BE Power Equipment 96393-LJ User manual

96393-LJP1715EN

12.2021

1,700 PSI

OPERATOR'S MANUAL

ELECTRIC PRESSURE WASHER

MANUEL D’UTILISATION DU LAVEUSES PRESSION

MANUAL DEL OPERADOR DE LA LAVADORA A PRESIÓN

2

bepowerequipment.com

Congratulations on your purchase of a BE Power Equipment pressure washer. You can be confident that

this pressure washer is constructed and tested with optimum performance and quality in mind.

Reading this manual will help get you the best results for set-up, operation, maintenance and avoid

personal injury or damage to your machine. By knowing how best to operate this machine, you will be

better positioned to show others who may also operate the unit.

All the information in this manual is based on the latest product information available at the time of printing.

BE Power Equipment reserves the right to make changes at any time without notice or incurring any

obligation.

Owner/Operator Responsibility

The owner/operator must have a thorough understanding of the operation, maintenance and dangers

associated with using this machine. It must be understood that it is ultimately up to the owner/operator to

safely use this machine as outlined in this manual.

This manual is considered a part of the machine and needs to be kept in a safe location. If the machine is

resold or given to someone else, this manual needs to be included.

Record Identification Numbers

It is recommended that you record the product identification numbers in this manual. These numbers are

important to have on hand if you need to contact technical support (1-866-850-6662). The model and serial

number can be found on the box and on decal on the machine.

PRODUCT IDENTIFICATION

Model Number: P1715EN

Date of Purchase:

Dealer Name:

3

bepowerequipment.com

TABLE OF CONTENTS

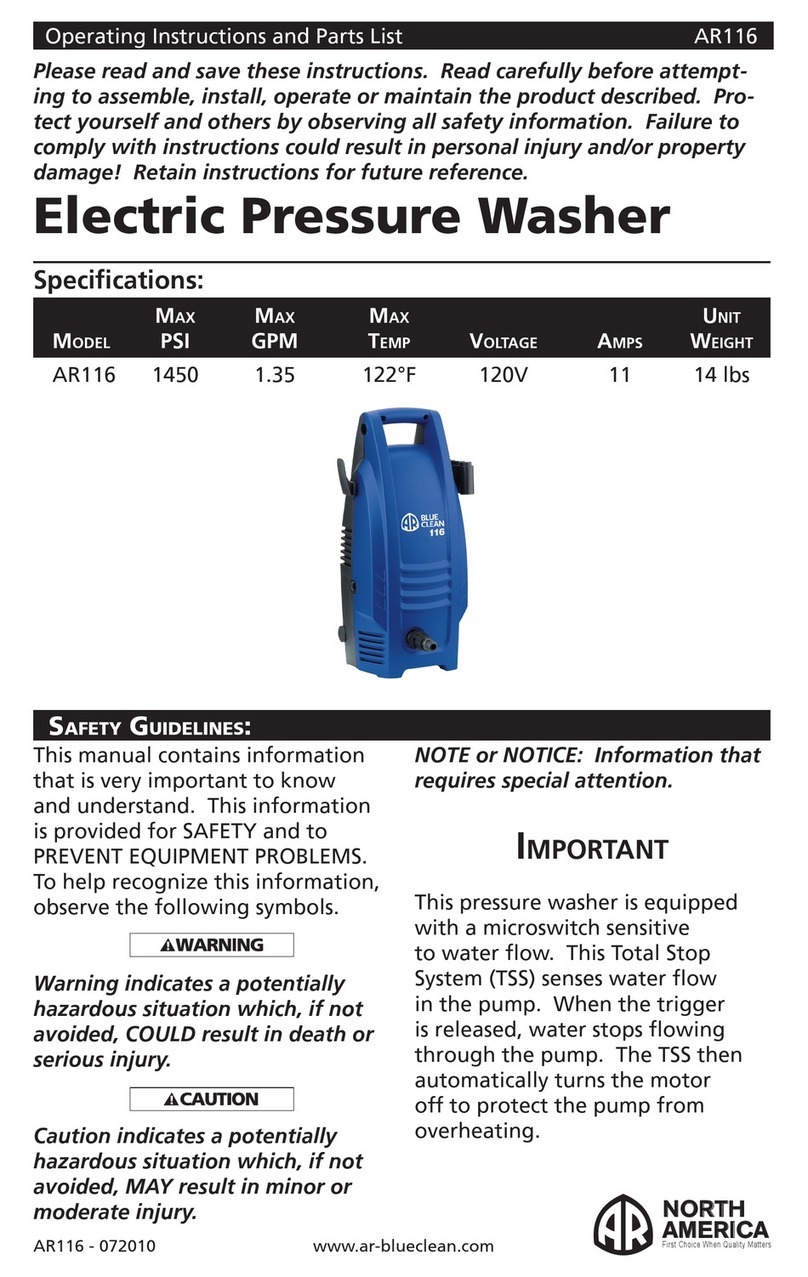

SPECIFICATIONS

Model

Max PSI

(lbs/sq. in.)

Max GPM

(Gal/per min)

Cold Water

Volts

Frequency

(Hz) Amps

Weight

(lbs.)

P1715EN 1700 1.7 ✓120 60 11 16.1

PRODUCT SPECIFICATIONS

Product Specications.......................................................................................... 3

Package Contents ................................................................................................ 4

Hardware Contents............................................................................................... 4

Safety Information ................................................................................................ 5

Assembly Instructions........................................................................................... 7

Operating Instructions ......................................................................................... 11

Care and Maintenance ....................................................................................... 13

Pump Saver........................................................................................................ 14

Troubleshooting.................................................................................................. 15

Limited Warranty ................................................................................................ 16

Replacement Parts List ...................................................................................... 17

4

bepowerequipment.com

PACKAGE CONTENTS

PACKAGE CONTENTS

HARDWARE CONTENTS

PART DESCRIPTION QUANTITY

G Spray Gun Lock/Unlock 1

H Foam Cannon 1

I Extension Lance 1

J 15°Quick Connect Nozzle 1

K Nozzle Cleaning Wire 1

L O-Ring Kit 1

AA Screws 2

PART DESCRIPTION QUANTITY

A Spray Gun Holster 1

B Handle 1

C Power Washer Unit 1

D Cord Hook 1

E Super Soft High Pressure

Hose

1

F Spray Gun 1

AA

Screws

Qty. 2

OFF/O

ON/I

H

750ml

600ml

450ml

300ml

150ml

F

G

E

B

C

K

A

DL

AA

PW95824

J

I

15° – Yellow

Note: Screws are located in

package with manual.

5

bepowerequipment.com

SAFETY INFORMATION

SAFETY INFORMATION

Please read and understand this entire manual before

attempting to assemble and operate the product.

This manual contains information that relates to

PROTECTING PERSONAL SAFETY and PREVENTING

EQUIPMENT PROBLEMS. It is very important to read this

manual carefully and understand it thoroughly before using

the product. The symbols listed below are used to indicate

this information.

DANGER

Potential hazard that will result in serious injury

or loss of life.

WARNING

Hazard that could result in serious injury or loss

of life.

CAUTION

Potential hazard that may result in moderate

injury or damage to equipment.

Note: The word “Note” is used to inform the reader of

something the operator needs to know about the tool.

WARNING

To reduce the risk of injury, the user must read

and understand the instructions before using

this product.

1. Warning – When using this product, basic precautions should

always be followed, including the following.

2. Read all the instructions before using the product.

3. Know how to stop the product and bleed pressures quickly. Be

thoroughly familiar with the controls.

4. Keep operating area clear of persons.

5. Do not overreach or stand on unstable support. Keep good

footing and balance at all times.

6. Follow the maintenance instructions as specied in the

manual.

7. To avoid personal injury and/or damage to property and to

maximize your power washer experience, carefully follow all

of the safety tips, instructions, warnings and safeguards and

become familiar with all of the controls. Be sure you know how

to quickly bleed o the pressure from all parts of your power

washer and how to turn o the power washer.

8. This power washer conforms to CSA and other safety and

consumer standards. DO NOT modify or rebuild any part of

your power washer.

9. DO NOT use your power washer when you are under the

inuence of alcohol or drugs. Use this power tool carefully and

only when you are alert.

10. Watch your balance and footing while using your power

washer. Surfaces become slippery when wet and are extra

slippery when using a detergent or cleaner.

11. NEVER operate the power washer in bare feet, sandals, or

open-toed shoes.

12. When using the power washer near children, make sure they

are closely supervised by an adult to avoid injury. NEVER let

a child use the power washer.

13. Keep ngers, hands, feet and any part of your body clear of

the stream of high pressure water. The powerful spray can

cause blindness or blast holes in the skin. It can break a

window if you are too close when you pull the trigger on the

spray gun.

14. ALWAYS wear eye protection to prevent injury to eyes when

operating the power washer.

15. To avoid mishaps or injury, ALWAYS use the trigger

safety lock when not using the power washer even if

only stopping briey.

16. The power washer is equipped with a Ground Fault Circuit

Interrupter (GFCI) (For US unit only) which greatly reduces the

chance of electric shock while the unit is in use. If replacement

of the plug or cord is needed, use only identical replacement

parts.

17. Point the spray gun in a safe direction when beginning a

power washer session.

18. Warning- NEVER spray directly at a person, animal, electrical

device or the unit itself.

19. When rst using the spray gun, hold the spray gun and lance

with two hands when pulling the trigger (one hand to pull the

trigger and the other to stabilize the gun assembly) until you

get used to the “kickback” from the spray gun.

20. When you turn the power switch o, water pressure may

remain in the system. To discharge the pressure, point the

spray gun in a safe direction and pull the trigger.

21. NEVER spray ammable liquids.

22. NEVER use the power washer in areas that contain

combustible dust, liquids or vapors.

23. Avoid contact of the pressure hose with sharp objects and

examine the hose regularly. Replace if damaged. Due to

the high pressure involved, it cannot be repaired if cut or

damaged.

24. Only use detergent specically formulated for power washers

and follow instructions on the detergent’s label. Dish or

laundry soap is too thick and will clog the nozzle of your foam

cannon.

6

bepowerequipment.com

Double Insolated Product

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE.

Servicing of a Double-Insulated Appliance

Ground Fault Circuit Interrupter Protection (For US unit

only):

This pressure washer is equipped with a ground-fault

circuit-interrupter (GFCI) built into the plugs of the power-

supply cord. This device provides additional protection

from the risk of electric shock. Should replacement of

the plug or cord become necessary, use only identical

replacement parts that include GFCI protection.

In a double-insulated product, two systems of insulation

are provided instead of grounding. Grounding means

are not provided for a double insulated product, nor should

grounding means be added to the product.

Servicing a double-insulated product requires extreme

care and knowledge of the system, and should only be

done by qualied service personnel.

Replacement parts for a double-insulated product must be

identical to the original parts.

A double-insulated product is marked with the words

“Double Insulation” or “Double Insulated”. Product may

also be marked with symbol shown here.

SAFETY INFORMATION

SAFETY INFORMATION

25. Protect eyes, lungs, and skin from exposure to

detergent.

26. Warning-If connection is made to a potable water

system, the system Should be protected against

backow.

CAUTION

Store the power washer indoors to prevent the

water in the unit from expanding under freezing

conditions. When the water freezes and expands,

your power washer will be damaged and become

inoperable. Or, if storing outdoors, it is

recommended you use pump saver (not included)

to protect pumps.

27. NEVER use hot water with your power washer. It will

overheat and damage the high pressure pump.

28. NEVER leave the power washer unattended while it is

powered “ON”.

29. ALWAYS turn the water supply on before turning the

power washer power to on. Running the pump dry will

cause damage to the internal components.

30. NEVER use a water supply to your power washer that

exceeds 150 PSI maximum.

31. NEVER disconnect the high pressure hose from the

power washer while the system is pressurized.

32. NEVER permanently engage the trigger mechanism on

the spray gun.

33. NEVER operate the power washer unless all

components are properly and securely connected.

34. NEVER allow the power washer pump to run for more

than one minute after you have turned o the water

supply. This can cause the motor and pump to overheat

and fail.

35. NEVER use lances or other parts that are not

compatible for this specic unit.

36. NEVER use an extension power cord since it defeats

the eectiveness of the GFCI (For US unit only) and

increases the chance of electrocuting the operator.

37. NEVER spray any electrical outlet with your power

washer.

38. Inspect the power cord before using. DO NOT use it if it

is damaged.

39. Stay alert - watch what you are doing.

7

bepowerequipment.com

PREPARATION

Before beginning assembly of product, make sure all parts

are present. Compare parts with package contents list and

hardware contents list. If any part is missing or damaged,

DO NOT attempt to assemble the product. Please call

customer service at 1-866-850-6662 for assistance.

Estimated Assembly Time: 5 minutes.

Tools Required for Assembly (not included): Phillips

screwdriver.

ASSEMBLY INSTRUCTIONS

PREPARATION

1

C

B

AA

OFF/O

ON/I

2

C

A

Power Unit Assembly

Install handle (B) to power washer unit (C). Secure with

screws (AA).

Note: DO NOT use a power screwdriver. When the

screw is completely tight, give a small nal clockwise

twist of the screwdriver.

DO NOT overtighten.

Screws x 2

AA

AA

Screw

Qty. 2

Slide spray gun holder (A) onto left side, when facing the

power washer unit (C) as shown.

Note: This step does not require any screws.

Hardware Used:

8

bepowerequipment.com

OFF/O

ON/I

3

C

D

Slide cord hook holster (D) onto right side, when facing

thepower washer unit (C) as shown.

Note: This step does not require any screws.

4

C

E

Super Soft High Pressure Hose Assembly

Screw Super Soft high pressure hose (E) clockwise onto

bottom front of power washer unit (C). Pull back collar and

insert o-ring post into water outlet far enough so collar can

thread onto outlet threads until hand tight. If it takes fewer

than six turns you have not properly tightened the Super

Soft high pressure hose tting. It is easier to position the

power washer in front of you to ensure that the threads

are started correctly. Failure to properly tighten high

pressure hose will result in the hose slipping or popping

o immediately upon turning unit on. Do not worry about

damage if this occurs–just reinstall and take extra care

when screwing on the Super Soft high pressure hose

tting.

Note: DO NOT use pliers or locking pliers to tighten.

5

E

F

Connect the other end of Super Soft high pressure hose

(E) to spray gun (F) by inserting the silver metal tip of

high pressure hose into the tting just ahead of trigger

guard. It will lock into spray gun with a “click”. Conrm

hose is locked into spray gun by slightly pulling on hose.

The hose is now securely attached to spray gun.

Note: DO NOT press button on underside of gun when

connecting hose to gun.

2

1

6

E

F

To release hose (E) from spray gun (F), press button on

underside of gun toward trigger guard. The hose will slide

out from connection.

ASSEMBLY INSTRUCTIONS

9

bepowerequipment.com

ASSEMBLY INSTRUCTIONS

Attach nozzle (J) into end of lance (I) by pressing selected

nozzle into place. It will make a “click” sound when rmly in

place.

Note: Always turn the safety lock dial to lock trigger when

changing lances and nozzles to ensure that they do not

accidentally eject with force during removal.

Locking Spray Gun (Before Lance Installation)

To lock trigger of spray gun (F), point gun away

from you and turn dial to lock (“3” and “9” position).

Squeeze or pull trigger to make sure it is locked.

ALWAYS leave in locked position when not in

use. This ensures the gun is in “safe” mode until it

is ready for use. Turn dial to unlock (“12” and “6”

position) to release spray gun trigger.

Note: The trigger lock prevents trigger from being

accidentally engaged.

7

F

Unlocked Locked

1

2

8

I

F

Extension Lance Installation

With spray gun (F) in locked position, attach extension

lance (I) directly to spray gun. Insert lance extension

into gun, pushing together and turning clockwise

simultaneously. Turn the extension collar clockwise to lock

into place. To remove extension lance (I), turn extension

collar counterclockwise to unlock, then push together and

turn counterclockwise to release.

Note: The extension lance must be inserted in gun

before using any of the other attachments, and in place

for storage. It is recommended that once extension is

connected to leave it in place.

9

I

J

1

2

10

I

J

To remove nozzle (J) pull back on collar of lance (I) and

pull out nozzle.

10

bepowerequipment.com

ASSEMBLY INSTRUCTIONS

14

C

Attach a standard garden hose to the black collar of

the garden hose adapter located on the back of the

power washer unit (C). The water is now connected

to your power washer.

Note: Flush out garden hose before connecting

to garden hose adapter.

11

1

750ml

600ml

450ml

300ml

150ml

2

H

1

F

H

12

2

13

750ml

600ml

450ml

300ml

150ml

C

H

Insert foam cannon (H) into spray gun (F), push in

and turn clockwise.

Note: Always lock spray gun when changing the foam

cannon to ensure it does not eject with force.

Foam Cannon Installation

The foam cannon comes with a straw which is tted

into high pressure top. If you do not see the straw,

look inside the foam cannon and attach it to the high

pressure top. When using foam cannon, ll it with a

properly formulated detergent or cleaner with a water

ratio according to instructions on the container.

• Pressure washer detergents are recommended.

See page 13 for more information.

•DO NOT use thick or gel-like detergents as they will

clog the foam cannon and can cause damage.

Foam Cannon Storage

Store the foam cannon (H) on the back of the power

washer unit (C).

ASSEMBLY INSTRUCTIONS

11

bepowerequipment.com

OPERATING INSTRUCTIONS

• Make sure the “ON/OFF” switch is in the “OFF”

position. The power switch has international

symbols for ‘on’ and ‘o’: On (|) O (O).

• Unwind the power cord completely and plug the

GFCI (For US unit only) into a grounded 120 volt

outlet.

• Turn on water supply at the faucet to completely

open.

• Release safety push trigger lock up and back into

trigger. While pointing the spray gun in a safe

direction, squeeze the trigger on the spray gun

until there is a steady stream of water, letting the

water and air out of the hose. Push trigger lock

back down to lock back into place.

• Turn the power switch to the “ON” (|) position. The

unit will turn on for 1 - 2 seconds and shut o. This

is a normal function of the auto start feature.

• Begin power washing by squeezing the trigger on

the spray gun all the way into the handle.

• Release the spray gun trigger to stop the power

washer

• Allow the motor to come to a complete stop before

squeezing the trigger again.

• Squeezing rapidly will cause the auto start feature

to miss an on/o cycle that may prevent it from

turning on while squeezing trigger after rapid

squeezing. Use slow deliberate trigger pulls to

avoid such symptoms.

• Always test a small area to avoid chance of

damaging the surface.

OFF/0

ON/I

OFF/0

ON/I

12

bepowerequipment.com

OPERATING INSTRUCTIONSOPERATING INSTRUCTIONS

Operation Tips

• Note:

Test the GFCI (For US unit only) before each

use:

1. Plug GFCI into power outlet. Indicator should

turn green to show that cord has power.

2. Press test button, green indicator should turn

o to verify that GFCI cut o power to the cord.

3. Press reset button – green indicator should

turn on to show that cord has power again.

4. When GFCI is working properly, green

indicator will turn on when power is applied.

If green indicator turns o, it has detected

electric leakage and the GFCI cut o power to

theappliance.

• If you hear the motor run intermittently when the

trigger is not being squeezed, that is normal. The

pump is priming itself so it is ready to operate

when the trigger is squeezed. Turn o the power

washer if not being used after ve minutes.

• The o-rings on the bayonet end of the nozzle

lance should be cleaned regularly and lubricated

with non-water soluble grease such as petroleum

jelly.

• Keep the nozzle cleaning wire for use in

unclogging the nozzle. If you lose the cleaning

wire, a straightened paper clip also works.

How to Avoid Damaging Surfaces

• Damage to surfaces being cleaned occurs

because the impact force of the water pressure

exceeds the durability of the surface. Bare wood

can be penetrated; paint can be peeled o, etc.

You can vary the force of your power washer by

controlling:

1. The angle of the surface being cleaned.

2. The distance of the nozzle from the surface

being cleaned.

• NEVER use a narrow high pressure stream of

water on soft surfaces susceptible to damage.

Adjusting Soap Levels on Foam Cannon

Twist knob to adjust the level of soap as indicated

on the top of the Foam Cannon (H). Twist toward the

higher concentration of bubbles for more soap, or the

opposite direction for less.

H

F

13

bepowerequipment.com

Detergents

• Use detergents designed for power washers.

Hardware stores or home centers also have power

washer detergents for dierent cleaning projects.

The cleaning solution should be the consistency of

water in order to prevent clogging your detergent

bottle and nozzle.

• This system applies detergent under low pressure.

The cleaning power of the detergents is enhanced

when applied with low pressure and enough

time is given to break down dirt and grime. The

combination of low pressure and chemical action

is very eective and can be better than scrubbing

if applied properly. ALWAYS spray detergent on a

dry surface. DO NOT pre-soak area. Wetting the

surface rst dilutes the detergent and reduces its

cleaning ability. DO NOT allow detergent to dry

on surface. On vertical surfaces being cleaned,

apply detergent to lower surfaces and work your

way up to prevent detergent from causing streaks

in the dirt and grime. Rinse detergent by pressure

washing from bottom up for same reason.

• If a stain is particularly tough, it may be necessary

to reapply the detergent and use a bristled brush

to scrub the stain. Subsequent power washing

after brushing should successfully complete your

cleaning job.

Cleaning Garden Hose Adapter

• The screen inside the adapter should be cleaned

periodically. Remove it by dragging a thumb over

the screen with enough pressure to pull the screen

and washer out. Rinse it with clean water and then

place it back in the adapter.

Cleaning Nozzles

• A clogged or partially clogged nozzle can cause

signicant reduction of water pressure coming out

of the nozzle and/or cause the unit to pulsate while

spraying.

• Turn o the unit.

• Turn o the water supply to the unit.

• Relieve any pressure trapped in the hose by

squeezing the trigger 2-3 times, and then lock the

spray gun by pushing the lock button from left to

right.

• Remove the lance from the extension lance.

• Take o the variable spray nozzle lance. Rotate

the nozzle to narrow the stream setting which

opens up the fan blades.

• Using the nozzle tip cleaner provided (or an

unfolded paper clip), insert the wire into the nozzle

hole and move back and forth until debris is

dislodged.

• Tap quick connect end of lance on hard surface

several times.

• Back ush water through the nozzles using garden

hose and highest pressure available (either

standard water nozzle or use your thumb over the

nozzle to create water pressure for back ush).

CARE AND MAINTENANCE

14

bepowerequipment.com

CARE AND MAINTENANCE

PUMP SAVER

Pump Saver is a product that protects and prolongs

the life of the pump. This will keep the internal parts

of the pump lubricated and protected from freezing

while being stored in ALL climates. It also assists with

protection from internal corrosion. The BE Power

Equipment part number is: 85.490.046. Purchase at a

BE Power Equipment retailer near you.

Pump Saver Instructions

Follow the previous storage instructions for your

power washer. To prevent staining, protect the surface

under the power washer from any excess uid. Wear

eye protection when using this product.

Turn unit o and disconnect the gun before adding

pump protector. Unscrew threaded top from bottle to

remove seal and reattach threaded top to bottle.

Remove black cap from bottle.

1) Place top of pump saver bottle onto the garden

hose adapter.

2) Secure pump saver bottle by turning in a clockwise

direction.

3) Turn the power on.

4) Squeeze bottle to help it into the pump.

5) Turn power o when pump saver exits the

machine’s water outlet.

Note: Instructions on Pump Saver Bottle are generic

and not model specic.

1

2

Storage

• When your pressure washer session has been

completed, turn o the power switch located on

the front of the power washer. Unplug the power

cord from the outlet. Turn o the water supply.

Pull the trigger on the spray gun 2-3 times to

drain out the excess water and to release any

remaining water pressure. Disconnect the garden

hose adapter from the water inlet. DO NOT allow

the power washer to run with no water owing

through it.

• Remove high pressure hose from spray gun.

• Remove lance from the gun. Place the gun in the

holster on the side. Lances are placed into any of

the slots in the back of the unit.

• Make sure to discard any remaining detergent

from the bottle. Residual chemical will stick to

the container which could become cotaminated,

and can cause the detergent injector to clog and

not function properly. Flush the bottle and nozzle

head with fresh water to prevent clogging.

• Hook the power cord around the cord hook on the

right side of the machine when facing it.

• The pressure hose is stored on the hose hook

located on the back of the handle.

• DO NOT store the power washer where it is

exposed to freezing temperatures unless you

use an antifreeze designed for pumps. Store the

power washer indoors to prevent the water in the

unit from expanding under freezing conditions.

When the water freezes and expands, your power

washer will be damaged and become inoperable.

Or, if storing outdoors, it is recommended you use

pump saver (not included) to protect pumps.

15

bepowerequipment.com

PROBLEM CORRECTIVE ACTION

Unit will not turn on. 1. The GFCI module on the end of the power cord must be plugged directly into an

outlet.

2. Do not use an extension cord.

3. With the GFCI Connected make sure the power switch is turned on.

Note: When power switch is turned on, the power washer will turn on by itself for 1-2

seconds and shut o. This is normal.

The high pressure

(HP) hose will

not connect/stay

connected to the

spray gun. Is this a

spray gun problem?

1. In most cases, the spray gun is not the problem. The problem is the rubber sleeve

covering the tting at the end of the high pressure hose. It has likely slipped up

toward the metal tip. To x: wiggle, twist and/or pull the rubber sleeve down until the

entire tip is visible plus an 1/8 in. of the metal tting below the tip. Now try to insert

the hose tip into the spray gun. It should “click” into place and will not come out

until the hose is released by pushing in the lever on the underside of the gun. You

may cut away the end of the sleeve with a sharp knife if unable to move the sleeve

down. Be careful not to cut or puncture the hose.

2. Do not push in the release button when connecting the high pressure hose.

The unit is running

but there is no water

ow.

1. Power should NOT be turned on until water comes through the spray gun. Doing so

will damage the motor.

2. Check the water source.

3. Eject the nozzle from the lance to determine if clog is coming from the nozzle (If

nozzle is clogged, see nozzle cleaning instructions under “Cleaning nozzles”).

4. Take o the lance and just spray out of the spray gun. This will indicate if the

problem is with the lance.

5. Check Garden Hose Adapter for loose connection and the lter for debris.

Why is water

leaking where the

high pressure hose

connects to the spray

gun?

1. Make sure there is an o-ring at the end of the metal tip of the high pressure hose.

If no o-ring is present, the connection between the hose and spray gun will leak.

O-Ring Replacement Kit (L) is included with purchase.

I can’t remove the

lance from the spray

gun. What should I

do?

1. All lances and the detergent bottles are attached and removed from the extension

lance in the same manner. Insert the quick-release end of the lance/detergent

bottle into the extension lance. Press the extension lance and lance together

(about a 1/8”) and turn clockwise. The lance will lock in place. Remove the lance

by reversing this procedure. Press the extension lance and lance together and

turn counter clockwise. The lance will slide out.

2. Or, hold the extension lance and lance in an upright position with the nozzle end

on the oor. Push the whole assembly straight down to loosen the connection,

and then follow the removal process again. You may also spray soapy water or a

lubricant in the area where the lance connects to the extension lance.

If you have any questions regarding the product,please call customer service at 1-866-850-6662.

TROUBLESHOOTING

16

bepowerequipment.com

TROUBLESHOOTING

LIMITED WARRANTY

BE Power Equipment Inc. warrants the original retail purchaser that this pressure washer is free from defects

in material and workmanship for the periods set forth below. If defects are found in BE Power Equipment

products within the limitations outlined in this warranty statement, BE Power Equipment, at its sole discretion,

will repair or replace the product free of charge.

The warranty coverage is for one year and begins on the date of purchase by the end-user. Valid proof of

purchase must be presented with the warranty claim.

This warranty is limited to defects that occurred during regular operational use. This warranty does not cover

failures due to lack of service, negligence, abuse or misuse. Including, but not limited to, freezing damage,

alterations, chemical deterioration, scale build-up, rust, corrosion, thermal shock, thermal expansion,

transportation damage, oil changes, valve adjustments, fuel system maintenance or using incorrect repair

parts. Furthermore, Using the wrong fuel, water or power supply is considered a form of misuse.

This warranty also does not cover normal wearing items such as O-rings, valves, seals, lters, sparkplugs or

packings. These are considered to be maintenance items.

To obtain warranty, the claimant must take the product, with their original proof of purchase, to an authorized

BE Power Equipment service center. These service centers are located on the website:

https://www.bepowerequipment.com/service-centers

If you cannot resolve the warranty claim satisfactorily, contact the BE Power Equipment Warranty Department

(1-866-850-6662). Be prepared with details of the defect, proof of purchase,and model.

Please note: Power washers sent to the company without an RMA Number will NOT be accepted and will be

shipped back at the expense of the sender.

PROBLEM CORRECTIVE ACTION

The power washer

turns on for

2 seconds, shuts

o, and will not turn

back on. Do I have a

defective unit?

1. It sounds like your power washer is working just ne. When the water is connected,

the accessories are assembled properly, and the power switch is turned on, the

power washer may turn on for 1 - 2 seconds to prime the pump. It automatically

shuts o and waits for the spray gun trigger to be pressed. When the trigger is

pressed, water starts owing through the pump. The water sensor in the pump

“senses” the moving water and automatically turns the power washer on.

2. Turn the power switch to o, hold in the trigger on the spray gun, so that you have a

steady stream of water. While you are holding the trigger open on the spray gun, at

the same time, turn the power switch on.

17

bepowerequipment.com

REPLACEMENT PARTS LIST

For replacement parts, call our customer service department at 1-866-850-6662 8 a.m. - 4:30 p.m., PST,

Monday - Friday.

PART DESCRIPTION

G Cord Hook

H Gun Holder

IGarden Hose Adapter

J Handle

K O-Ring Kit

PART DESCRIPTION

A Foam Cannon (25 oz.)

B Super Soft Hose

C Spray Gun

D Extension Lance

E 15°Quick Connect Nozzle

FGFCI Assembly (For US unit only)

15° – Yellow

D

E

C

B

H

I

G

F

J

KPW95824

A

750ml

600ml

450ml

300ml

150ml

96393-LJP1715EN

1,700 PSI

MANUEL D’OPÉRATEUR

LAVEUSE À PRESSION ÉLECTRIQUE

ELECTRIC PRESSURE WASHER OPERATOR'S MANUAL

MANUAL DEL OPERADOR DE LA LAVADORA A PRESIÓN

12.2021

20

bepowerequipment.com

TABLE DES MATIÈRES

SPÉCIFICATIONS DU PRODUIT

Spécications du produit .................................................................................... 20

Contenu de l'emballage...................................................................................... 21

Matériel inclus..................................................................................................... 21

Consignes de sécurité........................................................................................ 22

Instructions d'assemblage .................................................................................. 24

Mode d’emploi ..................................................................................................... 28

Entretien et maintenance.................................................................................... 30

Protecteur de pompe.......................................................................................... 31

Dépannage......................................................................................................... 32

Garantie limitée .................................................................................................. 33

Liste des pièces de rechange............................................................................. 34

SPÉCIFICATIONS

Modèle PSI maximum

(k/cm2)

(lb/po2)

Débit maximum

(Litre/min)

(Gal./min)

Eau froide Volts Fréquence

(Hz)

Ampères Poids

(kg)

(lb)

P1715EN 4 975

(1 700)

6.4

(1.7) ✓120 60 11 7.3

(16.1)

This manual suits for next models

1

Table of contents

Languages:

Other BE Power Equipment Pressure Washer manuals

BE Power Equipment

BE Power Equipment P1815EN User manual

BE Power Equipment

BE Power Equipment P1915EN User manual

BE Power Equipment

BE Power Equipment HW4013HBG Manual

BE Power Equipment

BE Power Equipment HW3024HG12V User manual

BE Power Equipment

BE Power Equipment COMMERCIAL Series User manual

BE Power Equipment

BE Power Equipment P2115EN User manual

BE Power Equipment

BE Power Equipment P1515EPN User manual

BE Power Equipment

BE Power Equipment HW152EMD User manual

BE Power Equipment

BE Power Equipment HW4013HBG Service manual

BE Power Equipment

BE Power Equipment P1515EPNW User manual