4

4 Operation 41

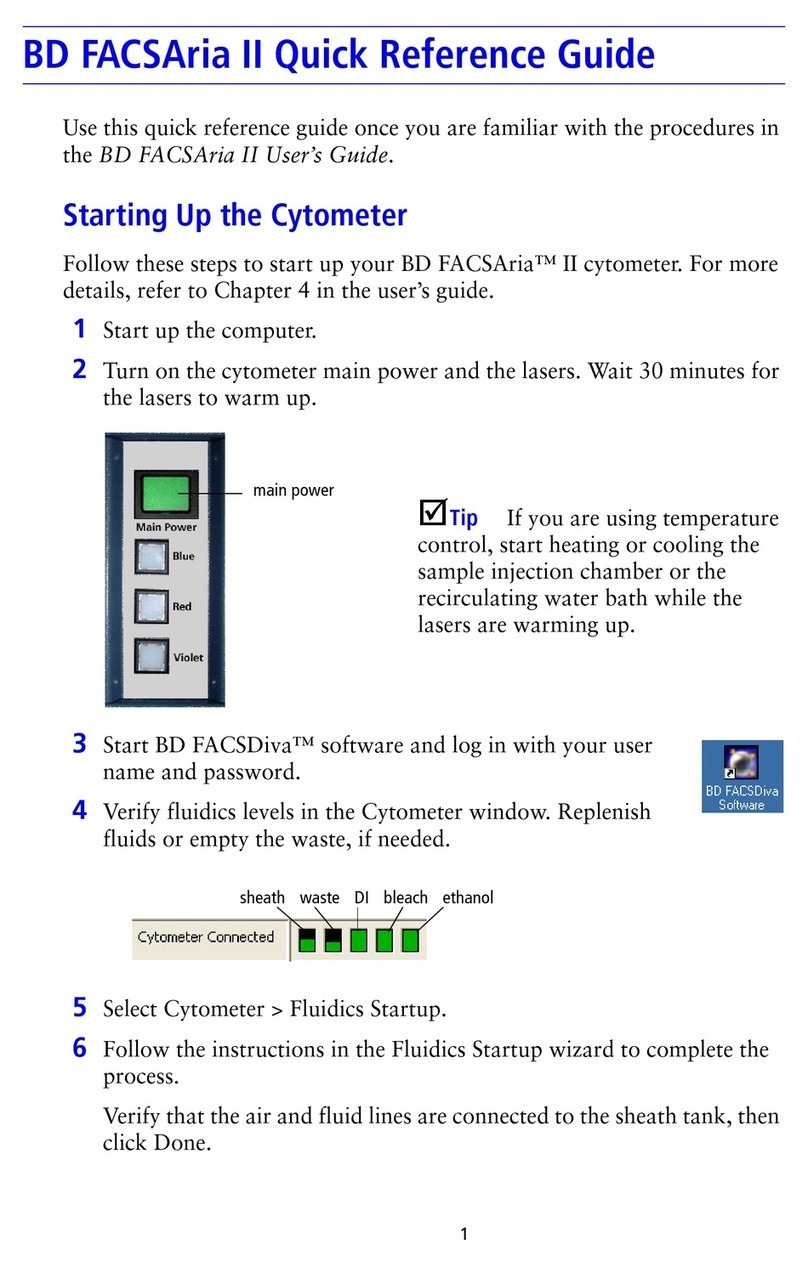

4.1 Startup 41

4.2 Login 43

4.3 Starting normal operation 43

4.4 Responding to notifications 44

4.5 Pausing operation 45

4.6 Emergency stop 45

4.7 Managing consumables 45

4.7.1 Selecting a media template 46

4.7.2 Filling destackers with plates 46

4.7.3 Loading pipette tips 46

4.7.4 Beads 47

4.7.5 Loading the SPM slide rack 48

4.7.6 Loading the SA slide dispenser 49

4.8 Fully automated specimen processing 49

4.8.1 Printing broth tube labels 50

4.8.2 Placing broth tubes in racks 51

4.8.3 Loading broth tube racks 51

4.8.4 Relabeling broth tubes 52

4.8.5 Placing specimen containers in racks 52

4.8.6 Loading specimen container racks 55

4.8.7 Starting fully automated processing 55

4.8.8 Processing Stat racks 56

4.8.9 Processing Stat slides 56

4.8.10 Unloading stackers 57

4.8.11 Unloading specimen container racks 57

4.8.12 Unloading the SPM slide rack 57

4.9 Semi-automated specimen processing 58

4.9.1 Defining a specimen batch 58

4.9.1.1 Deleting a specimen during batch creation 60

4.9.1.2 Adding or deleting a media protocol during batch creation 60

4.9.2 Starting semi-automated processing 61

4.9.2.1 Rejecting a plate during inoculation 63

4.9.2.2 Reprinting labels 64

4.10 End of run cleanup 64

4.11 Shutdown 65

5 Routine cleaning and maintenance 67

5.1 Cleaning and disinfection 67

5.2 Frequency of routine cleaning 68

5.3 Cleaners and disinfectants 68

5.4 Cleaning methods 68

5.4.1 Dry cleaning 69

5.4.2 Wet cleaning 69

5.5 Cleaning components 69

5.6 Cleaning table 73

5.7 Incidental cleaning 74

5.8 Decontamination 75

5.9 Preventive maintenance 76

5.10 Replacing the BarcodA printer ribbon and labels 76

5.11 BarcodA printer alignment 80

5.12 Replacing the InoqulA printer ribbon and labels 81

5.13 Purging the SPM print head 82

5.14 Replacing the Slide Processing Module ink cartridge 83

5.15 Cleaning the Slide Processing Module ink cartridge head 83

BD Kiestra™ InoqulA User's Manual