BEAMEX MC6-WS User manual

MC6-WS

Advanced Workshop

Calibrator and Communicator

Applies to firmware version 3.2

Dear user,

We have made every effort to ensure the accuracy of the contents of this

manual. Should any errors be detected, we would greatly appreciate to receive

suggestions to improve the quality of the contents of this manual.

For more detailed technical data about Beamex MC6 Advanced Workshop

Calibrator and Communicator, please contact the manufacturer.

© Beamex 2023

Beamex Oy Ab

Ristisuonraitti 10

FIN-68600 Pietarsaari

Finland

Tel:

E-mail:

Website:

+358-10-5505000

https://www.beamex.com

8860500 / MC6-WSuEng / Version 3.3

Table of Contents - ii

Table of Contents

Feedback..........................................................................................6

Part 1, Introduction.........................................................................7

General.......................................................................................................7

About This Manual............................................................................7

Where am I?.............................................................................8

Typographical Conventions......................................................8

Unpacking and Inspection.................................................................8

About MC6-WS...........................................................................................9

Starting MC6-WS...............................................................................9

Firmware..........................................................................................10

Hardware......................................................................................... 14

General...................................................................................14

Pressure Modules...................................................................15

Front Panel Connection Details............................................. 16

Connectors At The Back of MC6-WS.................................... 17

Memory...................................................................................18

Display....................................................................................18

Batteries..................................................................................19

PC Communication/Calibration software.........................................19

UBS Communication Driver................................................... 20

MC6-WS Related Tools Available for PC...............................20

Options......................................................................................................20

Software Options.............................................................................20

Hardware Modules/Options and Accessories..................................21

Related Products.............................................................................22

Part 2, Active Terminals and Connections.................................23

General.....................................................................................................23

Measurements..........................................................................................24

Pressure Measurement...................................................................24

Connecting and Disconnecting External Pressure Modules...24

Zeroing a Pressure Module....................................................25

Current Measurement......................................................................25

Voltage Measurement..................................................................... 26

Temperature Measurement (Thermocouple)...................................27

Temperature Measurement (RTD)..................................................27

Resistance Measurement................................................................28

Frequency Measurement.................................................................29

Pulse Counting................................................................................29

Switch Sensing................................................................................30

Generations/Simulations...........................................................................31

Changing the Generated/Simulated Value......................................31

Table of Contents - iii

Using the Soft Numeric Keypad.............................................31

Spinning..................................................................................32

Current Generation (Source or Sink).............................................. 33

Voltage Generation..........................................................................34

Thermocouple Simulation................................................................34

RTD Sensor Simulation...................................................................35

Resistance Simulation.....................................................................36

Frequency Generation.....................................................................37

Pulse Generation.............................................................................37

Thermocouple Connections......................................................................38

Part 3, Meter.................................................................................. 40

About Meter..............................................................................................40

Part 4, Calibrator...........................................................................42

About Calibrator........................................................................................42

Tools.........................................................................................................43

General............................................................................................43

Part 5, Documenting Calibrator...................................................47

General.....................................................................................................47

Calibration Software........................................................................48

Calibrating Instruments.............................................................................48

Generating/Simulating the Input Value............................................49

Instrument List.................................................................................49

Instruments.............................................................................50

Plant Structure Levels............................................................51

Instrument List Window Menu................................................52

Instrument Overview Window..........................................................53

Calibrating an Instrument Using MC6-WS...................................... 54

Changing the Pressure Module During Calibration................58

About Fieldbus and HART Device Specifics..........................58

Group Calibration..................................................................................... 60

Collecting Instruments/Functions for Group Calibration..................60

Editing a Group......................................................................62

Calibrating a Group.........................................................................63

Group Settings........................................................................63

Performing the Calibration......................................................64

Calibration Results................................................................................... 65

Deleting Calibration Results............................................................66

Digital Communication and MC6-WS's Instrument Data..........................66

Getting and Editing Mapped Data...................................................67

Preparations............................................................................67

Getting Default Mappings.......................................................67

Customizing the Mappings.....................................................68

Part 6, Data Logger.......................................................................72

General.....................................................................................................72

Table of Contents - iv

Doing a Data Log.....................................................................................73

Configuring.......................................................................................73

Saving and Opening Configurations.......................................74

Starting the Data Log......................................................................75

Viewing and Saving or Deleting the Results...................................76

Viewing Saved Data Log Results....................................................77

Transferring Data Log Results to a Personal Computer................. 78

Part 7, Communicator...................................................................80

General.....................................................................................................80

Warnings..........................................................................................82

Connections..............................................................................................83

Selecting the Instrument.......................................................................... 84

List of Found Devices..................................................................... 84

About Instrument Parameters.................................................................. 86

Instrument Parameters in General..................................................86

Calibrating or Data Logging HART Instruments..............................87

Calibrating or Data Logging Fieldbus Instruments..........................88

Editing Parameters..........................................................................88

Trimming a Fieldbus Instrument......................................................89

Trimming a HART Instrument......................................................... 91

HART Device Description Specifics.........................................................93

General............................................................................................93

Basic View..............................................................................95

Managing Smart Transmitter Configurations............................................96

General............................................................................................96

Tools in MC6-WS............................................................................97

Saving Configurations............................................................ 97

Viewing/Managing Configurations..........................................97

Beamex MC6 Fieldbus Configuration Viewer..................................98

Uploading Configurations....................................................... 99

Linking Configurations to CMX...............................................99

Part 8, Settings............................................................................100

Settings...................................................................................................100

Optional Security Tool............................................................................101

General..........................................................................................101

Applied Restrictions..............................................................101

Part 9, Additional Information....................................................103

Additional Information.............................................................................103

User Defined Pressure Units.........................................................104

User Defined PRT/RTD Sensors.................................................. 105

General.................................................................................105

Callendar van Dusen Formula for PRTs..............................107

ITS-90 PRT Sensor..............................................................108

Factor....................................................................................110

Check Sensor Conversion....................................................111

Table of Contents - v

User Defined Transfer Functions..................................................112

User Defined Steps/Calibration Points..........................................114

Controller Communication.............................................................115

What Can be Done With Controller Communication............ 115

Configuring Controller Communication.................................117

Changing Controller During Calibration................................118

Appendix...................................................................................... 119

Safety......................................................................................................119

Approvals.......................................................................................119

Symbols Used............................................................................... 119

Safety Precautions and Warnings.................................................120

Operating Conditions............................................................120

General Warnings.................................................................120

Warnings Concerning the Lithium Polymer Battery Pack.... 121

Disposal/Replacement of Battery Pack................................121

Charging the Lithium Polymer Battery Pack.........................122

Storing...................................................................................123

Warnings Concerning Electrical Measurement and

Generation........................................................................123

General Warnings Concerning Pressure Measurement.......124

Warnings Concerning High Pressure...................................125

Disposal of Waste Electrical and Electronic Equipment.........................126

Beamex and WEEE...................................................................... 126

Disposal of Battery Pack......................................................126

Service....................................................................................................127

Cleaning MC6-WS.........................................................................127

The Battery Charger......................................................................127

Sending MC6-WS for Service.......................................................127

Firmware Update...........................................................................128

Resetting MC6-WS........................................................................129

Recalibrating MC6-WS..................................................................129

Uninstalling/installing Modules to/from CENTRiCAL.....................130

MC6-WS's Battery Pack And Charger.......................................... 130

Removing/Replacing the MC6-WS Battery Pack................. 130

Index................................................................................................................132

Feedback - 6

Feedback

We want to improve our products and services constantly. Therefore we’d like

to know Your opinion of the product You use. Please spend a moment of Your

valuable time by giving us feedback about the product.

Beamex Oy Ab

Quality Feedback

Ristisuonraitti 10

FIN-68600 Pietarsaari

Address:

FINLAND

E-mail: [email protected]

Fax: +358 - 10 - 5505404

Internet: https://www.beamex.com

Part 1, Introduction - 7

Part 1, Introduction

Things discussed in this part:

• About this manual

• Briefly about MC6-WS's hardware and firmware

• Available software and hardware options

General

Thank you for buying Beamex MC6 Advanced Workshop Calibrator and

Communicator. Because of its versatile features, it really is "more than a

calibrator".

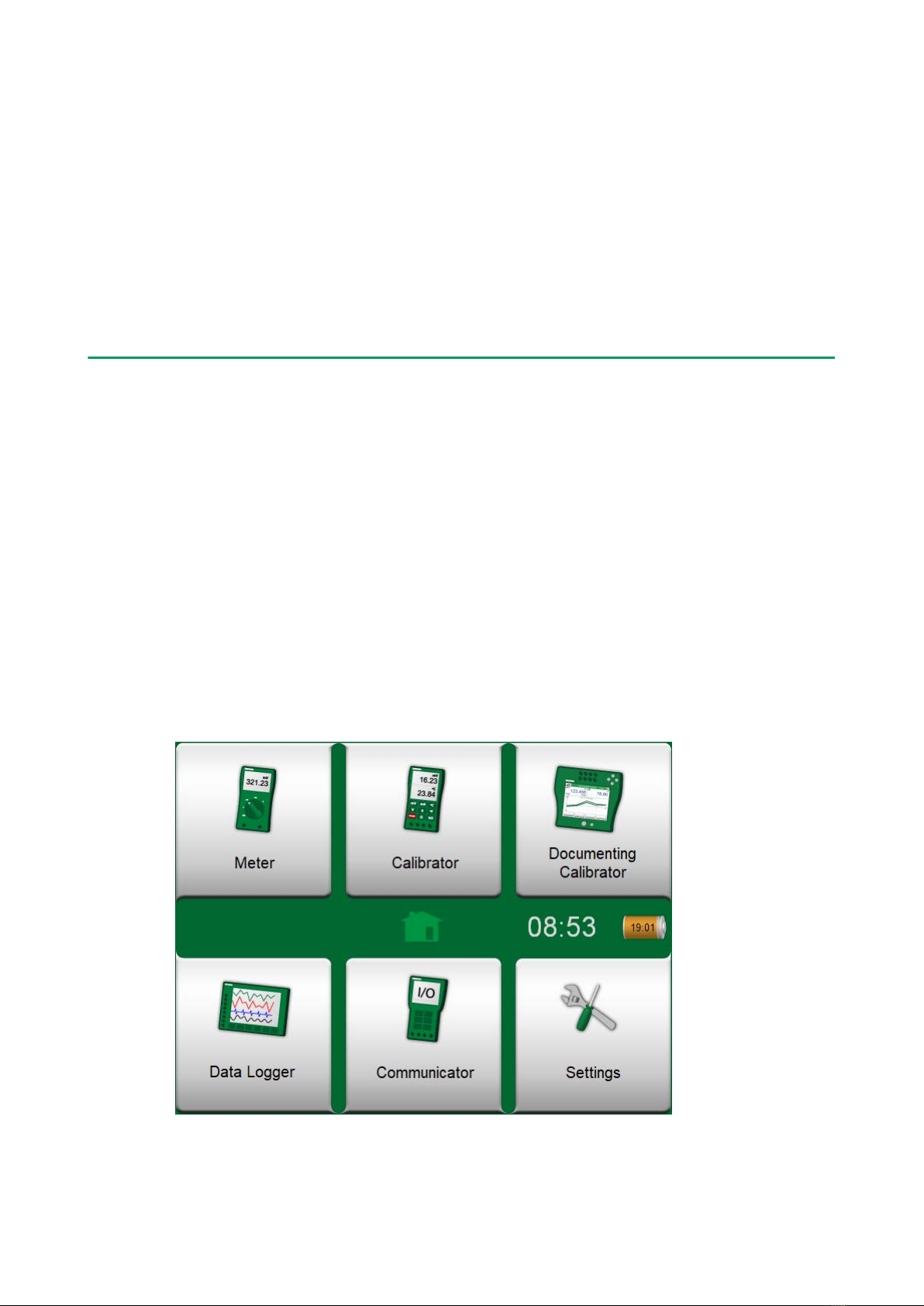

MC6-WS is one device with five different operational modes: Meter, Calibrator,

Documenting Calibrator, Data Logger and Fieldbus Communicator.

Note: Before taking MC6-WS into use, please read the warnings

available in Appendix.

About This Manual

MC6-WS User Manual is divided into several parts as follows:

•Part 1, Introduction discusses general matters.

•Part 2, Active Terminals and Connections. Whatever you measure, generate

or simulate, here's how to make the necessary connections.

•Part 3, Meter introduces the metering tool, which is handy for making quick

measurements. One measurement at a time.

•Part 4, Calibrator. A more versatile tool which allows you to measure/

generate/simulate two things simultaneously etc.

•Part 5, Documenting Calibrator concentrates on instrument calibration using

the full featured documenting calibrator.

•Part 6, Data Logger. Collecting and reviewing data and transferring logged

data to a PC.

•Part 7, Communicator. Invoking digital communication with modern

instruments.

•Part 8, Settings. How to customize MC6-WS and what the About window

contains.

•Part 9, Additional Information. About advanced tools for, e.g. adding custom

pressure units, connecting external devices etc.

Part 1, Introduction - 8

Where am I?

The header of each spread in MC6-WS User Manual informs you of where you

are: The even page shows the part you are in and the odd page shows the main

topic you are currently viewing.

Example of even page header:

2 – Part 1, Introduction

Example of odd page header:

About This Manual – 3

Typographical Conventions

The following typographical conventions apply to MC6-WS User Manual:

Bold text is used in following situations:

• References to User Manual topics and parts,

• MC6-WS keywords, i.e. terms shown in the User Interface and

• other keywords, e.g. the names of fieldbus parameters.

Note: This is a note. Notes typically inform you of something useful

concerning the current topic.

Caution: This is a caution. Whenever you see a caution, read it

carefully and take it seriously. By not observing cautions, you may

damage the calibrator.

Warning: This is a warning. Whenever you see a warning, read it

carefully and take it seriously. By not observing warnings, you may -at

worst- damage the calibrator and/or even risk your life.

Unpacking and Inspection

At the factory each new MC6-WS passes a careful inspection. It should be

free of scrapes and scratches and in proper operation order upon receipt.

The receiver should, however, inspect the unit for any damage that may have

occurred during transit. If there are signs of obvious mechanical damage,

package contents are incomplete, or MC6-WS does not operate according to

specifications, contact the purchasing sales office as soon as possible.

If you have to return the instrument to the factory for any reason, use the

original packing whenever possible. Include a detailed description of the reason

for the return. Read also chapter Sending MC6-WS for Service in Appendix.

For a description of available options, see Options.

Part 1, Introduction - 9

Standard accessories:

• Accredited calibration certificate,

• this User Manual,

• Warranty Card,

• test leads and clips,

• USB cable.

About MC6-WS

Starting MC6-WS

To start MC6-WS, switch the CENTRiCAL on. The MC6-WS will start

automatically. To switch on just the MC6-WS, press and hold the Power button

for a few seconds. The startup procedure ends in Home View. From MC6-

WS's Home View you may advance to any of the available main functions. This

manual contains detailed information of main functions as follows:

•Meter in Part 3,

•Calibrator in Part 4,

•Documenting Calibrator in Part 5,

•Data Logger in Part 6,

•Communicator in Part 7 and

•Settings in Part 8.

Figure 1: Home view

Part 1, Introduction - 10

Figure 2: Power button (left) and Home button (right)

With the Home button (see Figure 2: Power button (left) and Home button

(right)) you can always return to Home View from wherever you are.

When MC6-WS is already running, pressing the Power button briefly opens a

dialog with the following options:

•Power Off to shut down MC6-WS in Backup Mode, i.e. minimum power

consumption and full startup procedure.

•Standby to set MC6-WS in Standby Mode allowing faster startup when the

Power button is pressed again.

•Backlight Off to temporarily set the backlight off.

The button on the right side of the dialog:

•Power Management to define Backlight Brightness and other power

management related settings. More in Part 8, Settings.

MC6-WS will shut down immediately when the bench's Main switch is switched

off. The Battery Charging status window will not be displayed. MC6-WS can

still be operated normally on battery power, when the bench's Main switch is

switched off.

Note: Certain main functions are options. They may not be available

in your MC6-WS. More of this in chapter Options.

Firmware

You can interact with MC6-WS by tapping on available buttons/controls

displayed on the touch screen. Optionally: use the hardware arrow keys

to move between the available buttons/controls. The first time you push a

hardware arrow key the Hardware Focus Indicator is displayed (a blue border

around the active button/control). When using the hardware arrow keys, use the

hardware Enter key to select ("tap") a button/control.

Figure 3: Button without and with a Hardware Focus Indicator

Buttons often open a pop-up window for entering data, e.g. a unit button with

the text "mmH2O" opens a pop-up window of available units. Certain buttons

do have special functionality, like "Accept" and "Close" buttons. They close

Part 1, Introduction - 11

a pop-up window and either accept or reject the changes. There are other

buttons, e.g. for going to the next/previous page pages, scrolling through a

wide table of data, removing a number in a numeric field (backspace), clearing

a numeric field, etc. Most of them are familiar since they look similar as in

personal computer software.

Figure 4: Accept button (left) and Close button (right)

One important button is the Menu button which is available in the upper left

corner of almost any window. Tap on it to open a context-sensitive menu with,

among other things.

Figure 5: Menu button (on the left)

Figure 6: An example of an opened menu

Check Boxes are special buttons that are either "checked" or "unchecked".

See Figure 7: Check Boxes, both a checked and an unchecked one. Again, the

functionality is familiar from personal computers.

Part 1, Introduction - 12

Figure 7: Check Boxes, both a checked and an unchecked one

MC6-WS also has some "flat" buttons. They are used in, e.g. lists. The color of

the flat buttons may vary depending on the context.

The following editable fields are available:

•Text Fields,

•Numeric Fields, in certain cases including Spinning and

•Date/Time Fields.

Figure 8: Example of a list with flat buttons

The letters/numbers on all editable fields are blue to indicate that they are

editable. Black texts are descriptive user interface texts that are not editable. An

example of a Text Field and the Text Edit Window are shown in Figure 9: Text

Field and Figure 10: Text Edit window.

Figure 9: Text Field

Part 1, Introduction - 13

Figure 10: Text Edit window

Use of Numeric Fields and Spinning is described in Part 2, Active Terminals and

Connections and Part 5, Documenting Calibrator.

Date Fields are actually special cases of Numeric Fields. Entering the date is

just like entering any numeric value.

Setting MC6-WS's time is a special case of the Spinning functionality. The "Left"

and "Right" arrow buttons move the highlight to another digit. The "Up" and

"Down" arrow buttons change the value of the highlighted digit.

Figure 11: Time Setting window

Part 1, Introduction - 14

Hardware

General

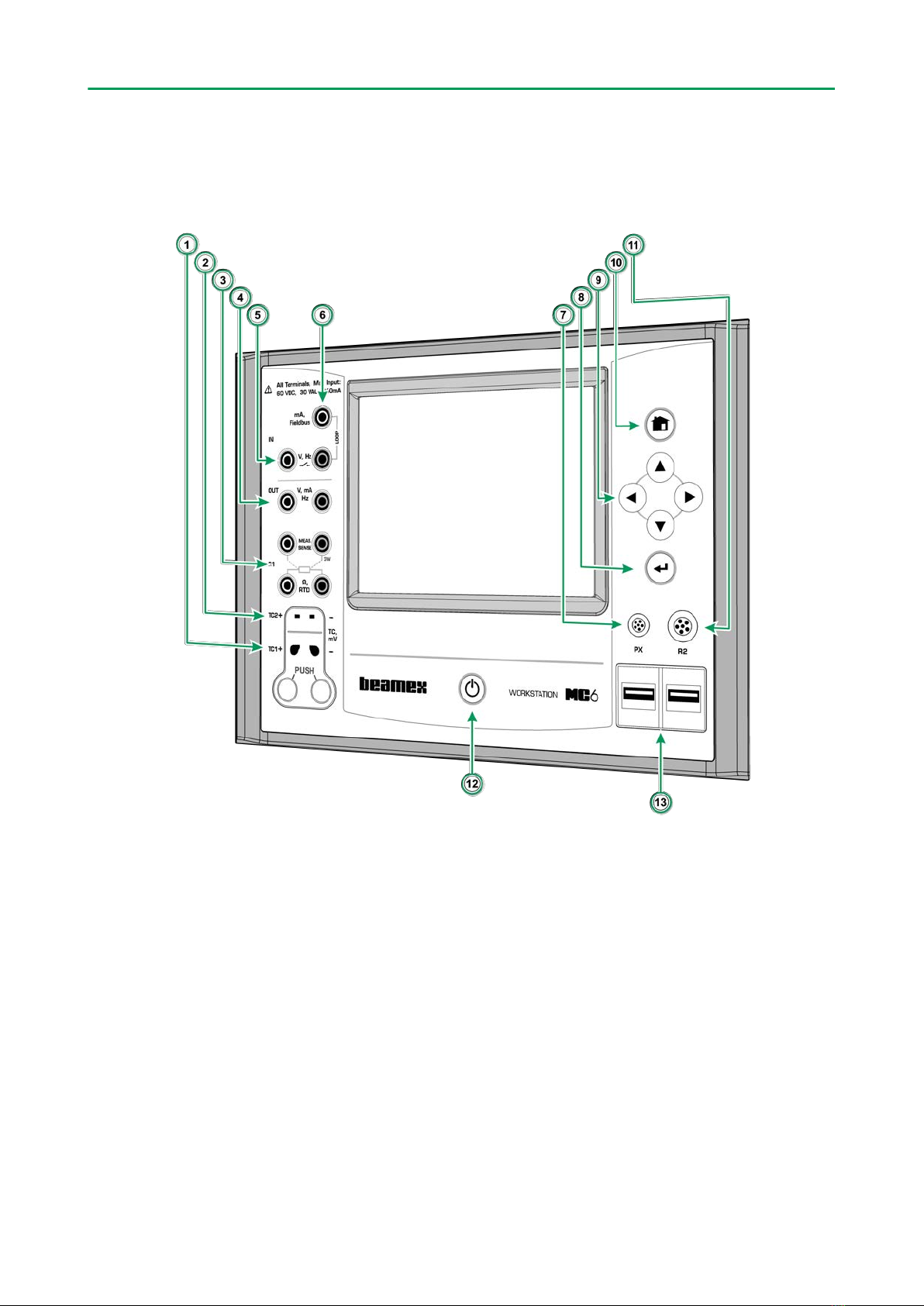

Figure 12: MC6-WS, front view

Legend:

1. Thermocouple connector (TC1) with release buttons. For cables and

standard TC plugs.

2. Thermocouple connector (TC2). For TC plugs with flat contacts.

3. RTD and Resistor connector (R1). An R2 connector is on the top of MC6-

WS.

4. Voltage, Current and Frequency output (OUT).

5. Voltage, Frequency and Switch input (IN).

6. Current Measurement, Loop Supply, HART® and Fieldbus connection

(IN).

7. Connector for External Pressure Modules (PX).

Part 1, Introduction - 15

8. Enter button for selecting the item surrounded with the Hardware Focus

Indicator.

9. Arrow buttons. First press displays the Hardware Focus Indicator. Further

presses move the indicator on the touch screen.

10. Home button. Press this button to return to Home View.

11. R2 connector. A possibility to connect an external RTD sensor to MC6-WS.

See also Hardware Modules/Options and Accessories.

12. Power button, see chapter Starting MC6-WS.

13. Two USB-A connectors for connecting USB devices to MC6-WS. See also

chapter Firmware Update.

Pressure Modules

MC6-WS supports up to ten pressure modules plus a barometric module

connected to it via a daisy chain communication cable inside the CENTRiCAL.

The amount of modules varies depending on the system at hand. MC6-WS

User Interface refers to Pressure Modules as PX: P1C.

Where:

•X is the ID address of a pressure module (0 to 9)

• P1C etc. are the pressure module types

Figure 13: Example of set of Pressure Modules in CENTRiCAL

The recommended pressure medium for pressure modules is clean air. Clean

non-corrosive liquids may optionally be used in modules with a measuring

range of 20 bar/300 psi or more. Avoid spilling liquid on MC6-WS when

connecting/disconnecting pressure hoses to/from pressure modules.

Part 1, Introduction - 16

To avoid damaging the module, use hand tightening only when connecting the

pressure measurement hoses (max. torque 5 Nm, approx. 3.6 lbf ft). If the use

of tools is required to secure the connection (typically pressure modules with a

pressure range higher than 20 bar), apply the counterforce by placing a 14 mm

(approx. 9/16”) A/F spanner on the flats found in the module’s connector. The

overpressure protection of the internal pressure modules vents to the inside of

the module rack.

Barometric Module

Barometric Modules are shown as PB: PB in the MC6-WS's User Interface.

The connection in front of a Barometric Module is meant for calibration use. The

thread is M5. To ensure valid barometric pressure measurements, do not use

the connection unless calibrating the module.

See Appendix for information on installing and uninstalling Pressure Modules.

Note: Remember to be cautious when working with pressure

and pressure modules. See also chapter Safety Precautions and

Warnings.

Front Panel Connection Details

If you use other pressure hoses than the one delivered by Beamex, remove the

connector meant for Beamex's pressure hoses and replace them with your own

connectors. The thread available in a Pressure Module's body is 1/8" BSP.

Figure 14: Pressure module connector's thread

Figure 15: Outside view of the female connector in MC6-WS

R2 connector's pin order:

1. Excitation current +

2. Sense +

3. Not in use

4. Sense -

Part 1, Introduction - 17

5. Excitation current -

Note: Leave pins 3, 6 and 7 unconnected in the male connector

meant for MC6-WS's R2 connector.

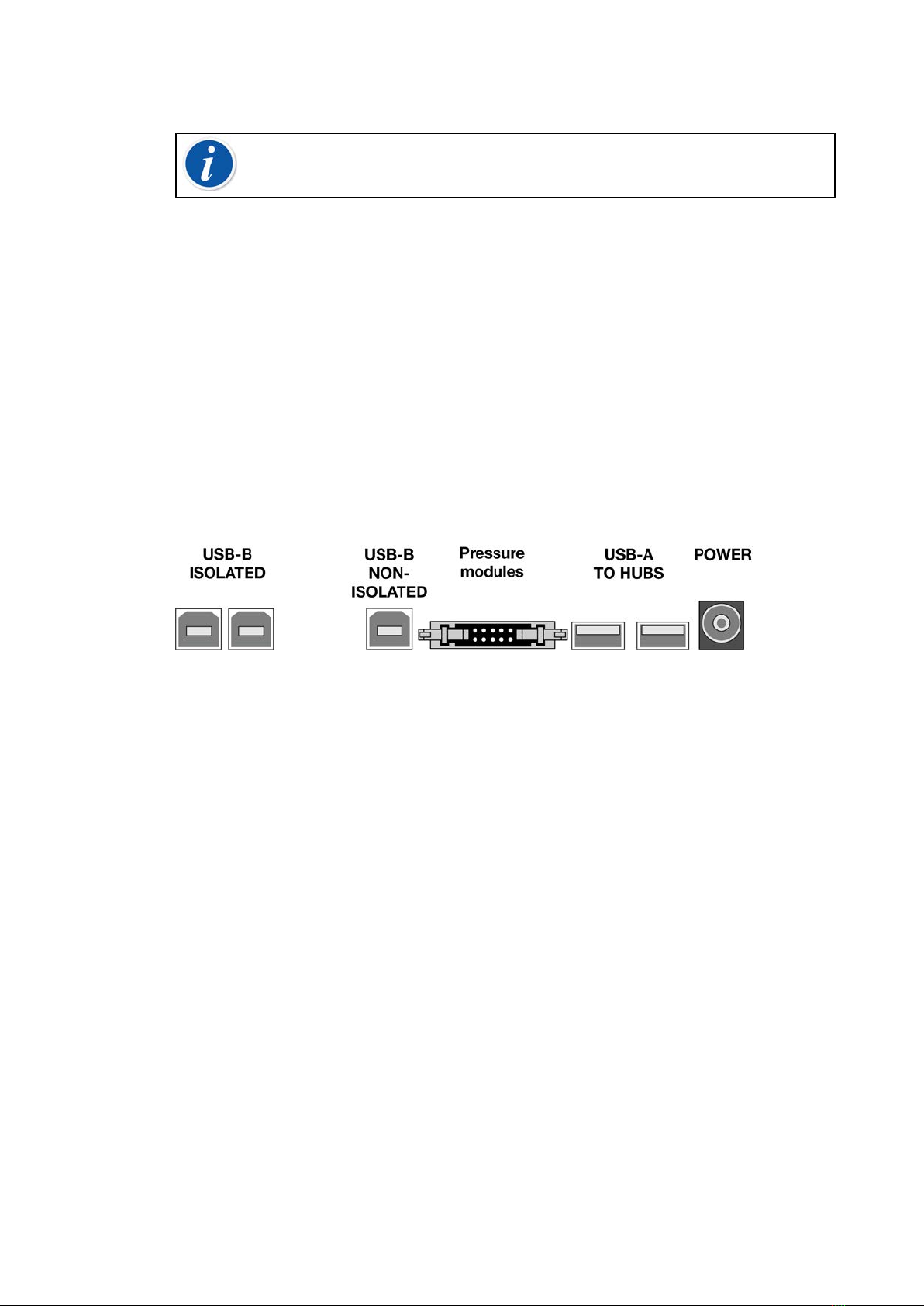

Connectors At The Back of MC6-WS

The rear end of MC6-WS (inside CENTRiCAL Instrument Panel) includes

the same connectors as in a portable MC6. There's also a Pressure Module

connector for connecting Pressure modules in CENTRiCAL.

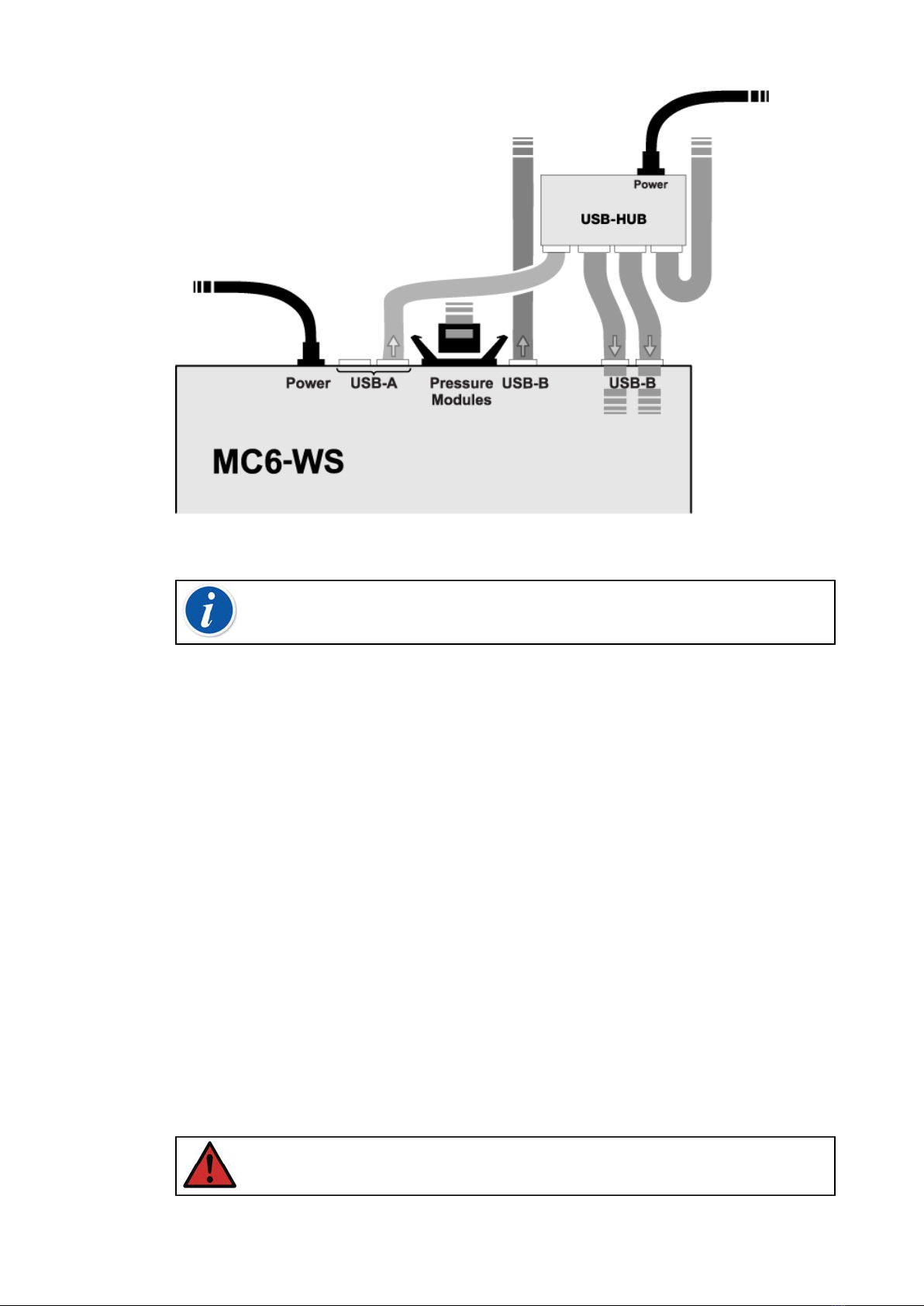

USB Ports

The need for USB connectors in MC6-WS may be more than is available in

a portable MC6. That is why there is an isolated hub included with MC6-WS

inside CENTRiCAL Instrument Panel. Two of the hub's ports are connected to

the USB-A ports in MC6-WS's front panel allowing communication with, e.g. Dry

Blocks.

Figure 16: Rear view of MC6-WS (inside CENTRiCAL)

A USB-B connector in MC6-WS is connected to USB PC - MC6 connector

located in equipment Panel in the Function Board (under the Flaps).

Part 1, Introduction - 18

Figure 17: Defult connections inside CENTRiCAL. Top view of MC6-WS

Note: All USB connectors are USB 2.0 Full Speed ports.

Memory

MC6-WS maintains data very much like personal computers. Data is saved

on a solid state memory that does not need any power to maintain its state.

Solid state memory is shock-proof so the data is not lost when the calibrator

is transported. Also, you can safely save a large amount of instruments,

calibration results and data log results.

Available memory can be used for anything that requires it (e.g. instrument

data, calibration results etc.).

Display

MC6-WS has a backlit 640 × 480 pixel 5.7" TFT touch screen display. Use the

touch screen with your fingers, gloves on or off. Optionally, use a stylus meant

for touch screen use.

See also brightness settings in Part 8, Settings.

Warning: Using sharp tools such as a screwdriver on the touch

screen may damage it. More warnings in Appendix.

Part 1, Introduction - 19

Batteries

MC6-WS has internal rechargeable Lithium Polymer (LiPo) batteries for

powering the internal clock when CENTRiCAL is shut off. The charger is

connected to CENTRiCAL's power supply so the battery is automatically

charged when the CENTRiCAL is on. LiPo batteries do not suffer from the

memory effect, so they may be charged at any time. However, there are some

serious safety issues concerning them, so read Warnings Concerning the

Lithium Polymer Battery Pack in Appendix.

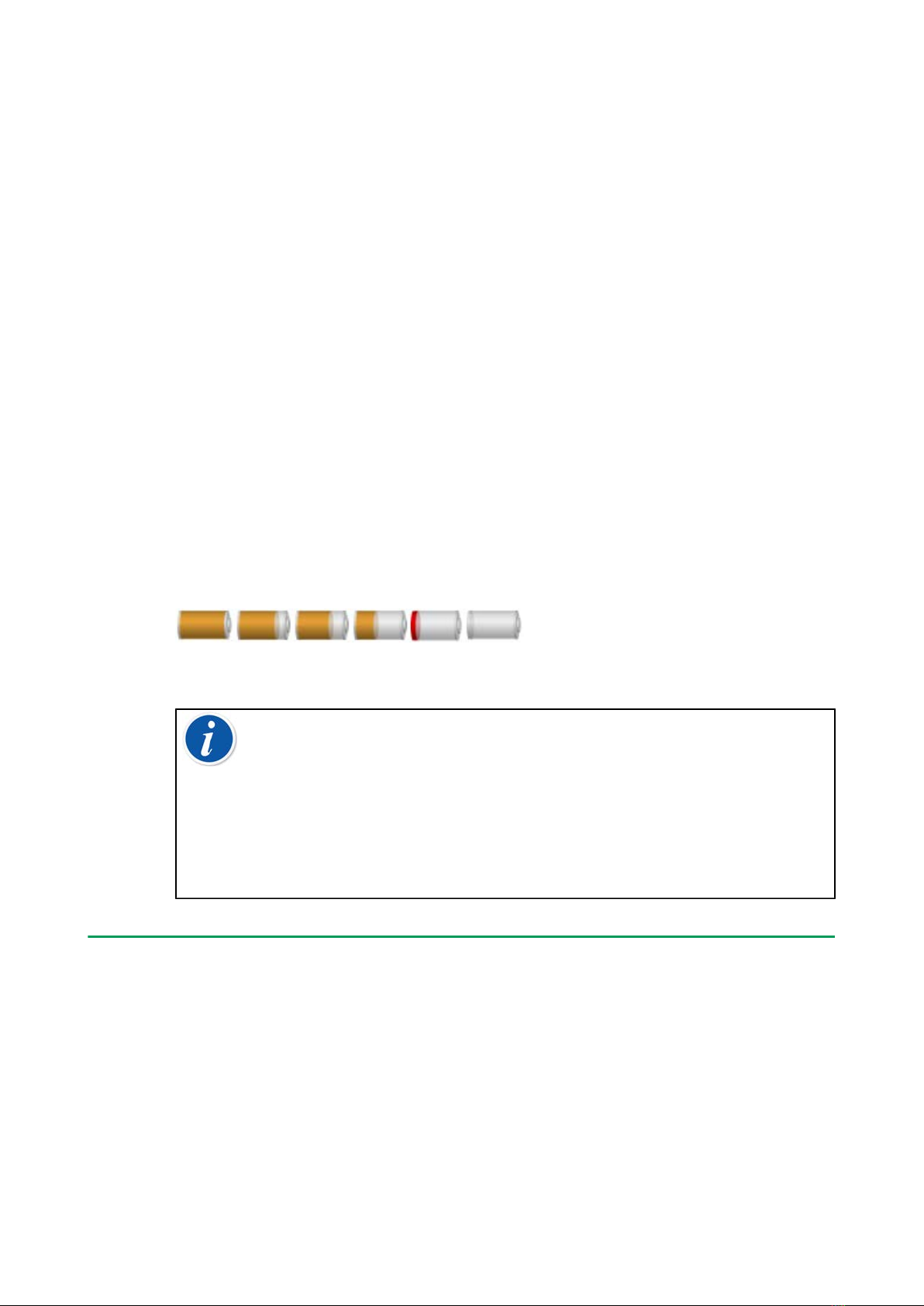

A picture of a battery (or a plug, when charging or running on AC power) is

shown on many of MC6-WS views. The "content" of the battery corresponds to

the approximated charge level of MC6-WS rechargeable batteries.

The maximum operating time of the batteries without recharging varies

depending on the usage of the display back light. The usage of the 24 V

transmitter supply also affects the maximum operating time. Even with constant

maximum load, the standard rechargeable batteries should last for 10 hours. A

good average operating time is 16 hours.

The capacity of all batteries deteriorate with time. If MC6-WS internal clock is

reset, it is time to replace the battery pack with a new one. See Appendix for

information on how to replace the Battery pack.

Figure 18: Full battery - empty battery

Note: A time approximate (hh:mm) is shown on the battery symbol.

During charging it is the charging time left, otherwise it is remaining

usage time.

MC6-WS internal clock/calendar uses a small amount of power even

when CENTRiCAL/MC6-WS is switched off. Remember to check the

capacity of the batteries from time to time although MC6-WS is not

in use. Recharge if needed. Tap the battery icon to open a window

displaying detailed battery/charging information.

PC Communication/Calibration software

Beamex CMX Calibration Management Software supports MC6-WS from

version V2, revision 2.8 onwards and also in Beamex LOGiCAL Calibration

Management Software.

Part 1, Introduction - 20

UBS Communication Driver

MC6-WS uses Windows' generic USB driver (WinUSB) provided by Microsoft.

Supported operating systems: Windows® 7 … Windows® 10. Starting from

Windows 8, the driver installation is self-contained, older versions may require

Windows Update connection.

MC6-WS Related Tools Available for PC

The following tools are available for download at Beamex's website: https://

www.beamex.com. Look for Download Center and Software tools for MC6

family.

•Beamex MC6 Data Log Viewer, for transferring Data Log results to a PC

and viewing them on the PC.

•Beamex MC6 Device Description Installer, for installing new Device

Descriptions of smart transmitters from a PC to MC6-WS.

•Beamex MC6 Fieldbus Configuration Viewer, for downloading smart

transmitter configurations read into MC6-WS to a PC.

•Beamex MC6 Remote Controller, for controlling MC6-WS via a PC.

Options

Software Options

The following software options are available:

•Mobile Security Plus, a solution which ensures the integrity of calibration

data throughout the Beamex ICS solution. This option is also required in the

CMX Calibration Management Software version V2, revision 2.11 or later,

• Multichannel Data Logger,

•Communicator, HART®,

•*) Communicator, FOUNDATION Fieldbustm,

•*) Communicator, PROFIBUS PAtm,

• +) Drivers for External Controllers (Pressure and Temperature) and

•Special Temperature Sensors.

Table of contents

Other BEAMEX Test Equipment manuals