16 BEPOWEREQUIPMENT.COM

CLEANING WITH DETERGENTS

1. The black soaper nozzle must be installed on the spray wand. It is the only nozzle that will draw

detergent through the pressure washer system.

2. Prepare detergent solution according to label directions. Never pump acids, alkaline, abrasive

uids or solvents through the unit. Due to the unknown and often corrosive characteristics of

many detergents commonly used in the pressure washer cleaning industry, it is recommended

to use only mild detergents with this unit.

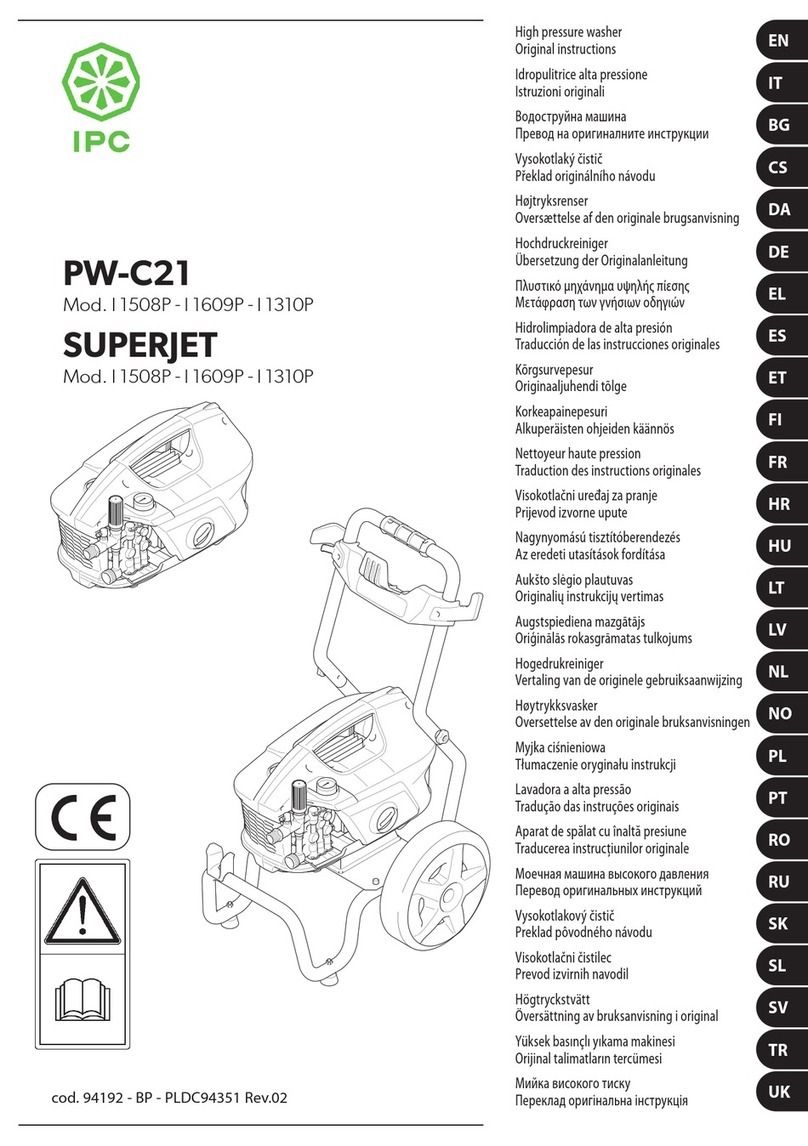

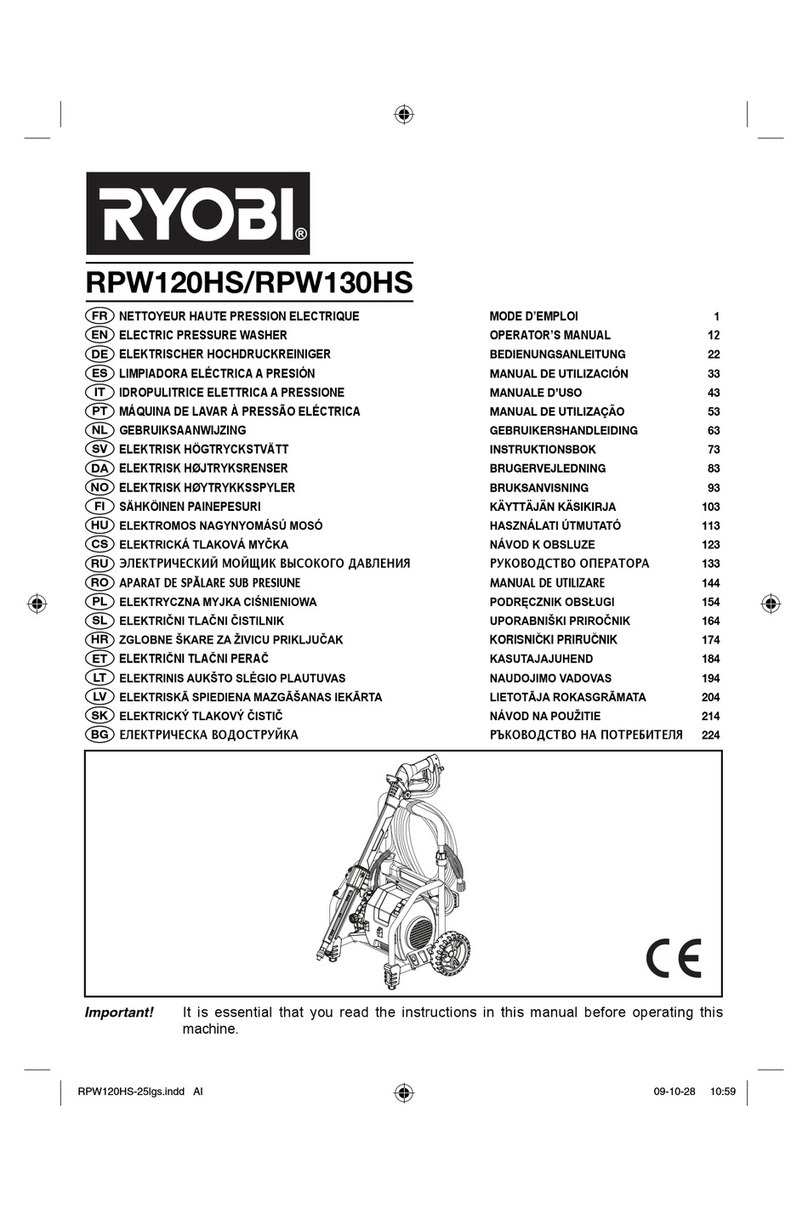

3. Connect the detergent pick-up tube assembly to the pump. There are two types: Image 3.1 -

connect plastic tube to the brass barb on the pump. Image 3.2 - Insert the plug into the pump

outlet and then connect the high-pressure hose to the other end of the tting.

4. Fully immerse the detergent strainer end of the pick-up tube into the detergent solution.

5. To apply solution, squeeze trigger and begin spraying. You will be able to see the detergent

move through the pick-up tube and then spray out the nozzle.

6. Start spraying the lower portion of the surface being cleaned and move up, using long

overlapping strokes. Applying from the bottom up helps avoid streaking and gives the detergent

a chance to soak in and begin to breakdown the dirt.

7. Be careful to not let the detergent solution to dry on the surface. This may result in damaged

surfaces. Avoid working on hot surfaces or in direct sunlight.

8. To rinse, lock the trigger gun in the "OFF" position. Then remove the black nozzle and replace

with the green or white nozzle. It will take about 30 seconds to purge all the detergent from the

system. For best rinsing results, start at the top and work down.

9. When done with the detergent system, always ush the system by siphoning clean water

through the detergent pick-up tube while spraying for at least one minute. This helps prevent

detergent from building up or causing corrosion from causing mechanical problems.

NOTICE

This feature is designed for use with mild detergents only. DO NOT use corrosives as they will

cause extensive damage as well as pose a considerable safety hazard.

BRASS- STAINLESS STEEL

LOW PRESSURE CHEMICAL

INJECTOR, 4000PSI, 2.5GPM,

3/8"QC, 3/8:" PLUG

DO NOT SCALE DRAWING

85.400.001(R2)

SHEET 1 OF 1

10/04/19

HAMID L

UNLESS OTHERWISE SPECIFIED:

SCALE: 1.5:1

WEIGHT:

REV

DWG. NO.

B

SIZE

TITLE:

NAME

DATE

COMMENTS:

Q.A.

MFG APPR.

ENG APPR.

CHECKED

DRAWN

FINISH

MATERIAL

INTERPRET GEOMETRIC

TOLERANCING PER:

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

ANGULAR: MACH

BEND

TWO PLACE DECIMAL

THREE PLACE DECIMAL

APPLICATION

USED ON

NEXT ASSY

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

<INSERT COMPANY NAME HERE>. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

<INSERT COMPANY NAME HERE> IS

PROHIBITED.

A A

B B

4

4

3

3

2

2

1

1

GENERAL PRESSURE WASHER OPERATION TECHNIQUES

1. Always follow safety practices as outlined.

2. Always begin spraying at a safe distance from the intended surface and move closer until the

desired cleaning eect can be observed.

3. Generally, do not use a 90° spray angle. Instead, it is usually more eective to use a shallower

angle so that the reecting spray can be directed in a safe and controlled direction.

4. Holding down the trigger, move the wand side-to-side to clean the surface. Once you get a feel

for how the cleaning performance behaves you will naturally nd your rhythm.

5. Always be aware of what you are spraying and take greater care on fragile surfaces such as

wood or glass to prevent damage.

6. Always remember to squeeze the trigger once every 30 seconds to ush the pump with cool

water to prevent overheating.

7. If you have to stop washing for more than a few minutes, you should turn o the machine.

OPERATION

3.1 3.2