14 15

1. Assurez-vous que la tension principale est la même que celle indiquée sur

l'étiquette d'identication de la machine.

2. Assurez-vous que la che est conforme à la réglementation locale et qu'elle

est munie d'une prise de terre.

3. La prise de courant doit être protégée par un disjoncteur différentiel d'une

sensibilité de 30 milliampères.

4. Ne branchez pas d'autres appareils sur la même prise.

5. Insérez la che après vous être assuré que l'interrupteur de la machine est en

position OFF.

RACCORDEMENT À L'ALIMENTATION ÉLECTRIQUE Fonctionnement

DÉMARRAGE DE LA MACHINE

AVERTISSEMENT

En cas de panne de courant pendant le fonctionnement, éteignez la machine

pour des raisons de sécurité.

1. Allumez l'arrivée d'eau.

2. Réglez la pression à zéro en tournant la buse dans le sens inverse des ai-

guilles d'une montre.

3. Allumez l'appareil.

4. Maintenez la gâchette du pistolet enfoncée pendant quelques secondes pour

permettre à l'air de s'échapper des tuyaux et de l'assemblage du pistolet.

5. Utilisez le bouton du déchargeur (illustré à l'étape 4 ci-dessous) pour régler la

pression.

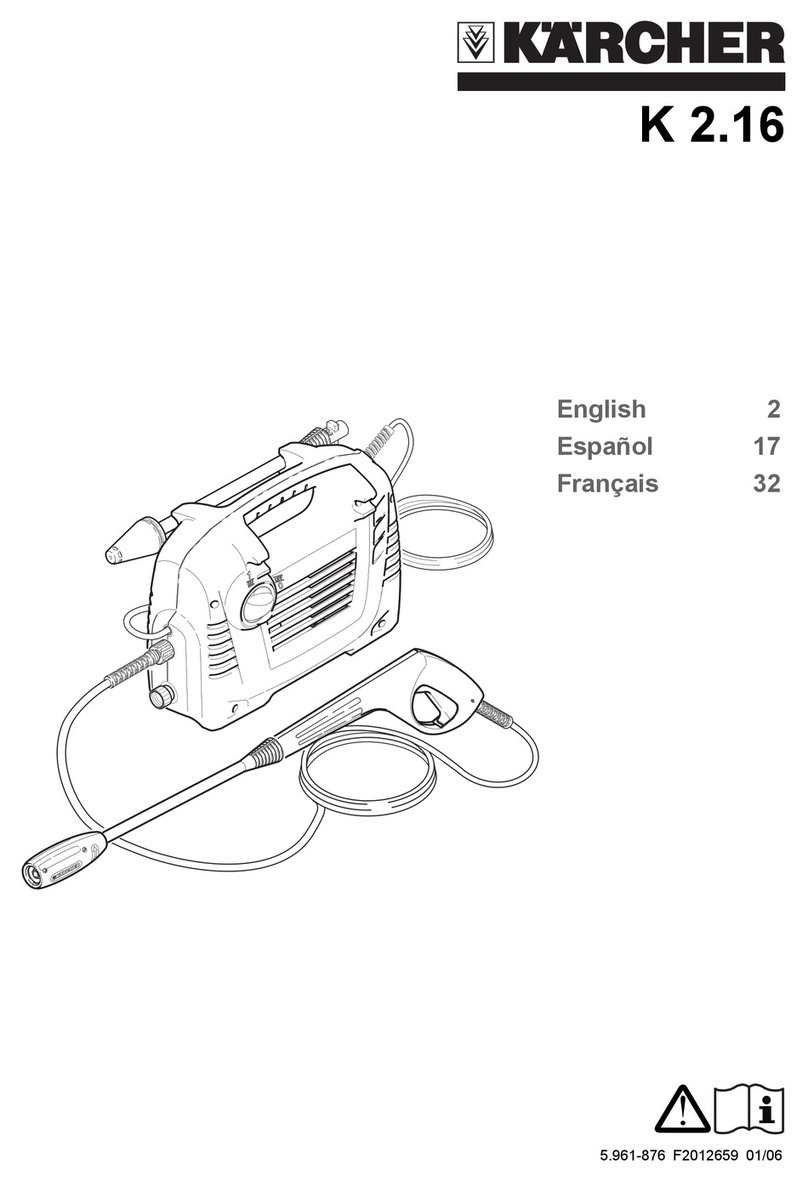

Connection to electrical supply:

1. Make sure that the main voltage is the same as shown on the identification lable on the machine.

2. Make sure that the plug complies with your local regulations, and that it is provided with ground connection.

3. The power outlet must be protected by a residual circuit breaker having a sensitivity of less than 30 amp.

4. Do not connect other appliances to the same outlet.

5. Insert the plug after making sure that the switch on the machine is in the OFF position.

WARNING: In case of power failure during operation, turn the machine OFF for safety reasons.

Starting the machine:

1. Turn on the water.

2. Set the pressure to zero by turning the know counter-clickwise.

3. Switch on the unit.

4. Hold the gun in the open position for a few seconds to allow the air to excape from the hoses.

5. At this point adjust the machine to your pressure requirement and you are ready to begin.

CHECKING AND CHANGING THE OIL

- The level of the oil must be checked periodically.

- The first important oil change must be carried out after the first 20 hours of work and successively every 150 hours.

- In any case we suggest an oil change at least once a year.

- Oil type: 15W-40 SAE

- Capacity: 14 oz.

GENERAL PRECAUTIONS FOR USE

1. Keep the machine out of the reach of children.

2. High pressure water jets are potentially dangerous if used incorrectly. In particular, the jet must not be directed

against persons or animals, electrical equipment or the machine itself.

DO NOT USE the machine when persons and/or animals are within the reach of the jet.

3. The user must operate the machine in safe conditions and situations avoiding any situations of potential danger to

himself or other persons. In particular the user will have to:

- Avoid operating in unstable balance conditions.

- Remember that the high pressure jet generates a recoil when the gun is opened. The force of this recoil is less

than 3.0 pound-force.

- Use adequate protective clothing.

- Wear protective goggles and anti-slip rubber shoes.

- Avoid contaminating the environment with polluting, toxic or harmful substances.

4. This machine is build in compliance with the requirements of the current safety regulations. The use of electrical

appliances involves the respect of some basic rules:

- Do not touch electrical parts or components.

- All operations of inspection, maintenance or repair must be made by qualified personnel only. ALWAYS

disconnect the plug before proceeding to any of the above mentioned operations.

5. Do not pull power cord to unplug. Do not pull high pressure hose to move unit.

6. Before using the machine, inspect power cord to make sure it is not damaged. If it is damaged, have it replaced

by qualified personnel. Replace power cord only with a cable of the same type as the original, this can be

identified by the marking on the outer sleeve. Do not damage or effect risky repair on power cord.

7. Before using the machine, inspect high pressure hose to make sure it is not damaged. In case of replacement

make sure the new hose has at least the same specifications as the original. Technical specifications (maximum

working pressure, date of manufacture, name of manufacturer) must be marked on the outer sleeve of hose.

CONTRÔLE ET VIDANGE DE L'HUILE

COMMENT UTILISER LA BUSE VARIABLE

- Le niveau d'huile doit être vérié périodiquement.

- La première vidange importante doit être effectuée après les 20 premières

heures d'utilisation. Il doit être changé toutes les 150 heures d'utilisation par la

suite.

- Nous recommandons que l'huile soit changée au moins une fois par an.

- Type d'huile : 15W-40 SAE

- Capacité : 14 oz.

GENERAL PRECAUTIONS FOR USE (continued)

8. While the machine is running, do not cover it and do not place it in an cnclosed space with insufficient ventilation.

9. Do not leave the machine running for more than 5 minutes with the gun closed. Should it run for a longer period,

the temperature of the recirculating water will increase rapidly and could risk damaging the pump and pump seals.

10. When the machine is not in use, lock gun trigger in safe position to prevent it from being opened by accident.

11. For the sake of safety use only approved spare parts and accessories.

HOW TO USE THE VARIABLE NOZZLE

A) Selection of high or low

pressure by push-pull action.

The selection of the pressure

must be carried out with the gun

in closed position (1).

B) Adjustment from straight (4)

to fan (5) of water jet by simple

turning of the NOZZLE.

HOW TO USE THE DETERGENT KIT

The unit can suck and mix detergents and other liquid chemicals

thanks to an automatic device incorporated in the unit itself, which

is remote-controlled by operating the variable nozzle. The unit is

equipped with a chemical suction kit (Fig A).

- Fit the siphon hose into the chemical

injector and filter into chemical container

(Fig. B).

- Select low pressure with the variable

nozzle (Fig. C)

- At this point the suction and mixing of the

chemical will start automatically.

- When you wish to stop using chemicals in

order to clean or rinse, simply release the

gun trigger and adjust the variable nozzle

to high pressure.

- At this point the chemical injection

automatically stops.

- If you foresee not using the unit for a long

period of time, we suggest to clean the

chemical suction kit with clear water to

avoid chemical deposit build-up.

CHECKING THE WATER FILTER

It is important

to check the

filter before

using the

machine.

Remember that a

well-cleaned

filter means

good performance

and long life for

your machine.

Low pressure

High pressure

GENERAL PRECAUTIONS FOR USE (continued)

8. While the machine is running, do not cover it and do not place it in an cnclosed space with insufficient ventilation.

9. Do not leave the machine running for more than 5 minutes with the gun closed. Should it run for a longer period,

the temperature of the recirculating water will increase rapidly and could risk damaging the pump and pump seals.

10. When the machine is not in use, lock gun trigger in safe position to prevent it from being opened by accident.

11. For the sake of safety use only approved spare parts and accessories.

HOW TO USE THE VARIABLE NOZZLE

A) Selection of high or low

pressure by push-pull action.

The selection of the pressure

must be carried out with the gun

in closed position (1).

B) Adjustment from straight (4)

to fan (5) of water jet by simple

turning of the NOZZLE.

HOW TO USE THE DETERGENT KIT

The unit can suck and mix detergents and other liquid chemicals

thanks to an automatic device incorporated in the unit itself, which

is remote-controlled by operating the variable nozzle. The unit is

equipped with a chemical suction kit (Fig A).

- Fit the siphon hose into the chemical

injector and filter into chemical container

(Fig. B).

- Select low pressure with the variable

nozzle (Fig. C)

- At this point the suction and mixing of the

chemical will start automatically.

- When you wish to stop using chemicals in

order to clean or rinse, simply release the

gun trigger and adjust the variable nozzle

to high pressure.

- At this point the chemical injection

automatically stops.

- If you foresee not using the unit for a long

period of time, we suggest to clean the

chemical suction kit with clear water to

avoid chemical deposit build-up.

CHECKING THE WATER FILTER

It is important

to check the

filter before

using the

machine.

Remember that a

well-cleaned

filter means

good performance

and long life for

your machine.

Low pressure

High pressure

A) Sélection de la

pression haute ou

basse par poussée-

tirage.

La sélection de la

pression doit être

effectuée avec le

pistolet en position

fermée (1).

B) Réglage du jet

d'eau de direct (4)

à vaporisateur (5)

par simple rotation

de la BUSE.

INSTALLATION FONCTIONNEMENT