenance ....................................................... 34

Replacing the Fuses ......................................................... 34

Recalibration .................................................................... 34

Manufacturer’s Guarantee ................................................ 35

Return and Environmentally Sound Disposal ....................... 35

4

BC Biomedical

Applications and Classification of Devices Under Test

1

Applications

Measuring Categories and their Significance per IEC 61010-1

The measuring instrument is intended for quick, safe

measurement of repaired or modified electrical medical devices

and their components (e.g. applications parts) in accordance with

IEC 62353.

Adherence to technical safety requirements assures safe handling

of electrical medical devices for users of the measuring

instrument. The safety of the patient is also assured during use of

tested electrical medical devices.

Use for Intended Purpose

•

The measuring instrument can be used as a benchtop device

which must be isolated and set up on a solid base while

measurements are being performed.

Only those measurements which are described in the following

chapters may be performed with the measuring instrument.

The measuring instrument, including the measuring probe,

may only be used within the specified measuring category (see

page 8, as well as the table below regarding significance).

Overload limits may not be exceeded. See technical data on

page 30 for overload values and overload limits.

Measurements may only be performed under the specified

ambient conditions. See page 32 regarding operating temper-

ature range and relative humidity.

The measuring instrument may only be used in accordance

with the specified degree of protection (see page 33).

!

Attention!

The measuring instrument may not be used for

measurements within electrical systems!

•

•

•

•

•

BC Biomedical

5

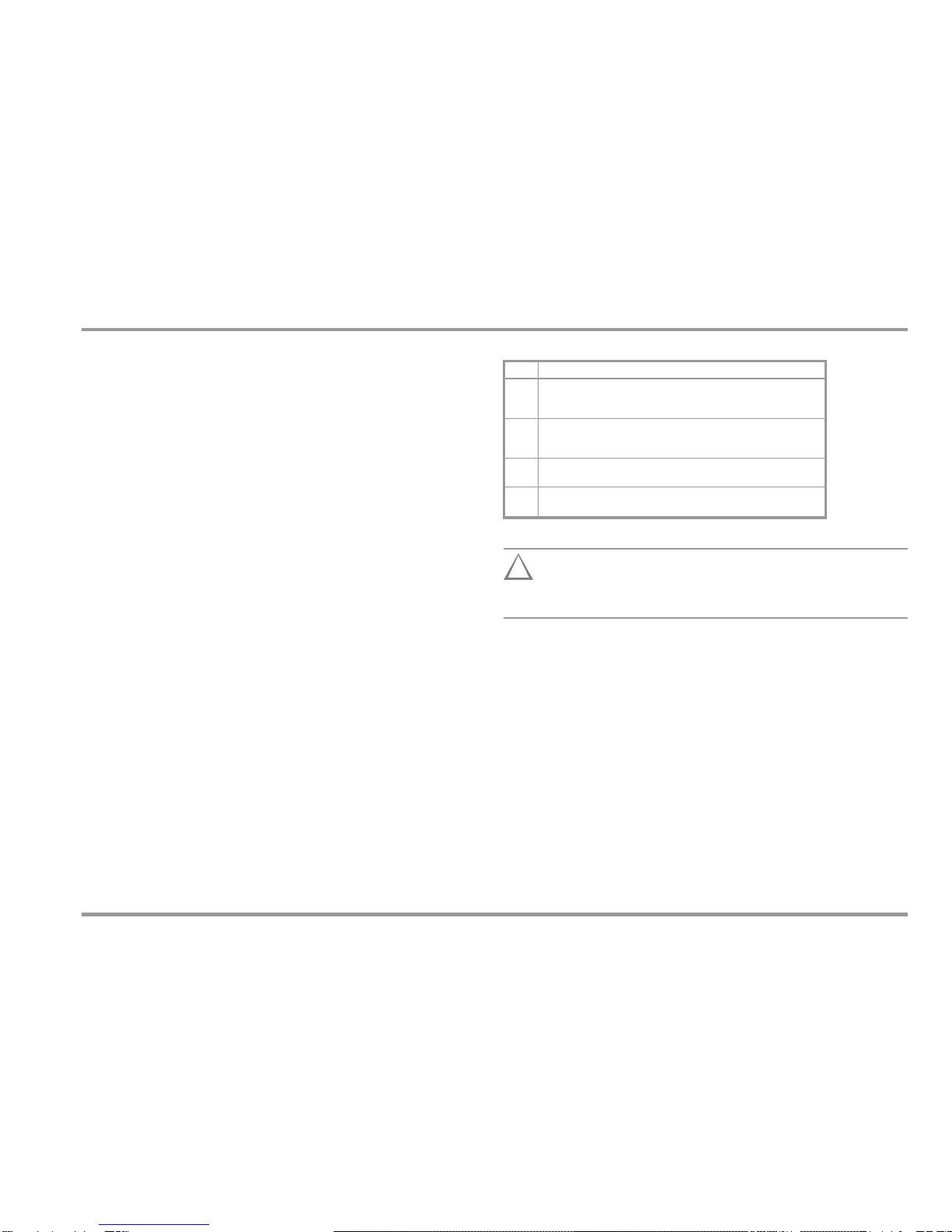

CAT

Definition

I

Measurements in electrical circuits which are not directly connected to

the mains: for example electrical systems in motor vehicles and

aircraft, batteries etc.

II

Measurements in electrical circuits which are electrically connected to

the low-voltage mains: via plug, e.g. in household, office and

laboratoryapplications

III

Measurements in building installations: stationary power consumers,

distributor terminals, devices connected permanently to the distributor

IV

Measurements at power sources for low-voltage installations:

meters, mains terminals, primary overvoltage protection devices

Applications and Classification of Devices Under Test

1.1 Classification of Devices Under Test

1.1.1 Protection Classes

Devices assigned to all of the following protection classes are

equipped with basic insulation, and provide for protection against

electrical shock by means of various additional precautions as well.

1.1.2 Applied Parts (electrical medical devices)

Type B Applied Parts

(body)

Devices of this type are suitable for both internal and external

patient applications, except for use in direct proximity to the heart.

These devices provide for adequate protection against shock,

especially as regards:

•

Reliable leakage current

•

Reliable protective conductor connection if utilized

Protection Class I Devices

Exposed, conductive parts are connected to the protective

conductor so that they are not charged with voltage if the basic

insulation should fail.

Type BF Applied Parts

(body float)

Same as type B, but with type F insulated applied parts.

Protection Class II Devices

These devices are equipped with double insulation or reinforced

insulation.

Type CF Applied Parts

(cardiac float)

Devices of this type are suitable for use directly at the heart. The

application part maynot be grounded.

Protection Class III Devices

These devices are powered with safety extra-low voltage (SELV).

Beyond this, no voltages are generated which exceed SELV.

These devices may not be connected to the mains.

Note: Only a visual inspection can be conducted for devices of this

protection class with the BC Biomedical SA-2500.

6

BC Biomedical

Safety Warnings

2

Safety Features and Precautions

Observe the following safety precautions:

•

The instrument may only be connected to electrical supply

systems with which conform to the valid safety

regulations

(e.g. IEC 60364, VDE 0100) and are protected with

a fuse or

circuit breaker with a maximum rating of 16 A.

Measurements within electrical systems are prohibited.

Be prepared for the occurrence of unexpected voltages at

devices under test (for example, capacitors may be

dangerously charged).

Make certain that the measurement cables are in proper

working

condition, e.g. no damage to insulation, no cracks in

cables or

plugs etc.

Insulation Resistance Measurement (alternative leakage current):

Testing is conducted with up to 500 V. Current limiting is

utilized (I < 10 mA), but if the terminals (L and N) are touched,

electrical shock may occur which could result in consequential

accidents.

Leakage Current Measurement

It is absolutely essential to assure that the device under test is

operated with line voltage during performance of leakage

current measurements. Exposed conductive parts may

conduct dangerous contact voltage during testing, and may

not under any circumstances be touched (mains power is

disconnected if leakage current exceeds approx. 10 mA).

Function Test

This instrument fulfills the requirements of applicable European

and national EC directives. This is confirmed by means of the CE

mark. A corresponding declaration of conformity can be

requested from BC Biomedical.

TheSA-2500 measuringinstrumenthasbeenmanufactured

and

tested in accordance with the following safety regulations:

IEC61010-1 / DIN EN 61010-1 / VDE 0411-1, DIN VDE 0404

IEC 61577 / EN 61577 / VDE 0413 part 1, 2 and 3

When used for its intended purpose, the safety of the user, the

measuring instrument and the device under test (electrical

equipment or electrical medical device) is assured.

Readtheoperatinginstructionscarefullyandcompletelybeforeplacing

yourmeasuringinstrumentintoservice.Followallinstructionscontained

therein.Makesurethattheoperatinginstructionsareavailable to all

usersof the instrument.

Tests may only be performed by qualified personnel, or under

the supervision and direction of qualified personnel. The user

must be instructed by qualified personnel in the execution and

evaluation of tests.

•

•

•

•

•

Note

Manufacturers and importers of electrical medical devices

must provide documentation for the performance of

maintenance by trained personnel.

•

!

Attention!

The function test may only be performed after the DUT has

successfully passed the safety test!

BC Biomedical

7

Safety Warnings

•

Power Consumers with High Inrush Current (> 16 A) –Function Test

(e.g. fluorescent tubes, halogen lamps, headlights etc.):

Observe the following instructions in order to prevent

excessive contact loads.

Meanings of Symbols on the Instrument

300 V CAT II

Maximumpermissiblevoltageandmeasuringcategory

between connections 1 through 4, the test socket and

ground

I

System with maximum 16 A nominal current

!

Attention!

Starting the Function Test

For reasons of safety, the device under test must be

switched off before the function test is started. This

precaution prevents inadvertent start-up of a device under

test which may represent a hazard during operation, e.g. a

cetrifuge.

Ending the Function Test

After completion of the function test, devices under test

must be turned off with their own switch –especially

devices with motors or other inductive loads.

Warning regarding dangerous electrical voltage

Warning concerning a point of danger

(attention: observe documentation!)

!

Per European Council Directive WEEE

2012/19/EU, do not dispose of this product as

unsorted municipal waste.

The measuring instrument may not be used:

•

•

If it demonstrates visible damage

With damaged connector cables, measuring cables or

patient ports

If it no longer functions properly

•

In such cases, the instrument must be removed from operation

and secured against unintentional use.

8

BC Biomedical

Terminals

3

Terminals

Jacks 1 through 10 for Applied Parts

USB Slave, to PC

1

10

Standard Socket (test socket)

for connecting the DUT

S1

S2

nection

Connections for Probes

Insertthedoubleplugoftheprobeintosockets 1and2suchthat

the plug with the white ring makes contact with socket 1 (silver

ring).

If 2 probes are used: If the first probe is, for example, the 25 m cable

drum (1-2), the test point is contacted with the second probe (3-4).

1)

For a lot of measurements, the protective conductor of the

test socket is not connected with the protective conductor

of the mains terminal.

1)

4-wire measurement possible

2)

4-wire measurement not provided for, see ”Measuring and Storing an

Offset Value when Using a 2

nd

Probe” on page 15

BC Biomedical

9

Connection

Application

TopConnections

Standardsocket

Testsocket

Sockets 1 through 10

Applied parts connection

USB-SI

USB slave, to PC

Bottom Connections

Sockets 1 and 2

Test probe connection (max. 300 V CAT II)

Sockets 3/4 (green)

Terminal for second test probe

2)

(max. 300 V CAT II)

Inlet socket

Connection for supply power (90 to 240 V, 50 to 400 Hz)

MainsCon

Fuses

Initial Start-Up –Setup

4 Initial Start-Up

4.1 Connection to the Mains (90 to 240 V, 50 to 400 Hz)

➭

Connect the mains plug at the measuring instrument to the

mains power outlet.

4.1.1 Automatic Recognition of Mains Connection Errors

The measuring instrument’s protective conductor connection is

tested each time the start-stop key is pressed.

If a voltage of greater than 25 V is detected between the

protective conductor and the finger contact, no measurements

are possible. Disconnect the measuring instrument from the

mains immediately in the event of a mains connection error, and

arrange for the error to be corrected!

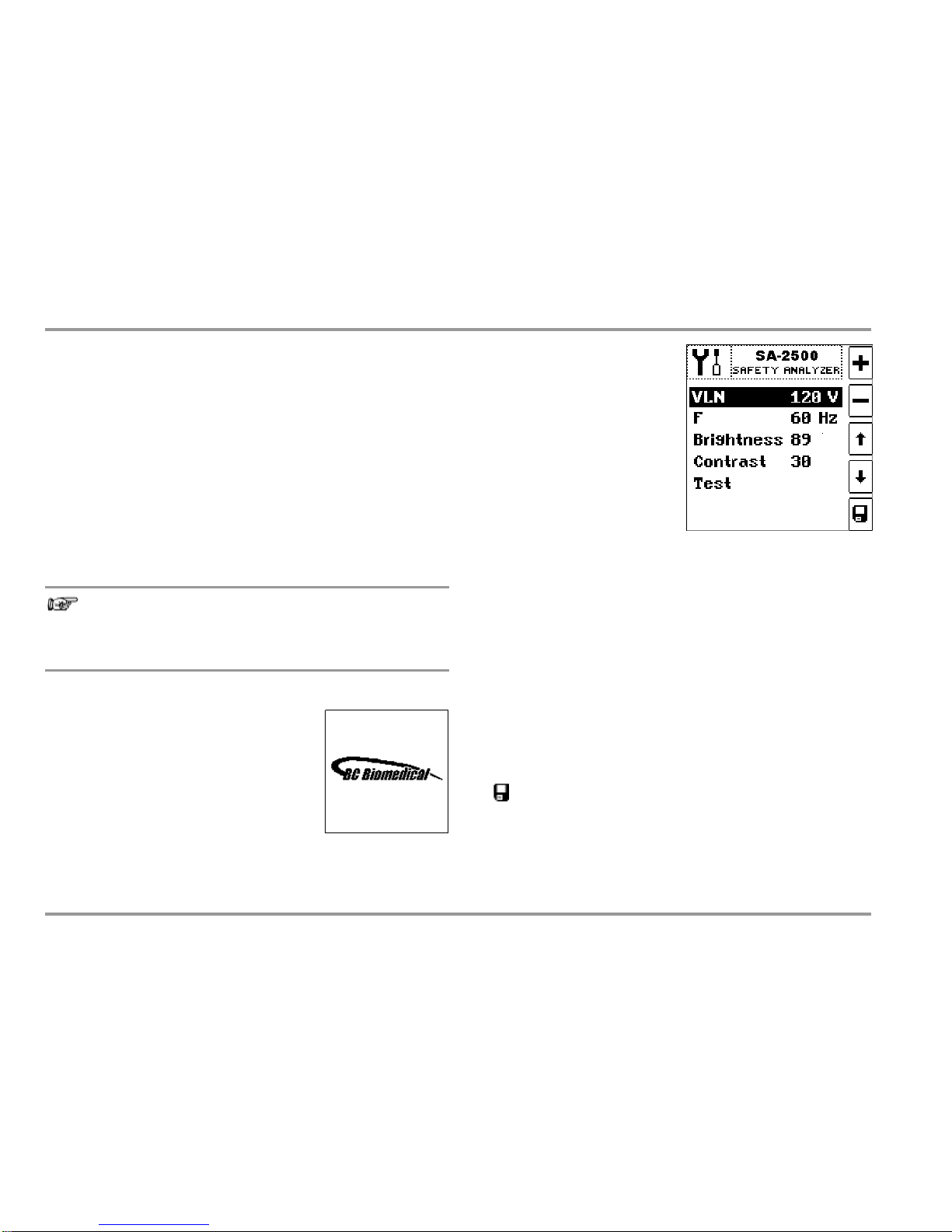

Selecting Nominal Line Voltage VLN

Measured values acquired by

means of leakage current mea-

surement are normalized to the

selected VLN voltage value. Line

voltage parameter VLN (100, 110,

115, 117, 120, 127, 220, 230,

240 or 250 V) can be selected

with the

keys, and adjusted

with the +/–keys. The voltage

value selected here is generated

by the measuring instrument for alternative measurement.

Setting Nominal Frequency

The frequency selected here is generated by the measuring in-

strument for alternative measurement of leakage current. Nominal

line frequency parameter F (50 or 60 Hz) can be selected with the

keys, and adjusted with the +/–keys. This setting is irrelevant

for direct measurement and differential current measurement.

Setting Brightness and Contrast

Brightness (1 ... 40 ... 100) and contrast (0 ... 40 ... 63) for the LCD panel

can be selected with the

keys, and adjusted with the +/–keys.

Activating Device Parameters

Changed values are permanently saved after acknowledging with

Note

Voltage at the mains protective conductor may cause

erroneous measured values during the measurement of

leakage current.

4.2 Switching the Measuring Instrument On

InitialWindow

The initial window shown at the right ap-

pears in the event of mains connection.

the

key. The display is then switched to the main menu. If the

setup menu is exited with the ESC key, the changed values only re-

main active until supply power to the instrument is interrupted.

Function Test

For testing the keys, LCD segments and the acoustic warning sig-

nal.

4.3 Configuring Device Parameters –Setup Menu

All of the settings which are required for operation of the

measuring instrument can be entered in the setup menu.

10

BC Biomedical

Local Operating Mode

Manual Test

5

Manually Triggered Measurements

Adjustable measuring parameters

are displayed as softkeys.

DIR

DIF

ALT

Direct measurement

Diff. current measurement

Alternative meas. method

PRINT:

Key for hardcopy functions

(inpreparation)

L/N

N/L

ESC:

Return to previous level

Mains polarity

ARROW

UP

HELP:

Access context sensitive help

Select measuring function

ARROW

DOWN:

MENU:

Access the main menu

(R

PE

measuringfunction)

Select measuring function

START

STOP: Start or stop measurement /

function test

SETUP:

Access the setup menu

–

Line voltage

–

Line Frequency

–

LCD brightness

–

LCD contrast

Contact Surface

For finger contact –PE potential check

Main Menu Display

!

Attention!

Remotecontrol ofthe SA-2500 should alwaysbe coordinated

with the user who is in contact with the measuring

instrument at the same time, for example in order to ex-

clude the possibility of contact hazards.

BC Biomedical

11

Operating Mode Display

–

Remote: highlighted display

–

Local: display not highlighted (see below)

Local Operating Mode

Manual Test

5.1 General Procedure

5.2

Overview

➭

➭

➭

Select the main menu: MENU key.

Select a menu function:

keys.

Depending upon the measuring function select either

–

Type of test current: DIR / DIF / ALT / DL key.

or

–

Protectionclassandtypeofconnection:PC1/PC2/FIX key.

Connect the device under test in accordance with the

previously selected type of test current.

14

➭

Depending upon the type of test current, it may be necessary to

use the probe.

The device under test is checked for short circuiting for all active

measurements during which the mains are connected to the test

socket (e.g. for leakage current measurements).

➭

Start the test with the START

STOP

key.

During measurement, a symbol representing a runner appears

at the upper left-hand corner instead of the measurement icon.

During measurement and after the measurement has been com-

pleted, measurement data can be read from the display.

➭

Ifnecessary,repeatthetestwithreversedmains

power

polarity:L/NN/Lkey.

➭

The display is returned to the main menu by pressing the ESC

key or the MENU key.

26

AP=appliedpart;PC1/2=protectionclassI/II;FIX=permanentconnection

12

BC Biomedical

Abbreviation

Measurement Type Parameter

Description

Measured Quantity /

Method

Type of

’Connection

Sockets:

Probe 1–2

APA ...K

Resistance Measurements

R PE

Protective conductor

resistance

PC1

l

Probe 1–2

Page

R INS

Insulationresistance

PC1

—

Page

16

PC2

l

Probe 1–2

FIX

Leakage Current Measurement

I E

Equipment leakage

current

DIR

Directmeasurement

Testsocket

l

AP A ... K

Probe 1–2

Page

18

DIF

Differential current

measurement

ALT

Alternativemeasurement

(alternative equipment

leakagecurrent)

I T

Touch current

DIR

Directmeasurement

Testsocket

l

Probe 1–2

Page

20

DIF

DifferentialCurrent

Measurement

ALT

Alternativemeasurement

(alternative equipment

leakagecurrent)

DL

Measurement with 2 probes

(cable drum at 1–2)

Probe 1–2

Probe 3–4

I P

Patient leakage current

DIR

Patient leakage current,

direct

Testsocket

l

AP A...K

Page

24

I AP

Appliedpartsleakage

current

DIR

Directmeasurement

(mainsat applied part)

Testsocket

l

AP A...K

Page

ALT

Alternative measurement

(altern.patientleakagecurrent)

Functions Tests

TEST

Voltage / Load current

Active/apparent power P/A

Power factor PF

Testsocket

Page

28

This page has been left blank to display the following measure-

ments on opposite pages for better clarity.

BC Biomedical

13

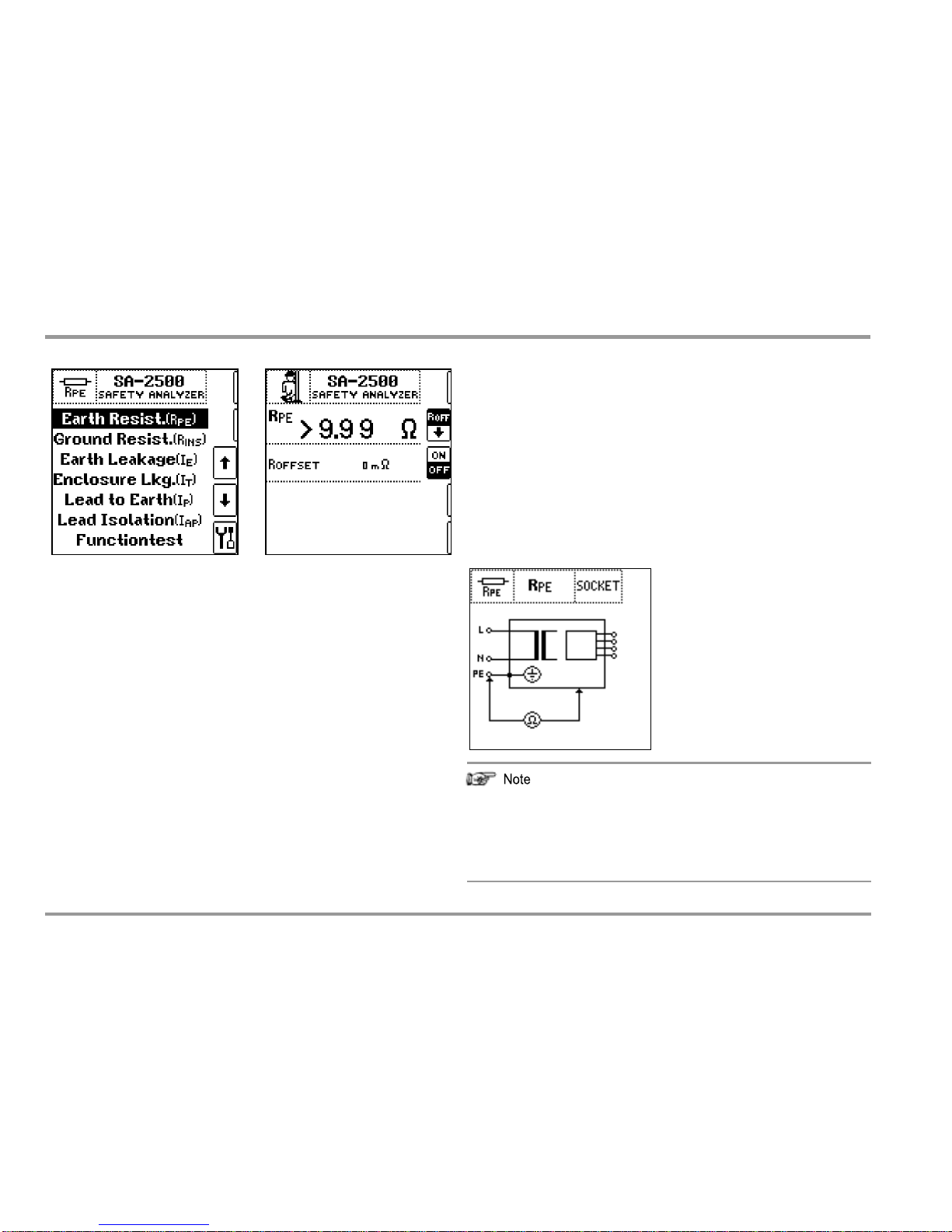

R

PE

ProtectiveConductorResistance

Measuring Method

Resistance is measured:

•

Betweeneachexposedconductivepart of the housing which

is connected to the protectiveconductor (probecontact) and

theearthingcontactsatthemainsand thedeviceplug(ifa

removablemainsconnectorcableisused).

•

Between the earthing contacts at the mains plug and the

earthing contacts at the device plug for device connector

cables

TestSocketConnection

Applications

Continuity and resistance of the protective conductor must be

measured.

Definition

Protectiveconductorresistanceistheresistanceofthe

connectionofaprotectionclassIdevice(PC1)betweenany

exposed conductiveparts whichareconnectedtothe protective

conductor and the protective contact at the mains plug or the

mains sideofthepermanentconnection.

Protective conductor resistance is the sum of the following

resistances:

The protective conductor of the test socket (which is not

connected with the protective conductor of the mains termi-

nal for this measurement) is permanently connected with

sockets 3 and 4 to which a second probe can be con-

nected.

•

•

•

Connector cable or device connector cable resistance

Contact resistance of the plug and terminal connections

Resistance of the extension cable

14

BC Biomedical

R

PE

ProtectiveConductorResistance

Measuring and Storing an Offset Value when Using a 2

nd

Probe

When a second probe is used which is connected to sockets 3

and 4, 4-wire measurements are not provided for. However, the

ohmic resistance of the cable for the second probe can be auto-

matically deducted from the measuring result by determining an

offset value. Please proceed as follows to this end:

➭

➭

Startthetest:PresstheSTART

STOPkey.

1

probe: Contact one of the conductive parts of the housing which is con-

nected to the protective conductor with the probe (socket 1–2).

2

probes: A cable drum or extension cable (socket 1–2) is contacted

with the reference point (e.g. overall earth electrode of a unit), the sec-

ond probe (socket 3-4) is contacted with the test point.

➭

Ð

Connect the two probes to sockets 1 and 2 or 3 and 4,

respectively. The probe extension cable or the probe

cable drum must generally be connected with sockets 1

and 2. Contact both probes with the same reference point.

This is equivalent to short-circuiting the two probes. The offset

value established in this way is retained by pressing the key on

the right (only for values < 2

), displayed briefly and will be

deducted from all future measuring results. You can store this

offset value, see key below.

After measuring the offset value, the latter can be per-

manently stored with the key on the right so that it is

available after switching the instrument on again.

Press the key on the right for loading a stored offset

value.

During measurement, the connector cable must only be moved to the ex-

tent that it is accessible during repair, modification or testing. If a change

in resistance occurs during the manual test step of the continuity test, it

must be assumed that the protective conductor is damaged, or that one

of the connector contacts is no longer in flawless condition.

➭

➭

➭

Measured values are displayed.

Endthetest:PresstheSTART

STOPkey.

Read the measured value and compare it with the table of

permissible limit values.

Ð

Examples of Maximum Permissible Limit Values for Protective Conductor

Resistance for Connector Cables with Lengths of up to 5 m

Ð

Cable

Only use this function if you work with extension cables.

When using different extension cables, the procedure

described above must principally be repeated.

Sequence

➭

Selectthetest:

keys.

➭

ConnecttheDUT tothetestsocket andconnecttheprobe.

BC Biomedical

15

Test

Standard

Test current

Open-

Circuit

Voltage

R

PE

Housing –

DevicePlug

R

PE

Housing –

Mains Plug

Connector

IEC 60601

IEC 61010

Production

Not defined

0.1

0.1

1.1

IEC 62353

(VDE0751-1)

> 200 mA

4 V < U

L

<

24 V

1.2

1.3

0.1

VDE 0701-

0702

—

0.3

+ 0.1

for each addi-

tional 7.5 m

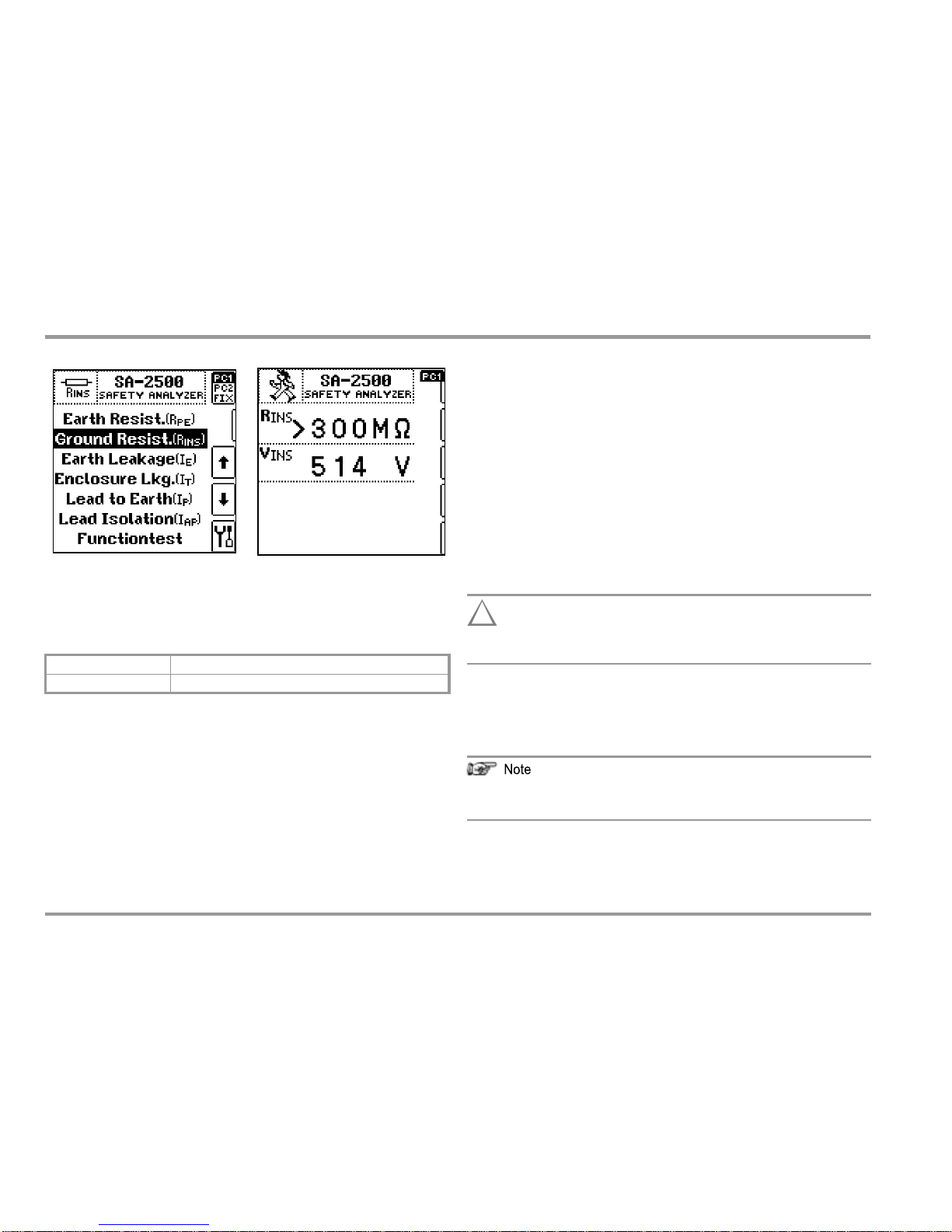

R

INS

InsulationResistance

Measuring Method

Protection Class I (PC1)

Insulation resistance is measured between short-circuited mains

terminals and the protective conductor.

Protection Class II (PC2)

Insulation resistance is measured between short-circuited mains

terminals and external conductive parts which can be contacted

with the probe.

Connection of Permanently Installed Protection Class I Devices

!

Attention!

Deactivate the electrical system which supplies power to

the device under test before connecting the test system!

Applications

Insulation resistance must be measured for:

➭

Remove the mains fuses from the device under test and

disconnectneutralconductorNinsidethedeviceundertest.

Connect the probe to phase conductor L at the device under

test in order to measure insulation resistance.

In order to assure that all insulation which is exposed to line

voltage is tested during this measurement, make sure that

switches, temperature regulators etc. are closed.

Definition

Insulation resistance is active resistance between the electrical

circuits of the device and its exposed conductive parts.

➭

ThePEcontact of thetestsocket isconnectedwiththe pro-

tective conductor of the mains terminal.

16

BC Biomedical

PC1: protection class l

Between L + N and PE

PC2: protection class ll

Between L + N and user accessible conductive parts

R

INS

Insulation Resistance

PC1 Connection

PC2 ConnectionI

Allswitches at the deviceunder test mustbeset tothe on posi-

tion during measurement of insulation resistance, including

temperature controlled switches and temperature regulators as

well. Measurement must be performed in all program steps for

devices equipped with program controllers.

➭

Start the test: Press the START

STOP

key.

!

Attention!

Testingisconducted with upto500 V.Currentlimiting is uti-

lized (I < 10 mA), but if the terminals (L and N) are touched,

electrical shock may occur which could result in conse-

quential accidents.

Permanent connection

Note: Open-circuit voltage is always greater than nominal voltage.

➭

PC2 connection:Contact exposed conductive parts with the

probe during measurement.

All measured values are displayed.

Endthetest:PresstheSTART

STOPkey.

Read the measured value and compare it with the table of

permissible limit values.

➭

➭

➭

Sequence

Protection class I devices: The protective conductor test must already

have been passed as a prerequisite for the insulation resistance test.

Examples of Minimum Permissible Limit Values for Insulation Resistance

➭

➭

Select the test:

keys.

Select the protection class and the type of connection:

PC1/PC2/FIX.key.

Connect the DUT to the test socket, and connect the probe if necessary.

➭

BC Biomedical

17

Test

Standard

TestVoltage

R

ISO

PC I

PC II

PC III

Heat

IEC 62353

(VDE 0751-1)

500 V

2 M

7 M

70 M

70 M

VDE0701-0702

1

M

2

M

0.25M

0.3 M

I

E

EquipmentLeakageCurrent(differentialcurrent–protectiveconductorcurrent–faultcurrent)

Definition of Alternative Measurement(alternative equipment leakage current)

Alternativeleakagecurrentis currentwhichflowsthroughthe

activeconductors of the device whichare connected toeach

other (L/N) to the protective conductor, or to the exposed,

conductive parts and the applied parts.

Direct Measurement Method

The device under test is operated with mains power. Current

which flows through the PE conductor to earth at the mains side

of the device connection is measured. The value which has been

adjusted to nominal line voltage is displayed (see section 4.3).

Theprotectiveconductorisineffectiveduringmeasurement!

Differential Current Measurement Method

The device under test is operated with mains power. The sum of

the momentary values of all currents which flow through all active

conductors (L/N) at the mains side of the device connection is

measured. The measurements must be performed with mains

plug polarity in both directions. The value which has been adjus-

ted to nominal line voltage is displayed (see section 4.3).

AlternativeMeasurementMethod(alternativeequipmentleakagecurrent)

The device under test is tested with the nominal voltage which

has been selected in the setup menu. Current which would flow

with this nominal voltage is displayed.

Type of Test Current Parameter

Applications

Equipment leakage current must be measured for all devices.

Definition of Equipment Leakage Current / Protective Conductor Current

IEC62353(VDE0751-1)

Current which flows from a power pack to ground via the protec-

tiveconductor, and viaexposedconductive partsof thehousing

and the applied parts.

Definition of Direct Measurement

Total amount of current which flows through the protective con-

ductor, probe and applied parts in the case of housings which are

isolated from ground.

Definition of Differential Current Measurement

Sum of instantaneous current values which flow via the L and N

conductors at the device mains connection. Differential current is

practically identical to fault current in the event of an error. Fault

current: Current which is caused by an insulation defect, and

which flows via the defective point.

–

DIR

–

DIF

–

ALT

Protectiveconductorcurrent,direct

Differential current

Alternative equipment leakage current

Mains Polarity Parameter

Polarity can be reversed for tests in accordance with the direct

and differential current methods.

18

BC Biomedical

I

E

EquipmentLeakageCurrent(differentialcurrent–protectiveconductorcurrent–faultcurrent)

Equipment Leakage Current with the Direct Measurement Method

Equipment Leakage Current with the Alternative Measurement Method

Sequence

The protective conductor is ineffective during measurement!

➭

➭

➭

➭

➭

➭

➭

➭

Select the test:

keys.

Connect the DUT to the test socket.

Select type of test current: DIR / DIF / ALT key.

Select mains polarity reversal: L/N / N/L key.

Start the test: Press the START

STOP key.

Measured values are displayed.

Endthetest:PresstheSTART

STOPkey.

Read the measured value and compare it with the table see bel.

EquipmentLeakageCurrentwiththeDifferential Current Measurement Method

Examples of Maximum Permissible Limit Values for Device Leakage

Current / Protective Conductor Current

BC Biomedical

19

Test Standard

Protec-

tionClass

Direct/DifferentialCur-

rent Measurement

Alternative Measurement

IEC 60601 3rd ed.

PC1

5 mA

10 mA

IEC 62353

(VDE 0751-1)

PC1

0.5mA

1 mA

PC2

0.1mA

0.5mA

VDE 0701/702

PC1

3.5mA

PC2

0.5mA

I

T

Touch Current –Testing for Absence of Voltage

Definition of Touch Current

Leakage current that flows from the housing or parts thereof –

with the exception of the patient ports –with which the user or the

patient may come into contact during use for intended purpose,

to ground or another part of the housing via an external

connection, except for the protective conductor.

Definition of Direct Measurement

Current which flows through the probe in the case of housings

which are isolated from ground.

Definition of Differential Current Measurement

Sum of instantaneous current values which flow via the L and N

conductors at the device mains connection. Differential current is

practically identical to fault current in the event of an error. Fault

current: Current which is caused by an insulation defect, and

which flows via the defective point.

Definition of Alternative Measurement (alternative equipment leakage

current)

Alternative leakage current is current which flows through the

active conductors of the device which are connected to each

other (L/N), to theexposed,conductiveparts.

Applications

ForprotectionclassIdevices,itmaybenecessarytoseparately

measureleakagecurrentfromexposedconductivepartswhich

are not connected to the protective conductor.

Only methods direct measurement and differential current mea-

surement can be used for devices for which isolation in the power

pack is not taken into consideration by the measurement (e.g. re-

sulting from a relay which is only closed in the operating state).

Leakage current measurement may only be performed at

protection class I devices after the protective conductor test has

been passed.

The device must be measured in all intended functional states

(e.g. switch positions) which influence leakage current. The

highest acquired value, as well as the corresponding function if

applicable, must be documented. The manufacturer’s

specifications must be adhered to.

20

BC Biomedical

Table of contents

Other BC Biomedical Measuring Instrument manuals

BC Biomedical

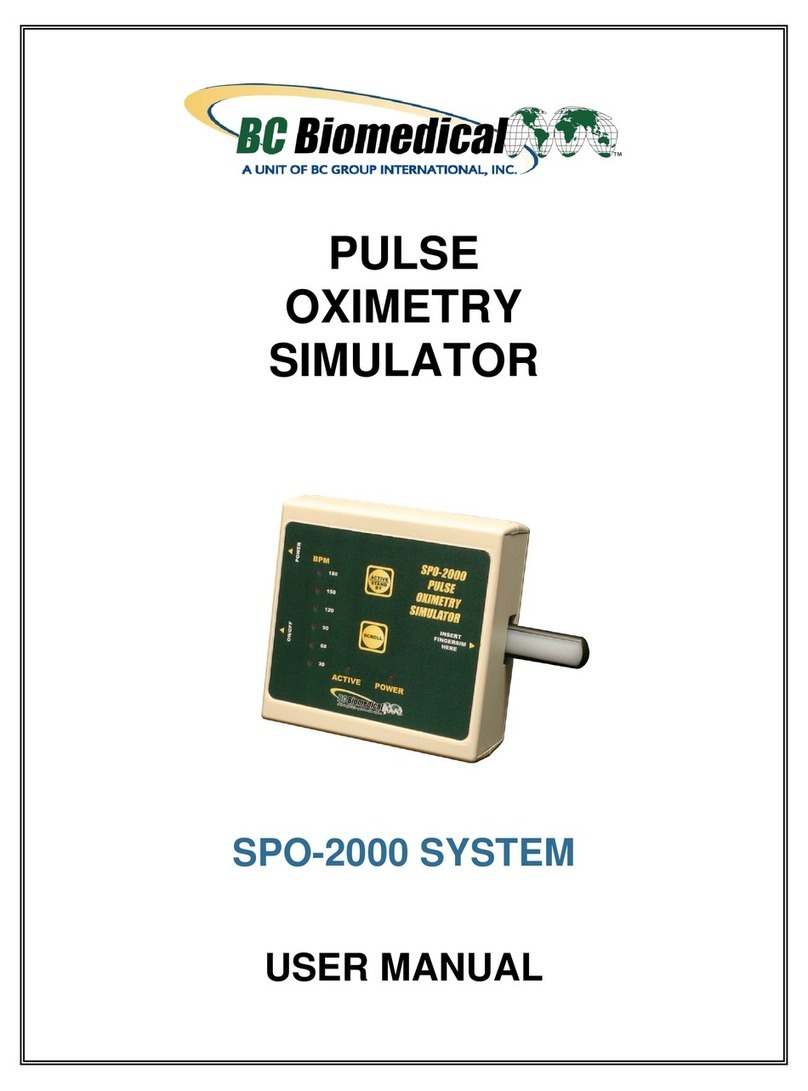

BC Biomedical SPO-2000 User manual

BC Biomedical

BC Biomedical DPM-2350 SERIES User manual

BC Biomedical

BC Biomedical USP-100A User manual

BC Biomedical

BC Biomedical USP-30 User manual

BC Biomedical

BC Biomedical PFC-3000 SERIES User manual

BC Biomedical

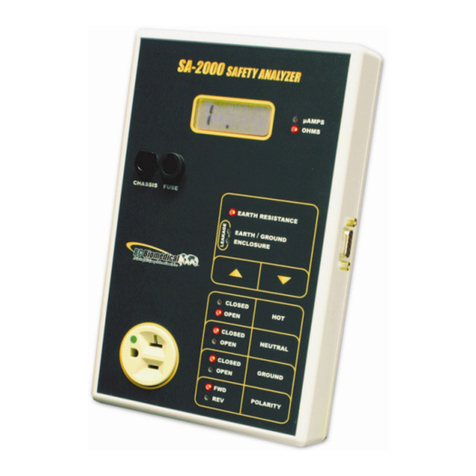

BC Biomedical SA-2010 User manual

BC Biomedical

BC Biomedical IPA-2000 User manual

BC Biomedical

BC Biomedical SPO-2000 User manual

BC Biomedical

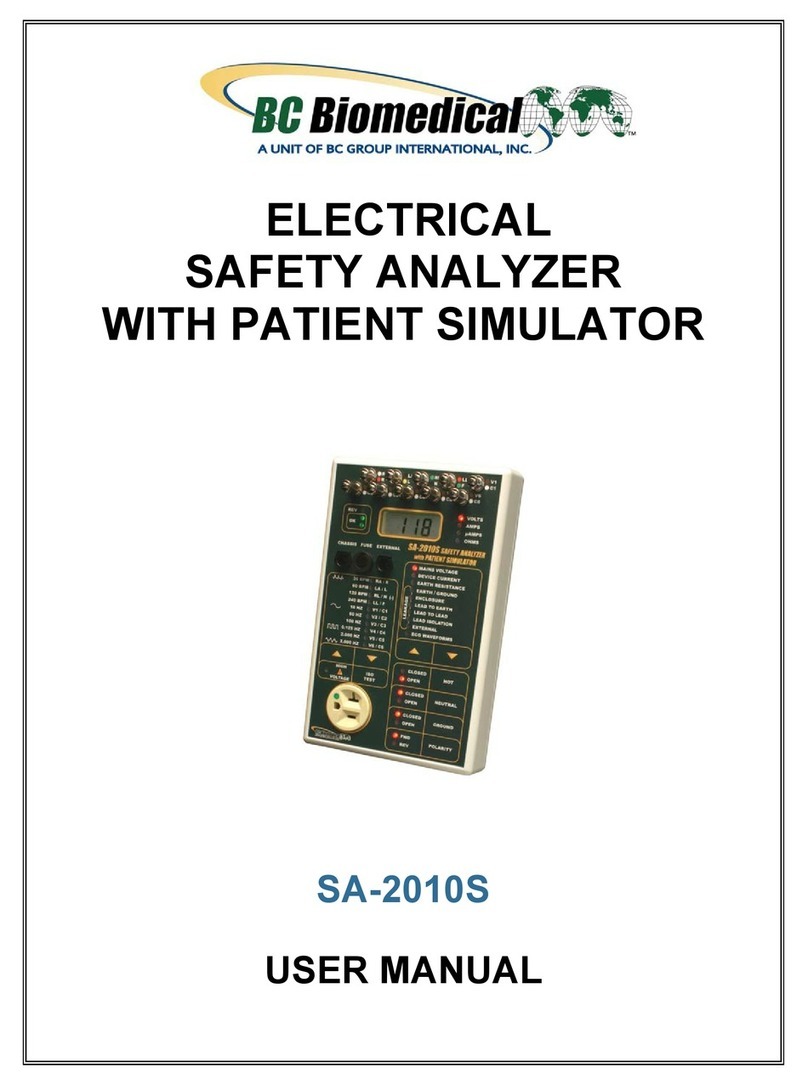

BC Biomedical SA-2010S User manual

BC Biomedical

BC Biomedical DA-2006 User manual